Abstract

In this study, an activated peroxide system was established for low-temperature bleaching of cotton by incorporating N-[4-(triethylammoniomethyl)benzoyl]caprolactam chloride (TBCC), hydrogen peroxide (H2O2) and sodium bicarbonate (NaHCO3) into an aqueous solution. The bleaching performance was modelled by response surface methodology based on a central composite rotatable design of experiment, in which concentration of TBCC ([TBCC]), concentration of NaHCO3 ([NaHCO 3]), temperature (T) and time (t) were four independent variables, and the degree of whiteness (DoW) of bleached cotton was measured as the response variable. For each individual bleaching experiment, TBCC and H2O2 were used in a molar ratio of 1:1.1 and NaHCO3 in a molar amount greater than that of H2O2 for the purpose of driving reactions to completion. A reduced quadratic model (RQM) was constructed using regression analysis with backward elimination, which was used to conduct a practical low-temperature bleaching process for cotton. In comparison to the typical conventional peroxide system, the TBCC-activated peroxide system based on the RQM predication provided cotton with an equivalent DoW and slightly inferior water absorbency, resulted in no apparent damage to cotton fibers, but worked under much milder conditions. This study provides useful insights into scaling up the TBCC-activated peroxide system for low-temperature bleaching of cotton.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Cotton can be bleached at a low temperature with an activated peroxide system which is formed by incorporating a so-called bleach activator (BA) into an aqueous solution of hydrogen peroxide (H2O2). In the activated peroxide system, BA is converted to peracid (PA) by reaction with H2O2 as shown in Scheme 1 (Hofmann et al. 1992). This reaction is also called perhydrolysis. In general, PA is more kinetically active than H2O2 and allows cotton to be bleached under milder conditions.

Activated peroxide systems have been initially developed for and now widely applied in domestic laundry (Milne 1998). Since the beginning of the twenty-first century, activated peroxide systems have been attempted in the textile industry as an alternative approach to bleaching of cotton owing to the fact that the conventional bleaching process of cotton with H2O2 is often performed under strongly alkaline conditions at temperatures above 95 °C and as such leads to extensive energy consumption and severe fiber damage (Zeronian and Inglesby 1995). A variety of BAs have been tested for use in activated peroxide systems, such as tetraacetylethylenediamine (TAED) (Hebeish et al. 2009; Long et al. 2013; Scarborough and Mathews 2000), nonanoyloxybenzenesulfonate (NOBS) (Cai et al. 2001; Wang and Washington 2002), guanidine derivatives (Cai and Evans 2007), N-[4-(triethylammoniomethyl)benzoyl]lactam chlorides (TBLCs) (Lee et al. 2010), thiourea (Abdel-Halim and Al-Deyab 2013), and aminonitrile (Wang et al. 2014). In spite of much effort, however, there was little progress made in developing activated peroxide systems for low-temperature bleaching of cotton until a clear mechanism for BAs on activation of H2O2 and PAs on bleaching of cotton was elucidated (Xu et al. 2013, 2015).

It is a common practice in the textile industry to assume that an activated peroxide system would be preferably established for bleaching of cotton under strongly alkaline conditions with the addition of BA in the presence of a large excess of H2O2. However, recent studies have revealed that the activated peroxide systems based on TAED and TBLCs may be most effective under near-neutral pH conditions using BAs and H2O2 in amounts close to stoichiometric ratios (Xu et al. 2010b, 2013, 2015). This impels researchers to reconsider the strategy for conducting activated peroxide systems as an effective approach to low-temperature bleaching of cotton. It has been reported in a previous study that a screening design of experiment was used to identify statistically significant variables associated with activated peroxide systems for low-temperature bleaching of cotton (Fei et al. 2015). In this study, it is proposed that an activated peroxide system is conducted by incorporating a prototype of TBLCs, i.e. N-[4-(triethylammoniomethyl)benzoyl]caprolactam chloride (TBCC) into H2O2 and NaHCO3 solution, and its performance on bleaching of cotton is modeled by response surface methodology (RSM) based on a central composite rotatable design (CCRD) of experiment in which four independent variables are included, namely concentration of TBCC ([TBCC]), concentration of NaHCO3 ([NaHCO 3]), temperature (T) and time (t).

