Abstract

Nanofibrillated cellulose offers new technological solutions for the development of paper products. Here, composites of nanofibrillated cellulose (NFC) and Ag nanoparticles (NP) were prepared for the first time via the electrostatic assembly of Ag NP (aqueous colloids) onto NFC. Distinct polyelectrolytes have been investigated as macromolecular linkers in order to evaluate their effects on the building-up of Ag modified NFC and also on the final properties of the NFC/Ag composite materials. The NFC/Ag nanocomposites were first investigated for their antibacterial properties towards S. aureus and K. pneumoniae microorganisms as compared to NFC modified by polyelectrolytes linkers without Ag. Subsequently, the antibacterial NFC/Ag nanocomposites were used as fillers in starch based coating formulations for Eucalyptus globulus-based paper sheets. The potential of this approach to produce antimicrobial paper products will be discussed on the basis of complementary optical, air barrier and mechanical data.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Due to the renewable nature, biocompatibility, biodegradability and high specific strength of vegetable cellulose fibers, a growing interest has been devoted to its use in new composite materials in the last decades (Gandini 2011; Belgacem and Gandini 2008; Klemm et al. 2005; Amash and Zugenmaier 2000; Karlsson et al. 2000; Smiechowicz et al. 2011). In addition to conventional vegetal cellulose fibers, other forms of cellulose have attracted the attention of the scientific community in the last few years, namely, nanofibrillated cellulose (NFC) and microbial cellulose, due to the nanosized dimensions of these fibers that might impart improved, and in many cases new properties to the ensuing (nano)composite materials. Nanofibrillated cellulose can be obtained from cellulose fibers by distinct methods, in the form of aqueous suspensions of nanoscale fibers with high aspect ratio (5–30 nm diameter and lengths in the micrometer range) and specific surface areas combined with remarkable strength and flexibility (Paakko et al. 2007; Henriksson et al. 2007; Saito et al. 2007; Siró and Plackett 2010). The excellent mechanical properties of NFC make it a good candidate for reinforcement materials in nanocomposites (Zimmermann et al. 2004, 2010; Yano and Nakagaito 2005; Eichhorn et al. 2010; Hubbe et al. 2008; Klemm et al. 2011). Nanosized cellulose based composites have potential for applications in several areas, such as transparent materials (Tome et al. 2011; Fernandes et al. 2010), biomedical applications (Maneerung et al. 2008) or gas barrier films (Hubbe et al. 2008). Although the preparation of polymer coated Ag nanoclusters in NFC has been recently reported (Diez et al. 2011), the production of innovative NFC based materials has not yet been fully explored, especially in what concerns the context of antimicrobial paper research. Therefore, the use of NFC/silver nanocomposites for the preparation of antibacterial paper is reported here for the first time.

With the increasing awareness of infectious diseases caused by different microorganisms and the development of antibiotic resistance, the search for new and efficient antibacterial materials is imperative. Among inorganic antibacterial agents, silver has been extensively studied and its use to fight infections dates back to ancient times (Rai et al. 2009). Silver, both in metallic or in ionic form, exhibits strong inhibitory and bactericidal activities towards a broad spectrum of microorganisms. In recent years there has been a renewed interest on silver as antimicrobial agent, namely due to unprecedented progress observed on nanomaterials science in the last decades that prompted innovative strategies on the use of colloidal Ag in antimicrobial products (Marini et al. 2007; Pinto et al. 2009). As compared to the bulk form, Ag NP have higher surface area per volume and therefore surface mediated phenomena are expected to be more effective (Maneerung et al. 2008). Although the antibacterial mechanism of Ag NP is still not completely understood, some mechanisms have been suggested that highlight the relevance of the metal surface (Sondi and Salopek-Sondi 2004; Morones et al. 2005; Potara et al. 2011).

In the last years, reports on the production of antibacterial nanocomposites of vegetal or bacterial cellulose and silver nanoparticles have been published (Pinto et al. 2009; Maneerung et al. 2008; Silva and Unali 2011; El-Shishtawy et al. 2011), but to the best of our knowledge, the preparation of nanocomposites of NFC and Ag NP using polyelectrolytes as macromolecular linkers has not been reported. Cellulose-silver nanocomposites can be used as functional materials on textiles and polymers, leading to innovative products with antibacterial properties. For example, the use of such nanocomposites in paper coating formulations is an interesting approach to produce antibacterial papers with improved mechanical, surface and barrier properties that might find interest in packaging and air filters. Recently, reports concerning the production of antibacterial paper coated with Ag nanoparticles have appeared in the literature, namely by using the direct deposition or in situ synthesis of Ag nanoparticles (Dankovich and Gray 2011; Tankhiwale and Bajpai 2009; Gottesman et al. 2011). However these approaches might present limitations such as tendency for particle agglomeration and poor adherence of the nanoparticles onto the cellulose fibers (Dankovich and Gray 2011). Therefore the fabrication of antibacterial paper was investigated here using an alternative strategy. In this context, we report the preparation of antibacterial NFC/Ag nanocomposites by the electrostatic assembly of Ag NP onto NFC using polyelectrolytes, and their use in paper coating formulations to produce papers with antibacterial properties.

