Abstract

Sm2MoO6/Ni(OH)2 was successfully immersed in water first, and the sensitizer is Eosin Y and the sacrificial agent is triethanolamine agent for high-efficiency photocatalytic production of H2. When Sm2MoO6 was loaded onto the surface of Ni(OH)2, the photocatalytic activity (2407.48 μmol g−1 h−1) was 2.6 times that of Ni(OH)2 (925.36 μmol g−1 h−1), which was Sm2MoO6 (169.36 μmol g−1 h−1) is 14.2 times. From a series of characterizations, Sm2MoO6 is an effective cocatalyst to improve the separation of photo-generated charges and the efficiency of electron transfer. Large specific surface areas are a primary requirement for high efficiency catalysts, and the catalyst is sufficiently into contact with the sensitizer and the sacrificial agent to soar the photocatalytic activity.

Graphic Abstract

The first condition for an excellent catalyst is that it has a large specific surface area and can provide more active sites. In the dye sensitization system, the photocatalytic activity of Sm2MoO6/Ni(OH)2 is 2.6 times that of Ni(OH)2 and 14.2 times that of Sm2MoO6. Sm2MoO6 is an effective co-catalyst.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Because traditional energy sources such as oil, coal, and natural gas are not renewable, they will destroy the atmosphere during use. Therefore, the energy issue has risen to social hotspots [1, 2]. Hydrogen is a renewable energy source that is non-polluting and can be obtained by water splitting [3,4,5]. The absorption range (ion doping, noble metal loading, metal ion implantation, dye sensitization and conjugated polymer modification, etc.) can be expanded by modification, and a novel oxide photocatalyst having visible light-driven activity can be developed to improve sunlight utilization [6,7,8]. At present, obtaining efficient, stable and inexpensive photocatalytic water-decomposing photocatalysts remains a huge challenge [9].

Ni-based materials are effective catalysts for such energy conversion and storage reactions as the oxygen evolution, the oxygen reduction and supercapacitors [10,11,12]. Because nano-Ni(OH)2 has good electrochemical performance, proton diffusion coefficient, fast activation speed and grain resistance are low, it has become a hot topic in the research fields of optoelectronic materials, gas sensing materials and battery cathode materials [13, 14]. As a hydrolysis accelerator, Ni(OH)2 can destroy the H–OH bond after introduction, thereby increasing the catalytic activity [15]. Ni(OH)2 can be prepared by precipitation [16], hydrothermal synthesis [17], and ion exchange [18]. When the mass ratio of the flower Ni/Ni(OH)2 to CdS is 0.5, the hydrogen production rate is 373.5 μmol h−1, which is 1.7 times that of 1 wt% Pt/CdS [19].

Rare earth compound based on an electronic, optical and chemical properties of the 4f electron generation, are widely used in high-performance light emitting device, the catalyst material and other functional areas [20, 21]. Metal molybdate is a typical binary metal oxides having abundant resources and non-toxic [22,23,24]. Transition metal molybdate can be used for photochemical degradation of different dyes [25,26,27]. It is reported that the samarium molybdic can be used as a fluorescent agent, and the preparation method is complicated [21, 28]. However, there have been few studies using rare earth molybdate as a photocatalyst. We used a simple method to prepare rare earth molybdate (mixing (NH4)6Mo7O24·4H2O and Sm(NO3)3·6H2O at a molar ratio of 1:1 at ambient temperature) for the first time as a cocatalyst. The photocatalytic activity of Ni(OH)2 is effectively improved. Sm2MoO6/Ni(OH)2 was successfully prepared by simply hydrothermal then impregnation. Sm2MoO6/Ni(OH)2 composites has strong photocatalytic activity and high photocatalytic stability under visible light irradiation.