Experimental

Materials

100 % single jersey circular-knitted greige cotton fabric was used as a substrate for bleaching, and was kindly provided by Hongdou Group (Wuxi) Textiles Co., Ltd., China. TBCC was synthesized and purified according to the previously reported method (Wei et al. 2014). H2O2 (30 % w/w) was purchased from Sinopharm Chemical Reagent Co., Ltd., China. A nonionic wetting agent (Penetrant JFC) and a polyacrylate-based peroxide stabilizer (DM-1403) were used as bleaching auxiliaries, and were purchased from Dynamic Chemicals Ltd., China. Cupriethylenediamine (0.1 M) was used for preparing cellulose dispersions from cotton fabrics, and purchased from the Fisher Scientific Company, USA. All other chemicals were of analytical grade unless otherwise stated. Tap water was used throughout the bleaching experiments.

Central composite rotatable design of experiment

A five-level-four-variable CCRD was performed using Design Expert software 7.0 (Stat-Ease Inc., USA). The four independent variables were defined as [TBCC], [NaHCO 3], T and t, and the response variable was defined as the degree of whiteness (DoW) of bleached cotton. Table 1 shows the CCRD design matrix with actual variable levels, in which sixteen factorial points (Standard No. 1–16), eight axial points (Standard No. 17–24) and six center points (Standard No. 25–30) were included.

Bleaching experiment

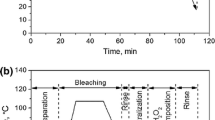

Bleaching of cotton with the TBCC-activated peroxide system

To a solution containing 1 g/L wetting agent and 1 g/L peroxide stabilizer, TBCC and NaHCO3 were added at dosages as given in Table 1, and H2O2 was added in a 1.1:1 molar ratio with respect to TBCC. The slight excessive amount of H2O2 was used in bleaching for driving reactions to completion. A sample of cotton fabric (10 g) was immersed in the solution using a liquor-to-goods ratio of 15:1, and bleached at a target temperature for a desired time. The bleaching process was performed in an Ahiba Nuiance laboratory dyeing machine (Datacolor International, USA) with a ramp rate of 3 °C/min. When bleaching was completed, the bleached cotton fabric was rinsed thoroughly in copious amounts of tap water and dried under ambient conditions. All thirty samples were bleached randomly according to the run number shown in Table 1 to minimize error sources.

Bleaching of cotton with a conventional peroxide system

The bleaching solution was prepared by adding 6 g/L H2O2 (30 % w/w), 3 g/L NaOH, 1 g/L wetting agent and 1 g/L peroxide stabilizer. A sample of cotton fabric (10 g) was immersed in the bleaching solution using a liquor-to-goods ratio of 15:1, and bleached at 95 °C for 40 min. The bleaching process was performed in the Ahiba Nuiance laboratory dyeing machine with a ramp rate of 3 °C/min. When bleaching was completed, the bleached cotton fabric was rinsed thoroughly in copious amounts of tap water and dried under ambient conditions. Such a bleached cotton fabric was used as a reference standard for evaluating the performance of the TBCC-activated peroxide system on bleaching of cotton fabric.

Evaluation of bleached cotton fabric

Degree of whiteness

CIE whiteness index was used as a measure of the DoW of bleached cotton fabric as described in the AATCC Test Method 110-2011. The whiteness measurement was performed on a Datacolor 650 spectrophotometer under the CIE Standard Illuminant D65 and the CIE 1964 10° Standard Observer. The bleached cotton fabric was folded twice to give an opaque sample with four plies, and measured four times with 90° rotation to give an average value of DoW. The DoW value was recorded as the response in CCRD as given in Table 1.

Degree of polymerization

Cotton fiber damage resulting from oxidative bleaching was evaluated by measuring the degree of polymerization (DP) of the bleached cotton fabric. According to the AATCC Test Method 82-2007, the bleached cotton fabric was dissolved in cupriethylenediamine solution to give a cellulose dispersion of which the fluidity (F) was determined for calculation of DP using Eq. 1. A higher DP value indicates a lower cotton fiber damage.

Water absorbency

The water absorbency of cotton fabric was evaluated by measuring the elapsed time of a water drop on the cotton fabric according to the AATCC Test Method 79-2010. A shorter elapsed time of water drop on cotton fabric indicates a better water absorbency.

Results and discussion

Bleaching performance modeling

RSM is an efficient tool to quantify the relationship between multiple input variables and one or more response variables, and has been successfully employed in investigations of activated peroxide systems for bleaching of cotton (Lim et al. 2004; Long et al. 2013; Xu et al. 2010b). In this study, a mathematical model was constructed by RSM for understanding the performance of the TBCC-activated peroxide system on bleaching of cotton. The experimental data shown in Table 1 were fitted to linear, 2-factor interaction (2FI), quadratic and cubic models, respectively. The lack-of-fit test results for these models are shown in Table 2. As can be seen, the quadratic and cubic models produced insignificant lack of fit (p > 0.05), indicating that they were statistically significant and could be selected as a candidate to model the performance of the TBCC-activated peroxide system on bleaching of cotton. However, the cubic model was aliased because the experimental runs were inadequate to support a full cubic model. The summary statistics shown in Table 3 suggests that the quadratic model was more desirable than others with the maximal adjusted and predicted R2 as well as the minimal press. Therefore, the quadratic model was preferably selected for describing the experimental data.

