Abstract

Conifers, which are the most abundant biomass species in Nordic countries, USA, Canada and Russia, exhibit strong resistance towards depolymerization by cellulolytic enzymes. At present, it is still not possible to isolate a single structural feature which would govern the rate and degree of enzymatic hydrolysis. On the other hand, the forest residues alone represent an important potential for biochemical production of biofuels. In this study, the effect of substrate properties on the enzymatic hydrolysis of softwood was studied. Stem wood spruce chips were fractionated by SO2–ethanol–water (SEW) treatment to produce pulps of varying composition by applying different operating conditions. The SEW technology efficiently fractionates different types of lignocellulosic biomass by rapidly dissolving hemicelluloses and lignin. Cellulose remains fully in the solid residue which is then treated by enzymes to release glucose. The differences in enzymatic digestibility of the spruce SEW pulp fibers were interpreted in terms of their chemical and physical characteristics. A strong correlation between the residual lignin content of SEW pulp and enzymatic digestibility was observed whereas cellulose degree of polymerization and hemicellulose content of pulp were not as important. For the pulps containing about 1.5 % (w/w) lignin, 90 % enzymatic digestibility was achieved at 10 FPU enzyme charge and 24 h of hydrolysis time.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

For the economical conversion of biomass into chemicals and fuels numerous technological pathways are being investigated globally (Kamm et al. 2006). One of the main difficulties for the implementation of biorefineries, where lignocellulosics are converted into liquid biofuels through biochemical means, remains the techno-economics of enzymatic deconstruction of lignocellulosics, especially that of softwood (SW). It is crucial to understand and overcome the chemical and structural barriers that prevent the cost effective enzymatic disassembly of biomass (Himmel et al. 2007).

Enzymatic hydrolysis is considered a key technology for production of renewable fuels and much research is ongoing in the field. The new findings are expected to notably improve the techno-economic potential of industrial biochemical processes. On the other hand, other hydrolysis technologies, such as dilute-acid, are considered to be in a mature phase of development with not much cost improvements expected (Hamelinck et al. 2005). Also, enzyme prices have been decreasing and more efficient commercial mixtures are being developed. However, the enzymatic hydrolysis of SW biomass still remains very challenging and there are no commercial enzyme solutions optimized for SW feedstocks. Since SW resources in Northern hemisphere are abundant, it is essential for these regions to gain a better understanding of the factors determining enzymatic hydrolysis of SWs.

Specific properties of lignocellulosic substrates can limit both the rate and degree of enzymatic hydrolysis. These factors include accessible surface area, crystallinity, degree of polymerization (DP) of cellulose, lignin content, hemicellulose content and acetyl content (Mansfield et al. 1999; Zhang and Lynd 2004). Some studies have summarized the relationship between these structural features and digestibility but there is still dispute about the relative importance of specific features. Also, it is generally difficult to assess the effect of individual factors since pretreatments simultaneously alter several of them.

Enzymatic hydrolysis is a surface-dominated phenomenon and cellulase enzymes must bind to the surface of substrate to facilitate hydrolysis. Therefore, available surface area has been identified as one of the important factors affecting substrate digestibility. Besides the external surface available, internal surfaces and porosity of the substrate also notably affect the overall enzyme accessibility (Leu and Zhu 2013; Arantes and Saddler 2011). Pretreatments soften the rigid structure of biomass and increase the porosity and accessible surface area by dissolving lignin and hemicelluloses. In addition, cellulose hydrolysis rates are thought to be limited by the availability of cellulose chain ends. Thus, low DP of cellulose is beneficial for efficient cellulose deconstruction because the number of cellulose chain ends available to the action of cellobiohydrolase is higher (Hallac and Ragauskas 2011).

Hemicelluloses act as a barrier preventing the access of cellulase to the cellulose surface and thus, their removal during the pretreatment/fractionation stage is beneficial. The removal of hemicelluloses also increases the pore size of the substrate improving cellulose accessibility (Mansfield et al. 1999). Cellulases can be supplemented with accessory enzymes for simultaneous hydrolysis of cellulose and residual hemicelluloses (Öhgren et al. 2007; Várnai et al. 2011). Várnai et al. (2010) have reported that xylan limits the cellulose hydrolyzability especially in delignified samples. Also, the location of hemicellulose with respect to cellulose and lignin is of importance. Due to a layered structure of cellulose and xylan chains in the cell wall simultaneous action of cellulase and xylanase is beneficial (Zhang et al. 2011).

Lignin is considered one of the main reasons for biomass recalcitrance. In enzymatic hydrolysis, lignin reduces the efficiency due to unproductive adsorption of enzymes on lignin (Kumar et al. 2012; Palonen et al. 2004; Rahikainen et al. 2011). Secondly, lignin forms a physical barrier preventing access of cellulase on cellulose surfaces and restricts cellulose swelling (Kumar et al. 2012). Furthermore, lignin also causes problems in enzyme recycling. In particular, cellulases associated with SW derived residual substrates have been reported to have less potential for recycling (Gregg and Saddler 1996). All the above mentioned problems are promoted at high lignin content and therefore, efficient delignification significantly reduces biomass recalcitrance. However, complete delignification is costly and difficult, and therefore also other approaches for improved enzymatic hydrolysis should be considered.

