Abstract

Carboxymethyl cellulose-silver nanoparticle (AgNp)-silica hybrids have been synthesized in a modified Stöber process. The hybrid synthesis was optimized to obtain an efficient immobilization matrix for diastase alpha amylase, a multimeric enzyme of high technological significance. The synthesized hybrids were characterized using FTIR, XRD, SEM, TGA and BET studies. The enzyme immobilization was done by adsorption and using the immobilized enzyme, the hydrolysis of soluble starch has been optimized in comparison to free enzyme. The optimum usable pH for the immobilized enzyme ranged from pH 4 to 5, while pH 5 was optimum pH for the free enzyme activity. The kinetic parameters for the immobilized, (K M = 3.4610 mg ml−1; V max = 6.3540 mg ml−1 min−1) and free enzyme (K M = 4.1664 mg ml−1; V max = 4.291 mg ml−1 min−1) hydrolysis indicated that the immobilization at the nanohybrid has significantly improved the catalytic property of the enzyme. In the immobilized state, the enzyme remained usable for many repeated cycles like our previous material, gum acacia-gelatin-AgNp-silica. Storage experiments indicated that the immobilization has increased the stability of the enzyme and also that AgNps play a role in stabilizing the immobilized enzyme.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Many bio-composites have been evolved by silicification of a preformed biopolymer-based material or from silica precursor/biopolymer mixed solutions in a sol–gel method (Benmouhoub et al. 2008). The process includes the hydrolysis of silica precursor in water followed by the condensation reactions which first leads to a silica sol and then to a cross linked hybrid silica gel. Sol–gel derived silica hybrid materials have many fascinating applications including adsorption of enzymes and metal ions as they have good mechanical properties, thermal stability, and resistance against microbial attack and organic solvents. Immobilized enzymes can lead to cleaner and easier work up of enzymatic transformations. Many carrier substrates increase the ability and stability of the enzymes (Singh and Kumar 2011a, b; Singh and Ahmed 2012) because of the specific interaction between them and the immobilized enzyme. Mostly enzyme activity diminishes on immobilization due to mass transfer effects. On the other hand, improved stability under working conditions often compensates for such drawbacks and results into an overall benefit. Polysaccharides being renewable, biodegradable and multifunctional are the attractive materials for silica biocomposite synthesis. Silica component in such hybrids is responsible for the properties like temperature and mechanical resistance, porosity while the biopolymer offers extra functionality and framework to the ensuing hybrid matrices. Polysaccharides of different charge types can be employed as templates for the sol–gel polymerization of silica precursors to result hybrid biocomposites of different properties and performances. As a matter of fact, in the current years, a large variety of biopolymers have been used to fabricate biopolymer-silica hybrids for technological advancement in enzyme technology (Shchipunov et al. 2004, 2005). These studies involve enzyme entrapment in silica matrix under circum-neutral pH at room temperature during polysaccharide templated polymerization of silica sols. The entrapment method of biocomposite synthesis often becomes detrimental, as the alcohols that are produced/or required (as co-solvents) in the hydrolysis of common silica precursors such as tetraethoxysilane (TEOS) (Copello et al. 2011; Lai et al. 2006) or tetramethoxysilane (TMOS) (Singh and Kumar 2011a, b; Singh and Ahmed 2012) have denaturing effect on the entrapped enzymes or biological samples. Enzyme denaturing could be easily avoided by using custom-synthesized biocompatible precursors such as water soluble silicates (Wang et al. 2006) and tetrakis-(2-hydroxyethyl)orthosilicate (THEOS) (Shchipunov and Karpenko 2004; Bakunina et al. 2006).

Based on our studies on the adsorption behavior of polysaccharide silica biocomposites (Singh et al. 2010; Singh and Kumar 2011a, b; Singh and Singh 2011), we have recently used carboxymethyl tamarind gum (CMT)-silica (Singh and Kumar 2011a, b) and gum acacia-gelatin-AgNp-silica biocomposites as adsorption carriers for alpha amylase (Singh and Ahmed 2012). These studies revealed that the biocomposites synthesized out of common silica precursors can immobilize enzyme by adsorption. It is reported that the life time of the adsorbed enzyme is lesser than the entrapped enzyme in silica ensued from water soluble silicates or THEOS polymerization (Shchipunov et al. 2004, 2005). This challenge was successfully met by the incorporation of trace amount of silver nanoparticles (Singh and Ahmed 2012) in the hybrids.