Using regression analysis with backward elimination, the quadratic model was improved by eliminating the model terms with p values >0.05 that were statistically insignificant at a 95 % confidence level, resulting in a reduced quadratic model (RQM). As a result, the adjusted and predicted R2 were increased from 0.8941 and 0.7098 to 0.9274 and 0.8104, respectively, and the lack-of-fit p value was increased from 0.0647 to 0.1658. This indicates that the RQM was more robust than the full quadratic model. The results of analysis of variance (ANOVA) for the RQM are shown in Table 4. As can be seen, the RQM produced a p value <0.0001, indicating that it was significant. The lack-of-fit p value of 0.1658 indicates that the lack of fit was not significant relative to the pure error. The significance of model terms in the RQM can be evaluated according to the F values. It was found that the model term T was most significant, followed by the model terms [TBCC] and t. This indicates that the variables T, [TBCC] and t had significant influence to the performance of the TBCC-activated peroxide system on bleaching of cotton. However, [NaHCO 3] was excluded from the RQM because of its insignificance with a p value >0.05. Additionally, the model terms [TBCC]2 and T 2 were found to be significant, indicating that the variables [TBCC] and T had quadratic relationships with the DoW of bleached cotton. These quadratic relationships would be useful for optimizing the bleaching performance.

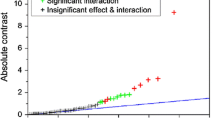

The RQM is mathematically represented by Eq. 2, in which the model terms are based on the actual variable levels. The RQM produced a coefficient of determination (R 2) of 0.9399, which indicates a good fit to experimental data. Figure 1 shows a plot of the DoW predicted from the RQM against the DoW observed in experiments. It can be seen that the data points are roughly distributed around the straight dash line. This indicates that the RQM was in a good agreement with the experimental data and could be used for describing the performance of the TBCC-activated peroxide system on bleaching of cotton within the investigated level range of variables.

Variable effect prediction

The effects of significant variables on the performance of the TBCC-activated peroxide system on bleaching of cotton fabric were predicted by using the RQM (Eq. 2), and described in three-dimensional response surface plots as shown in Fig. 2.

The TBCC-activated peroxide system contributes to bleaching of cotton by the perhydrolysis of TBCC as demonstrated in Scheme 2, from which 4-(triethylammoniomethyl)perbenzoic acid (TPA) would be in situ generated and responsible for bleaching of cotton at low temperatures. After bleaching of cotton, TPA would be converted into 4-(triethylammoniomethyl)benzoic acid (TBA) as demonstrated in Scheme 3. Therefore, the key to improving the performance of the TBCC-activated peroxide system on bleaching of cotton is to increase the quantity of TPA in the bleaching solution. In this study, a 1:1.1 molar ratio of TBCC to H2O2 was used to drive the perhydrolysis of TBCC to completion. The quantity of TPA in situ generated in the bleaching solution would be mainly dependent on the concentration of TBCC. As reported in previously studies (Fei et al. 2015; Xu et al. 2015), TPA may undergo bimolecular and H2O2-attacked decompositions under strongly alkaline conditions. In this work, NaHCO3 was used in the TBCC-activated peroxide system for maintenance of a near-neutral pH and as such avoidance of TPA decompositions.

As shown in Fig. 2a, b, an increase in [TBCC] resulted in an increase in DoW. However, the effect of [TBCC] on DoW tended to be diminished in a higher level [TBCC] range. This indicates that it was applicable to improve the performance of the TBCC-activated peroxide system on bleaching of cotton by increasing the concentration of TBCC in the lower level range rather than in the higher level range. The diminished effect of [TBCC] on DoW in higher level range was mostly due to the fact that the interaction between TPA and cotton fiber was inhibited. In a solution of TBCC with a relatively low concentration, the TBCC and TPA molecules with a positive charge tend to be adsorbed onto negatively charged cotton fibers, which is helpful for enhancing the performance of the TBCC-activated peroxide system on bleaching of cotton (Xu et al. 2010a). However, in a solution of TBCC with a high concentration, the adsorbed molecules which could be TBCC, TPA or TBA may form a barrier around cotton fibers to adsorbing more TPA molecules, thereby resulting in low bleaching effectiveness. Hence, it can be deduced that there may be a limit on [TBCC] at which the TBCC-activated peroxide system provided cotton the optimal DoW.

