Abstract

A major by-product of biodiesel production is waste glycerol, which has numerous potential applications. In this study, we isolated a novel bacterium capable of producing cellulose from waste glycerol, and identified it as a novel strain (named NEDO-01) of Gluconacetobacter intermedius. Scanning electron microscopy revealed that the morphology of the pellicle produced by NEDO-01 was similar to that of cellulose produced by Gluconacetobacter hansenii ATCC23769. Furthermore, X-ray diffraction and solid-state nuclear magnetic resonance spectroscopic analyses suggested that cellulose produced by NEDO-01 had molecular and crystalline structures similar to those of cellulose produced by ATCC23769. After the optimization of cultivation conditions, NEDO-01 mediated the one-step production of nanofibrillated bacterial cellulose (NFBC) from waste glycerol in a medium supplemented with carboxymethyl cellulose. Transmission electron microscopic analysis revealed that the NFBC was composed of relatively uniform fibers with diameters of approximately 20 nm. NFBC was produced as uniform water suspensions, the yield of which was 3.4 g/L from cultivation in 7.5 L medium in a 10-L jar fermenter. The bioconversion of waste glycerol to NFBC, which has superior fluidity, moldability, and miscibility, has a wide variety of applications, including potential uses in the medical and materials engineering fields.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Biodiesel fuel (BDF) has attracted recent attention as an alternative diesel fuel, and is generated via an ester exchange reaction between lipids and methanol. By-products constitute approximately 10 % of the total BDF produced (Chi et al. 2007), and include high concentrations of glycerol (termed waste glycerol). To date, the production of several materials via bioconversion of waste glycerol has been reported, including 1,3-propanediol, dihydroxyacetone, ethanol, and succinate (da Silva et al. 2009). Waste glycerol contains various impurities in addition to glycerol; therefore, the selection of bacteria suitable for cultivation using waste glycerol as a carbon source is of considerable importance for materials production.

Cellulose, a naturally abundant linear homopolymer of D-glucopyranose linked by β-1,4-glycosidic bonds, is one material that could potentially be generated from waste glycerol. Cellulose is produced by many different organisms, including vascular plants, algae, certain types of bacteria, and even some animals (Saxena and Brown 2005; Ross et al. 1991; Doblin et al. 2002; Kimura and Kondo 2002; Taylor 2008). The bacterial cellulose (BC) produced by Gram-negative obligate aerobe Gluconacetobacter species is a pure cellulose nanofiber with a diameter of approximately 50 nm (Haigler et al. 1982). BC has exceptional physicochemical properties, such as an ultrafine reticulated structure, high crystallinity, high tensile strength, high hydrophilicity, and biocompatibility, although its chemical structure is similar to the cellulose produced by plants and algae (Ross et al. 1991; Yamanaka et al. 1989; Yoshinaga et al. 1997). Under static culture conditions, cellulose nanofibers form a 3D network structure to generate a gel-like membrane, termed the pellicle, which has been used for various applications (Czaja et al. 2006; Nogi and Yano 2008). However, the pellicle has low fluidity, moldability, and miscibility because of its strong 3D network structure, and this property imposes a limitation on the range of applications of BC. Therefore, the production of nanofibrillated BC (NFBC), which is dispersed in water and thus does not form a strong 3D network structure, could significantly expand the potential applications of BC.

Recently, nanofibrillated cellulose (NFC) has attracted attention as a new cellulose material (Abdul Khalil et al. 2012). Generally, NFC is produced by the physical and/or chemical treatment of cellulose microfibers from plants (i.e., a top-down process) (Abe and Yano 2009; Saito et al. 2006), and is obtained as uniform water suspensions. In contrast, since BC naturally has a nanofiber structure, it may be possible to produce bacterial NFC (i.e., NFBC) in a one-step, bottom-up process through the optimization of culture conditions for Gluconacetobacter species. In fact, it has been reported that segmentalized BC was produced by the addition of carboxymethylcellulose (CMC) to the culture medium, which prevents the aggregation of microfibrils during BC synthesis (Cheng et al. 2009, 2011).