Softwood materials are more resistant to both pretreatment and enzymatic hydrolysis than hardwood (HW) (Mansfield et al. 1999) and require higher enzyme dosages. At the same lignin content, HW is easier to digest than SW (Yu et al. 2011). Also, SW lignin is considered to be more harmful for hydrolytic enzymes than the lignin derived from annual plants (Nakagame et al. 2010). The mechanism behind the easier hydrolysis of HW is not fully understood but it is likely due to clear differences in lignin structure and chemistry (Achyuthan et al. 2010) with HW lignin consisting of mixed guaiacyl and syringyl units, whereas SW lignin contains mostly guaiacyl units. The lower degree of unit crosslinking of syringyl lignin also explains the easier delignification of HW in pretreatments. Apparently, the hemicellulose and lignin occupy smaller spaces in SW resulting in smaller increase in pore volume upon their removal or redistribution and thus, inferior digestibility (Mansfield et al. 1999). Also, guaiacyl lignin in SW fibers impairs swelling and accessibility of enzymes more than syringyl lignin (Ramos et al. 1992).

Also the delignification method has been shown to significantly affect the hydrolysis (Pan et al. 2005a). In addition, the degree of delignification required highly depends on the pretreatment/fractionation method. These factors emphasize the importance of lignin structure and distribution within substrate rather than its absolute amount. Still, it is important to gain more understanding on how the lignin content and composition, together with all the other structural and chemical features of biomass, affect the digestibility.

Substrate properties are determined by the raw material and pretreatment/fractionation method used prior to hydrolysis. Unlike fractionation methods, pretreatment methods (e.g., steam explosion, dilute acid, SPORL (Zhu et al. 2009)) generally do not achieve both extensive delignification and hemicellulose removal (Iakovlev and van Heiningen 2012a). Pretreatment methods also fail to utilize all biomass components for conversion into valuable products. A promising fractionation method to overcome the weaknesses of pretreatment processes is SO2–Ethanol–Water (SEW) fractionation which has recently been intensively studied for different types of lignocellulosics (Iakovlev et al. 2014; Iakovlev and van Heiningen 2012a, b). The advantages of this process include rapid and selective removal of lignin and hemicellulose. Sugar degradation and formation of inhibitive compounds is very low. The method is omnivorous and allows simultaneous fractionation of different types of lignocellulosics. The conversion of dissolved wood in the SEW liquor to monomer sugars is part of a patented process termed AVAP® by American Process Inc., a member of the industrial consortium supporting the present research (Retsina and Pylkkanen 2011). The process has been demonstrated also on logging residues and it has been developed as a part of forest biorefinery concept where SEW fractionated biomass is converted to a mixture of butanol, isopropanol and ethanol (Sklavounos et al. 2013; Survase et al. 2012; Yamamoto et al. 2011, 2014).

In this study, the goal was to investigate the enzymatic digestibility of the pulps produced by SEW fractionation and to get valuable insight into the effect of the substrate properties on enzymatic digestibility. The results obtained revealed a strong correlation between the residual lignin content in pulp and both the rate and degree of hydrolysis. Hemicellulose content and DP of cellulose had a significantly smaller effect on enzymatic digestibility. Lignin sulfonation and condensation were also speculated to affect enzymatic digestibility.

Materials and methods

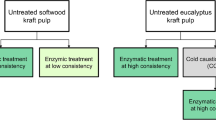

Fractionation

Softwood pulps with controlled chemical composition were prepared from air-dried spruce stem wood chips (thickness 2.0–5.9 mm) by selecting the appropriate fractionation conditions based on earlier SEW kinetics studies (Iakovlev et al. 2009; Iakovlev and van Heiningen 2012b). SEW fractionation was done in a thermostated silicon oil bath using bombs of 220 mL each filled with 25 g (o.d. basis) spruce chips. The experimental flow diagram (Fig. 1) shows details on the processing of the spruce chips including the conditions during the fractionation. Liquor-to-wood ratio (L:W 6 L kg−1) and ethanol–water concentration (55 v/v %, based on the sum of the volumes of ethanol and water) were kept constant in the fractionation experiments whereas the SO2 concentration, temperature and cooking duration varied significantly in order to produce pulps with clear differences in the chemical composition. The reported durations include 8–9 min of equivalent heat-up time (Iakovlev et al. 2011).

After fractionation, the bombs were cooled in cold water. Spent liquors were collected by squeezing the pulp suspension contained in washing bags. Pulps were washed twice with 40 v/v % ethanol–water at 60 °C (L:W 2 L kg−1) and twice with deionized water at room temperature (L:W 20 L kg−1). Optimized conditions of SEW treatment and pulp washing of stem wood chips have been determined by Iakovlev et al. (2009; 2012b, 2014).

Pulp properties characterization

Pulp intrinsic viscosity in cupriethylenediamine (CED) solution was determined according to SCAN-CM 15:99. Pulp no. 2 (see Table 1) was exposed to chlorite delignification (T230 om-66) prior to viscosity measurement due to its high lignin content. The DP of cellulose was calculated from the intrinsic viscosity according to da Silva Perez and van Heiningen (2002). Cellulose DP of pulp 8 was estimated based on the kinetics of DP decrease (Iakovlev et al. 2014), since it could not be analyzed due to the high content of fiber bundles.

Extractives content was analyzed gravimetrically through acetone extraction (SCAN 49:03). Carbohydrates and lignin were determined according to NREL/TP-510-42618 (Sluiter et al. 2008) which includes double stage sulfuric acid hydrolysis followed by HPAEC-PAD (Dionex ICS-3000, CarboPac PA20 column) analysis. Cellulose content of feedstock and pulps was calculated by subtracting the glucose present in hemicelluloses from the total glucose. Glucose in hemicellulose was calculated based on the mannose-to-glucose ratio of 4.15 reported for SW glucomannan (Janson 1974). An exception to the standard was the determination of acid soluble lignin by measuring the absorbance at 205 nm (Shimadzu UV-2550 spectrophotometer). The absorptivity value used was 128 L g−1 cm−1. Acetyl groups were measured as acetic acid according to the same standard by HPLC (Dionex UltiMate 3000 with diode array detector, Acclaim OA column).