Temperature was the most significant variable affecting the performance of the TBCC-activated peroxide system on bleaching of cotton. As shown in Fig. 2a, c, an increase in temperature resulted in an increase in the DoW of cotton fabric. This was mainly ascribed to the fact that an increase in temperature led to faster rates of the perhydrolysis of TBCC (Scheme 2) and bleaching of cotton (Scheme 3). However, it was found in Fig. 2a, c that the temperature effect tended to be flat partly due to the TPA decomposition which could take place at elevated temperatures (Xu et al. 2015). Therefore, appropriately decreasing temperature would be beneficial to increasing the efficiency of TPA for bleaching of cotton.

Though the variable t was statistically significant as shown in Table 4 (p value = 0.0106), it is shown in Fig. 2b, c that the time effect was so slight that it was hard to visibly discern the difference in DoW between the lowest and highest levels of time. This indicates that the TBCC-activated peroxide system provided a rapid process for bleaching of cotton. In common practice, it may be helpful to appropriately extend the bleaching time so as to achieve a more uniform treatment.

Importance of [NaHCO 3]

As demonstrated in Schemes 2 and 3, TBCC would be converted through perhydrolysis of TBCC and bleaching of cotton to TBA. The generation of TBA in solution would result in a drastic drop of pH so as to decelerate or even terminate the perhydrolysis of TBCC. The role of NaHCO3 is to neutralize TBA and as such maintain a desired pH range for maximizing the performance of the TBCC-activated peroxide system on bleaching of cotton (Xu et al. 2015). It is shown in Table 1 that NaHCO3 was added to each bleaching solution in a molar amount in excess of TBCC. However, the variable [NaHCO 3] was found to be insignificant and thus excluded from the RQM. The insignificance of [NaHCO 3] indicates that NaHCO3 played the role of neutralizing TBA while the use of an excess amount of NaHCO3 in the TBCC-activated peroxide system had no effect on the bleaching performance. It is thus advisable in practical bleaching of cotton to use a slightly excess amount of NaHCO3 to ensure a complete conversion of TBCC to TBA.

Model application

The RQM (Eq. 2) may provide a useful approach to conducting a practical low-temperature bleaching process for cotton fabric. As shown in Table 5, based on the DoW of 68.46 of cotton fabric which was bleached with a conventional peroxide system, the TBCC-activated peroxide system could be predictively conducted using a preset temperature of 50 °C, and a preset time of 40 min by adding 21.69 mmol/L TBCC to a solution of 2.7 g/L H2O2 (w/w 30 %) (i.e. 23.86 mmol/L) and 2.19 g/L (i.e. 26.03 mmol/L) NaHCO3, and was practically applied for bleaching of cotton. In comparison to the conventional peroxide system, the TBCC-activated peroxide system provided cotton fabric with an equivalent DoW but worked under much milder conditions.

Additionally, the TBCC-activated peroxide system based on the RQM was also compared with the conventional peroxide system for fiber damage and water absorbency of bleached cotton fabric. Unlike the conventional peroxide system that caused an extensive reduction in the degree of polymerization of the bleached cotton fabric, as shown in Table 6, the TBCC-activated peroxide system had no apparent effect on the degree of polymerization of the bleached cotton fabric. This indicates that the TBCC-activated peroxide system had the advantage over the conventional peroxide system in protecting cotton fibers from damage. It seems that the TBCC-activated peroxide system was slightly inferior to the conventional peroxide system for improving the water absorbency of cotton fabric. It is expected that the water absorbency of cotton fabric bleached with the TBCC-activated peroxide system would be adequate for post treatments.

Conclusions

The performance of the TBCC-activated peroxide system on bleaching of cotton was modelled by RSM based on a CCRD of experiment. A comparison of the lack-of-fit tests for various models indicated that the quadratic model best described the experimental data. The quadratic model was improved by using regression analysis with backward elimination. The ANOVA for the RQM revealed that the variables T, [TBCC] and t were significant but the variable [NaHCO 3] was not. The effects of these significant variables on the bleaching performance were predicted by using the RQM. It was found that the performance of TBCC-activated peroxide system on bleaching of cotton could be improved by increasing T, [TBCC] and t. Though [NaHCO 3] had no apparent effect, NaHCO3 was essential to the TBCC-activated peroxide system for maintaining the bleaching pH within a desired range. Based on the model prediction, the TBCC-activated peroxide system was conducted for practical low-temperature bleaching of cotton using a 1:1.1:1.2 molar ratio of TBCC, H2O2 and NaHCO3. In comparison to the typical conventional peroxide system, the TBCC-activated peroxide system provided cotton fabric with an equivalent DoW and slightly inferior water absorbency, resulted in no apparent fiber damage, but worked under much milder conditions.