In this study, we aimed to identify a bacterium capable of producing NFBC from waste glycerol in one step. A novel bacterium capable of producing cellulose from waste glycerol was isolated from fruits by using an enrichment cultivation method, and was identified as a novel strain of Gluconacetobacter intermedius based on its physiological properties and 16S ribosomal DNA (rDNA) sequence. Furthermore, NFBC was prepared by rotating and agitating cultivation of the bacterium, and the structure of the NFBC was analyzed by transmission electron microscopy (TEM), fourier transform infrared spectroscopy (FT-IR), and wide angle X-ray diffraction analysis (WAXD).

Materials and methods

Chemicals

Luria–Bertani (LB) medium was purchased from Life Technologies Japan, Ltd. (Tokyo, Japan). Bacto peptone, yeast extract, glucose, disodium hydrogen phosphate (Na2HPO4), citric acid, and sodium CMC were purchased from Wako Pure Chemical Industries (Osaka, Japan). Waste glycerol (biodiesel fuel by-product) was kindly provided by Hokusei Kigyo Co., Ltd. (Sapporo, Japan). Calcofluor white was purchased from Sigma-Aldrich Japan (Tokyo, Japan). Nanofibrillated cellulose (NFC) from pulp (BiNFi-s) was purchased from Sugino Machine Ltd. (Toyama, Japan).

Bacteria and medium

Gluconacetobacter intermedius NEDO-01 (NITE P-1495) was isolated from fruits by an enrichment cultivation method in this study. Gluconacetobacter hansenii ATCC23769 and Gluconacetobacter xylinus ATCC53582 were used as control BC-producing bacteria. Hestrin and Schramm’s (HS) medium (Hestrin and Schramm 1954) was used as a standard medium, and CMC was added when needed.

Pretreatment of waste glycerol

The waste glycerol provided by Hokusei Kigyo Co., Ltd. (Sapporo) was diluted with an equal weight of water. The mixture was neutralized by 5 M aqueous H2SO4 and then poured into a separating funnel. The funnel was kept at 60 °C for 3 h and then allowed to stand at room temperature overnight. The mixture was divided into two phases, and the aqueous phase was used as waste glycerol in this study.

Isolation and identification of a bacterium capable of producing cellulose from waste glycerol

Several kinds of fruit were used as potential sources of bacteria able to produce cellulose from waste glycerol. A small piece of each fruit was added to HS medium containing 2 % (w/v) glycerol instead of glucose to perform enrichment cultivation. The culture was spread on HS plates containing 2 % (w/v) glycerol instead of glucose. A fluorescent brightener, which selectively interacts with cellulose and fluoresces under ultraviolet light, was used to identify bacterial colonies producing a pellicle. Colonies that produced fluorescence under ultraviolet light were inoculated into 10 mL of medium containing 2 % (w/v) glycerol and incubated at 30 °C under static conditions. The pellicle weight was measured to select bacteria with high cellulose productivity. Finally, one bacterium was selected as a candidate for cellulose production from waste glycerol by repeating colony isolation and pellicle weight measurement.

The 16SrDNA sequence of the selected bacterium was analyzed with MicroSeq Full Gene 16SrDNA PCR and Sequencing kits and an ABI PRISM 3100 genetic analyzer (Applied Biosystems Japan Ltd., Tokyo, Japan). BLAST searches using the 16SrDNA sequence were performed to identify the selected bacterium.

Cultivation of bacteria

Static cultivation

Frozen bacteria were inoculated into 10 mL of HS medium and then incubated at 30 °C for 3 days under static conditions. The pellicle formed at the air/liquid interface was pressed using a sterilized toothpick to isolate bacteria retained in the pellicle. The culture medium (1 mL) was inoculated into HS medium (10 mL) and then incubated at 30 °C under static conditions. Standard BC (used as a reference) was produced under static cultivation conditions using glucose as a carbon source. Products were dispersed into 1 % (w/v) aqueous NaOH and treated for an appropriate length of time. After the alkaline treatment, the samples were collected and then washed with deionized water until the pH became 6–7. The BC used for TEM observation was homogenized with a mixer (Mill & Mixer, Toshiba Co., Tokyo, Japan).