2 Experimental Section

2.1 Preparation of Catalysis

Synthesis of Ni(OH)2 nanosheets: Added 900 mg urea and 1087.6 mg Ni(NO3)2·6H2O to 60 mL of ethylene glycol solution (25 mL water and 57.5 mL ethylene glycol). Stirred for 1 h and heat at 120 °C for 4 h. The product was collected by centrifugation and washed several times with water and ethanol.

Synthesis of Sm2MoO6: Added (NH4)6Mo7O24·4H2O and Sm(NO3)3·6H2O to 60 mL of deionized water. After stirred for 12 h, the product was collected and washed several times with water and ethanol. The molar ratio of (NH4)6Mo7O24·4H2O to Sm(NO3)3·6H2O was 1:1.

Synthesis of Sm2MoO6/Ni(OH)2: Dispersed 100 mg of Ni(OH)2 nanosheet into 60 mL of deionized water solution. Added a certain amount of (NH4)6Mo7O24·4H2O and Sm(NO3)3·6H2O (the molar ratio of (NH4)6Mo7O24·4H2O and Sm(NO3)3·6H2O is 1:1.). After stirred for 12 h, the product was collected and washed several times with water and ethanol.

All of the above catalysts were dried at 60 °C for 4 h.

2.2 Characterizations

The morphology of the sample was measured by TEM and HRTEM (HRTEM, JEOL JEM-2100, Japan). The chemical structure of the sample is determined by X-ray diffraction (XRD, Rigaku RINT-2000), and CuKα was irradiated at 30 mA and 40 kV. The chemical elements were determined by X-ray photoelectron spectroscopy (XPS, ESCALAB 250Xi). Fluorescence spectra were determined by a FluoroMAX-4 spectrometer (HORIBA Scientific, France). The specific surface area was measured by a Micromeritics ASAP 2020 nitrogen adsorption unit.

2.3 Photocatalytic Hydrogen Production

The photocatalytic hydrogen production experiment was carried out in a 250 mL closed quartz bottle, and the light source was a 300 W Xe lamp (λ ≥ 420 nm). The 20 mg photocatalyst was added to 100 mL TEOA (10%) solution. After ultrasonic dispersion for 10 min, 50 mg of Eosin Y were added, and the dark gas was stirred magnetically for 30 min, and nitrogen was purged for 40 min. The 0.5 mL of H2 was extracted every 1 h under visible light, and the generated hydrogen was measured by gas chromatography (N2 as a carrier gas) using a 13X molecular sieve column and a thermal conductivity detector (TCD).

2.4 Photoelectrochemical Measurements

Photocurrent measurements were performed on an electrochemical workstation (CHI660D, CH Instruments, China) with an electrolyte solution of 0.1 M Na2SO4. The catalyst was ultrasonically dispersed in absolute ethanol for 30 min to prepare a slurry, which was applied onto the surface of an ITO conductive glass and dried at room temperature to obtain a working electrode having an effective area of 1 × 1 cm2. The light source is a 300 W Xe lamp (λ ≥ 420 nm). The prepared sample electrode was used as the working electrode, the platinum wire was the counter electrode and the standard, and the saturated calomel electrode (SCE) was used as the reference electrode.

3 Results and Discussion

3.1 XRD

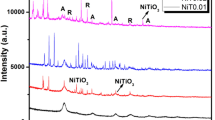

Figure 1 is the XRD pattern of Ni(OH)2, Sm2MoO6 and Sm2MoO6/Ni(OH)2. The 2θ of Sm2MoO6 is 28.10° and 47.28°, which corresponding to the (− 321) and (640) crystal planes of Sm2MoO6, respectively. The crystal face is identical the monoclinic phase of Sm2MoO6 (PDF-#24-0997). The 2θ of Ni(OH)2 is 11.63°, 22.56°, 33.67°, 37.48° and 59.60°, corresponding to (001), (002), (110), (200) and (300) of Ni(OH)2, respectively. The crystal face is identical to the hexagonal phase Ni(OH)2 (PDF-#22-0444). The diffraction peak of Sm2MoO6/Ni(OH)2 is consistent with Ni(OH)2 and Sm2MoO6. It is indicated that Ni(OH)2, Sm2MoO6 and Sm2MoO6/Ni(OH)2 are successfully prepared. The particle size of the sample can be calculated according to the Scherrer formula. The crystallite size of Ni(OH)2 is 13.60–68.47 nm, the crystallite size of Sm2MoO6 is 37.71–47.19 nm, and the crystallite size of Sm2MoO6/Ni(OH)2 is 14.71–73.02 nm. The results show that the composite catalyst Sm2MoO6/Ni(OH)2 with rare earth molybdate as cocatalyst was successfully prepared.