Materials and methods

Materials

Nanofibrillated cellulose suspension (2 % solid content) was kindly supplied by Centre Technique du Papier (France) and was obtained by submitting a softwood pulp to an enzymatic pre-treatment followed by mechanical treatment using a high-pressure homogenizer. The aqueous silver colloid (1 % w/w, average diameter 40 nm ± 12.4 nm) was supplied by Colorobbia (Italy) and was obtained by reducing Ag(I) at 85 °C, using an aqueous solution of glucose as a soft reducing agent, in the presence of soda and polyvinylpyrrolidone. Water diluted suspensions of Ag NP with metal contents between 0.8 × 10−5 and 5.0 × 10−3% (w/v) were prepared from the initial Ag colloid and were used in the preparation of the nanocomposites. The polyelectrolytes poly(diallyldimethylammonium chloride) (PDDA, 20 % in water, MW 100,000–200,000), poly(sodium 4-styrenesulfonate) (PSS, MW 70,000), poly(allylamine hydrochloride) (PAH, MW 15,000) and branched polyethylenimine (PEI, MW 25,000) were purchased from Aldrich and used as received. Native starch was provided by Grupo Portucel-Soporcel, Figueira da Foz.

Non-commercial A3-size papers sheets (100 % E. globulus bleached kraft pulp with a grammage of 76.4 g/m2 and an average thickness of 100 μm, produced by AKD-based sizing system and filled with precipitated calcium carbonate) without any surface treatment, gently ceded by the Grupo Portucel-Soporcel, Figueira da Foz, Portugal, were used as paper substrates (control sheets CS) for the coating essays.

Stock cultures and culture media

All microbial strains used were provided by DSMZ, Deutsche Sammlung von Mikroorganismen und Zellkulturen GmbH (German Collection of Microorganisms and Cell Cultures). Staphylococcus aureus ATCC 6538 (DSM 799) and Klebsiella pneumoniae ATCC 4352 (DSM 789) were maintained frozen (−80 °C) and transferred monthly on PCA (Plate Count Agar) made of 5 g/L tryptone; 2.5 g/L yeast extract; 1 g/L glucose and 9 g/L neutralized bacteriological agar.

Preparation of NFC/Ag nanocomposites

Solutions (0.1 % w/v) of cationic (PDDA, PAH and PEI) and anionic (PSS) polyelectrolytes were prepared in 0.5 M aqueous NaCl. In a first step, NFC (5.8 g of the 2 % suspension) was surface modified with the polyelectrolytes by alternate mixing with a cationic polyelectrolyte (70 mL), anionic polyelectrolyte (70 mL) and again with the cationic polyelectrolyte (70 mL) solutions. After each mixing step with a given polyelectrolyte (20 min), NFC fibers were separated by filtration and washed twice with distilled water to remove the excess of polyelectrolyte. Finally, the surface modified NFC was mixed with the Ag colloid (70 mL) during 20 min and the resulting nanocomposite was filtered and washed with distilled water. For nanocomposites submitted to more than one deposition cycle, the materials were mixed with cationic polyelectrolyte followed by mixing with Ag NP and this procedure was repeated until the required number of deposition cycles. The resulting NFC/Ag nanocomposites were lyophilized, with exception of those samples evaluated for their antimicrobial activity as aqueous suspensions. Table 1 lists the samples reported in this work.

Paper coating experiments

Among the several NFC/Ag nanocomposites prepared with one deposition cycle, the Ag/PDDA6 sample presented the highest Ag content per mass of composite and as such was selected for paper coating experiments. Two different starch-based coating aqueous formulations with a total solid content of 6 % and distinct NFC/Ag contents (11 and 29 % of Ag/PDDA6 with respect to starch content) were prepared. Paper sheets were then coated using a size press machine (MathisLAB reverse roll coater type RRC-BW 350 mm). The coating speed was fixed at 20 m/min and the distance between the cylinders at zero micrometer (adjusting precision 0.001 mm). Two different coating levels were applied, with one or two layers on one side of the paper sheets.