Rotating cultivation

The culture medium (5 mL), prepared as described in the “Static cultivation” section, was inoculated into a new HS medium (100 mL) containing CMC and glycerol or waste glycerol instead of glucose. The culture medium was incubated at 30 °C on a rotating shaker (BR-43FL, TAITEC Co. Ltd., Saitama, Japan) at 150 rpm. The culture was treated with 1 % (w/v) aqueous NaOH and purified as described above for static cultivation.

Agitating cultivation

The culture medium was prepared according to the method described above for static cultivation and inoculated into HS medium (5–7.5 L) in a 10-L jar fermenter (BMS-10NP3, ABLE & Biott Co., Ltd., Tokyo, Japan) and then incubated at 30 °C for 4 days with aeration and agitation. The product was treated with 1 % (w/v) aqueous NaOH and purified as described above for static cultivation.

Microscopy

Scanning electron microscopy (SEM)

After freeze drying, the samples were mounted on SEM grids, and gold particles were evaporated to the sample surfaces. The specimens were observed with a JSM-6500F scanning electron microscope (JEOL Ltd., Tokyo, Japan) at an accelerating voltage of 5 kV.

Transmission electron microscopy (TEM)

The aqueous dispersion samples [ca. 0.001 % (w/v)] were mounted or sprayed onto copper grids and dried. The samples were then negatively stained by 5 % aqueous gadolinium acetate and observed using a JEM-2000FX microscope (JEOL Ltd., Tokyo, Japan) at an accelerating voltage of 80 kV. The samples observed via TEM were also observed using an optical microscopy BX 40 (OLYMPUS Co., Tokyo, Japan) equipped with a polarizing plate.

Wide angle X-ray diffraction measurement

Dried samples were placed onto a silicon plate. WAXD measurements using a RINT2200 X-ray Diffractometer (Rigaku Co., Tokyo, Japan) were carried out in reflection mode with a scanning speed of 1.000°/min and in the 5°–30° diffraction angle range. Diffraction data were collected at 40 kV and 20 mA.

Solid-state nuclear magnetic resonance spectroscopy

Solid-state 13C nuclear magnetic resonance (NMR) spectra were recorded at 25 °C on a Brucker Biospin MSL-300 spectrometer (Brucker Biospin K.K., Yokohama, Japan) with a 1H frequency of 300 MHz. Dipolar-decoupled/magic angle spinning (DD/MAS) 13C NMR experiments were performed. 13C-excitation pulse length, data acquisition time, and repetition time were set to 1.5 μs, 20 ms, and 20 s, respectively.

Fourier transform infrared spectroscopy analysis

FT-IR spectra for film samples were measured using a JASCO FTIR-4200 spectrophotometer (JASCO Corporation, Tokyo, Japan). The conditions for the FT-IR measurements were as follows: 32 or 64 scans, 2 or 4 cm−1 resolution, and a 4,000–400 cm−1 scan range.

Results and discussion

Isolation and identification of a bacterium capable of producing a pellicle from waste glycerol

To obtain bacteria capable of producing cellulose from waste glycerol, we first carried out enrichment cultivation using media containing glycerol as a carbon source instead of glucose. We successfully isolated a bacterium that could produce a gel-like membrane (pellicle) from waste glycerol, and performed analyses of its microbiological and physiological properties for identification purposes. The bacterium was found to be an aerobic Gram-negative bacillus, and was able to grow in a cultivation temperature of up to 37 °C, but did not grow at 45 °C. The bacterium was positive for catalase activity and negative for oxidase activity, and was able to oxidize N-propanol, glucose and ethanol. Furthermore, the bacterium assimilated ethanol, glycerol, sodium lactate, and sucrose, and cell growth was observed in the presence of 3 % (v/v) ethanol or 30 % (w/v) glucose.

Additionally, the sequence of the 16SrDNA of the bacterium was determined and subjected to BLAST analysis (http://blast.ncbi.nlm.nih.gov/Blast.cgi), which indicated that the bacterium belongs to the genus Gluconacetobacter and that the closest phylogenetic neighbor of the isolated strain is G. intermedius (99 % identity). Based on the microbiological and physiological properties and 16SrDNA sequence, the isolated bacterium was identified as G. intermedius and designated NEDO-01 (NITE P-1495).

