Abstract

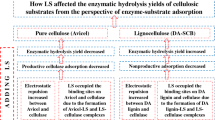

The effects of lignosulfonate (LS) on enzymatic saccharification of pure cellulose were studied. Four fractions of LS with different molecular weight (MW) prepared by ultrafiltration of a commercial LS were applied at different loadings to enzymatic hydrolysis of Whatman paper under different pH. Using LS fractions with low MW and high degree of sulfonation can enhance enzymatic cellulose saccharification despite LS can bind to cellulase nonproductively. The enhancing effect varies with LS properties, its loading, and hydrolysis pH. Inhibitive effect on cellulose saccharification was also observed using LS with large MW and low degree of sulfonation. The concept of “LS-cellulase aggregate stabilized and enhanced cellulase binding” was proposed to explain the observed enhancement of cellulose saccharification. The concept was demonstrated by the linear correlation between the measured amount of bound cellulase and saccharification efficiency with and without LS of different MW in a range of pH.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Producing biofuel and chemicals from lignocelluloses can be a sustainable practice to reduce our dependence on petroleum (Goldemberg 2007; Zhu and Zhuang 2012). The sugar platform that utilizes enzymes to saccharify structural carbohydrates is a preferred pathway for its flexibility in using sugars as building blocks to produce biofuel and a variety of chemicals (Bozell and Petersen 2010). The natural resistance of plant biomass to enzymatic deconstruction of structure carbohydrate is a major barrier to lignocelluloses saccharification. Factors affecting enzymatic hydrolysis of lignocellulose can be classified into enzyme, substrate, and interface related (Leu and Zhu 2013). The enzyme-related factors include performance characteristics of catalytic and cellulose binding domains, synergies among different enzymes in cellulase formulation (Henrissat 1994; Himmel et al. 2007). The substrate-related factors include cellulose accessibility to cellulase (Rollin et al. 2011; Wang et al. 2012), substrate lignin and hemicellulose content and structure (Lou et al. 2013; Nakagame et al. 2011a, b; Wang et al. 2013b). The interface-related factor is defined as those affecting the driving force and the amount of cellulase bound to cellulose, including additives such as surfactants (Ooshima et al. 1986), pH (Lan et al. 2013; Lou et al. 2013), temperature, ionic strength (Eriksson et al. 2002; Liu and Zhu 2010; Liu et al. 2010).

Previously, we reported that the application of lignosulfonate (LS) as an additive can enhance enzymatic saccharification of pretreated lignocelluloses (Wang et al. 2013a, b; Zhou et al. 2013a). While, LS can bind cellulase nonproductively, we suggested that it can act as a surfactant to reduce nonproductive cellulase binding to solid substrate lignin to result in a net gain in cellulose activity and therefore saccharification. We also found that the binding of cellulase to lignin on substrate can be mediated by pH. An elevated pH around 5.5, higher than 5.0 commonly used for saccharification, can significantly reduce nonproductive cellulase binding to lignin on solid substrate to enhance cellulose saccharification (Lan et al. 2013; Lou et al. 2013). Because LS is a commercial product from sulfite wood pulping and available in large quantities, its application for enzymatic saccharification of lignocelluloses may have less unintended consequences for downstream processing than using surfactants. It is also more cost effective than most common surfactants. Furthermore, LS is naturally present in the hemicellulose sugar streams from sulfite pretreatments such as SPORL (Zhu et al. 2009) that has demonstrated robust performance for bioconversion of a variety of lignocellulosic biomass (Leu et al. 2013; Zhou et al. 2013b; Zhu et al. 2011). Therefore, understanding the mechanism of LS enhancement of enzymatic saccharification has significant implications to sulfite pretreatments, i.e., washing of solid substrates can be eliminated, and simultaneous enzymatic saccharification and combined fermentation of enzymatic and pretreatment hydrolysates can be implemented to improve biofuel yield.