Fiber saturation point (FSP) of the pulps was analyzed by solute exclusion technique (Maloney 2000; Stone et al. 1968) with dextran according to the internal method of Aalto University. For the analysis of cellulose crystallinity, the ground pulp samples (Wiley mill, 20 mesh) were pressed in metal rings of 1 mm thickness and measured in perpendicular transmission geometry. The X-ray setup consisted of a Seifert ID 3003 X-ray generator (voltage 36 kV, current 25 mA) equipped with a Cu tube (wavelength 1.54 Å), a Montel multilayer monochromator and a MAR345 (Marresearch) image plate detector. The data treatment and the calculation of cellulose crystal size and crystallinity are described by Penttilä et al. (2013). Margin of error was ±3 %.

Enzymatic hydrolysis

The commercial state-of-the-art enzyme mixture used in the hydrolysis experiments was Cellic CTec2 kindly provided by Novozymes. The filter paper activity (FPU = 161 FPU/mL) of the enzyme solution was measured according to the IUPAC method (Ghose 1987). Enzymatic hydrolysis was carried out according to NREL/TP-510-42629 (Selig et al. 2008) and the conditions are shown in Fig. 1. Constant temperature aluminum blocks on top of a heating plate with magnetic stirring function were used to hold several hydrolysis tubes. Sample volume was 10 mL in 40 mL tubes. At each sampling time 1 mL sample was taken from the hydrolysis tubes. The hydrolysis was terminated by boiling for 10 min to inactivate the enzymes. Hydrolysis references included substrate blanks obtained by incubating the substrates without enzymes, and enzyme blanks prepared by boiling the enzymes without substrates. Samples were centrifuged and the concentration of dissolved sugars in the supernatant was analyzed by HPAEC (Dionex ICS-3000, CarboPac PA20 column and pulsed amperometric detection (PAD)). For the determination of total sugars in the 72 h samples, supernatants were hydrolyzed in an autoclave at 121 °C for 60 min. The acid concentration of the samples was set to 4 % with 72 % (w/w) sulfuric acid according to NREL/TP-510-42623 (Sluiter et al. 2006). Reported results are the average of duplicate hydrolysis measurements, showing the percentage of theoretical maximum yield and the error bars represent the standard deviation. For clarity, the error bars were not included in all figures.

Results and discussion

Characteristics of the pulps

The eight spruce pulps produced at different SEW fractionation conditions (Table 1) had a wide range of lignin content (1.4–21.1 %), cellulose DP (1,800–8,000) and hemicellulose content (5.0–13.5 %). High SO2 concentration combined with either high temperature or long fractionation time were required to reach the lowest residual lignin content. The conditions applied had also a significant effect on the hemicellulose content, crystallinity, viscosity and cellulose DP of the pulps. However, the extractives content and the amount of acetyl groups were mostly the same except for the least delignified pulp which had higher contents. Table 1 also lists the 24 h glucose yields after enzymatic hydrolysis (at 10 FPU/g cellulose). The pulps are organized in order of increasing lignin content, and clearly show that enzymatic digestibility is strongly affected by the lignin content. This will be discussed in more detail in the following sections.

The FSP data represents the total amount of water in the cell wall and it is considered the most well-defined and best measure of fiber swelling (Maloney et al. 1999). It indicates the level of hornification, which is an important factor especially for the hydrolysis of waste fibers, and is shown to reduce substrate enzymatic digestibility (Luo and Zhu 2011). The differences observed in the present FSP are too small to draw any distinct conclusion. Crystallinity values analyzed for three pulps indicates that the crystallinity increases through SEW fractionation, most likely due to the selective removal of amorphous hemicelluloses and lignin. Pulps exhibiting the best performance in enzymatic hydrolysis have gone through extensive fractionation and thus, have somewhat higher crystallinity. However, it should be noted that cellulose crystallinity is an important factor for enzymatic hydrolysis of pure cellulose whereas for lignocelluloses other factors, such as cellulose accessibility, are more important (Agarwal et al. 2013).

Optimizing enzyme dosage

The enzyme dosage was optimized by determining the dosage curves (Fig. 2) for two pulps, with high (12.9 %, pulp 7) and very low (1.6 %, pulp 2) lignin content.

It was obvious that the pulp 7 required notably higher enzyme dosage (30 FPU) to reach 90 % glucose yield in 72 h. On the other hand, for pulp 2 almost 90 % yield was reached within 24 h at a dosage of 10 FPU/g cellulose. In the latter case, initial hydrolysis rate was improved by higher enzyme dosage but the final yield was the same for the three dosages tested. For further experiments comparing the digestibility of all the pulps produced, 10 FPU/g cellulose dosage (equal to 4.5–6.8 % (w/w) enzyme preparation on substrate) was selected in order to observe clear differences in glucose yields. This dosage is also commonly used in laboratory studies since it provides a hydrolysis profile with relatively high glucose yields in reasonable time (48–72 h) and at reasonable enzyme cost (Gregg and Saddler 1996).

Softwood lignocellulosics are known to require higher enzyme charges compared to HW lignocellulosics. Also, the higher the lignin content the more enzymes are usually required to reach sufficient cellulose conversion to glucose. The enzyme dosage required for the high lignin SEW pulps is well in accordance with the values reported for SW materials at similar lignin content. To reach about 90 % conversion within 48 h for partially delignified SW, around 15–20 FPU/g cellulose dosage is often required (Iakovlev and van Heiningen 2012a; Pan et al. 2005a; Yu et al. 2011). However, each pretreatment or fractionation method causes different types of changes in the biomass and therefore, the comparison is complicated.