Structural analysis of a pellicle produced by G. intermedius NEDO-01 under static cultivation conditions

To confirm that the pellicle produced by NEDO-01 consisted of cellulose, its structure was analyzed by SEM, WAXD, and solid-state NMR spectroscopy. Figure 1 shows SEM images of pellicles produced by NEDO-01 and ATCC23769, a representative cellulose-producing bacterium. The NEDO-01 pellicle had a 3D network structure composed of nanofibers (Fig. 1a), which was similar to the ATCC23769 pellicle (Fig. 1b) with respect to the size-order of the nanofibers and the network structure. Furthermore, WAXD analysis suggested that the pellicle produced by NEDO-01 had a cellulose I crystal structure, which was similar to that produced by ATCC23769 (Fig. 2). The structures of the pellicles produced by NEDO-01 and ATCC23769 were also assessed by solid-state 13C-NMR (Fig. 3). The NMR peaks corresponding to C1, C4, C2,3,5, and C6 were observed from low to high magnetic field, and the peaks from both samples were completely consistent with each other, indicating that the pellicle produced by NEDO-01 was cellulose and that it had similar molecular and crystalline structures to the cellulose produced by ATCC23769. Additionally, the C1 peak with an almost single peak profile suggested that the cellulose produced by NEDO-01 had an Iα-rich crystalline structure (Yamamoto and Horii 1993), similar to that produced by ATCC23769. These results confirmed that the pellicle produced by NEDO-01 consisted of cellulose and had similar molecular and crystalline structures to the cellulose produced by ATCC23769.

Bacterial cellulose production from waste glycerol under rotating cultivation conditions

BC is generally produced under static cultivation conditions; however, although BC with a strong 3D network structure can be produced by this cultivation method, it is not suitable for large-scale production of BC. Rotating and agitating cultivations are more likely to be effective for large-scale material productions using bacteria, and the production of BC by agitating cultivation has been reported (Kouda et al. 1997; Cheng et al. 2009, 2011). Additionally, Cheng et al. (2011) reported that segmentalized BC (a BC pellet) was produced and BC production was enhanced by the addition of CMC to the culture medium, which prevented the aggregation of microfibrils. On the basis of these findings, we examined the rotating and agitating cultivation conditions of NEDO-01 in medium containing waste glycerol as a carbon source and CMC as an inhibitor of cellulose microfibril aggregation, in an attempt to achieve a one-step, large-scale production of NFBC from waste glycerol.

We first performed rotating cultivation using a baffled Erlenmeyer flask, for which requirement studies are relatively easy, and assessed the NEDO-01-mediated production of BC from waste glycerol. Figure 4a shows the yields of BCs produced from waste or pure glycerol by NEDO-01, ATCC53582, and ATCC23769 in rotating cultivation. Although ATCC23769 produced cellulose from pure glycerol, no cellulose was produced from waste glycerol within the 72 h of cultivation time. Waste glycerol contains various kinds of impurities such as lipids, fatty acids, and methanol, and these may have affected the cellulose production by ATCC23769. In contrast, NEDO-01 produced cellulose from both waste and pure glycerol with comparable yields. For ATCC53582, cellulose was not produced from either waste or pure glycerol under these cultivation conditions. The production of NFBC by ATCC23769 under rotating culture conditions suggested that the production of NFBC is not necessarily solely dependent on the type of strain. Taken together, these results led us to conclude that NEDO-01 is suitable for cellulose production from waste glycerol under rotating cultivation conditions.

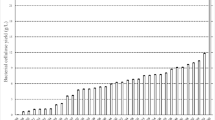

We next performed rotating cultivation in media containing various concentrations of CMC [1, 1.5, 2, 2.5, and 3 % (w/v)] to examine the effects of CMC concentration on BC production (Fig. 4b). The BC yield increased with the concentration of CMC up to 2.5 % (w/v), but was reduced when the CMC concentration was increased to 3 % (w/v). The decrease in BC yield at the highest CMC concentration could be due to the high viscosity of the medium containing 3 % (w/v) CMC. On the basis of these results, media including 2 % (w/v) CMC were used for subsequent experiments.