This study is focused on the understanding of the application of LS on enzymatic hydrolysis of pure cellulosic substrates to provide better understanding of the effects of LS on bioconversion of lignocellulosic biomass. The objectives are: (1) to investigate the effect of LS structures, i.e., molecular weight (MW) and sulfonic acid group content on enzymatic saccharification of pure cellulose; (2) to understand the mechanisms of the observed enhancement or inhibitive effects on saccharification by LS. The understanding developed in this study can help to develop potential approaches and strategies for effective application of LS to improve bioconversion of lignocellulosic biomass.

Materials and methods

Materials

Commercial cellulase enzyme Cellic® CTec2 (abbreviated CTec2) was generously provided by Novozymes North America (Franklinton, NC). Bio-Rad (Bradford) protein assay kit and Bovine serum albumin (BSA) were obtained from Bio-Rad Laboratories (Hercules, CA). BSA was used as a standard to calibrate the protein content of CTec2 by the Bradford method (Bradford 1976). The protein concentration of CTec2 was 73.6 mg/mL with cellulase activity of 147 FPU/mL. All chemicals were ACS reagent grade and used as received from Sigma-Aldrich (St. Louis, MO).

Whatman filter paper (grade 1, catalogue number 1001 150, Whatman International, UK) was first torn into small pieces of 1 × 1 cm and then disintegrated using a disintegrator (Model 73-06-01,TMI, Ronkonkoma, New York, USA) for 5,000 revolutions at 312 rpm and 5 % solids consistency at room temperature. The resultant pulp was filtered using a nylon membrane with pore size of 0.45 μm. The pulp cake was used as a pure cellulose substrate.

A commercial sodium LS (D748) from softwood was donated by LignoTech USA (Rothschild, WI). Another commercial sodium LS (SXSL) from poplar wood was produced by Shixian papermaking Co. Ltd. (Yanbing, Jilin province, China). SXSL consists of 70 wt% sodium LS, approximately 10 wt% reductive substances, and 20 wt% low MW organic acid and inorganic salts.

Fractionation of LS

SXSL was fractionated using polyether sulfone (PES) ultrafiltration membranes with cut-off MW of 50,000, 10,000, and 2,500 Da in an ultrafiltration apparatus (Wuxi Membrane Science and Technology Co., China). The resultant four fractions were labelled as SX1, SX2, SX3 and SX4 in the order of high to low MW. Table 1 lists the MW and sulfonic acid group content of all LSs used in this study.

Enzymatic hydrolysis

Enzymatic hydrolysis was conducted at 2 % solids (w/v) in a flask on a shaker/incubator (Thermo Fisher Scientific, Model 4450, Waltham, MA) at 50 °C and 200 rpm. Whatman paper of 0.5 g oven dry (od) weight was added into a 25 mL acetate buffer solution along with CTec2. The buffer solutions were prepared by using different ratios of sodium acetate and acetic acid to result in a pH range of 4.5–6.0. The buffered suspension of Whatman paper was adjusted to a desired pH using dilute NaOH of 5 % or acetic acid before adding CTec2. The amount of glucose in the enzymatic hydrolysate was determined using a biochemistry analyzer (YSI 2700S, Yellow Springs, OH). Substrate enzymatic digestibility (SED), defined as the percentage of substrate glucan enzymatically saccharified to glucose, was used to represent the enzymatic saccharification efficiency. Duplicate runs of enzymatic hydrolysis were carried out and the averages were reported.

Cellulase binding

Cellulase binding experiments were conducted in acetate buffer solutions of pH 4.5, 4.8, 5.0, 5.2, 5.5, and 6.0 at 50 °C using Whatman paper powder of 40 mesh (Wiley milled) at solids consistency of 2 % (w/w). The initial concentration of CTec2 was 500 mg protein/L. After incubation for 30 min (kinetic experiments were not conducted), the solution (10 mL) was centrifuged at 35,000g for 10 min. The supernatant was then centrifuged at 150,000g for 10 min. An aliquot of the final supernatant was diluted with the corresponding buffer solution and placed into a sampling cuvette. The amount of free cellulase in the sample was quantified using UV–vis absorption at 280 nm (Liu et al. 2011) by a spectrophotometer (Model 8453, Agilent Technologies, Palo Alto, CA). The LS solution containing Whatman paper powder (without CTec2) was used as a blank to correct for spectral absorption from LS present in the LS-cellulase solution. The amount of CTec2 bound to Whatman paper powder was calculated by subtracting the amount of free CTec2 measured in the supernatant from the total amount of CTec2 initially applied.

