Abstract

The global reaction between acetic anhydride and a fatty acid yields, at equilibrium, an asymmetric acetic-aliphatic anhydride in a medium containing finally: acetic-fatty anhydride, acetic anhydride, fatty acid, acetic acid and fatty anhydride. No solvent or catalyst was used to evaluate the impact of the actual reactivity of the anhydrides. The competition between the formation of acetyl and fatty acyl ester functions was evaluated by determining the ratio of acetyl/fatty acyl groups grafted on solid cellulose. The influence of temperature, reaction time, and length of fatty chain on the total degree of substitution and on the ratio of acetyl/fatty acyl ester functions was investigated. For the first time, a correlation has been established between esterification and the length of the aliphatic chain of the fatty acid. Reactivity of the medium decreased with the number of carbons in the fatty acid, raised to the power 2.37.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Mixed cellulose esters (MCE), i.e. substituted by different aliphatic chains, are polymers with interesting properties. In particular, cellulose acetate-propionate (CAP) and cellulose acetate-butyrate (CAB), are very important industrially. Research on other mixed acetic-aliphatic cellulose esters has led to the discovery of polyfunctional materials combining both good mechanical properties and high hydrophobicity (Vaca-Garcia et al. 1998).

Two step preparations of MCE, with acetylation usually first, followed by the other substituent, or with two different anhydrides, are common, even in industrial processes. Alternatively, a reaction mixture can be used comprising one anhydride and carboxylic acids. Malm and Hiatt (1939) proposed chloroacetic anhydride, plus a fatty acid with at least 6 C atoms, such as stearic acid, in the presence of an inert, low-boiling solvent such as methylene chloride and an esterification catalyst such as p-toluenesulfonic acid.

Another procedure uses trifluoroacetic anhydride as co-reagent, with a mixture of two different carboxylic acids to form mixed anhydrides in situ (trifluoroacetic-aliphatic or aliphatic-aliphatic). The former permits fatty acylation without reacting the fluorinated moiety, whereas the latter can graft either of the aliphatic moieties (Matsuzaki and Miyata 1967). The same technique has also been used for the synthesis of various mixed esters of starch (Yang and Montgomery 2008).

The procedure we will consider in this paper consists of the acylation of cellulose with mixed acetic-aliphatic anhydrides produced in situ by the reaction between acetic anhydride and a carboxylic acid (Vaca-Garcia et al. 1998; Vaca-Garcia and Borredon 1999; Chemeris 2003). In this way, either of the moieties of the asymmetric anhydride is grafted on the cellulose (Fig. 1).

The esterification of cellulose using this mixture depends on three factors: the relative proportion of acetylium and acylium ions, the effect of steric hindrance and the relative activation energies of each reaction.

The aim of this paper is to study the overall reactivity of this mixture on cellulose, and to compare the impact of the aliphatic chain length (f), of the different fatty acids used, on cellulose acylation.

Experimental

Chemicals

Acetic anhydride and the carboxylic acids: acetic (C2:0), octanoic (C8:0), capric (C10:0), lauric (C12:0), myristic (C14:0), palmitic (C16:0), and oleic (C18:1) of 99%+ purity were purchased from Sigma-Aldrich France. Pentadecanoic acid (C15:0) was used as internal standard (I·S.) in gas chromatography and was obtained from Fluka France (99% purity). Phosphoric acid, 85% solution in water, was purchased from Acros France. Alpha-cellulose from Sigma-Aldrich France was the initial biopolymer (this cellulose was characterized and gave: degree of polymerization = 960, 4% pentosans, 7% moisture content).

Trimethylsulphonium hydroxide (TMSH) was obtained from Macherey-Nagel France as a 0.2 mol/L solution in methanol. Tert-butyl methyl ether (MTBE) HPLC grade was purchased from Scharlau Spain. All chemicals were stored at 4 °C prior to use.

Preparation of the mixed acetic-fatty anhydrides

The appropriate amounts (molar ratio 3:2) of fatty acid and acetic anhydride were added to a glass reactor fitted with a condenser. Reactions were carried out at 100 °C with mechanical stirring at 500 rpm for 1 h. The reaction media were analyzed by reversed-phase HPLC (Peydecastaing et al. 2008) and used without purification for the synthesis of MCE.