3.2 XPS

The elemental composition and valence state analysis of the composite photocatalyst Sm2MoO6/Ni(OH)2 was provided by X-ray photoelectron spectroscopy (XPS). Figure 2a is the total spectrum of Sm2MoO6/Ni(OH)2, which indicates the presence of Sm, Mo, Ni and O elements in the composite catalyst. Figure 2b is the XPS of Ni 2p with two strong peaks of 855.2 eV and 872.8 eV corresponding to Ni2p3/2 and Ni 2p1/2, respectively. This is the classical value of Ni2+ in Ni(OH)2. Two satellite peaks were also observed with binding energies of 861.0 eV and 879.5 eV [29]. Figure 2c is the XPS of Sm 3d, the two peaks with binding energies of 1083.5 eV and 1110.4 eV are Sm 3d5/2 and Sm 3d3/2, respectively. It is indicated that Sm exists in the form of Sm3+ in Sm2MoO6 [30]. Figure 2d is the XPS of Mo 3d. The two peaks with binding energies of 235.0 eV and 232.0 eV correspond to Mo 3d3/2 and Mo 3d5/2, respectively. The difference between the two peaks is 3 eV. It is indicated that Mo exists in the form of Mo6+ in Sm2MoO6 [31]. Figure 2e is the XPS of O 1 s, and the peak with a binding energy of 531.0 eV is attributed to Sm2MoO6.

3.3 TEM

Figure 3a is a TEM of 3% Sm2MoO6/Ni(OH)2, and the catalyst consists of nanosheets in the form of fungus. Figure 3b is the HRTEM of 3% Sm2MoO6/Ni(OH)2 with a lattice spacing of 0.76 nm corresponding to the (001) crystal plane of Ni(OH)2. The lattice spacing is 0.31 nm, which corresponds to the (− 321) crystal plane of Sm2MoM6. It is in keeping with the XRD results. Figure 3d–g is the STEM image of 3% Sm2MoO6/Ni(OH)2 and corresponding energy dispersive X-ray (EDX) element mapping images of Ni, Mo, Sm and O, indicating that all elements are present in photocatalyst, and evenly distributed.

3.4 BET

The large specific surface area provides more active sites and can adsorb more EY. Figure 4a is the N2 adsorption–desorption isotherm of Sm2MoO6, Ni(OH)2 and 3% Sm2MoO6/Ni(OH)2. Sm2MoO6/Ni(OH)2 and Ni(OH)2 have a type III isotherm. Sm2MoO6 and Sm2MoO6/Ni(OH)2 have an H3 hysteresis loop and are slit holes formed by stacking of flaky particles. Ni(OH)2 has an H4 hysteresis loop and is a slit hole produced by a layered structure. Figure 4b shows the pore size distribution curve. Sm2MoO6, Ni(OH)2 and 3% Sm2MoO6/Ni(OH)2 have a similar curve, mainly 0–50 nm mesopores. Table 1 is the specific surface area, pore size and pore volume of the catalyst. The specific surface area of Ni(OH)2 is 78.78 m2 g−1. After loading Sm2MoO6, the specific surface area was 148.55 m2 g−1. As is clear from Table 1, the specific surface area and pore volume of Sm2MoO6/Ni(OH)2 are the largest. This is due to the growth of Sm2MoO6 on the surface of Ni(OH)2. The high specific surface area and large pore volume of the composite are beneficial for the decomposition of hydrogen produced by hydrogen in photocatalytic applications.