Determination of MW of LS

The MW and distributions of LS were determined by gel permeation chromatography (GPC) using Ultrahydrogel TM 120, TM 250, and TM 500 columns. A NaNO3 aqueous solution of 0.10 mol/L with pH 8 was used as eluent at a flow rate of 0.5 mL/min. The effluent was monitored at 280 nm using a Waters 2487 UV detector (Waters Corp., USA). Polystyrene sulfonates (PSS) with MW from 2,000 to 100,000 Da were employed as standard for calibration. All samples were prepared by double distilled water and filtrated by a 0.22 μm filter.

Sulfur content analysis

Sulfur content of LS was analyzed using ICP-MS (Ultima model, Horiba Jobin–Yvon, Edison, New Jersey, USA). Samples were weighted and then transferred to Teflon digestion flasks. All samples were digested at 145 °C for 15 min in a microwave oven (MDS-2000, CEM Corp., Matthews, North Carolina, USA) using approximately 5 mL of 70 % HNO3 and 3 mL of 30 % H2O2 before ICP analysis.

Results and discussion

Effect of LS on enzymatic saccharification of pure cellulose

Previously, we reported that the application of a commercial LS D748 at 5 g/L reduced enzymatic saccharification of pure cellulose in an acetate buffer of pH 4.8 (Liu et al. 2010; Wang et al. 2013b). The application of a LS of a poplar wood from the same source of SXSL had negligible or slightly enhancing effect on enzymatic saccharification of the same Whatman paper used in this study (Zhou et al. 2013a). Similar results were observed in this study at LS loading of 5 g/L, i.e., D748 inhibited (by 8 percentage point) while SXSL enhanced saccharification (by 15 percentage point) as shown in Fig. 1. Similar trends were also observed at a cellulase loading of 10 FPU/g glucan. The acetate buffer concentration was 50 mmol/L with pH of 4.80 ± 0.02 at the beginning (0 h) before adding cellulase and ending pH (72 h) of 4.80 ± 0.05. SXSL had a higher sulfonic acid group content and lower MW than D748 (Table 1), suggesting both sulfonic acid group content and MW probably affected enzymatic hydrolysis of pure cellulose, in agreement with our previous study (Zhou et al. 2013a).

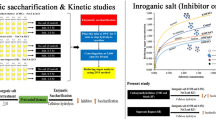

The different effect on cellulose saccharification by different LS was further observed at different loadings. As stated above, lignosulfonate can bind cellulase nonproductively to reduce cellulose saccharification. Previously, we reported that D748 inhibited cellulose saccharification, however, cellulose saccharification did not decrease continuously beyond D748 loading of approximately 0.5 g/L (Wang et al. 2013b). This suggests that the competition between productive binding to cellulose and nonproductive binding to lignosulfonate reached an equilibrium. At low loadings of SXSL (<0.5 g/L), inhibition of cellulose saccharification was also observed (Fig. 1b). The reduction in saccharification reached maximum at SXSL loading of 0.1 g/L and then gradually recovered. Enhancement of saccharification was observed when SXSL loading was increased over 0.5 g/L, indicating the surfactant effect of lignosulfonate dominates at increased dosages. Furthermore, saccharification efficiency SED was increased linearly as SXSL loading increased (Fig. 1b). When a low MW fraction SX3 (Table 1) fractionated from SXSL was applied, similar effects on saccharification of Whatman paper were observed, i.e., saccharification reduced at low dosages and then recovered and increased linearly with dosage (Fig. 1b). Cellulose saccharification enhancement by SX3 was approximately 3 times greater than applying SXSL at 5 g/L. However, the enhancement was plateaued when SX3 loading reached 5 g/L. When the lowest MW fraction SX4 of SXSL was applied, cellulose saccharification was also linearly increased with dosage up to 3 g/L with almost the same effectiveness as SX3 but with negligible reduction in saccharification at very low dosages. This is because SX4 is highly sulfonated (Table 1) with much lower affinity to cellulase than SX3 and SXSL. However, enhancement in cellulose saccharification was reduced at SX4 dosage beyond 3 g/L. The inhibition of cellulose saccharification at low LS dosages using SXSL and its fractions SX3 and SX4 shown in Fig. 1b suggests that LS can bind cellulase nonproductively, in agreement with our previous study using a large MW LS D748 (Wang et al. 2013b). The inhibitive effect by SX4, the smallest MW fraction, at high dosages is probably due to impurities in this smallest molecular fraction. Furthermore, SX4 is highly sulfonated (Table 1) with high negative charges. Although the formation of LS-cellulase aggregates can stabilize and enhance cellulase binding to cellulose as will be discussed later, the highly negatively charged SX4-cellulase aggregates can produce strong enough electrostatic repulsion between the aggregates and cellulose fibers that are also negatively charged to reduce the overall amount of cellulase bound to cellulose.