Cellulose is one of the most abundant natural polysaccharide. Its derived forms such as hydroxyethyl cellulose (Shchipunov et al. 2005) and carboxymethyl cellulose (Benmouhoub et al. 2008) have been used for synthesizing silica biocomposites. Carboxymethyl cellulose or cellulose gum (CMC) is soluble form of cellulose having carboxymethyl groups (CH2COOH) at glucopyranose monomer units that make up the cellulose backbone (Fig. 1). Cellulose is structurally different from tamarind gum in being linear and having different primary structure and hence their carboxymethyl derivatives. CMC-silica hybrid gels have been synthesized using aqueous silicates (Benmouhoub et al. 2008) but so far no attempt has been made to synthesize CMC-silica biocomposites from silica alkoxides.

In the present study we have undertaken the synthesis of carboxymethyl cellulose-AgNp-silica hybrid nanocomposites. The hybrid synthesis has been carried out by polymerizing tetramethoxysilane (TMOS) in presence of CMC and AgNps. Silver nanoparticles have been synthesized by in situ reduction of silver ions by CMC (Mohan et al. 2007). The AgNp solution was incorporated in the hybrid silica matrix owing to the known antibacterial nature of AgNps (Travan et al. 2009).

Materials and methods

Reagents

Tetramethoxysilane (98 % TMOS; Merck, Germany) was used as silica precursor. Carboxymethylcellulose (Loba Chem) was used as supplied. Analytical grades of fungal diastase amylase (Merck, Germany), AgNO3, 3, 5-dinitrosalicylic acid, NaOH, phosphate salts (Merck, India) and soluble starch (Merck Germany (Mv = 4451 Da) were used. Dialysis of diastase alpha amylase (Merck, Germany) was done using 10 kDa dialysis bags (Banglo Genei, Banglore India).

Characterization

UV/Vis Spectrophotometer UV 100, Cyber lab, USA was used for the characterization of AgNps and spectrophotometric determination of enzyme. X-ray diffraction (XRD) was carried out on (XRD Pananalytical X-Pert Pro X-ray powder diffractometer). IR was done through Fourier transform infrared (FTIR) spectrophotometer, JASCO FTIR, within the spectral range of 400–4000 cm−1 and resolution 4 cm−1. TGA was done using Perkin–Elmer TGA-7 at a heating rate of 10 °C min−1 under nitrogen atmosphere. SEM analysis was done on EDAX, FEI Quanta 200 machine. Temperature treatment of the hybrids was done in N2 atmosphere using electric muffle furnace (Metrex Scientific Instruments (P) Ltd., New Delhi). Nitrogen adsorption–desorption isotherms were obtained using a WT Classic BET Surface Area Analyzer WAKO, India at 26 °C and prior to gas adsorption, all the samples were degassed for 4 h at 260 °C.

Fabrication of silver nanoparticles

Silver nanoparticles (AgNps) were synthesised (Hebeish et al. 2010) by stirring 3 ml of 5 mM silver nitrate solution in 5 ml of 2 % (w/v) carboxymethyl cellulose solution at 80 °C for 2 h. UV–vis spectrum of the resulting solution was recorded to evidence the formation of AgNps. In the spectrum surface plasmon resonance peak of AgNps was observed at 410 nm (Singh and Ahmed 2012) (spectrum not shown). This AgNp containing solution was used for the hybrid synthesis.

Dialysis of enzyme

Enzyme solution (5 ml of 400 μg ml−1) contained in a dialysis bag (‘1’ width) was hanged in 2 L of 0.02 M phosphate buffer solution for 8 h. This process was repeated thrice after which the dialysis bag was dipped in a sugar solution bed (0.02 M) for 4 h for the dialysis.