The coated-papers obtained were dried after each single layer deposition for 120 s at 100 °C in the dryer section of the size press. Five replicates were prepared for each coating formulations. An A4 sample was then cut out from the inner region of each original A3 sheet in order to eliminate the inevitable irregularities associated with its coated borders. Before their characterization, all coated papers were conditioned at 23 ± 1 °C and 50 ± 5 % RH during 3 days following the TAPPI T402 om-93 standard. The coating weights (pick-up) were obtained by subtracting the weight of the paper sheets after and before the coating procedure.

Assessment of antibacterial activity of NFC/Ag nanocomposites and coated papers

The adopted testing method for the assessment of antibacterial activity was based on the AATCC 100 standard test method under static conditions (AATCC Test Method 100, Quantitative assessment of antibacterial activity). The antibacterial tests were carried out on NFC based nanocomposites (water suspensions) as well as on paper coated derivatives. In the cases of the water suspensions of NFC nanocomposites, a suspension of known concentration of bacteria was dispersed in the nanocomposite sample, while in the cases of paper samples, the paper specimens were impregnated by the bacteria suspension. After bacteria inoculation the samples were set at conditions for optimal microbe growth.

The inoculated samples were subjected to 24 h incubation at 37 °C and at the end of the incubation period the bacteria were extracted from the samples under investigation by using a neutralizing solution. The number of living cells (CFU = colony forming units) in the extracted suspension was evaluated by count plate agar method. Specifically the following testing conditions were adopted:

-

Tested Microorganisms: Gram positive bacteria: Staphylococcus aureus ATCC 6538. Gram negative: Klebsiella pneumoniae ATCC 4352.

-

Tested material: About 400 mg of NFC composite suspension (corresponding to 4 mg NFC dry weight) or about 60 mg of treated paper sheet (size paper specimens: 3 × 3 cm). The samples were subjected to sterilization by autoclave before testing.

-

Quantity of inoculum: 100 μL of nutrient broth (NB) or a solution of 12.5 % diluted NB in physiological saline, the initial number of bacteria amounted to about 1 × 105 CFU/100 μL (1 × 106 CFU/ml).

-

Bacteria extraction: At the end of antibacterial tests the surviving bacteria were extracted by using 50 ml of neutralizing solution: Azolectin 3 g/L, Polysorbate 80 30 g/L, sodium thiosulphate 5 g/L, L-Hystidine 1 g/L, KH2PO4 0.68 g/L, (pH a 7.2 ± 0.2).

-

Control Samples: NFC suspension non treated with polyelectrolytes and not subjected to Ag addition or non coated paper.

The antibacterial activity of the sample, as bacteria log reduction, was calculated as follows:

where CFU T24 is the colony forming number corresponding to the bacteria living cells at time 24 h.

Instrumentation and materials characterization

Scanning electron microscopy (SEM) images were obtained using a HR-FESEM SU-70 Hitachi instrument operating at 4 or 15 kV. Samples were placed on carbon tape and coated with carbon before SEM analysis. The optical spectra of the solid nanocomposites were recorded using a Jasco V-560 UV/VIS spectrophotometer in the diffuse reflectance mode using MgO as reference. Zeta potential measurements were performed using a Zeta Sizer Nano Series (Malvern) equipment. The Ag content in the composite materials was evaluated by Inductively Coupled Plasma (ICP) using a Jobin–Yvon 70 Plus instrument. Before ICP analysis the samples were submitted to acid digestion with an acidic mixture of HCl, HNO3 and HF in a microwave oven.

The Brightness of the papers was measured using an Elrepho 2000 data color unit according TAPPI T 452 m-98. The air permeability was measured according to ISO 5636/3:1992 using an L&W Bendtsen tester (lorentzen & Wettre, model 114). The tensile index was determined using an Alwetron TH1 tensile tester (model 65-F, AB Lorentzen & Wettre). The preconditioned sheets were cut into 15 mm × 180 mm strips and tested according to ISO 1924/2. The initial clamp distance was 100 mm, and the strain rate was 20 mm/s. The burst index was determined in accordance with ISO 2758 with a Burst-O-Matic (model 04BOM, Lorentzen & Wettre).