MW and pH effects on enhancement of saccharification of pure cellulose by LS

Comparisons of enzymatic hydrolysis of Whatman paper were made when different fractions of SXSL were applied but at the same LS loading of 5 g/L. UV measurements were used to determine LS concentration to account for the difference in LS purity among different fractions. At pH 4.8, the small MW LS fractions of SX2, SX3, SX4 all enhanced pure cellulose saccharification with identical degree throughout the entire process, while the large MW fraction SX1 slightly inhibited saccharification (Fig. 2a). This agrees with our previous study (Zhou et al. 2013a). When the buffer pH was elevated to 5.5 (Fig. 2b), SX1 also enhanced cellulose enzymatic saccharification like the other three fractions. The order of enhancement at 72 h is SX3 ≈ SX2 > SX4 > SX1. This suggests that the effects of LS with different MW on enzymatic hydrolysis of pure cellulose were influenced by pH.

Saccharification of Whatman paper with and without the application of different fractions of SXSL at 5 g/L were carried out in a pH range of 4.5–6.0 to further investigate the pH effect. As can be seen from Fig. 3a, SX1 inhibited the cellulose enzymatic saccharification in a low pH range of 4.5–4.85 but enhanced saccharification in a high pH range of 5.0–6.0. In contrast, SX4 enhanced saccharification in a low pH range of 4.5–5.85 and inhibited saccharification in a narrow range of high pH of 5.9–6.0. SX2 and SX3 enhanced cellulose saccharification in the entire pH range of 4.5 – 6.0 examined. There is an optimal pH for maximal enhancement of saccharification for each fraction investigated. The optimal pH for different SXSL fractions at LS loading of 5 g/L fits to the logarithmic MW of the fractions well (Fig. 3b). The optimal pH for achieving maximum saccharification of Whatman paper without the application of LS (control run) was between 4.5 and 4.8 (Fig. 3a), in agreement with our previous study (Lan et al. 2013; Lou et al. 2013). The enhancement of saccharification, ΔSED, when compared with that of the control run at the same pH optimal for the application of SX1, SX2, SX3 and SX4 was 11.5, 30.8, 32.2 and 21.2 percentage point, respectively (Fig. 3b), or 5.0, 28.0, 30.5, 21.0 percentage point, respectively, when compared with the maximal saccharification of Whatman paper achieved at optimal pH between 4.5 and 4.8 without LS fractions.

Mechanistic understanding of LS enhancement of enzymatic saccharification of pure cellulose

Effects of surfactants on enhancing enzymatic cellulose saccharification have been extensively studied. Preventing nonproductive binding of cellulase to substrate lignin by surfactant is one of the major suggested mechanisms. However, consensus on the mechanism of surfactant enhancement of pure cellulose saccharification is still lacking. Three mechanisms have been proposed: (1) Surfactant could hinder the immobilization of the enzymes on solid substrate by reducing the binding strength and facilitate desorption before inactivation occurs (Castanon and Wilke 1981; Helle et al. 1993). (2) Surfactant could increase enzyme stability and prevent its denaturation during hydrolysis (Kim et al. 1982). (3) Surfactant could disturb adsorption of endoglucanase and vary the adsorption balance of endo- and exoglucanase to enhance enzymatic saccharification of cellulose (Li et al. 2012; Ooshima et al. 1986). However, these proposed mechanisms were negated by other studies (Eriksson et al. 2002). As a result, interpretation of the observed enhancement of cellulose hydrolysis by LS is difficult because LS has surface activities like a surfactant but is also a lignin.