Material synthesis

Carboxymethylcellulose templated nanohybrid (A series hybrids)

Hybrid gels (Aa–Ad) (Table 1) were synthesized (Singh and Kumar 2011a, b) by stirring a known weight of CMC with 20 ml of H2O, 1.5 ml TMOS and 1.5 ml of methanol for a known time period at ambient temperature to obtain gels that were stirred well with distilled water and dried under reduced pressure. Using a fixed amount of CMC (200 mg), volumes of TMOS, MeOH and H2O were varied, one at a time to obtain other “A” series hybrid gels; (AB1–AB3), (AbA–AbC) and (AbX–AbY) respectively (Table 1).

Carboxymethyl cellulose-AgNp-silica nanohybrid (B series hybrids)

For synthesizing B series hybrids (Table 1) (Singh and Ahmed 2012) (Ba–Be), a known volume of AgNp solution was added during TMOS polymerization under the synthetic conditions of optimum “A” series hybrid gel Ab.

Calcination of the hybrids

For obtaining heat treated “A” (Abc2–Abc5) and “B” series (Bbc2–Bbc5) hybrids, optimum samples of both series (Ab and Bb respectively) were calcined separately in silica crucibles at different temperatures ranging from 200 to 500 °C (for 2 h at each temperature, under nitrogen atmosphere) in an electric muffle furnace. After the calcination at desired temperature, the hybrid samples were left inside the furnace and allowed to cool (to room temperature) before use.

Control silica

TMOS (1 ml) was polymerized without CMC and AgNps (under the synthetic conditions of optimum hybrid sample (Ab), and the obtained gel was calcined at 300 °C to obtain CS.

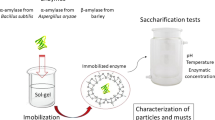

Immobilization of amylase onto the nanohybrids

0.1 ml of diastase (0.4 mg ml−1) was adsorbed on Bbc3 (100 mg) at pH 5.5 and left for 2 h at 40 °C. The pH of the enzyme solution was adjusted to pH 5.5 using the phosphate buffer (European Pharmacopeia 5, 2005). Enzyme weight refers for solid enzyme in preparing enzyme stock solution (0.4 mg ml−1). All the enzyme impregnated hybrids were washed with deionized distilled water, dried in vacuum at 40 °C and were evaluated for their bioactivities (Singh and Kumar 2011a, b) for hydrolyzing soluble starch. Among the “A” and “B” series hybrid samples, samples Abc3 and Bbc3 respectively had optimum activities (Table 2). Sample Bbc3 being more efficient (Table 2) was used for the characterization and optimization of the hydrolysis conditions. Enzyme loaded Abc3 and Bbc3 were designated as Abc3-Enz and Bbc3-Enz respectively.

Activity of immobilized enzyme

The activity of diastase was determined through the detection of released reducing sugars from starch using 3,5-dinitrosalicylicacid (DNS) method (Hu et al. 2008; Miller 1959). The hydrolysis of starch was monitored using predialyzed free and immobilized diastase alpha amylase at different substrate concentrations, temperatures and pH values. The commercial enzyme was dialyzed before use so that the stabilizers (if present), were removed. The activity was assayed for 1 ml of the reaction mixture containing soluble starch (0.5 ml of 1 % (w/v) solution in 0.02 M phosphate buffer), free dialyzed diastase alpha amylase (0.1 ml of 0.4 mg ml−1) and distilled H2O (0.4 ml) at pH 5 after 10 min incubation at 40 °C. Under identical conditions, the hydrolysis of soluble starch was also monitored using Bbc3-Enz (100 mg) with 0.5 ml of H2O, and 0.5 ml of 1 % (w/v) starch solution in 0.02 M phosphate buffer at 40 °C. To interrupt the enzyme reaction, 1 ml of 3,5-dinitrosalicylic acid reagent was introduced as coupling reagent. The tube containing this mixture was heated for 4 min in boiling water and then cooled in running tap water. After addition of 10 ml of water, the reaction mixture was centrifuged and the optical density of the centrifugate containing the brown reduction product was determined spectrophotometrically at λmax 540 nm. A blank was prepared in the same manner but without enzyme. Diastase alpha amylase activity was expressed in terms of micromoles of the reducing sugar.