Results and discussion

Preparation and characterization of NFC/Ag nanocomposites

The NFC/Ag nanocomposites were produced by electrostatic assembly of Ag NP onto NFC via polyelectrolytes linkers. It is well known that cellulose fibers are negatively charged in aqueous medium over a wide range of pH, due to the presence of ionisable moieties such as carboxylic acid groups, resulting from chemical processing, or from the minor presence of polysaccharides such as glucuronoxylans. Typically, the NFC aqueous suspensions exhibited a zeta (ζ) potential of −16.3 mV and the Ag colloid a ζ potential −18 mV, both at pH 6.0. As both materials surfaces were negatively charged the direct attachment of Ag NP onto NFC was not favored and this was confirmed here. In fact, the simple mixture of colloidal Ag NP with NFC led to agglomerates loosely attached to the cellulose fibers. Therefore the deposition of the AgNP was mediated by the assembly of oppositely charged polyelectrolytes. Cellulose nanofibers were firstly treated with a cationic polyelectrolyte, followed by an anionic polyelectrolyte and again with the cationic polyelectrolyte. As previously reported for a variety of cellulose based hybrid nanostructures (Pinto et al. 2007, 2009; Goncalves et al. 2009), this preliminary modification promotes charge homogeneity of the nanofibers surfaces hence favoring the subsequent deposition of inorganic NP.

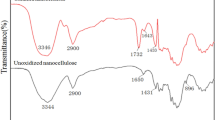

Table 1 lists the nanocomposite samples investigated here along with the respective Ag content as determined by ICP. These nanocomposites have been prepared by varying the number of deposition cycles (n), chemical nature of the polyelectrolytes and Ag content in the starting colloid. SEM analysis of the NFC/Ag nanocomposite samples confirmed the presence of Ag NP covering the NFC fibers, as illustrated in Fig. 1 for the samples Ag/PDDA1 and Ag/PDDA5. A typical UV–VIS spectrum of a NFC/Ag nanocomposite is shown in Fig. 2 whose maximum peaked at 435 nm is characteristic of the Ag NP surface plasmon resonance. The increment of the number of deposition cycles led to an increase of the Ag content (% w/w) in the nanocomposites as inferred by visual inspection of the color of the samples but also confirmed by ICP (Table 1). Representative SEM images (Fig. 1) seem also to indicate higher amounts of AgNP at the NFC surface for the composite Ag/PDDA5 as compared to Ag/PDDA1.

Among the polyelectrolytes investigated in this work, the most efficient deposition of Ag NP onto NFC has been accomplished by using the cationic polyelectrolytes PDDA and PEI, and the anionic polyelectrolyte PSS (Table 1). The use of PAH as cationic polyelectrolyte led to a deposition of Ag NP about 20 and 10 % of the minimal values achieved with PDDA and PEI respectively (Table 1). This might be due to charge effects because for solutions with a pH near the neutrality, such as the Ag colloid used here (pH = 6.5), a high fraction of the PAH polyelectrolyte is in the non-ionized form (pKa value of 8.5) as compared to PEI (pKa ~ 9.7) and PDDA (side groups are ionized at a wide pH range) (Mak et al. 2008). Finally, and as expected, we note that the Ag content in the final nanocomposites increased with increasing amounts of Ag in the starting colloid (Table 1).

Paper coating with NFC/Ag nanocomposites

Non-commercial A3-size papers sheets (control sheets CS) were coated with two starch-based coatings with different amounts of Ag/NFC nanocomposite, specifically 11 and 29 % (with respect to the starch content) of Ag/PDDA6. The AgPDDA6 sample has been selected as filler due to its higher Ag content after one single deposition cycle. Blank samples were also produced using a coating formulation containing only starch (6 %).

The coating weights (pick-up) of the paper samples and their Ag content, as determined by ICP, are presented in Table 2. As expected, the coating weights increased with the number of layers. The silver contents are below the detection level of the analytical technique used (ICP), in the case of NFC-Ag/starch 1, NFC-Ag/starch 2 and NFC-Ag/starch 3; in fact Ag was only detected by ICP in sample NFC-Ag/starch 4.

The morphology of CS and coated papers was investigated by SEM analysis (Fig. 3). The micrographs of the CS and paper coated with starch clearly show the presence of the characteristic features of a paper: fibers and inorganic fillers (calcium carbonate). The papers coated with NFC-Ag/starch formulations show large areas were the fibers and fillers are covered with the coating components. The NFC fibers and Ag NP are clearly observed at high magnification of the paper coatings.