Most cellulases contain distinct cellulose binding modules (CBMs), which is connected through a linker peptide with the catalytic domain (CD) (Igarashi et al. 2011; Lehtio et al. 2003). CBMs do not possess any catalytic function but recognize crystalline cellulose surface to lead a CD to the substrate to result in an increased cellulase concentration on the surface (Shiiba et al. 2013; Várnai et al. 2013). A recent study indicated that at high solids processing, there was no difference in hydrolysis performance between cellulase with and without CBM (Várnai et al. 2013). This suggests CD contribute to cellulase binding (Igarashi et al. 2011). We hypothesize that CD is primarily bound to the hydrophobic sites of cellulose just like CBM. Therefore, CD should contain some hydrophobic domains. As a result, CD would make the binding between CBM and hydrophobic cellulose sites in an aqueous solution unstable because of the incompatible interface between hydrophobic domains in CD and cellulose that is mostly hydrophilic in nature and associated with water. The unstable cellulase binding may have reduced the efficacy of cellulase catalytic activities, especially at low solids loadings under which cellulase binding through CBM is important as in the present study. Therefore, unstable binding can be treated as less effective binding or less specific or nonproductive binding. LS could be adsorbed to cellulase through hydrophobic interactions to form aggregates like “oil-in-water micelles”, as evidenced by our recent study (Wang et al. 2013a) where we used the term “LS-cellulase complex”. When a LS-cellulase aggregate binds to a hydrophobic cellulose site, the hydrophilic group of LS faces toward water to produce a stable binding between cellulase and cellulose. Therefore, we propose that the LS effect can be described as “LS-cellulase aggregate stabilized and enhanced cellulase binding to cellulose”. This mechanism of LS enhancement of enzymatic saccharification of pure cellulose can be pictorially illustrated using a carton shown in Fig. 4. Larger MW LS is often less sulfonated with lower sulfonic acid group content to result in a lower hydrophilicity in the hydrophilic domain. Therefore larger MW LS such as SX1 in the present study or unfractionated LS D748 has less stabilization effect for cellulase binding. Furthermore as shown in Fig. 4, they form a different kind of LS-cellulase aggregate that is less hydrophilic and larger. Therefore, it can be easily precipitated to result in non-productive binding because of its lower water-solubility.

To demonstrate that “LS-cellulase aggregate stabilized and enhanced cellulase binding” is responsible for the observed LS enhancement of saccharification of Whatman paper, the saccharification efficiencies, SEDs, at CTec2 loading of 10FPU/g glucan in a range of buffer pH from 4.5 to 6.0 were plotted (Fig. 5) against measured total cellulase binding (to both cellulose and LS) with and without the application of different SXSL fractions. Most cellulase enzymes though mixtures have isoelectric point (pI) around 4.8 (Lou et al. 2013; Nakagame et al. 2011b). For the controls runs without LS, increasing pH beyond pI (=4.8) result in repulsion between cellulase and filter paper fibers as the fibers are also negatively charged. Consequently, increase pH reduced cellulase binding to cellulose, agree with classic protein binding studies (Haynes et al. 1994). Despite nonproductive cellulase binding existed with the application of LS fractions, the results indicate that SED of Whatman paper at 72 h increased linearly with the increases in measured total CTec2 binding, except for the data point at pH 4.8 with the application of the largest MW fraction SX1. This suggests nonproductive cellulase binding to LS (LS-cellulase aggregate is not considered nonproductive binding as it actually stabilized cellulase binding to cellulose) is negligible for the small MW fractions of SX2, SX3, SX4, even for the large MW fraction SX1 at pH 5.5 because elevated pH of 5.5 can reduce cellulase nonproductive binding to sulfonated lignin (SX4 in this case) according to our previous study (Lou et al. 2013). Productive cellulase binding to cellulose increased with the application of LS to result in enhanced saccharification. The data set for the runs with LS can be fitted with the data set for the control runs (without LS) at different pH to the same slope (Fig. 5).