The determination of the released sugar during the reaction was estimated using maltose standard curve. To study the thermal stability of the enzyme, 0.1 ml of 0.4 mg ml−1 free dialyzed enzyme solution was incubated for 10 min at different temperatures ranging from 25 to 50 °C using a temperature controlled incubator shaker at 200 rpm and was used for hydrolyzing 0.5 ml of 1 % (w/v) starch solution. To determine the activity of immobilized enzyme, a known weight of enzyme impregnated nanohybrid with 0.5 ml of 1 % (w/v) starch and 0.5 ml of H2O was incubated for 10 min at different temperatures ranging from 25 to 50 °C. Enzyme activity was tested as described above. One unit of α-amylase activity is defined as the amount of enzyme, which produces reducing ends equal to 1.0 μmol maltose in 1 min at 40 °C and pH 5.

To study the pH effect on the enzyme stability, 0.1 ml of 0.4 mg ml−1 enzyme was added to 0.5 ml of 1 % (w/v) starch solution that had been pre adjusted at different pH values using 0.02 M phosphate buffer. The buffer was prepared using Na2HPO4 (Anhydrous) and NaH2PO4·H2O solutions; phosphoric acid was added where required (European Pharmacopeia 5, 2005). After the addition of 0.5 ml H2O, the reaction mixture was incubated for 10 min.

For the immobilized enzyme, a known weight of immobilized enzyme was used and the enzyme activity was determined as above. After the first cycle, the reaction mixture was centrifuged to separate the used nanohybrid, which was washed well with distilled water, dried and stored for recycling at room temperature. For kinetic study, concentration of starch was varied from 0.25 to 1.5 % (w/v) at pH 5, keeping the other conditions same as described above. For evaluating the shelf life of the immobilized enzyme, the enzyme impregnated hybrids were stored as dry solids at room temperature (~40 °C) for desired time period. The free enzyme was stored in phosphate buffer for same period at room temperature. They were evaluated for their bioactivities as described above.

Results and discussion

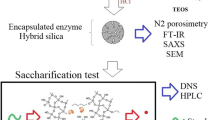

The preparation of optimum “A” and “B” series hybrids (Abc3 and Bbc3 respectively) and enzyme loading onto them for obtaining Abc3-Enz and Bbc3-Enz have been depicted in Scheme 1. Since Bbc3-Enz had higher biocatalytic activity than Abc3-Enz (Table 2), Bbc3-Enz was used for optimizing the soluble starch hydrolysis. Bbc3 has been characterized using FTIR, XRD, SEM, TGA and BET in comparison with Bbc3-Enz, however to understand the effect of AgNp incorporation to the hybrid, FTIR spectra of Abc3 and Abc3-Enz were also compared.

Characterization

FTIR

Silica incorporation in the hybrids was evidenced by FTIR spectra, where Si–O stretching modes (Fig. 2) are observed below 1250 cm.−1 In Infra-red spectrum of optimum CMC-silica hybrid (Abc3), peaks at 1086 cm−1 (Si–O stretching) and 796 (Si–OH stretching) evidenced the formation of Si–O-Si bond by dehydration and polycondensation of silinols. The peak at 464 cm−1 corresponds to the bending vibration mode of the SiO4 tetrahedron or a symmetric oxygen stretching vibrations of Q3 surface silanol. The IR peak of surface silanols is seen merged with CMC hydroxyl group peak at 3453 cm−1.