BC production from waste glycerol under agitating cultivation conditions

Based on the results of the rotating cultivation experiment, agitating cultivation using a jar fermenter was performed for a large-scale production of BC. The BC yield for a 4 days cultivation of 7.5 L of medium in a 10-L jar fermenter was 3.4 g/L. This yield was significantly higher than that of BC produced by rotating cultivation without CMC (1.3 g/L), possibly as a result of the prevention of ribbon formation, which is thought to be a rate-determining step of BC production. The apparatus and cultivation conditions used in this experiment were standard; therefore, we expect that a larger-scale production of BC under similar conditions could be carried out without difficulty.

Structural analyses of BC produced by NEDO-01 from waste glycerol under agitating cultivation conditions

The BC produced by NEDO-01 from waste glycerol under agitating cultivation conditions was obtained as uniform water suspensions, which were used to examine the structure of the BC in detail via TEM, FT-IR, and WAXD analyses. Figure 5 shows TEM images of BCs produced by NEDO-01 from waste glycerol under agitating (Fig. 5a) and static (Fig. 5b; mixer-homogenized) cultivation conditions. The BC fibers produced by agitation of NEDO-01 in a medium containing CMC were narrower than BC fibers produced by static culture in medium without CMC (Fig. 5), with diameters of 21 ± 11 and 55 ± 22 nm, respectively. TEM observation also indicated that the BC produced under agitating cultivation conditions had a nanofibrillated structure (i.e., NFBC was produced). BC is thought to be synthesized by terminal complex (TC) (the cellulose synthase complex), and many TCs exist in the cell membrane of Gluconacetobacter species (Brown 1996). The whole structure of the TC in Gluconacetobacter species has not yet been determined; however, it has been shown that 1.5 nm-wide sub-elementary fibrils (SEF) extrude from each TC, and that SEFs aggregate to form microfibrils, which self-assemble into fibers (ribbons) (Brown 1996). CMC is thought to prevent the aggregation of microfibrils (Yamamoto et al. 1996), thereby promoting the formation of nanofibers with ~20 nm diameters. Additionally, the shear stress generated by agitation could also promote narrow nanofiber formation. In our experiment, the fiber length of NFBC could not be determined, because the nanofibers were connected to each other in all 3 dimensions in the water suspensions.

Figure 6 shows micro- and nano-scale images from polarization microscopy and TEM of NFBC and NFC from pulp. A few microfibers were observed in addition to nanofibers in the NFC (Fig. 6b, d), whereas only nanofibers were observed in the NFBC (Fig. 6a, c). As mentioned above, NFC is produced by the physical and/or chemical treatment of cellulose microfibers from plants (a top-down process); thus, it is difficult to downsize microfibers to nanofibers completely, and NFC contains small amounts of micro- or submicrofibers in addition to nanofibers, which are present in a large majority. In contrast, BC originally contains no microfibers, hence, NFBC produced via a bottom-up process is composed of nanofibers only, which is very beneficial for material applications of NFBC. Furthermore, compared to top-down processes, which rely on mechanical and/or chemical treatments, (Henriksson et al. 2007; Wågberg et al. 2008; Isogai et al. 2011; Pei et al. 2013), the bottom-up process is more environmentally friendly, since it uses various kinds of waste materials as carbon sources and reduces the use of chemicals.

Cheng et al. (2009, 2011) and Chen et al. (2011) reported the production of BC using a jar fermenter and a medium containing CMC, resulting in the production of pelleted and segmentalized BC. In our study, nanofibers with approximately 20-nm diameters were obtained as uniform water suspensions. This difference could be due to the differences in cultivation conditions, such as medium, CMC concentration, and agitation speed.