Antibacterial activity of cellulosic composites

The antibacterial activity of NFC/Ag suspensions and coated papers was tested towards gram positive (Staphylococcus aureus) and gram negative (Klebsiella pneumoniae) bacteria. NFC modified with polyelectrolytes, i.e. in the absence of Ag NP, have also been used for comparative purposes. All the tests were performed in the presence of nutrients (100 or 12.5 % diluted nutrient broth) in the buffer testing media (bacteria growing conditions). In these conditions, the antimicrobial activity has been evaluated for (1) bactericidal effect: reduction (killing) of the number of bacteria initially inoculated (at least 1 log reduction respect to the inoculated bacteria, CFU at time 0) and (2) bacteriostatic effect: inhibition of bacteria growth, at least 1 log reduction respect to growth in the control sample at time 24 h.

Modified NFC suspensions

Antibacterial tests carried out on NFC modified by the sole addition of the different polyelectrolytes revealed distinct behavior depending on the nutrient conditions. In Fig. 4 the results obtained at low (12.5 %) and high (100 %) nutrients concentration are reported in respect to S. aureus and K. pneumoniae. These results show that NFC treated with different polyelectrolytes display strong antibacterial activity (complete killing) at low nutrients concentration. However, these samples have no antibacterial activity at high nutrients concentration. In fact, the polyelectrolytes modified NFC samples support the same bacteria growth as the untreated NFC (control sample). At low nutrient concentration and in contact with chemicals the bacteria cells might be more sensible to stress action. In particular, cationic polyelectrolytes, as well as other molecules with a net positive charge, are capable of killing microorganisms (Rabea et al. 2003; Melo et al. 2010; Friedrich et al. 2000). The mechanism of antibacterial action of cationic polyelectrolytes is not completely understood but it has been suggested that these polymers can interact electrostatically with anionic groups at the bacterial cell walls causing an increase of membrane permeability and subsequent leakage of cellular proteins which ultimately leads to cell death (Rabea et al. 2003). In the context of this research, the observed antibacterial action of the polyelectrolytes is an interesting finding because in principle the antimicrobial activity of the final NFC/Ag composites can be adjusted using favorable ratios for the amounts of polyelectrolyte and Ag NP.

Antibacterial activity of NFC treated with polyelectrolytes, toward S.aureus and K.pneumoniae at low and high nutrient concentration. Analysed samples: NFC-PDDA (NFC treated by PDDA/PSS/PDDA); NFC-PEI (NFC treated by PEI/PSS/PEI); NFC-PAH (NFC treated by PAH/PSS/PAH). Horizontal dark line refers to the initial inoculum (log CFU at time 0)

Figures 5 and 6 show the results of the antibacterial tests for Ag based nanocomposites prepared by polyelectrolytes (PDDA/PSS/PDDA) assembly. As expected, at low nutrient concentration (Fig. 5) the Ag based samples showed strong antibacterial activity (complete killing), as previously observed for the polyelectrolytes modified NFC (Fig. 4). However, at high nutrient concentration (Fig. 6), corresponding to conditions in which the polyelectrolyte did not show antibacterial effect, the NFC/Ag composites still exhibit antibacterial activity due to the presence of Ag NP. As shown in Fig. 6, the antibacterial effect depends on the Ag content in the nanocomposite. Bacteriostatic and partial bactericidal activity could be detected respect to S. aureus for Ag concentrations higher than 0.1 % (w/w), while similar effects were observed in respect to K. pneumoniae for Ag content as low as 0.018 %. As previously observed for other Ag based composites (Pinto et al. 2009; Yuan et al. 2010), these results suggest that the NFC/Ag composites are more active against K. pneumoniae microorganisms. It is known that Gram positive bacteria (e.g., S. aureus) have a stronger defense system as compared to Gram negative bacteria (e.g., K. pneumoniae) (Rai et al. 2009; Gottesman et al. 2011). While Gram positive bacteria have a thick peptidoglycan cell wall, Gram negative bacteria membrane is mostly made of tightly packed lipopolysaccharides (LPS) that offer a less effective protection against silver ions penetration in the cytoplasm.