In CMC-AgNp-silica (Bbc3), the shift in hydroxyl peak (to 3470 cm−1) indicates involvement of the hydroxyl groups in stabilizing the AgNps, which have partially disrupted the association state of hydroxyls. While the silica related peaks do not shift appreciably except minor shift in peak at 1871 cm−1. Thus the incorporation of AgNps did not alter the spectral pattern of the hybrid silica indicating that no formal bonding is present between silver nanoparticles and hybrid silica matrix. The silver CMC-AgNp-silica hybrid after immobilization of amylase (Bbc3-Enz) shows hydroxyl stretching at 3465 cm−1 which indicates that the presence of enzyme affects the association state of surface silanols in the hybrid silica. Enzyme amide (I) and amide (II) bands are not observed separately as these peaks are merged with the carbonyl peaks of the CMC.

The C = O stretching is observed as a strong asymmetric stretching band between 1609–1617 cm−1 and 1400–1417 cm−1 in all the samples. In Bbc3, the disappearance of two peaks at 1420 cm−1 and appearance of one peak at 1400 cm−1 may be attributed to the stabilization of the AgNPs where OH bond deformation by silver metal surface (Rao et al. 2010) takes place. In Bbc3 the bridging is involved in-between silver nanoparticle surface and oxygen atoms of carbonyls of the carboxymethyl groups.

XRD

The XRD (Fig. 3) evidenced Bbc3 to be an amorphous material having diffraction angle centre 2θ 22 º as that of control silca (XRD not shown). Similar to our previous material, the silver peaks are not detected separately as very broad peak of silica might have overlapped the silver peaks, which are in trace amount to be detected by XRD (Singh and Ahmed 2012).

SEM

The surface morphology of the Bbc3 and Bbc3-Enz is shown by SEM image in Fig. 4. SEM pictures indicate the materials to have layered structures which do not reveal the embedded nanoparticles. After immobilization not much change in the hybrid surface is observed.

TGA

Thermogravimetric analyses of the hybrids reveal them to be thermally stable (Fig. 5). Both Bbc3 and Abc3 show weight loss in two stages. First 10–11 % weight loss extends up to 200 °C, which is due to bound and trapped water and solvent while the second phase of weight loss extends up to 600 °C which can be attributed to the loss of the CMC and densification of the hybrid gel. The nanoparticle incorporation does not much effect the thermal behavior of the CMC-silica except that this material entraps less moisture and solvent, which is evident from the first smaller weight loss (10.48 %) for Bbc3.

BET

The surface area the optimum CMC-Silica (Abc3) and CMC-Silica-AgNps (Bbc3) were analyzed by BET method using nitrogen adsorption–desorption isotherms. Bbc3 had higher (>4 times) surface area (58.358 m2 g−1) as compared to Abc3 which had surface area of 13.29 m2 g−1. The surface areas of B series hybrids ranging from Bbc2 to Bbc5 were determined (Table 3). After AgNps incorporation there is no appreciable change in bioactivity of the immobilized enzyme indicating no role of the AgNps in the enzyme activity. Again from Table 3, it is evident that there is no direct correlation between the surface area and the bioactivity of the hybrids. The AgNp incorporation increases the shelf life of the impregnated enzyme which can be related to the known antibacterial activity of the AgNps (Lee et al. 2005; Rojas et al. 2000) (Table 4).

Enzyme immobilization

Hybrids from Aa to Ad were synthesized varying the amount of CMC (100–400 mg) at fixed volumes of TMOS (1.5 ml), MeOH (1.5 ml) and H2O (20 ml). In a preliminary investigation, the enzyme was immobilized on these hybrids and using the immobilized hybrids, the hydrolysis of soluble starch was carried out. Among these hybrid samples, “Ab” was found to be most efficient (Table 1). Therefore volumes of TMOS, MeOH and H2O were varied, one at a time while keeping the amount of CMC (200 mg) and other process parameters fixed to obtain hybrids from AB1 to AB3, AbA to AbC and AbX to AbY respectively (Table 1).

The optimum hybrid sample (Ab) thus obtained gelled in 45 min, the synthetic parameters being 200 mg CMC, 20 ml H2O, 1.5 ml TMOS and 1.5 ml MeOH (Table 1). The amylase immobilized Ab (Ab-Enz), when used for hydrolyzing 0.5 ml of 1 % (w/v) soluble starch solution, showed a bioactivity of 16 U mg−1. The immobilization conditions were: hybrid support (100 mg), enzyme solution (0.1 ml of 0.4 mg ml−1), pH (pH 5.5) and temperature (40 °C).