Molecular and crystalline structures of NFBC

The FT-IR spectrum of NFBC produced by NEDO-01 was similar with that of BC produced under static culture conditions (Fig. 7), suggesting that NFBC had essentially the same molecular structure as BC obtained under static culture conditions. In WAXD analysis, the profile obtained from NFBC demonstrated three main characteristic peaks (2θ = 14.7°, 16.8°, and 22.7°) corresponding to crystal planes (\(1 {\overline{1}}0\)), (110), and (200) in Fig. 8, suggesting that NFBC possessed a cellulose I crystalline structure (Kataoka and Kondo 1999; Kim et al. 2010) and that the addition of CMC into the medium did not alter the crystalline morphology. In contrast, no reflections corresponding to cellulose II (2θ = 12.1° and 20.7°) (Mansikkamäki et al. 2005) were observed. The NFBC crystal size calculated on the basis of the Scherrer’s equation (Toda et al. 2013) was 4.06 nm, which was smaller than that of BC produced under static culture conditions (5.60 nm). As shown in Fig. 5, NFBC is composed of nanofibers that are narrower than those of BC. Generally, the crystal size of cellulose is closely related to the width of cellulose fibers (Yamamoto et al. 1996; Hirai et al. 1998); therefore, the decrease in the diameter of nanofibers resulting from the CMC-mediated inhibition of microfibril aggregation could influence the crystal size of NFBC.

Conclusion

We succeeded in isolating a novel bacterium capable of producing cellulose from waste glycerol. The isolated bacterium was identified as G. intermedius and the strain was named NEDO-01. After optimization of NEDO-01 cultivation conditions, nanofibrillated bacterial cellulose (NFBC) was directly produced from waste glycerol in one step. TEM observation revealed that the NFBC generated by NEDO-01 was composed of relatively uniform fibers which were approximately 20 nm in diameter. NFBC is superior in terms of fluidity, moldability, and miscibility; thus, it has a wide variety of potential applications, including uses in the medical field where its biocompatibility would be beneficial.

References

Abdul Khalil HPS, Bhat AH, Ireana Yusra AF (2012) Green composites from sustainable cellulose nanofibrils: a review. Carbohydr Polym 87:963–979

Abe K, Yano H (2009) Comparison of the characteristics of cellulose microfibril aggregates of wood, rice straw and potato tuber. Cellulose 16:1017–1023

Brown RM Jr (1996) The biosynthesis of cellulose. J Macromol Sci A 33:1345–1373

Chen H–H, Chen L-C, Huang H-C, Lin S-B (2011) In situ modification of bacterial cellulose nanostructure by adding CMC during the growth of Gluconacetobacter xylinus. Cellulose 18:1573–1583

Cheng K-C, Catchmark JM, Demirci A (2009) Effect of different additives on bacterial cellulose production by Acetobacter xylinum and analysis of material property. Cellulose 16:1033–1045

Cheng K-C, Catchmark JM, Demirci A (2011) Effects of CMC addition on bacterial cellulose production in a biofilm reactor and its paper sheets analysis. Biomacromolecules 12:730–736

Chi Z, Pyle D, Wen Z, Frear C, Chen S (2007) A laboratory study of producing docosahexaenoic acid from biodiesel-waste glycerol by microalgal fermentation. Process Biochem 42:1537–1545

Czaja W, Krystynowicz A, Bielecki S, Brown RM Jr (2006) Microbial cellulose—the natural power to heal wounds. Biomaterials 27:145–151

da Silva GP, Mack M, Contiero J (2009) Glycerol: a promising and abundant carbon source for industrial microbiology. Biotechnol Adv 27:30–39

Doblin MS, Kurek I, Jacob-wilk D, Delmer DP (2002) Cellulose biosynthesis in plants: from genes to rosettes. Plant Cell Physiol 43:1407–1420

Haigler CH, White AR, Brown RM Jr, Cooper KM (1982) Alteration of in vivo cellulose ribbon assembly by carboxymethylcellulose and other cellulose derivatives. J Cell Biol 94:64–69

Henriksson M, Henriksson G, Berglund LA, Lindström T (2007) An environmentally friendly method for enzyme-assisted preparation of microfibrillated cellulose (MFC) nanofibers. Eur Polym J 43:3434–3441

Hestrin S, Schramm M (1954) Synthesis of cellulose by Acetobacter xylinum 2. Preparation of freeze-dried cells capable of polymerizing glucose to cellulose. Biochem J 58:345–352

Hirai A, Tsuji M, Yamamoto H, Horii F (1998) In situ crystallization of bacterial cellulose III. Influences of different polymeric additives on the formation of microfibrils as revealed by transmission electron microscopy. Cellulose 5:201–213