3.5 Photocatalytic Hydrogen Evolution

Figure 5a is the photocatalytic hydrogen production activity of Ni(OH)2, Sm2MoO6 and 3% Sm2MoO6/Ni(OH)2 was tested by using triethanolamine as a sacrificial agent and Eosin Y as a sensitizer. Among them, the hydrogen production of Sm2MoO6 at 5 h is 42.34 μmol. The hydrogen production of Ni(OH)2 at 5 h is 231.34 μmol. The hydrogen production of 3% Sm2MoO6/Ni(OH)2 at 5 h is 601.87 μmol, which is 14.2 times that of Sm2MoO6 and 2.6 times that of Ni(OH)2. The photocatalytic performance is significantly improved. Sm2MoO6 can be used as a high-efficiency cocatalyst to significantly improve the separation efficiency of electron photogenerated electron–holes and accelerate the electron transfer on the surface of the composite photocatalyst to promote hydrogen evolution activity.

a Photocatalytic activities of different catalysts; b photocatalytic activity of Sm2MoO6/Ni(OH)2 with different molar ratios; c photocatalytic activity of Sm2MoO6/Ni(OH)2 for 20 h of continuous illumination; d stability of photocatalytic activity of 3% Sm2MoO6/Ni(OH)2; e XRD pattern of 3% Sm2MoO6/Ni(OH)2 before and after 4 hydrogen production cycles

Figure 5b shows that when the content of Ni(OH)2 is constant, the content of Sm2MoO6 is the key to the optimum photocatalytic activity, and the loading of Sm2MoO6 is from 1 to 5%. The introduction of Sm2MoO6 concentration from 1 to 3% onto Ni(OH)2 can gradually enhance the photocatalytic hydrogen production activity by promoting charge collection. When the loading of Sm2MoO6 reaches 3%, Sm2MoO6/Ni(OH)2 exhibits the best photocatalytic activity. However, when the loading amount of Sm2MoO6 exceeds 3%, the photocatalytic activity is remarkably lowered. This is because the excess Sm2MoO6: (1) covers the active site on the surface of Ni(OH)2, hindering its contact with the sacrificial agent and the sensitizer; (2) shielding the incident light and preventing the generation of light absorption and photogenerated charge; (3) as a charge recombination center. Therefore, the optimum loading of Sm2MoO6 for optimal hydrogen production is 3%.

In order to evaluate the stability of 3%Sm2MoO6/Ni(OH)2, we measured several cycles and the photocatalytic activity of continuous light for 20 h changed with time. Figure 5c shows the amount of hydrogen produced by continuous irradiation for 20 h. During the 20 h of illumination, the hydrogen production of 3%Sm2MoO6/Ni(OH)2 reached 1733.32 μmol, indicating a stable photocatalytic activity of about 4333.3 μmol·g−1·h−1. And after the 15th h, the amount of hydrogen production increased slowly due to the reduction of the sensitizer and the sacrificial agent.

As shown in Fig. 5d, during the four cycles with a total reaction time of 20 h, the first three photocatalytic activities were relatively stable. There was a significant decrease in the fourth cycle, which was due to the reduction of sensitizer and sacrificial agent in the reaction system, indicating that Sm2MoO6/Ni(OH)2 has good photocatalytic hydrogen production stability.

Figure 5e is the XRD of the catalyst before and after illumination. XRD before and after illumination showed a decrease in diffraction peaks, but there was no significant change. The results show that the photocatalytic activity of the catalyst is relatively stable.