Synthesis of MCE

Reactions were performed in 50 mL reactors fitted with a condenser. 1 g of undried cellulose (7% moisture) was stirred at 350 rpm into 15 mL of reaction medium without catalyst at the chosen temperature for the chosen duration. After cooling down to 80 °C, 20 mL of ethanol were added to precipitate the soluble fraction. Cellulose esters were separated by filtration over fritted glass and purified by Soxhlet extraction with ethanol for 8 h. The purified product was then vacuum dried to constant weight at 70 °C for at least 24 h.

DS determination

To our knowledge, there is no single analytical technique that allows the simultaneous and accurate determination of the DS of long and short substituents in MCE when the DS is below 0.1. Consequently, we have employed two different techniques. The first was used to determine the fatty acyl content and the second, to quantify the acetyl groups. Both analyses are required to evaluate the individual and total DS-values.

Determination of the fatty acyl content

The method based on the reaction of cellulose esters with TMSH followed by gas chromatography (GC) analysis, was used. The conditions were those recommended for low DS-values according to a previous work (Peydecastaing et al. 2009a). Basically, the MCE sample is reacted in a vial with TMSH for 1 h at 75 °C with MTBE as solvent. Once the sample has cooled down and the solid decanted, the fatty acid methyl esters (FAME) are quantified by GC and, from this, the concentration of fatty acyl groups C f in solution can be determined.

Determination of the acetyl content

This method is based on saponification of the MCE followed by GC analysis.

A precise amount (about 20 mg) of MCE was weighed and introduced into a 2 mL vial, to which 1 mL of aqueous sodium hydroxide (0.5 N) and 0.5 L of a 0.5 mmol/L propionic acid (internal standard) solution in water were added. The vial was stirred for 5 h in a shaking incubator, set at 1,200 rpm and 100 °C. The sample was then cooled down, 45 μL of H3PO4 added and the vial stirred again at 1,200 rpm for 10 min at room temperature. Once the solid had decanted, a small sample of the reaction mixture supernatant, was analyzed by GC. Separation was achieved in a CP-Select CB for FFAP fused silica capillary column (CP7845, Varian) 25 m, 0.32 mm i.d., 0.25 μm film thickness. Helium was used as carrier gas at a flow rate of 2.6 mL/min. The temperature of the injector was set at 250 °C, the FID detector at 270 °C, and the split ratio at 1:100. Oven temperature was programmed as follows: 80 °C for 1 min rising to 145 °C at a rate of 20 °C/min, and then to 250 °C, at a rate of 50 °C/min, for 2 min. This allowed the separation of the acetic and propionic acids in less than 12 min. From the GC analysis the concentration of acetyl groups C2 in solution can be determined.

DS calculation

The DS values of the grafted fatty chain (DS f ) and of the acetyl chain (DS2) are calculated as follows:

where:

- C f :

-

concentration of the FAME in MTBE determined by GC (in mol/L)

- V f :

-

volume of internal standard (pentadecanoic acid) solution added to the analyzed sample (in mL)

- m f :

-

mass of the MCE sample analyzed in MTBE with TMSH (in g)

- M f :

-

molar mass of the RCOOH fatty acid

- C 2 :

-

concentration of the acetic acid after saponification and acidification determined by GC (in mol/L)

- V 2 :

-

volume of internal standard (propionic acid) solution added to the analyzed sample (in mL)

- m 2 :

-

mass of the MCE sample analyzed in water (in g)

Results and discussion

Acylating agent

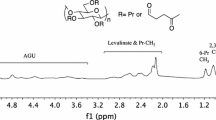

The mixed anhydrides are reactive molecules that allow the simultaneous reaction of two acyl moieties onto cellulose. Their reactivity is related to the asymmetry of the molecule. In acidic medium, the anhydride is protonated and readily cleaved to form an acylium ion and a carboxylic acid (Fig. 1). In the case of an acetic-fatty anhydride, both types of acylium ions can be formed.

Moreover, an asymmetric anhydride coexists with its symmetric anhydrides regardless of the synthetic pathway used to prepare it. This phenomenon has been thoroughly described by Peydecastaing et al. (2009b). At the end of the reaction, a mixture of five compounds: acetic acid, fatty acid, acetic anhydride, fatty anhydride, and acetic-fatty anhydride is obtained. Under non-catalyzed conditions, only the anhydrides are reactive to cellulose (Fig. 2). Acetic acid provides the proton to cleave the mixed anhydride and this can be considered as an auto-catalytic reaction. In order to study the reactivity phenomena on solid cellulose, a large excess of liquid reaction medium was used to maintain the concentration of the reactive species relatively constant. In addition, following the study of Peydecastaing et al. (2009b), a ratio of 1.5 mol of fatty acid per 1 mol of acetic anhydride was chosen to make the asymmetric anhydride the most abundant reactive entity (58%).