Isogai A, Saito T, Fukuzumi H (2011) TEMPO-oxidized cellulose nanofibers. Nanoscale 3:71–85

Kataoka Y, Kondo T (1999) Quantitative analysis for the cellulose Iα crystalline phase in developing wood cell walls. Int J Biol Macromol 24:37–41

Kim U-J, Eom SH, Wada M (2010) Thermal decomposition of native cellulose: influence on crystallite size. Polym Degrad Stab 95:778–781

Kimura S, Kondo T (2002) Recent progress in cellulose biosynthesis. J Plant Res 115:297–302

Kouda T, Yano H, Yoshinaga F (1997) Effect of agitator configuration on bacterial cellulose productivity in aerated and agitated culture. J Ferment Bioeng 83:371–376

Mansikkamäki P, Lahtinen M, Rissanen K (2005) Structural changes of cellulose crystallites induced by mercerisation in different solvent systems; determined by powder X-ray diffraction method. Cellulose 12:233–242

Nogi M, Yano H (2008) Transparent nanocomposites based on cellulose produced by bacteria offer potential innovation in the electronics device industry. Adv Mater 20:1849–1852

Pei A, Butchosa N, Berglund LA, Zhou Q (2013) Surface quaternized cellulose nanofibrils with high water absorbency and adsorption capacity for anionic dyes. Soft Matter 9:2047–2055

Ross P, Mayer R, Benziman M (1991) Cellulose biosynthesis and function in bacteria. Microbiol Rev 55:35–58

Saito T, Nishiyama Y, Putaux J-L, Vignon M, Isogai A (2006) Homogeneous suspensions of individualized microfibrils from TEMPO-catalyzed oxidation of native cellulose. Biomacromolecules 7:1687–1691

Saxena IM, Brown RM Jr (2005) Cellulose biosynthesis: current views and evolving concepts. Ann Bot Lond 96:9–21

Taylor NG (2008) Cellulose biosynthesis and deposition in higher plants. New Phytol 178:239–252

Toda K, Yamamoto H, Yoshida M (2013) Crystallization of cellulose microfibrils in wood cell wall by repeated dry-and-wet treatment, using X-ray diffraction technique. Cellulose 20:633–643

Wågberg L, Decher G, Norgren M, Lindström T, Ankerfors M, Axnäs K (2008) The build-up of polyelectrolyte multilayers of microfibrillated cellulose and cationic polyelectrolytes. Langmuir 24:748–795

Yamamoto H, Horii F (1993) CP/MAS 13C NMR analysis of the crystal transformation induced for valonia cellulose by annealing at high temperatures. Macromolecules 26:1313–1317

Yamamoto H, Horii F, Hirai A (1996) In situ crystallization of bacterial cellulose II. Influences of different polymeric additives on the formation of celluloses Iα and Iβ at the early stage of incubation. Cellulose 3:229–242

Yamanaka S, Watanabe K, Kitamura N, Iguchi M, Mitsuhashi S, Nishi Y, Uryu M (1989) The structure and mechanical properties of sheets prepared from bacterial cellulose. J Mater Sci 24:3141–3145

Yoshinaga F, Tonouchi N, Watanabe K (1997) Research progress in production of bacterial cellulose by aeration and agitation culture and its application as a new industrial material. Biosci Biotech Biochem 61:219–224

Acknowledgments

Waste glycerol was a kind gift from Hokusei Kigyo Co. Ltd. This work was supported by a Grant for Advanced Industrial Technology Development in 2011 (11B12009) from the New Energy and Industrial Technology Development Organization (NEDO) of Japan. We thank Mr. Kenji Ohkubo of Hokkaido University for his technical support in TEM and SEM observations. A part of this work was conducted at Hokkaido University, supported by “Nanotechnology Platform” Program of the Ministry of Education, Culture, Sports, Science and Technology (MEXT), Japan.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kose, R., Sunagawa, N., Yoshida, M. et al. One-step production of nanofibrillated bacterial cellulose (NFBC) from waste glycerol using Gluconacetobacter intermedius NEDO-01. Cellulose 20, 2971–2979 (2013). https://doi.org/10.1007/s10570-013-0050-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-013-0050-0