3.6 PL Analysis

Figure 6 is a steady-state fluorescence spectrum of EY, Sm2MoO6, Ni(OH)2 and Sm2MoO6/Ni(OH)2. Generally, the level of electron–hole recombination can be judged by the level of fluorescence intensity. The maximum emission peak position of EY is 538 nm. The PL emission peak of Sm2MoO6 was observed at a wavelength of 540 nm, and the fluorescence intensity was lowered. The fluorescence intensity of Ni(OH)2 also decreased, and the fluorescence intensity of Sm2MoO6/Ni(OH)2 was the lowest. It is indicated that after the modification of Ni(OH)2 by Sm2MoO6, the electron–hole separation rate is improved and the photocatalytic activity is improved. It is indicated that Sm2MoO6 facilitates the separation of electron-holes and improves the electron transfer efficiency, thereby promoting photocatalytic activity. Prove that Sm2MoO6 is a highly efficient cocatalyst.

3.7 Electrochemical Analysis

In order to find out the mechanism for enhancing the photocatalytic hydrogen production activity of Sm2MoO6/Ni(OH)2, a series of experiments were conducted. As shown in Fig. 7a, we first measure the transient photocurrent response of the sample. The photocatalyst can generate electron-hole pairs under the light, oxidize electrons on the Pt electrode, and reduce holes on the working electrode. There is a transient photocurrent response curve at four intermittent illuminations, and there is a fast and uniform photocurrent response with light illumination on and off, indicating that all samples can be used as excellent photocatalysts. The transient photocurrent response of Sm2MoO6/Ni(OH)2 is much larger than the transient photocurrent response of Sm2MoO6 and Ni(OH)2. The results show that the separation efficiency of photogenerated carriers in Sm2MoO6/Ni(OH)2 is high, which indicates that Sm2MoO6 can effectively improve the photoinduced charge separation and the transfer efficiency, thereby improving the photocatalytic activity.

We show the catalytic HER activity of Sm2MoO6/Ni(OH)2. For comparison, similar electrochemical measurements of Sm2MoO6 and Ni(OH)2 were also performed. Figure 7b shows the LSV curve with a scan rate of 0.5 mV s−1. Compared with Sm2MoO6 and Ni(OH)2, Sm2MoO6/Ni(OH)2 has the lowest overpotential. Because photocatalytic hydrogen production depends on the overpotential of the HER reaction, the results clearly indicate that Sm2MoO6/Ni(OH)2 is a better photocatalyst.

3.8 Photo-Catalytic Mechanism

Based on the above results, a possible photocatalytic hydrogen production mechanism is proposed in Fig. 8. Both the EY molecule and Ni(OH)2 can be photoexcited under the irradiation of visible light. Electron transfer and reaction are mainly divided into the following two parts: (1) The EY molecule absorbs photons to form a single excited state EY1*, and EY1* forms a triplet excited state through intersystem transitions. EY3* is reduced by TEOA to produce EY¯˙ and oxidized electron donors. EY¯˙ is transferred to Ni(OH)2 and further transferred to the reaction site of Sm2MoO6. Protons are reduced by electrons to produce H2. (2) Ni(OH)2 absorbs photons to generate electrons and holes, and electrons are transferred to the conduction band while the holes remain in the valence band. Electrons are transferred to Sm2MoO6, reducing protons to produce H2, and holes are reduced by TEOA. The EY molecule is returned to the ground state. Due to the synergy between Ni(OH)2 and Sm2MoO6, the charge transfer rate is promoted and the photocatalytic activity is improved. The corresponding chemical reaction is as follows:

4 Conclusions

For the first time, using Sm2MoO6 as a cocatalyst, the photocatalytic activity of Ni(OH)2 was significantly improved. Sm2MoO6/Ni(OH)2 was prepared by first hydrothermal followed by impregnation. Sm2MoO6/Ni(OH)2 has a high specific surface area, which is a major requirement for an effective catalyst, providing more active sites and allowing the catalyst to be in sufficient contact with the sensitizer and the sacrificial agent. From photocurrent response and steady-state fluorescence, Sm2MoO6 can effectively improve the electron transfer efficiency of Sm2MoO6/Ni(OH)2 and inhibit the recombination of electrons and holes. The hydrogen production rate of 3% Sm2MoO6/Ni(OH)2 was 2407.48 μmol g−1 h−1, which was 14.2 times that of Sm2MoO6 and 2.6 times that of Ni(OH)2. Moreover, the stability of 3% Sm2MoO6/Ni(OH)2 is good. Due to the synergistic effect between Sm2MoO6 and Ni(OH)2, the rapid transfer of charge can be promoted and the efficiency and activity of photocatalytic hydrogen production can be improved. Sm2MoO6 is a potentially efficient cocatalyst.

References

Zhang J, Liu Y, Xia B et al (2018) Facile one-step synthesis of phosphorus-doped CoS2 as efficient electrocatalyst for hydrogen evolution reaction. Electrochim Acta 259:955–961

Liu Z, Xu J, Li Y et al (2018) High performance photocatalytic based on Ce doped CoWO4: controllable synthesis and enhanced photocatalytic activity. Catal Lett 148(10):3205–3213

Zou X, Zhang Y et al (2015) Noble metal-free hydrogen evolution catalysts for water splitting. Chem Soc Rev 44(15):5148–5180

Xu J, Huo F, Zhao Y et al (2018) In-situ La doped Co3O4 as highly efficient photocatalyst for solar hydrogen generation. Int J Hydrog Energy 43(18):8674–8682

Liu Y, Yu G, Li GD et al (2015) Coupling Mo2C with nitrogen-rich nanocarbon leads to efficient hydrogen-evolution electrocatalytic sites. Angew Chem 127(37):10902–10907

Meng ZD, Ullah K, Zhu L et al (2014) Modified hydrothermal fabrication of a CoS2-graphene hybrid with improved photocatalytic performance. Mater Sci Semicond Process 27:173–180

Yu H, Xu J, Liu Z et al (2018) Functionalization of sheet structure MoS2 with CeO2-Co3O4 for efficient photocatalytic hydrogen evolution. J Mater Sci 53(21):15271–15284

Li Y, Xu J, Liu Z et al (2018) Performance of amorphous CoSx/oxygen vacancies ZnO heterojunction photocatalytic hydrogen evolution. J Mater Sci: Mater Electron 30(1):246–258

Zhu M, Han M, Zhu C et al (2018) Strong coupling effect at the interface of cobalt phosphate-carbon dots boost photocatalytic water splitting. J Colloid Interface Sci 530:256–263

Wang M, Lin M, Li J et al (2017) Metal-organic framework derived carbon-confined Ni2P nanocrystals supported on graphene for an efficient oxygen evolution reaction. Chem Commun 53(59):8372–8375

Zheng S, Li X, Yan B et al (2017) Transition-metal (Fe Co, Ni) based metal-organic frameworks for electrochemical energy storage. Adv Energy Mater 7(18):1602733

Dong B, Li W, Huang X et al (2019) Fabrication of hierarchical hollow Mn doped Ni(OH)2 nanostructures with enhanced catalytic activity towards electrochemical oxidation of methanol. Nano Energy 55:37–41

Li Q, Chen Y, Yang T et al (2013) Preparation of 3D flower-like NiO hierarchical architectures and their electrochemical properties in lithium-ion batteries. Electrochim Acta 90(5):80–89

Chen J, Zheng J et al (2015) A highly sensitive non-enzymatic glucose sensor based on tremella-like Ni(OH)2 and Au nanohybrid films. J Electroanal Chem 749:83–88

Liu C, Chen Q, Hao Y et al (2019) Ni(OH)2/NiSe2 hybrid nanosheet arrays for enhanced alkaline hydrogen evolution reaction. Int J Hydrog Energy 44(10):4832–4838

Wang T, Pan J, Gasore Achille K et al (2017) A green dual complexation precipitation synthesis of hierarchical α-Ni(OH)2, microspheres and their electrochemical performance. Int J Hydrog Energy 42(30):19139–19147