References

Abdel-Halim ES, Al-Deyab SS (2013) One-step bleaching process for cotton fabrics using activated hydrogen peroxide. Carbohydr Polym 92(2):1844–1849

Cai JY, Evans DJ (2007) Guanidine derivatives used as peroxide activators for bleaching cellulosic textiles. Colo Technol 123(2):115–118

Cai JY, Evans DJ, Smith SM (2001) Bleaching of natural fibers with TAED and NOBS activated peroxide systems. AATCC Rev 1(12):31–34

Fei X, Yao J, Du J, Sun C, Xiang Z, Xu C (2015) Analysis of factors affecting the performance of activated peroxide systems on bleaching of cotton fabric. Cellulose 22(2):1379–1388

Hebeish A, Hashem M, Shaker N, Ramadan M, El-Sadek B, Hady MA (2009) New development for combined bioscouring and bleaching of cotton-based fabrics. Carbohydr Polym 78(4):961–972

Hofmann J, Just G, Pritzkow W, Schmidt H (1992) Bleaching activators and the mechanism of bleaching activation. J Prak Chem Chem Ztg 334(4):293–297

Lee JJ, Hinks D, Lim SH, Hauser P (2010) Hydrolytic stability of a series of lactam-based cationic bleach activators and their impact on cellulose peroxide bleaching. Cellulose 17(3):671–678

Lim SH, Gursoy NC, Hauser P, Hinks D (2004) Performance of a new cationic bleach activator on a hydrogen peroxide bleaching system. Colo Technol 120(3):114–118

Long X, Xu C, Du J, Fu S (2013) The TAED/H2O2/NaHCO3 system as an approach to low-temperature and near-neutral pH bleaching of cotton. Carbohydr Polym 95(1):107–113

Milne N (1998) Oxygen bleaching systems in domestic laundry. J Surfactants Deterg 1(2):253–261

Scarborough SJ, Mathews AJ (2000) Using TAED in bleaching fiber blends to improve fiber quality. Text Chem Color Am Dyest Rep 32(3):33–37

Wang J, Washington NM (2002) Hydrophobic bleach systems and textile preparation: a discontinuity in fabric care. AATCC Rev 2(6):21–24

Wang S, Li S, Zhu Q, Yang CQ (2014) A novel low temperature approach for simultaneous scouring and bleaching of knitted cotton fabric at 60°C. Ind Eng Chem Res 53(24):9985–9991

Wei D, Sun C, Wang M, Du J, Xu C (2014) Synthesis of N-[4-(dimethylalkylammoniomethyl)benzoyl]caprolactam chlorides as cationic bleach activators for low-temperature bleaching of cotton fabric under near-neutral pH conditions. Colo Technol 130(6):432–436

Xu C, Hinks D, Shamey R (2010a) Bleaching cellulosic fibers via pre-sorption of N-[4-(triethylammoniomethyl)-benzoyl]-butyrolactam chloride. Cellulose 17(4):849–857

Xu C, Shamey R, Hinks D (2010b) Activated peroxide bleaching of regenerated bamboo fiber using a butyrolactam-based cationic bleach activator. Cellulose 17(2):339–347

Xu C, Long X, Du J, Fu S (2013) A critical reinvestigation of the TAED-activated peroxide system for low-temperature bleaching of cotton. Carbohydr Polym 92(1):249–253

Xu C, Hinks D, Sun C, Wei Q (2015) Establishment of an activated peroxide system for low-temperature cotton bleaching using N-[4-(triethylammoniomethyl)benzoyl]butyrolactam chloride. Carbohydr Polym 119:71–77

Zeronian SH, Inglesby MK (1995) Bleaching of cellulose by hydrogen peroxide. Cellulose 2(4):265–272

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant No. 21276106), the Prospective Joint Research Project of Jiangsu Province, China (Grant No. BY2015019-09), the National Undergraduate Training Programs for Innovation and Entrepreneurship (Grant No. 201410295035), and the Project for Jiangsu Scientific and Technological Innovation Team.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Luo, X., Sui, X., Yao, J. et al. Performance modelling of the TBCC-activated peroxide system for low-temperature bleaching of cotton using response surface methodology. Cellulose 22, 3491–3499 (2015). https://doi.org/10.1007/s10570-015-0741-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-015-0741-9