The fact that over 90 % yield on pulp no. 7 can be achieved by increasing enzyme loading indicates that cellulose in SEW pulps is accessible but that the enzymes are adsorbed on lignin thereby reducing its efficiency, and enzyme overdose is required. This suggests that non-productive enzyme binding sites on lignin surfaces have to be saturated for yield improvement. Proteins or surfactants added to pulp prior to the hydrolysis could be used to improve the yields for the higher lignin content pulps. Several attempts have been reported to overcome the non-productive binding of enzymes by lignin. Exogenous proteins (e.g., bovine serum albumin (BSA)) (Brethauer et al. 2011; Yang and Wyman 2006) or surfactants (Eriksson et al. 2002) are shown to improve the hydrolysis by covering the lignin if they are charged prior to enzyme addition. Also, lignin-metal complexes have been found to improve hydrolysis (Liu et al. 2010). Nevertheless, the implementation of this kind of additives is not considered feasible or is technically challenging for commercial production. However, lignosulfonates produced as by-product in SEW fractionation might provide yield improvements since those have been reported to enhance enzymatic saccharification (Zhou et al. 2013).

All the hydrolysis yields reported are based on dissolved glucose monomers. To estimate the total yields of enzymatic hydrolysis, acid hydrolysis was done for 72 h samples to hydrolyze also the dissolved oligomers and to estimate the total yield of hydrolysis. Total glucose yields observed were about 5 % higher than the monomer yields reported. Total yields of xylose and mannose were comparable with the glucose yields, which is a good sign of efficient total hydrolysis since the concurrent hydrolysis of hemicelluloses is crucial for efficient hydrolysis of cellulose (Várnai et al. 2011). Xylose monomer yields were comparable to glucose. However, a clear difference was observed in mannose monomer yields which were only about 20–30 % of the total mannose in pulp. Thus the much higher share of dissolved mannose oligomers as compared to the other sugars shows that β-mannosidase is required for the hydrolysis of glucomannan oligomers. Cellic CTec2 is optimized for corn stover and thus, lacks some activities required for complete hydrolysis of SW substrates. However, it is derived from Trichoderma Reesei which has some natural endomannanase activity facilitating the partial hydrolysis of mannan.

HPLC/HPAEC and YSI glucose analyzers are often used to determine the amount of dissolved monosaccharides during enzymatic hydrolysis. However, part of the dissolved sugars are present as oligosaccharides, and the oligomer/monomer fraction depends on the substrate and enzyme preparation used. Thus for better evaluation of the total hydrolysis performance, it is recommended to use methods which also determine the dissolved oligosaccharides. The rapid assay of reducing sugars (Miller 1959) quantifies the total sugars, but does not distinguish the different dissolved sugars. HPLC/HPAEC analysis after 4 % sulfuric acid hydrolysis provides an accurate and full characterization of the oligomer content in the solution although the procedure is time consuming.

The effect of pulp properties on enzymatic hydrolysis

The effect of lignin content and quality

Enzymatic hydrolysis of the spruce pulps revealed a strong correlation between the lignin content of the pulps and the rate and degree of hydrolysis (Fig. 3).

Recently it has been shown that complete removal of lignin from biomass results in extremely digestible material and thus, pretreatment/fractionation methods should maximize lignin removal while minimizing polysaccharide modification (Ding et al. 2012). As shown in Fig. 3a, here the SEW pulps with lowest residual lignin contents reached about 90 % glucose monomer yields within 24 h, while the pulp having the highest lignin content had only 48 % yield. Figure 3b shows that the effect of lignin content was significant especially after 24 h hydrolysis in the range of 1–5 % residual lignin content, whereas the digestibility was less affected at higher residual lignin content. This observation is contrary to some previously reported results. Yu et al. (2011) observed most improvement in the hydrolysis performance due to delignification at high residual lignin content from 30 to 19 %, when alkaline treatment followed by chlorite or ozone treatment was applied. At lower lignin contents, enzymatic hydrolysis nearly leveled off. Also Pan et al. (2005a) reported significant improvement in the digestibility when residual lignin content was reduced from 27 to 18 % by organosolv pulping. Yield improvement offered by further delignification was smaller but well comparable to the improvement shown here in the same lignin range. On the other hand, excellent conversion of cellulose can also be achieved despite the high lignin content. Shuai et al. (2010) reported over 90 % yield within 24 h on SPORL pretreated spruce containing 33 % lignin, at enzyme loading of 15 FPU/g cellulose. SPORL lignin is expected to have a high degree of sulfonation reducing lignin hydrophobicity and thus causing less non-productive binding of cellulase to lignin. This clearly indicates that the digestibility of pulps at certain lignin contents is highly dependent on pretreatment and delignification method and thus, on the quality and distribution of lignin.

Shown in Fig. 4 is the enzymatic digestibility of three of the spruce pulps (number 4, 5 and 6; see Table 1) produced at different SO2 charges in fractionation but resulting in almost the same lignin contents (4.8–5.4 %). This allowed evaluation of the effect of lignin quality and non-lignin components on the moderate differences in enzymatic digestibility in the section below.

Generally, lignin condensation reactions during pretreatment/fractionation are more pronounced at higher acidity, whereas too low acidity leads to limited hydrolytic depolymerization and associated inefficient enzymatic hydrolysis. In the SEW process, the presence of SO2 leads to lignin sulfonation consuming the reactive benzyl carbocations and thus decreasing lignin condensation. Therefore, increasing SO2 concentration leads to lower condensation, despite the moderate acidity increase. Thus, an optimum of acidity and sulfonation ability exists where the hydrolysis is maximized and lignin condensation minimized (Iakovlev 2011). Here, lignin condensation is occurring especially at lower SO2 concentrations which also require longer fractionation time. Condensation increases the hydrophobicity of lignin due to elimination of hydrophilic hydroxyl groups in the α-position of the lignin unit and increases the molecular weight. Thus, the adsorption of enzymes on lignin driven by hydrophobic attraction is likely increased at lower SO2 concentrations. In Fig. 4, it can be seen that the pulps prepared at lower SO2 concentrations had the lowest final glucose yields. Also other studies have mentioned the negative effect of lignin condensation on digestibility (Pielhop et al. 2012; Zhu et al. 2009). It should also be noted that this result can be explained neither by hemicellulose content nor DP of cellulose. Those values were the highest at 12 % SO2 charge which resulted in the highest final glucose yield.