Antibacterial activity at low nutrients concentration, toward S.aureus, of NFC/Ag nanocomposites. The bacterial load after 24 h contact time has been reported for untreated NFC (control), NFC only treated by polyelectrolytes (NFC-PDDA: NFC treated by PDDA/PSS/PDDA) and Ag nanocomposite samples. In the figure the Ag concentration in the different nanocomposites is reported as % w/w

Antibacterial activity at high nutrients concentration, toward S.aureus and K.pneumoniae of NFC/Ag nanocomposites. The bacterial load after 24 h contact time has been reported for untreated NFC (control), NFC only treated by polyelectrolytes (NFC-PDDA: NFC treated by PDDA/PSS/PDDA) and Ag nanocomposite samples. In the figure the Ag concentration in the different nanocomposites is reported as % w/w

NFC/Ag coated paper

The paper samples were tested for antibacterial activity toward S. aureus microorganism. As can be observed in (Fig. 7), no significant antibacterial effect was detected for samples coated with the formulations that contain 11 % AgPDDA6 relative to starch (NFC-Ag/starch 1 and NFC-Ag/starch 2), probably because of the low Ag content in these samples (Table 2). However, the samples coated with formulations that contain 29 % AgPDDA6 relative to starch (NFC-Ag/starch 3 and NFC-Ag/starch 4) show significant antibacterial effects. NFC-Ag/starch 3, that possesses one layer of coating, inhibits bacteria growth (bacteriostatic effect) despite of its low Ag content. With NFC-Ag/starch 4 both bacteriostatic and bactericidal effects (partial killing of the inoculated bacteria, about 2 log reduction respect T0 inoculum) are observed for an Ag content as low as 4.5 × 10−4 (% w/w). These results show that antimicrobial paper was produced.

Optical, barrier and mechanical properties, of the antibacterial NFC-Ag/starch coated paper

The NFC-Ag/starch coated paper sheets that presented antibacterial activity were further characterized in terms of their optical (brightness), barrier (air permeability) and mechanical (tensile strength and Bursting strength) properties (Table 3). The papers coated with the unfilled starch formulation showed a small decrease of their brightness. However, the papers coated with NFC-Ag/starch presented a dramatic brightness reduction. This behavior is obviously related with the fact that the NFC/Ag nanocomposite used in the formulations displayed a typically intense brown color. This is a drawback for applications such as for printing papers, but might be less relevant for example for air sanitization filters or for packaging applications in which the color of the paper is not so relevant. For the applications where brightness is not critical, the observed reduction in air permeability promoted by the coating with NFC/Ag and starch together with the maintenance of the mechanical properties of the paper sheets (Table 3) and with the reported antibacterial properties can indeed open interesting possibilities for the application of this materials for example for food packaging and preservation.

Conclusions

The electrostatic assembly of Ag NP onto nanofribillated cellulose mediated by polyelectrolyte linkage has been demonstrated for a series of NFC/Ag nanocomposites. This approach was successfully employed to impart antibacterial properties to NFC whose relevance for the paper making industry has increased considerably in the last years. The antibacterial activity observed for NFC/Ag materials against S. aureus and K. pneumoniae strains was due to both the polyelectrolytes and Ag NP, however the presence of the latter was crucial in order to observe antimicrobial activity for high nutrient conditions. This preparative method may also find applications in the development of paper-based products whose antibacterial properties can be adjusted by varying the amount and characteristics of NFC/Ag composites used as nanofillers.

References

Amash A, Zugenmaier P (2000) Morphology and properties of isotropic and oriented samples of cellulose fibre–polypropylene composites. Polymer 41(4):1589–1596

Belgacem MN, Gandini A (2008) Monomers, polymers and composites from renewable resources, 1st edn. Elsevier, London

Dankovich TA, Gray DG (2011) Bactericidal paper impregnated with silver nanoparticles for point-of-use water treatment. Environ Sci Technol 45(5):1992–1998. doi:10.1021/Es103302t

Diez I, Eronen P, Osterberg M, Linder MB, Ikkala O, Ras RHA (2011) Functionalization of nanofibrillated cellulose with silver nanoclusters: fluorescence and antibacterial activity. Macromol Biosci 11(9):1185–1191. doi:10.1002/mabi.201100099

Eichhorn SJ, Dufresne A, Aranguren M, Marcovich NE, Capadona JR, Rowan SJ, Weder C, Thielemans W, Roman M, Renneckar S, Gindl W, Veigel S, Keckes J, Yano H, Abe K, Nogi M, Nakagaito AN, Mangalam A, Simonsen J, Benight AS, Bismarck A, Berglund LA, Peijs T (2010) Review: current international research into cellulose nanofibres and nanocomposites. J Mater Sci 45(1):1–33. doi:10.1007/s10853-009-3874-0

El-Shishtawy RM, Asiri AM, Abdelwahed NAM, Al-Otaibi MM (2011) In situ production of silver nanoparticle on cotton fabric and its antimicrobial evaluation. Cellulose 18(1):75–82. doi:10.1007/s10570-010-9455-1