The hybrid Ab when calcined at 300 °C furnished most efficient A series gel (Abc3) (Table 1). Under the synthesis conditions of Ab, a known volume of AgNp solution was added during TMOS polymerization for obtaining “B” series hybrids (Ba to Bd) (Table 1) (Singh and Ahmed 2012). Out of these hybrids, Bb showed optimum results and thus was selected for calcination at known temperature (ranging from 200 to 500 °C) for 2 h to obtain Bbc2–Bbc5. On these heat treated gels, alpha amylase was immobilized and the resulting biocatalysts were used for hydrolyzing the soluble starch. It was observed that no pH change takes place during or after the hydrolysis, indicating 10 min incubation time is too short for any significant pH change to take place. Out of the synthesized hybrids, Bbc3 proved to be most efficient (21 U mg−1 activity) (Table 1) and thus was selected for a detailed study. Using Bbc3-Enz, conditions for the soluble starch hydrolysis have been optimized and the kinetic parmeters, K M and V max for the immobilized were determined using Lineweaver–Burk equation (Djabali et al. 2009) from the initial rates of the hydrolysis reaction of starch solutions of different concentrations.

Effect of pH

The pH optimum of the enzyme was determined by varying the pH of the assay reaction mixture using the phosphate buffers (Fig. 6A). The stability of diastase alpha amylase was determined by pre-incubating the immobilized enzyme in different buffers (pH 4–8) for 60 min. The residual enzyme activity was determined as described earlier. Both free and immobilized enzymes were found sensitive to the pH values. The immobilization at hybrid Bbc3 marginally changed the pH-response of the enzyme (Fig. 6), where the immobilized enzyme at pH 4 was found as active as at pH 5, in contrast to our previously studied hybrid (Singh and Ahmed 2012) which showed optimum activity at pH 5. Activity of both free and immobilized enzyme was significantly declined on increasing the pH value from pH 6 to pH 7. Alkaline pH (pH = 8) is not suitable for the immobilized enzyme as significant fall in enzyme activity was noticed at this pH. No change in pH of the reaction mixtures was observed during the hydrolysis or after completion of the hydrolysis even when no buffers were used, indicating 10 min incubation time is too short for a significant change in pH during the enzymatic reaction.

Effect of temperature

The temperature effect on the activity of free and the immobilized enzyme (Bbc3-Enz) is shown in the Fig. 6B. Both free and Bbc3-Enz show same activity up to 35 °C. Further increase in the temperature to 40 °C however significantly increased the activity of the immobilized enzyme. The immobilized enzyme showed better activity as compared to free enzyme in the temperature range of 40–50 °C, though the activity for the immobilized enzyme was most at 40 °C. Decrease in enzyme activity with increase in temperature >40 °C indicates enzyme denaturation but this decrease is less effective for the immobilized enzyme (Bbc3-Enz), which indicates that the nanostructured hybrid structure protects the enzyme denaturation to some extent.

Hydrolysis and kinetic parameters

Kinetic parameters, the Michaelis constant K M and the maximum activity V max for free and the immobilized diastase (H3-Enz) were determined (Fig. 7) using soluble starch as substrate. In general, the K M of an immobilized enzyme is different from that of the free enzyme due to diffusion limitations (Siso et al. 1990), steric effects (Tischer and Wedekind 1999) and ionic strength (Manelius and Bertoft 1996). The kinetic parameters of free enzyme (K M = 4.1664 mg ml−1, V max = 4.291 mg ml−1 min−1) and immobilized (K M = 3.4610 mg ml−1; V max = 6.3540 mg ml−1 min−1) enzyme indicated that the immobilization has improved the catalytic property of the enzyme. The elevation in V max and lowering of K M as compared to free enzyme indicated a positive distortion of the enzyme assembly inside the hybrid matrix. It appears that the hybrid matrix probably has a favorable environment for the immobilization, which prevents major conformational changes in the enzyme structure. Similar trend was observed in our previous study with carboxymethyl tamarind gum-silica nanocomposite (Singh and Kumar 2011a, b) while in our recently reported material Gum acacia-gelatin-AgNp-silica hybrid, both V max and K M decreased on immobilization (Singh and Ahmed 2012).