Contrary to condensation, sulfonation increases the hydrophilicity of lignin and reduces the hydrophobic interactions and nonproductive binding of cellulases to lignin (Zhu et al. 2009; Lou et al. 2013). Here, the lignin sulfonation degrees of the pulps produced were not analyzed but estimated values are given in Table 1. Based on an earlier study (Iakovlev and van Heiningen 2012b) it can be concluded that the pulps produced at higher SO2 charge have somewhat higher degree of sulfonation. This has likely contributed to the better glucose yields observed on the pulps produced at higher SO2 charge. Lou et al. (2013) have observed that the saccharification can be notably enhanced if the hydrolysis is carried out at elevated pH 5.5–6.0. The enhancement due to elevated pH is significant especially on pulps containing highly sulfonated lignin and this approach could be exploited to obtain further yield improvements.

The previous data shows that lignin inhibition can be reduced by chemical modification of lignin or by selective removal of lignin fractions. Specifically, this is achieved by selecting a fractionation or pretreatment method which promotes lignin sulfonation and reduces condensation. Lignin modification could also be more economical compared to complete lignin removal. Another example of this approach is mild treatment by NaOH to remove alkali-extractable lignin which has been suggested to notably inhibit the digestibility. This treatment was found to notably improve the cellulose conversion (Pan et al. 2005b). In case of bark containing SW biomass feedstock, NaOH treatment also dissolves the polyphenolic acids in bark which are highly resistant to acidic pretreatment (Fengel and Wegener 1989). This is beneficial when treating forest residues since polyphenolic acids impair delignification, as well as subsequent hydrolysis by forming complexes with enzyme proteins (Jensen et al. 1963). However, NaOH treatment in practice would not be practical because the required capital intensive recovery of caustic is not economical when producing biofuels. Therefore, the bark contamination problem should be solved by other means.

The effect of hemicelluloses and DP of cellulose

Hemicellulose content and DP of cellulose are also contributing to the recalcitrance of lignocellulosic biomass. Based on our results displayed in Fig. 5, there appears to be a weak correlation between the glucose yields and hemicellulose content and DP. However, compared to the enzymatic digestibility results obtained at different lignin content, significant variability was observed especially in the lower range of hemicellulose content and DP. R2 values representing the variation of the data were 0.81–0.97 for lignin versus glucose yield curves, whereas those for hemicellulose and DP were only 0.37–0.53 and 0.53–0.58, respectively. Therefore, it is evident that the effect of lignin content on SEW pulp digestibility is stronger than that of hemicellulose content also because lower hemicellulose content is somewhat correlated with lower lignin content.

Also when comparing the three pulps having approximately equal lignin contents (Fig. 4), no apparent correlation was found between the glucose yield and hemicellulose content or DP. In fact, the pulp with the highest hemicellulose content and DP had the highest final yield. Also this observation supports the statement that lignin content and sulfonation is more crucial for the enzymatic digestibility.

Based on the present results and those reported in literature it appears that there are several substrate features which would govern the rate and degree of enzymatic hydrolysis. Differences in substrate origin, pretreatment technology and enzyme preparation used increase the complexity of the comparison. Therefore, it seems necessary that for each biorefinery concept the enzymatic hydrolysis potential must be separately assessed.

The effect of hydrolysis conditions on enzymatic hydrolysis

Enzyme preparation used, substrate properties and conditions during enzymatic hydrolysis are the parameters affecting the obtainable yields. By carefully optimizing the conditions during enzymatic hydrolysis, yields can be notably improved. In this study, the conditions were selected based on the standard procedure used without further optimization. However, the effect of reduced temperature and increased substrate consistency were briefly studied.

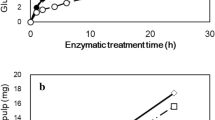

Non-productive enzyme binding to lignin is more pronounced at higher temperatures (Rahikainen et al. 2013; Zheng et al. 2013) and optimization of hydrolysis temperature would be beneficial especially when working with high lignin content pulps having more lignin inhibition. In the present study, a five degrees decrease in the hydrolysis temperature resulted in a three percent higher glucose yield (Fig. 6a). The experiment was carried out on pulp 7 with 12.9 % lignin content at enzyme dosage of 15 FPU/g cellulose. In addition to temperature, optimization of the pH during enzymatic hydrolysis has been found highly important since an elevated pH significantly improves the hydrolysis yields by reducing the non-productive cellulase binding to lignin (Lan et al. 2013; Lou et al. 2013). However, the effect of pH was not investigated in the present research.

The effect of substrate consistency was studied at 1.5 and 5 % consistencies for spruce pulp 7 at enzyme dosage of 20 FPU/g cellulose (Fig. 6b). For the samples at 5 % consistency the pulp was gradually added to the reaction within the first 2 h to facilitate constant and efficient mixing. Interestingly, the observed glucose yields were nearly the same from 24 to 72 h hydrolysis, although higher substrate consistency is generally known to increase end product inhibition and reduce hydrolysis yields (Kristensen et al. 2009). It is possible that at notably higher substrate consistencies the hydrolysis yield would thereby be reduced. However, it has been proposed that by employing appropriate mixing scheme, high hydrolysis yields can be maintained even at 20 % substrate consistency (Xue et al. 2012).