Fernandes SCM, Freire CSR, Silvestre AJD, Pascoal Neto C, Gandini A, Berglund LA, Salmén L (2010) Transparent chitosan films reinforced with a high content of nanofibrillated cellulose. Carbohydr Polym 81(2):394–401

Friedrich CL, Moyles D, Beveridge TJ, Hancock REW (2000) Antibacterial action of structurally diverse cationic peptides on gram-positive bacteria. Antimicrob Agents Chemother 44(8):2086–2092. doi:10.1128/AAC.44.8.2086-2092.2000

Gandini A (2011) The irruption of polymers from renewable resources on the scene of macromolecular science and technology. Green Chem 13(5):1061–1083. doi:10.1039/C0gc00789g

Goncalves G, Marques PAAP, Pinto RJB, Trindade T, Neto CP (2009) Surface modification of cellulosic fibres for multi-purpose TiO2 based nanocomposites. Compos Sci Technol 69(7–8):1051–1056

Gottesman R, Shukla S, Perkas N, Solovyov LA, Nitzan Y, Gedanken A (2011) Sonochemical coating of paper by microbiocidal silver nanoparticles. Langmuir 27(2):720–726. doi:10.1021/La103401z

Henriksson M, Henriksson G, Berglund LA, Lindstrom T (2007) An environmentally friendly method for enzyme-assisted preparation of microfibrillated cellulose (MFC) nanofibers. Eur Polymer J 43(8):3434–3441. doi:10.1016/j.eurpolymj.2007.05.038

Hubbe MA, Rojas OJ, Lucia AL, Sain M (2008) Cellulosic nanocomposites: a review. Bioresources 3(3):929–980

Karlsson JO, Henriksson A, Michalek J, Gatenholm P (2000) Control of cellulose-supported hydrogel microstructures by three-dimensional graft polymerization of glycol methacrylates. Polymer 41(4):1551–1559. doi:10.1016/s0032-3861(99)00277-3

Klemm D, Heublein B, Fink HP, Bohn A (2005) Cellulose: fascinating biopolymer and sustainable raw material. Angew Chem-Int Edit 44(22):3358–3393. doi:10.1002/anie.200460587

Klemm D, Kramer F, Moritz S, Lindstrom T, Ankerfors M, Gray D, Dorris A (2011) Nanocelluloses: a new family of nature-based materials. Angew Chem-Int Edit 50(24):5438–5466. doi:10.1002/anie.201001273

Mak WC, Cheung KY, Trau D (2008) Influence of different polyelectrolytes on layer-by-layer microcapsule properties: Encapsulation efficiency and colloidal and temperature stability. Chem Mater 20(17):5475–5484. doi:10.1021/Cm702254h

Maneerung T, Tokura S, Rujiravanit R (2008) Impregnation of silver nanoparticles into bacterial cellulose for antimicrobial wound dressing. Carbohydr Polym 72(1):43–51. doi:10.1016/j.carbpol.2007.07.025

Marini M, De Niederhausern S, Iseppi R, Bondi M, Sabia C, Toselli M, Pilati F (2007) Antibacterial activity of plastics coated with silver-doped organic-inorganic hybrid coatings prepared by sol-gel processes. Biomacromolecules 8(4):1246–1254. doi:10.1021/Bm060721b

Melo LD, Mamizuka EM, Carmona-Ribeiro AM (2010) Antimicrobial particles from cationic lipid and polyelectrolytes. Langmuir 26(14):12300–12306. doi:10.1021/La101500s

Morones JR, Elechiguerra JL, Camacho A, Holt K, Kouri JB, Ramirez JT, Yacaman MJ (2005) The bactericidal effect of silver nanoparticles. Nanotechnology 16(10):2346–2353. doi:10.1088/0957-4484/16/10/059

Paakko M, Ankerfors M, Kosonen H, Nykanen A, Ahola S, Osterberg M, Ruokolainen J, Laine J, Larsson PT, Ikkala O, Lindstrom T (2007) Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromolecules 8(6):1934–1941. doi:10.1021/Bm061215p

Pinto RJB, Marques PAAP, Martins MA, Neto CP, Trindade T (2007) Electrostatic assembly and growth of gold nanoparticles in cellulosic fibres. J Colloid Interface Sci 312(2):506–512