Recycling and storage

The immobilized enzyme could be successfully recycled for six cycles. Though after the first cycle there was ~16 % loss in the enzyme activity, the activity loss became quite insignificant beyond this cycle and the immobilized enzyme retained 74 % of its initial activity even in the sixth cycle (Fig. 8). This value is very close to the free enzyme activity observed in the first cycle (under identical conditions), indicating the advantage of the immobilization. Recycled material after 15 days storage at room temperature remained as active as freshly recycled material.

Free diastase α-amylase preparations were stored in phosphate buffer while the enzyme immobilized hybrids were stored as dry solids at room temperature (40 °C). The immobilized enzyme (Bbc3-Enz) on storage showed no activity loss even after 15 days and on recycling showed nearly same behavior as of freshly prepared material. However Abc3-Enz lost 12 % of its initial activity in 15 days, when stored under the identical storage conditions. Free enzyme on the other hand loses 26 % activity in the same storage time in phosphate buffer at 40 °C (Table 4) with simultaneous decrease in the pH value (to pH 4). These results indicate that immobilization is advantageous towards increasing the shelf life of the enzyme and AgNps have some role to play in providing high shelf life to Bbc3.

Conclusions

The CMC-AgNp-silica nanohybrid proved to be a good carrier for immobilization of amylase. The immobilization improved overall affinity and catalytic properties of amylase, besides the enzyme under immobilized state was more stable. The enzyme impregnated hybrid material could be easily separated from the reaction mixture by centrifugation and was reused for the next cycle. The immobilization at the nanohybrid significantly enhanced the enzyme activity besides improving the reaction workup. The enzyme was stable in the hybrid matrix and its activity did not change much when stored at room temperature (40 °C) for 15 days. The present study demonstrates a promising application of CMC for synthesizing promising carrier support for immobilizing diastase α-amylase.

References

Bakunina Yu, Nedashkovskaya OI, Zvyagintseva TN, Shchipunov YuA (2006) Immobilization of α-galactosidase inside hybrid silica nanocomposites containing polysaccharides. Russ J Appl Chem 79:827

Benmouhoub N, Simmonet N, Agoudjila N, Coradin T (2008) Aqueous sol-gel routes to bio-composite capsules and gels. Green Chem 10:957

Copello GJ, Mebert AM, Raineri M, Pesenti MP, Diaz LE (2011) Removal of dyes from water using chitosan hydrogel/SiO2 and chitin hydrogel/SiO2 hybrid materials obtained by sol-gel method. J Hazard Mater 186:932

Djabali D, Belhaneche N, Nadjemi B, Dulong V, Picton L (2009) Relationship between potato starch isolation methods and kinetic parameters of hydrolysis by free and immobilised α-amylase on alginate (from Laminaria digitata algae). J Food Compos Anal 22:563

European Pharmacopeia, 5.0 (2005), Council of Europe (COE)—European Directorate for the Quality of Medicines (EDQM), Chapter 4, Reagents, section 4.1.3., Buffer solutions, p 430

Hebeish AA, El-Rafie MH, Abdel-Mohdy FA, Abdel-Halim ES, Emam HE (2010) Carboxymethyl cellulose for green synthesis and stabilization of silver nanoparticls. Carbohydr Polym 82:933

Hu R, Lin L, Liu T, Ouyang P, He B, Liu S (2008) Reducing sugar content in hemicellulose hydrolysate by DNS method: a revisit. J Biobased Mater Bioener 2:156

Lai S-M, Yang Ar J-M, Chen W-C, Hsiao J-F (2006) The properties and preparation of chitosan/silica hybrids using sol-gel process. Polym-Plast Technol Eng 45:997

Lee D, Cohen RE, Rubner MF (2005) Antibacterial properties of Ag nanoparticle loaded multilayers and formation of magnetically directed antibacterial microparticles. Langmuir 21:9651