Synthesis of cellulose acetate-oleate

As expected, the substitution yield of acetyl and oleoyl moieties increases with temperature. And because this system has no external catalyst, the DS-values are relatively low compared to traditional setups using H2SO4 for cellulose esterification in heterogeneous systems. However, this choice allows the real reactivity of the molecules to be focused on. For the maximum tested temperature (175 °C), the values for the degree of substitution of oleates (DS 18:1) and acetates (DS 2) were 3.9 × 10−4 and 7.1 × 10−2 respectively. In other words, 2% of the hydroxyl groups in cellulose have been esterified.

The individual acetyl and oleoyl DS-values obtained at 160 °C are around ten and twenty times greater respectively than those obtained at 80 °C. These results highlight the fact that the acylation reaction is strongly temperature-dependent, and we found a linear correlation between DS-values and 1/T (Fig. 3). The value of the slope is directly related to the intrinsic reactivity of the moiety concerned. The gradient for acetylation is 170 times greater than that of oleoylation, and the temperature at which DS = 0 can be found by extrapolation. These points (72 and 89 °C for acetylation and acylation respectively) represent the temperature at which the reaction, carried out for 1 h with no external catalyst, becomes insignificant.

In order to confirm that these DS-values do not originate from residual reagents trapped in the structure of cellulose, we performed FTIR analysis of the solvent-extracted MCE. No characteristic carboxylic acid band was observed, however the characteristic ester band was clearly seen. In addition, the purification method was also validated by impregnating a sample of cellulose with the acylation mixture at 20 °C for 1 h followed by the same purification steps. The DS of this sample, determined by the very accurate GC method, was null (accuracy of the method for the fatty chains is up to 10−5 values of DS, see Peydecastaing et al. 2009a).

In the range of temperature studied, the proportion of grafted acetyl moieties to acyl moieties (DS 2 /DS 18:1) decreases from 389 to 187 as temperature increases from 80 to 175 °C as shown in Fig. 4, thus at lower temperatures fatty acylation is inhibited. A change in the composition of the reaction medium cannot account for this since in a previous article (Peydecastaing et al. 2009a, b), it was demonstrated that it remains practically constant with temperature.

The most likely hypothesis is that the activation energy for the acetylation is lower than for the acylation by oleoyl moities. At high temperatures (175 °C), there is the necessary energy for acetylation and fatty acylation and none of the reactions is inhibited. The ratio then reaches a plateau (linearization of the function DS = f(1/T), and here, esterification by acetyl groups is 200 times higher than by the fatty acyl groups. Such a difference can be accounted for by steric hindrance of the fatty chain, with the acetyl group more able to reach hydroxyl functions in the cellulose microfibrils. Moreover, in Fig. 1 the proportion of acylium ions (path A or B) will depend on the ease of forming the associated carboxylic acid. Since the pK of fatty acids is slightly higher than that of acetic acid, the acetylium ion will be more abundant than the fatty acylium ion.

The reaction time, between 1 and 4 h, has a typical influence on the reaction. The total DS-value increases rapidly and levels off after 3 h (at 140 °C). The weak reactivity of cellulose and the low accessibility of OH groups account for this.

It is interesting to note that the DS 2 /DS 18:1 ratio remains constant at about 200 over the whole reaction time range studied (Fig. 5). This means that acetyl and fatty acyl have different reaction rates but are not interdependent, confirming the hypothesis formulated above concerning the activation energies. In addition, as the reaction medium is in a state of equilibrium and the consumption of acetyl groups is greater than oleoyl ones, we would have expected a change in composition with time and then an effect on the ratio of grafting. However, this does not happen, and the explanation could be that the molar ratio of the acetyl/fatty acyl groups present in the reaction medium has only a small impact on the concentration of the mixed anhydride in the reaction medium. This observation was made in a previous paper concerning the study of the synthesis of acetic-oleic anhydride mixtures (Peydecastaing et al. 2009a b).