Pinto RJB, Marques PAAP, Neto CP, Trindade T, Daina S, Sadocco P (2009) Antibacterial activity of nanocomposites of silver and bacterial or vegetable cellulosic fibers. Acta Biomater 5(6):2279–2289. doi:10.1016/j.actbio.2009.02.003

Potara M, Jakab E, Damert A, Popescu O, Canpean V, Astilean S (2011) Synergistic antibacterial activity of chitosan-silver nanocomposites on Staphylococcus aureus. Nanotechnology 22(13):135101. doi:10.1088/0957-4484/22/13/135101

Rabea EI, Badawy MET, Stevens CV, Smagghe G, Steurbaut W (2003) Chitosan as antimicrobial agent: applications and mode of action. Biomacromolecules 4(6):1457–1465. doi:10.1021/Bm034130m

Rai M, Yadav A, Gade A (2009) Silver nanoparticles as a new generation of antimicrobials. Biotechnol Adv 27(1):76–83. doi:10.1016/j.biotechadv.2008.09.002

Saito T, Kimura S, Nishiyama Y, Isogai A (2007) Cellulose nanofibers prepared by TEMPO-mediated oxidation of native cellulose. Biomacromolecules 8(8):2485–2491. doi:10.1021/Bm0703970

Silva AR, Unali G (2011) Controlled silver delivery by silver-cellulose nanocomposites prepared by a one-pot green synthesis assisted by microwaves. Nanotechnology 22(31):315605. doi:10.1088/0957-4484/22/31/315605

Siró I, Plackett D (2010) Microfibrillated cellulose and new nanocomposite materials: a review. Cellulose 17(3):459–494. doi:10.1007/s10570-010-9405-y

Smiechowicz E, Kulpinski P, Niekraszewicz B, Bacciarelli A (2011) Cellulose fibers modified with silver nanoparticles. Cellulose 18(4):975–985. doi:10.1007/s10570-011-9544-9

Sondi I, Salopek-Sondi B (2004) Silver nanoparticles as antimicrobial agent: a case study on E-coli as a model for Gram-negative bacteria. J Colloid Interface Sci 275(1):177–182. doi:10.1016/j.jcis.2004.02.012

Tankhiwale R, Bajpai SK (2009) Graft copolymerization onto cellulose-based filter paper and its further development as silver nanoparticles loaded antibacterial food-packaging material. Colloid Surf B 69(2):164–168. doi:10.1016/j.colsurfb.2008.11.004

Tome LC, Pinto RJB, Trovatti E, Freire CSR, Silvestre AJD, Neto CP, Gandini A (2011) Transparent bionanocomposites with improved properties prepared from acetylated bacterial cellulose and poly(lactic acid) through a simple approach. Green Chem 13(2):419–427. doi:10.1039/c0gc00545b

Yano H, Nakagaito AN (2005) Novel high-strength biocomposites based on microfibrillated cellulose having nano-order-unit web-like network structure. Appl Phys A-Mater Sci Process 80(1):155–159. doi:10.1007/s00339-003-2225-2

Yuan J, Geng J, Xing Z, Shen J, Kang I-K, Byun H (2010) Electrospinning of antibacterial poly(vinylidene fluoride) nanofibers containing silver nanoparticles. J Appl Polym Sci 116(2):668–672. doi:10.1002/app.31632

Zimmermann T, Pohler E, Geiger T (2004) Cellulose fibrils for polymer reinforcement. Adv Eng Mater 6(9):754–761. doi:10.1002/adem.200400097

Zimmermann T, Bordeanu N, Strub E (2010) Properties of nanofibrillated cellulose from different raw materials and its reinforcement potential. Carbohydr Polym 79(4):1086–1093. doi:10.1016/j.carbpol.2009.10.045

Acknowledgments

The research leading to these results has received funding from the European Community’s Seventh Framework Programme under grant agreement no. 228802. The authors thank the Centre Technique du Papier (France) for supplying the NFC used in this work. We thank RAIZ- Centro de Investigação da Floresta e do Papel (Portugal) for all the facilities provided in the paper coating experiments. Ricardo J.B. Pinto is grateful to FCT for a PhD grant (SFRH/BD/45364/2008). Susana C.M. Fernandes thanks FCT for funding her Postdoctoral Research Grant (SFRH/BPD/70119/2010).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Martins, N.C.T., Freire, C.S.R., Pinto, R.J.B. et al. Electrostatic assembly of Ag nanoparticles onto nanofibrillated cellulose for antibacterial paper products. Cellulose 19, 1425–1436 (2012). https://doi.org/10.1007/s10570-012-9713-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-012-9713-5