Conclusions

It was demonstrated that softwood SEW pulps with about 1.5 % (w/w) residual lignin content were efficiently hydrolyzed by enzymes: 90 % sugar yields were obtained at 10 FPU enzyme charge after 24 h of hydrolysis. Also, the results show a strong correlation between the lignin content of SEW pulp and enzymatic digestibility. The effect of lignin was most pronounced in the range of 1–5 % residual lignin on pulp, whereas the hydrolysis yield of pulps with higher lignin content was affected less by lignin content. It was also speculated that condensation of lignin likely leads to lower digestibility while lignin sulfonation is beneficial in order to obtain higher glucose yields. Other characteristics of the pulps, such as DP of cellulose and hemicellulose content of the pulp, showed a weaker correlation with glucose yields than lignin content.

Based on current knowledge, the non-productive cellulase adsorption determined by lignin quality and content seems more critical than physical blocking governed by the amount of lignin. Lignin content can be reduced by efficient delignification during fractionation and pretreatment stages. However, other characteristics of the delignification process such as those which impart hydrophilicity to the residual lignin in the fibers are beneficial for enzymatic hydrolysis. Also, enzyme preparations optimized for softwood feedstocks should be implemented to improve the potential of softwood in biofuel production.

References

Achyuthan KE, Achyuthan AM, Adams PD, Dirk SM, Harper JC, Simmons BA, Singh AK (2010) Supramolecular self-assembled chaos: polyphenolic lignin’s barrier to cost-effective lignocellulosic biofuels. Molecules 15:8641–8688. doi:10.3390/molecules15118641

Agarwal UP, Zhu JY, Ralph SA (2013) Enzymatic hydrolysis of loblolly pine: effects of cellulose crystallinity and delignification. Holzforschung 67:371–377. doi:10.1515/hf-2012-0116

Arantes V, Saddler JN (2011) Cellulose accessibility limits the effectiveness of minimum cellulase loading on the efficient hydrolysis of pretreated lignocellulosic substrates. Biotechnol Biofuels 4. doi:10.1186/1754-6834-4-3

Brethauer S, Studer MH, Yang B, Wyman CE (2011) The effect of bovine serum albumin on batch and continuous enzymatic cellulose hydrolysis mixed by stirring or shaking. Bioresour Technol 102:6295–6298. doi:10.1016/j.biortech.2011.02.016

da Silva Perez D, van Heiningen A (2002) Determination of cellulose degree of polymerization in chemical pulps by viscosimetry. The 7th European Workshop on Lignocellulosics and Pulp (EWLP), August 26–29, Turku, Finland, pp 393–396

Ding S-, Liu Y-, Zeng Y, Himmel ME, Baker JO, Bayer EA (2012) How does plant cell wall nanoscale architecture correlate with enzymatic digestibility? Science 338:1055–1060. doi:10.1126/science.1227491

Eriksson T, Börjesson J, Tjerneld F (2002) Mechanism of surfactant effect in enzymatic hydrolysis of lignocellulose. Enzyme Microb Technol 31:353–364. doi:10.1016/S0141-0229(02)00134-5

Fengel D, Wegener G (1989) Wood—Chemistry, Ultrastructure, Reactions. Walter de Gruyter, Berlin

Ghose TK (1987) Measurement of cellulase activities, IUPAC (International Union of Pure and Applied Chemistry). Pure and Appl Chem 59:257–268. doi:10.1351/pac198759020257

Gregg DJ, Saddler JN (1996) Factors affecting cellulose hydrolysis and the potential of enzyme recycle to enhance the efficiency of an integrated wood to ethanol process. Biotechnol Bioeng 51:375–383. doi:10.1002/(SICI)1097-0290(19960820)51:4<375:AID-BIT1>3.0.CO;2-F

Hallac BB, Ragauskas AJ (2011) Analyzing cellulose degree of polymerization and its relevancy to cellulosic ethanol. Biofuel Bioprod Biorefin 5:215–225. doi:10.1002/bbb.269

Hamelinck CN, Gv Hooijdonk, Faaij AP (2005) Ethanol from lignocellulosic biomass: techno-economic performance in short-, middle- and long-term. Biomass Bioenergy 28:384–410. doi:10.1016/j.biombioe.2004.09.002

Himmel ME, Ding S-, Johnson DK, Adney WS, Nimlos MR, Brady JW, Foust TD (2007) Biomass recalcitrance: engineering plants and enzymes for biofuels production. Science 315:804–807. doi:10.1126/science.1137016

Iakovlev M (2011) SO2-ethanol-water (SEW) fractionation of lignocellulosics. Dissertation, Aalto University

Iakovlev M, van Heiningen A (2012a) Efficient fractionation of spruce by SO2–Ethanol–Water (SEW) treatment: closed mass balances for carbohydrates and sulfur. Chem- SusChem 5:1625–1637. doi:10.1002/cssc.201100600

Iakovlev M, van Heiningen A (2012b) Kinetics of fractionation by SO2–ethanol–water (SEW) treatment: understanding the deconstruction of spruce wood chips. RSC Adv 2:3057–3068. doi:10.1039/C2RA00957A

Iakovlev M, Pääkkönen T, van Heiningen A (2009) Kinetics of SO2–ethanol–water pulping of spruce. Holzforschung 63:779–784. doi:10.1515/HF.2009.109

Iakovlev M, Sixta H, van Heiningen A (2011) SO2-ethanol-water (SEW) pulping: II. Kinetics for spruce, beech, and wheat straw. J Wood Chem Technol 31:250–266. doi:10.1080/02773813.2010.523162