Krehula S, Ristića M, Wu C et al (2018) Influence of Fe(III) doping on the crystal structure and properties of hydrothermally prepared β-Ni(OH)2 nanostructures. J Alloys Compd 750:687–695

Zhao J, Zhang Q et al (2015) Synthesis of Ni(OH)2 nanoflakes through a novel ion diffusion method controlled by ion exchange membrane and electrochemical supercapacitive properties. Electrochim Acta 184:47–57

Chen X, Chen S, Lin C et al (2015) Nickels/CdS photocatalyst prepared by flowerlike Ni/Ni(OH)2 precursor for efficiently photocatalytic H2 evolution. Int J Hydrog Energy 40(2):998–1004

Jose G, Joseph C, Ittyachen MA et al (2007) Structural and optical characterization of CdSe nanocrystallites/rare earth ions in sol-gel glasses. Opt Mater 29(11):1495–1500

Mani KP, George V, Ramakrishnan BP et al (2015) Synthesis and photoluminescence studies of one dimensional Sm2MoO6 nanofibers derived from electrospinning process. J Mater Res Technol 4(2):224–227

Tao D, Meng L, Peng W et al (2018) Synthesis of hierarchical tube-like yolk-shell Co3O4@NiMoO4, for enhanced supercapacitor performance. Int J Hydrog Energy 43(31):14569–14577

Du P, Yu JS et al (2017) Near-ultraviolet light induced visible emissions in Er3+-activated La2MoO6 nanoparticles for solid-state lighting and non-contact thermometry. Chem Eng J 327:109–119

Yu L, Nogami M (2010) The synthesis and photoluminescent properties of one-dimensional ZnMoO4: Eu3+ nanocrystals. Mater Lett 64(14):1644–1646

Ghorai TK, Dhak D, Biswas SK et al (2007) Photocatalytic oxidation of organic dyes by nano-sized metal molybdate incorporated titanium dioxide (MxMoxTi1−xO6) (M = Ni, Cu, Zn) photocatalysts. J Mol Catal A 273(1):224–229

Ray SK, Dhakal D, Kshetri YK et al (2017) Cu-α-NiMoO4, photocatalyst for degradation of methylene blue with pathways and antibacterial performance. J Photochem Photobiol, A 348:18–32

Namvar F, Beshkar F, Salavati-Niasari M et al (2017) Novel microwave-assisted synthesis of leaf-like MnMoO4 nanostructures and investigation of their photocatalytic performance. J Mater Sci: Mater Electron 28(11):7962–7968

Mani Kamal P, Vimal G, Biju PR et al (2015) Optical nonlinearity and photoluminescence studies of red emitting samarium molybdate nanophosphor. ECS J Solid State Sci Technol 4(5):67–71

Chen L, Zhang J, Ren X et al (2017) Ni(OH)2-CoS2 hybrid nanowire array: a superior non-noble-metal catalyst toward the hydrogen evolution reaction in alkaline media. Nanoscale 9(43):16632–16637

Yu H, Xu J, Guo H et al (2017) Synergistic effect of rare earth metal Sm oxides and Co1-xS on sheet structure MoS2 for photocatalytic hydrogen evolution. RSC Adv 7(89):56417–56425

Huang Y, Cui F, Zhao Y et al (2018) NiMoO4 nanorod deposited carbon sponges with ant-nest-like interior channels for high-performance pseudocapacitors. Inorg Chem Front 5(7):1594–1601

Acknowledgements

This work was supported by the Natural Science Foundation of Ningxia Province (NZ17262).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, Z., Xu, J., Liao, Q. et al. Synthesis of Sm2MoO6/Ni(OH)2 by Simple Impregnation Method: Photocatalyst for Non-precious Metal and Efficient Hydrogen Production. Catal Lett 150, 39–48 (2020). https://doi.org/10.1007/s10562-019-02947-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-019-02947-9