This mechanism explains the observed inhibitive effect by LSs of large MW shown in Figs. 1a, 3a, and 5. This mechanism can also be referred to as “Surfactant-cellulase aggregate stabilized and enhanced cellulase binding to cellulose” to explain the surfactant enhanced enzymatic saccharification of pure cellulose.

Effect of ionic strengthen on enhancement of saccharification by LS

LS is a strong anion polyelectrolyte. LS-cellulase aggregate is negatively charged under the conditions examined because the LS concentration is much higher than cellulase. Salt can change the ionization of LS in solution and shield its negative charges (Ouyang et al. 2011), which reduces electrostatic repulsion between LS and cellulase to form a stable LS-cellulase aggregate, and the electrostatic repulsion among LS-cellulase aggregates adsorbed onto cellulose. This effect can be seen from the increased enzymatic saccharification efficiency of Whatman paper at pH 4.8 when acetate buffer concentration was increased from 25 to 100 mmol/L in hydrolysis with the application of different LS fractions (Fig. 6). However, this increment in saccharification was not observed for the control run without the application of LS. The reduced electrostatic repulsion by increased buffer concentration or ionic strength between LS and cellulase, and among LS-cellulase aggregates may have improved cellulase binding to cellulose to result in the observed increased saccharification. However, this buffer concentration effect on saccharification with the application of LS was not observed at elevated hydrolysis pH of 5.5 (Fig. 6). At the elevated pH of 5.5, higher than the bulk isoelectric point (pI) of common cellulase cocktails, cellulase became negatively charged while the negative charge of LS was increased (Lou et al. 2013). This negated the shielding effect of electrostatic interactions by the increased buffer concentration to negatively affect cellulase binding to cellulose. Furthermore, optimal pH for saccharification of pure cellulose is around 4.8. Elevated pH of 5.5 deviate the optimal pH for efficient cellulase binding to cellulose which also contributes to reduced saccharification efficiency as can be seen from the control run without LS (Fig. 6).

Conclusions

This study discovered that LS with low MW and good sulfonation can enhance enzymatic saccharification of pure cellulose though LS can bind cellulase nonproductively to different degrees. The enhancement by LS is affected by the MW of LS, LS loading, and hydrolysis pH. The study proposed the concept of “LS-cellulase aggregate stabilized and enhanced cellulase binding to cellulose” to explain the observed enhancement in enzymatic saccharification. LS-cellulase aggregates act as “oil-in-water micelles” to improve the binding stability of cellulase to cellulose. LS with large MW are often less hydrophilic to form a large and precipitable LS-cellulase aggregate especially at high LS loadings to result in binding cellulase nonproductively. pH affects LS enhancement of saccharification is through the pH induced LS and cellulase surface charge to affect the stability of LS-cellulase aggregate by electrostatic interactions. This “LS-cellulase aggregate stabilization and enhancement” concept was indirectly demonstrated by the linear correlation between the measured cellulase binding and saccharification efficiency with and without LS of different MW in a range of pH.

References

Bozell JJ, Petersen GR (2010) Technology development for the production of biobased products from biorefinery carbohydrates—the US Department of Energy’s “top 10” revisited. Green Chem 12(4):539–554

Bradford M (1976) A rapid and sensitive for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72(1–2):248–254

Castanon M, Wilke CR (1981) Effects of the surfactant Tween 80 on Enzymatic hydrolysis of Newspaper. Biotechnol Bioeng 13:1365–1372

Eriksson T, Borjesson J, Tjerneld F (2002) Mechanism of surfactant effect in enzymatic hydrolysis of lignocellulose. Enzym Microbial Technol 31(3):353–364