Iakovlev M, You X, van Heiningen A, Sixta H (2014) SO2–ethanol–water (SEW) fractionation of spruce: kinetics and conditions for paper and viscose-grade dissolving pulp. RSC Adv 4:1938–1950. doi:10.1039/C3RA45573D

Janson J (1974) Analytik der polysaccharide in Holz und Zellstoff. Faserforsch Textiltech 25:375–382

Jensen W, Kremer KE, Sieril P, Vartiovaara V (1963) The chemistry of bark. In: Browning BL (ed) The chemistry of wood. Interscience Publishers, New York, pp 587–666

Kamm B, Gruber PR, Kamm M (2006) Biorefineries—industrial processes and products: status quo and future directions. Wiley, Weinheim

Kristensen J, Felby C, Jorgensen H (2009) Yield-determining factors in high-solids enzymatic hydrolysis of lignocellulose. Biotechnol Biofuels 2:11. doi:10.1186/1754-6834-2-11

Kumar L, Arantes V, Chandra R, Saddler J (2012) The lignin present in steam pretreated softwood binds enzymes and limits cellulose accessibility. Bioresour Technol 103:201–208. doi:10.1016/j.biortech.2011.09.091

Lan TQ, Lou H, Zhu JY (2013) Enzymatic saccharification of lignocelluloses should be conducted at elevated pH 5.2–6.2. Bioenergy Res 6:476–485. doi:10.1007/s12155-012-9273-4

Leu S-Y, Zhu JY (2013) Substrate-related factors affecting enzymatic saccharification of lignocelluloses: our recent understanding. Bioenergy Res 6:405–415. doi:10.1007/s12155-012-9276-1

Liu H, Zhu JY, Fu SY (2010) Effects of lignin-metal complexation on enzymatic hydrolysis of cellulose. J Agric Food Chem 58:7233–7238. doi:10.1021/jf1001588

Lou H, Zhu JY, Lan TQ, Lai H, Qiu X (2013) PH-induced lignin surface modification to reduce nonspecific cellulase binding and enhance enzymatic saccharification of lignocelluloses. ChemSusChem 6:919–927. doi:10.1002/cssc.201200859

Luo X, Zhu JY (2011) Effects of drying-induced fiber hornification on enzymatic saccharification of lignocelluloses. Enzyme Microb Technol 48:92–99. doi:10.1016/j.enzmictec.2010.09.014

Maloney TC (2000) On the pore structure and dewatering properties of the pulp fiber cell wall. Dissertation, Helsinki University of Technology

Maloney TC, Laine JE, Paulapuro H (1999) Comments on the measurement of cell wall water. Tappi J 82:125–127

Mansfield SD, Mooney C, Saddler JN (1999) Substrate and enzyme characteristics that limit cellulose hydrolysis. Biotechnol Prog 15:804–816. doi:10.1021/bp9900864

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428

Nakagame S, Chandra RP, Saddler JN (2010) The effect of isolated lignins, obtained from a range of pretreated lignocellulosic substrates, on enzymatic hydrolysis. Biotechnol Bioeng 105:871–879. doi:10.1002/bit.22626

Öhgren K, Bura R, Saddler J, Zacchi G (2007) Effect of hemicellulose and lignin removal on enzymatic hydrolysis of steam pretreated corn stover. Bioresour Technol 98:2503–2510. doi:10.1016/j.biortech.2006.09.003

Palonen H, Tjerneld F, Zacchi G, Tenkanen M (2004) Adsorption of Trichoderma reesei CBH I and EG II and their catalytic domains on steam pretreated softwood and isolated lignin. J Biotechnol 107:65–72. doi:10.1016/j.jbiotec.2003.09.011

Pan X, Arato C, Gilkes N, Gregg D, Mabee W, Pye K, Xiao Z, Zhang X, Saddler J (2005a) Biorefining of softwoods using ethanol organosolv pulping: preliminary evaluation of process streams for manufacture of fuel-grade ethanol and co-products. Biotechnol Bioeng 90:473–481. doi:10.1002/bit.20453

Pan X, Xie D, Gilkes N, Gregg D, Saddler J (2005b) Strategies to enhance the enzymatic hydrolysis of pretreated softwood with high residual lignin content. Appl Biochem Biotechnol 124:1069–1079. doi:10.1385/ABAB:124:1-3:1069

Penttilä PA, Kilpeläinen P, Tolonen L, Suuronen J-, Sixta H, Willför S, Serimaa R (2013) Effects of pressurized hot water extraction on the nanoscale structure of birch sawdust. Cellulose 20:2335–2347. doi:10.1007/s10570-013-0001-9

Pielhop T, Studer M, von Rohr PR (2012) Use of carbonium ion scavengers in the pretreatment of spruce wood. 12th European Workshop on Lignocellulosics and Pulp (EWLP), August 27–30, Espoo, Finland, pp 20–23

Rahikainen J, Mikander S, Marjamaa K, Tamminen T, Lappas A, Viikari L, Kruus K (2011) Inhibition of enzymatic hydrolysis by residual lignins from softwood—study of enzyme binding and inactivation on lignin-rich surface. Biotechnol Bioeng 108:2823–2834. doi:10.1002/bit.23242

Rahikainen JL, Moilanen U, Nurmi-Rantala S, Lappas A, Koivula A, Viikari L, Kruus K (2013) Effect of temperature on lignin-derived inhibition studied with three structurally different cellobiohydrolases. Bioresour Technol 146:118–125. doi:10.1016/j.biortech.2013.07.069

Ramos LP, Breuil C, Saddler JN (1992) Comparison of steam pretreatment of eucalyptus, aspen, and spruce wood chips and their enzymatic hydrolysis. Appl Biochem Biotechnol 34–35:37–48. doi:10.1007/BF02920532