Synthesis of cellulose acetate-alkanoates

In the following series of experiments, the temperature and reaction time were kept constant (140 °C, 1 h) and only the nature of the fatty chain was varied, by preparing mixtures using acetic anhydride and different fatty acids with saturated aliphatic chains from C8 to C16, at a molar ratio of 1.5 (Table 1).

The steric hindrance evidently diminishes the fatty acylation (Fig. 6), and logically the DS2 /DS f ratio also decreases as the fatty acid chain length increases. This is well illustrated by the plot of this ratio as a function of the chain length on a logarithmic scale (Fig. 7). The regression trend is given by the equation DS2 /DS f = 5.1/n 2.37 for the conditions studied. Reactivity decreases with the number of carbon atoms, not in a linear way, nor to the square but to the power 2.37. This trend is valid for short (C2) to long (C8-16) and even mono-unsaturated (C18:1) side-chains. Other mono- and poly-unsaturated chains (linoleic, linolenic) must be tested to extend the validity of this equation to other cellulose unsaturated esters.

Conclusions

-

The reaction medium obtained from acetic anhydride and a fatty acid contains acetic-fatty anhydride as the most abundant reactive compound. On reaction with cellulose, it leads to the formation of mixed cellulose esters bearing acetyl and fatty acyl groups. In the absence of any external catalyst or cellulose solvent, low DS-values are obtained (DS2 ≥ 0.072; DS f ≥ 1.8 × 10−3 with 8 ≤ f ≤18) but this allows the impact of the actual reactivity of the molecules to be evaluated.

-

Precise DS determination was employed to accurately characterize these mixed, low substituted cellulose esters.

-

Straight reactivity revealed an acetyl to fatty acyl ratio varying from 27 to 659. Steric hindrance and the low pK of acetic acid account for preferential acetylation.

-

This ratio is dependent on the nature of the fatty acid and on the reaction temperature. However, it is not dependent on reaction time, being constant throughout the reaction.

-

Reactivity decreases with the number of carbon atoms to the power 2.37. This equation is valid for short and long and even mono-unsaturated (C18:1) side-chains.

References

Chemeris MM, Musko NP et al (2003). Synthesis of cellulose esters in a trifluoroacetic acid medium. Efiry Tsellyulozy i Krakhmala: Sintez, Svoistva, Primenenie, Materialy Yubileinoi Vserossiiskoi Nauchno-Tekhnicheskoi Konferentsii s Mezhdunarodnym Uchastiem, 10th, Suzdal, Russian Federation, 5–8 May 2003, pp 108–115

Malm CJ, Hiatt GD (1939) Mixed organic acid esters of cellulose such as mixed cellulose acetate-oleate, -linoleate or -stearate suitable for precipitation and washing with water. Eastman Kodak Co, USA. US Patent 2,172,250

Matsuzaki K, Miyata T (1967) Synthesis of mixed cellulose esters of a, b-unsaturated carboxylic and acetic acids and their utilization II. Reaction of mixtures of a, b-unsaturated carboxylic acid and acetic anhydride with cellulose. Kogyo Kagaku Zasshi 70:770–774

Peydecastaing J, Vaca-Garcia C et al (2008) Quantitative analysis of mixtures of various linear anhydrides and carboxylic acids. Chromatographia 68:685–688

Peydecastaing J, Vaca-Garcia C et al (2009a) Accurate determination of the degree of substitution of long chain cellulose esters. Cellulose 16(2):289–297

Peydecastaing J, Vaca-Garcia C et al (2009b) Consecutive reactions in an oleic acid and acetic anhydride reaction medium. Eur J Lipid Sci Technol 111:723–729

Vaca-Garcia C, Borredon ME (1999) Solvent-free fatty acylation of cellulose and lignocellulosic wastes. Part 2. Reactions with fatty acids. Bioresour Technol 70(2):135–142

Vaca-Garcia C, Thiebaud S et al (1998) Cellulose esterification with fatty acids and acetic anhydride in lithium chloride/N, N-dimethylacetamide medium. J Am Oil Chem Soc 75:315–319

Yang B, Montgomery R (2008) Preparation and physical properties of starch mixed esters. Starch 60:146–158

Acknowledgments

The authors would like to thank the LAPEYRE Company (France) for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Peydecastaing, J., Vaca-Garcia, C. & Borredon, E. Bi-acylation of cellulose: determining the relative reactivities of the acetyl and fatty-acyl moieties. Cellulose 18, 1015–1021 (2011). https://doi.org/10.1007/s10570-011-9528-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-011-9528-9