Goldemberg J (2007) Ethanol for a sustainable energy future. Science 315:808–810

Haynes CA, Sliwinsky E, Norde W (1994) Structural and electrostatic properties of globular proteins at a polystyrene-water interface. J Colloid Interface Sci 164(2):394–409

Helle SS, Duff SJB, Cooper DG (1993) Effect of surfactants on cellulose hydrolysis. Biotechnol Bioeng 42:611–617

Henrissat B (1994) Cellulases and their interaction with cellulose. Cellulose 1(3):169–196

Himmel ME, Ding SY, Johnson DK, Adney WS, Nimlos MR, Brady JW, Foust TD (2007) Biomass recalcitrance: engineering plants and enzymes for biofuels production. Science 315(5813):804–807

Igarashi K, Uchihashi T, Koivula A, Wada M, Kimura S, Okamoto T, Penttilä M, Ando T, Samejima M (2011) Traffic jams reduce hydrolytic efficiency of cellulase on cellulose surface. Science 333(6047):1279–1282

Kim MH, Lee SB, Ryu DDY, Reese ET (1982) Surface deactivation of cellulase and its prevention. Enzym Microbial Technol 4(2):99–103

Lan TQ, Lou H, Zhu JY (2013) Enzymatic saccharification of lignocelluloses should be conducted at elevated pH 5.2–6.2. Bioenerg Res 6(2):476–485

Lehtio J, Sugiyama J, Gustavsson M, Fransson L, Linder M, Teeri TT (2003) The binding specificity and affinity determinants of family 1 and family 3 cellulose binding modules. Proc Natl Acad Sci USA 100(2):484–489

Leu SY, Zhu JY (2013) Substrate-related factors affecting enzymatic saccharification of lignocelluloses: our recent understanding. Bioenerg Res 6(2):405–415

Leu S-Y, Gleisner R, Zhu JY, Sessions J, Marrs G (2013) Robust enzymatic saccharification of a Douglas-fir forest harvest residue by SPORL. Biomass Bioenergy 59:393–401

Li J, Li S, Fan C, Yan Z (2012) The mechanism of poly(ethylene glycol) 4000 effect on enzymatic hydrolysis of lignocellulose. Colloids Surf B 89(1):203–210

Liu H, Zhu JY (2010) Eliminating inhibition of enzymatic hydrolysis by lignosulfonate in unwashed sulfite-pretreated aspen using metal salts. Bioresour Technol 101(23):9120–9127

Liu H, Zhu JY, Fu S (2010) Effects of lignin-metal complexation on enzymatic hydrolysis of cellulose. J Agric Food Chem 58:7233–7238

Liu H, Zhu JY, Chai XS (2011) In situ, rapid, and temporally resolved measurements of cellulase adsorption onto lignocellulosic substrates by UV-vis spectrophotometry. Langmuir 27(1):272–278

Lou H, Zhu JY, Lan TQ, Lai H, Qiu X (2013) pH-induced lignin surface modification to reduce nonspecific cellulase binding and enhance enzymatic saccharification of lignocelluloses. ChemSusChem 6(5):919–927

Nakagame S, Chandra RP, Kadla JF, Saddler JN (2011a) Enhancing the enzymatic hydrolysis of lignocellulosic biomass by increasing the carboxylic acid content of the associated lignin. Biotechnol Bioeng 108(3):538–548

Nakagame S, Chandra RP, Kadla JF, Saddler JN (2011b) The isolation, characterization and effect of lignin isolated from steam pretreated Douglas-fir on the enzymatic hydrolysis of cellulose. Bioresour Technol 102(6):4507–4517

Ooshima H, Sakata M, Harano Y (1986) Enhancement of enzymatic hydrolysis of cellulose by surfactant. Biotechnol Bioeng 28:1727–1734

Ouyang X, Deng Y, Qian Y, Zhang P, Qiu X (2011) Adsorption characteristics of lignosulfonates in salt-free and salt-added aqueous solutions. Biomacromolecules 12(9):3313–3320