Retsina T, Pylkkanen V (2011) Method for the production of fermentable sugars and cellulose from lignocellulosic material. U S patent US 8030039 granted 4 Oct. 2011. Also patents: US 8038842 granted 11 Oct. 2011; US 8268125 granted 18 Sept. 2012; US 8585863 granted 19 Nov. 2013

Selig M, Weiss N, Ji Y (2008) Enzymatic saccharification of lignocellulosic biomass. Technical report NREL/TP-510-42629

Shuai L, Yang Q, Zhu JY, Lu FC, Weimer PJ, Ralph J, Pan XJ (2010) Comparative study of SPORL and dilute-acid pretreatments of spruce for cellulosic ethanol production. Bioresour Technol 101:3106–3114. doi:10.1016/j.biortech.2009.12.044

Sklavounos E, Iakovlev M, van Heiningen A (2013) Study on conditioning of so2–ethanol–water spent liquor from spruce chips/softwood biomass for ABE fermentation. Ind Eng Chem Res 52:4351–4359. doi:10.1021/ie303126x

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D (2006) Determination of sugars, byproducts, and degradation products in liquid fraction process samples. Technical Report NREL/TP-510-42623

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D, Crocker D (2008) Determination of structural carbohydrates and lignin in biomass. Technical Report NREL/TP-510-42618

Stone JE, Scallan AM, Abrahamson B (1968) Influence of beating on cell wall swelling and internal fibrillation. Svensk Papperstidning 19:687

Survase SA, van Heiningen A, Granström T (2012) Continuous bio-catalytic conversion of sugar mixture to acetone–butanol–ethanol by immobilized Clostridium acetobutylicum DSM 792. Appl Microbiol Biotechnol 93:2309–2316. doi:10.1007/s00253-011-3761-x

Várnai A, Siika-aho M, Viikari L (2010) Restriction of the enzymatic hydrolysis of steam-pretreated spruce by lignin and hemicellulose. Enzyme Microb Technol 46:185–193. doi:10.1016/j.enzmictec.2009.12.013

Várnai A, Huikko L, Pere J, Siika-aho M, Viikari L (2011) Synergistic action of xylanase and mannanase improves the total hydrolysis of softwood. Bioresour Technol 102:9096–9104. doi:10.1016/j.biortech.2011.06.059

Xue Y, Jameel H, Phillips R, Chang H- (2012) Split addition of enzymes in enzymatic hydrolysis at high solids concentration to increase sugar concentration for bioethanol production. J Ind Eng Chem 18:707–714. doi:10.1016/j.jiec.2011.11.132

Yamamoto M, Iakovlev M, van Heiningen A (2011) Total mass balances of SO2–ethanol–water (SEW) fractionation of forest biomass. Holzforschung 65:559–565. doi:10.1515/HF.2011.098

Yamamoto M, Iakovlev M, van Heiningen A (2014) Kinetics of SO2–ethanol–water (SEW) fractionation of hardwood and softwood biomass. Bioresour Technol 155:307–313. doi:10.1016/j.biortech.2013.12.100

Yang B, Wyman CE (2006) BSA treatment to enhance enzymatic hydrolysis of cellulose in lignin containing substrates. Biotechnol Bioeng 94:611–617. doi:10.1002/bit.20750

Yu Z, Jameel H, Chang H-, Park S (2011) The effect of delignification of forest biomass on enzymatic hydrolysis. Bioresour Technol 102:9083–9089. doi:10.1016/j.biortech.2011.07.001

Zhang Y-P, Lynd LR (2004) Toward an aggregated understanding of enzymatic hydrolysis of cellulose: noncomplexed cellulase systems. Biotechnol Bioeng 88:797–824. doi:10.1002/bit.20282

Zhang J, Siika-Aho M, Tenkanen M, Viikari L (2011) The role of acetyl xylan esterase in the solubilization of xylan and enzymatic hydrolysis of wheat straw and giant reed. Biotechnol Biofuels 4:60. doi:10.1186/1754-6834-4-60

Zheng Y, Zhang S, Miao S, Su Z, Wang P (2013) Temperature sensitivity of cellulase adsorption on lignin and its impact on enzymatic hydrolysis of lignocellulosic biomass. J Biotechnol 166:135–143. doi:10.1016/j.jbiotec.2013.04.018

Zhou H, Lou H, Yang D, Zhu JY, Qiu X (2013) Lignosulfonate to enhance enzymatic saccharification of lignocelluloses: role of molecular weight and substrate lignin. Ind Eng Chem Res 52:8464–8470. doi:10.1021/ie401085k

Zhu JY, Pan XJ, Wang GS, Gleisner R (2009) Sulfite pretreatment (SPORL) for robust enzymatic saccharification of spruce and red pine. Bioresour Technol 100:2411–2418. doi:10.1016/j.biortech.2008.10.057

Acknowledgments

Financial support of Tekes (Finnish Funding Agency for Innovation) and industrial project members (ABB, American Process Inc., Kemira, Neste Oil, Stora Enso, UPM) through the BioRefine program is greatly acknowledged. Thanks to Dr. Paavo Penttilä and Prof. Ritva Serimaa at University of Helsinki for the analysis of crystallinity of cellulose; Dr. Shrikant Survase and Johanna Aura for their help in the analysis of the enzyme properties; Rita Hatakka for the HPAEC analyses and Leena Nolvi for the FSP analysis. Authors also thank Dr. Aniko Varnai and Dr. Jenni Rahikainen for valuable discussions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yamamoto, M., Iakovlev, M. & van Heiningen, A. The effect of chemical and physical characteristics of spruce SEW pulps on enzymatic hydrolysis. Cellulose 21, 3395–3407 (2014). https://doi.org/10.1007/s10570-014-0396-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-014-0396-y