Manelius R, Bertoft E (1996) The effect of Ca2+-ions on the α-amylolysis of granular starches from oats and waxy-maize. J Cereal Sci 24:139

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426

Mohan YM, Raju KM, Sambasivudu K, Singh S, Sreedhar B (2007) Preparation of acacia-stabilized silver nanoparticles: a green approach. J Appl Polym Sci 106:3375

Rao YN, Banerjee D, Datta A, Das SK, Guin R, Saha A (2010) Gamma irradiation route to synthesis of highly re-dispersible natural polymer capped silver nanoparticles. Radiat Phys Chem 79:1240

Rojas IA, Slunt JB, Grainger DW (2000) Polyurethane coatings release bioactive antibodies to reduce bacterial adhesion. J Control Rel 63:75

Shchipunov YA, Karpenko TY (2004) Hybrid polysaccharide-silica nanocomposites prepared by the sol-gel technique. Langmuir 20:3882

Shchipunov YA, Karpenko TY, Bakunina IY, Burtseva YV, Zvyagintseva TN (2004) A new precursor for the immobilization of enzymes inside sol-gel-derived hybrid silica nanocomposites containing polysaccharides. J Biochem Biophys Meth 58:25

Shchipunov YA, Karpenko TY, Krekoten AV (2005) Hybrid organic-inorganic nanocomposites fabricated with a novel biocompatible precursor using sol-gel processing. Compos Interface 11:587

Singh V, Ahmed S (2012) Silver nanoparticle (AgNPs) doped gum acacia-gelatin-silica nanohybrid for diastase immobilization. Int J Biol Macromol 50:353

Singh V, Kumar P (2011a) Carboxymethyl tamarind gum-silica nanohybrids for effective immobilization of amylase. J Mol Catal B Enzym 70:67

Singh V, Kumar P (2011b) Design of nanostructured tamarind seed kernel polysaccharide-silica hybrids for mercury (II) removal. Sep Purif Technol 46:825

Singh V, Singh SK (2011) Synthesis and characterization of gum acacia inspired silica hybrid xerogels for mercury(II) adsorption. Inter J Biol macromol 48:445

Singh V, Singh SK, Pandey S, Sanghi R (2010) Adsorption behavior of potato starch-silica nanobiocomposite. Adv Mater Lett 1:40

Siso MIG, Graber M, Condoret J-S, Combes D (1990) Effect of diffusional resistances on the action pattern of immobilized alpha-amylase. J Chem Technol Biotechnol 48:185

Tischer W, Wedekind F (1999) Immobilized enzymes: methods and applications. Biocatalysis—From Discovery to Application. In: Fessner W-D (ed) Topics in Current Chemistry, Springer, Berlin Heidelberg, Vol. 200, pp 95–126

Travan A, Pelillo C, Donati I, Marsich E, Benincasa M, Scarpa T, Semeraro S, Turco G, Gennaro R, Paoletti S (2009) Non-cytotoxic silver nanoparticle-polysaccharide nanocomposites with antimicrobial activity. Biomacromolecules 10:1429

Wang G-H, Zhang L-M (2006) Using novel polysaccharide-silica hybrid material to construct an amperometric biosensor for hydrogen peroxide. J Phys Chem B 110:24864

Acknowledgments

The authors are grateful to the University Grants Commission, New Delhi India for the financial support to carry out this research work. IR, SEM and XRD facilities are acknowledged to Indian Institute of Mines, Dhanbad, Indian Institute of Technology Karagpur and National Centre of Experimental Mineralogy and Petrology, University of Allahabad respectively. Authors thank Dr. Anjana Pandey, Centre for Biotechnology, University of Allahabad, India for gifting dialysis bags.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, V., Ahmad, S. Synthesis and characterization of carboxymethyl cellulose-silver nanoparticle (AgNp)-silica hybrid for amylase immobilization. Cellulose 19, 1759–1769 (2012). https://doi.org/10.1007/s10570-012-9749-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-012-9749-6