Rollin JA, Zhu Z, Sathitsuksanoh N, Zhang Y-HP (2011) Increasing cellulose accessibility is more important than removing lignin: a comparison of cellulose solvent-based lignocellulose fractionation and soaking in aqueous ammonia. Biotechnol Bioeng 108(1):22–30

Shiiba H, Hayashi S, Yui T (2013) Molecular dynamics study of carbohydrate binding module mutants of fungal cellobiohydrolases. Carbohydr Res 374:96–102

Várnai A, Siika-Aho M, Viikari L (2013) Carbohydrate-binding modules (CBMs) revisited: reduced amount of water counterbalances the need for CBMs. Biotechnol Biofuels 6(1)

Wang QQ, He Z, Zhu Z, Zhang Y-HP, Ni Y, Luo XL, Zhu JY (2012) Evaluations of cellulose accessibilities of lignocelluloses by solute exclusion and protein adsorption techniques. Biotechnol Bioeng 109(2):381–389

Wang Z, Zhu JY, Fu Y, Qin M, Shao Z, Jiang J, Yang F (2013a) Lignosulfonate-mediated cellulase adsorption: enhanced enzymatic saccharification of lignocellulose through weakening nonproductive binding to lignin. Biotechnol Biofuels 6:156

Wang ZJ, Lan TQ, Zhu JY (2013b) Lignosulfonate and elevated pH can enhance enzymatic saccharification of lignocelluloses. Biotechnol Biofuels 6:9

Zhou H, Lou H, Yang D, Zhu JY, Qiu X (2013a) Lignosulfonate to enhance enzymatic saccharification of lignocelluloses: Role of molecular weight and substrate lignin. Ind Eng Chem Res 52(25):8464–8470

Zhou H, Zhu JY, Luo X, Leu S-Y, Wu X, Gleisner R, Dien BS, Hector RE, Yang D, Qiu X, Horn E, Negron J (2013b) Bioconversion of beetle-killed lodgepole pine using SPORL: Process scale-up design, lignin coproduct, and high solids fermentation without detoxification. Ind Eng Chem Res 52(45):16057–16065

Zhu JY, Zhuang XS (2012) Conceptual net energy output for biofuel production from lignocellulosic biomass through biorefining. Prog Energy Combust Sci 38(4):583–589

Zhu JY, Pan XJ, Wang GS, Gleisner R (2009) Sulfite pretreatment (SPORL) for robust enzymatic saccharification of spruce and red pine. Bioresour Technol 100(8):2411–2418

Zhu JY, Gleisner R, Scott CT, Luo XL, Tian S (2011) High titer ethanol production from simultaneous enzymatic saccharification and fermentation of aspen at high solids: a comparison between SPORL and dilute acid pretreatments. Bioresour Technol 102(19):8921–8929

Acknowledgments

This work was supported by a USDA Small Business Innovative Research (SBIR) phase II project (Phase II project (Contract No. 2010-33610-21589) through Biopulping International, a Agriculture and Food Research Initiative Competitive Grant (2011-68005-30416) from the National Institute of Food and Agriculture (NIFA) through the Northwest Advanced Renewables Alliance (NARA), China Excellent Young Scientist Fund (20925622), International Science and Technology Cooperation Program of China (2013DFA41670), and National Natural Science Foundation of China (21376100), The Chinese Scholarship Council (CSC). These programs made the visiting appointments of Hongming Lou and Haifeng Zhou at the US Forest Service (USFS), Forest Products Laboratory (FPL) possible. We acknowledge Fred Matt and Kolby Hirth (both USFS-FPL) for carrying out carbohydrate and sulfur content analyses. JYZ is a co-inventor of a sulfite pretreatment process—SPORL (US patent application published) that produces lignosulfonate.

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was conducted while Hongming Lou and Haifeng Zhou were visiting scientists at the USDA Forest Products Laboratory and on official government time of Zhu.

Rights and permissions

About this article

Cite this article

Lou, H., Zhou, H., Li, X. et al. Understanding the effects of lignosulfonate on enzymatic saccharification of pure cellulose. Cellulose 21, 1351–1359 (2014). https://doi.org/10.1007/s10570-014-0237-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-014-0237-z