Abstract

Herein we described the synthesis of a novel Schiff base-MWCNTs-Pd nanocatalyst by covalent grafting of naphto-Schiff base onto carbon nanotubes and subsequent deposition of Pd nanoparticles. The synthetic process of preparation of mentioned nanocatalyst (Schiff base-MWCNTs-Pd) has been described. The formation of nanocatalyst was analyzed by FTIR, Raman spectroscopy, powder XRD, energy dispersive spectroscopy (EDS), thermogravimetric (TGA) analysis, wavelength-dispersive X-ray spectroscopy (WDX) and CHN analysis. The morphologies of the nanocatalyst were characterized using scanning and transmission electron microscopes (SEM and TEM). Additionally, the (Schiff base-MWCNTs-Pd) nanocatalyst was successfully employed in Suzuki cross coupling reactions with wide variety of functionalized substrates. Design of experiments indicates that the use of 0.2 mol% of Pd, K2CO3 as the base, and aqueous ethanol are the best reaction conditions. The reactions of aryl iodides and aryl bromides take place at room temperature, and aryl chlorides react at 80 °C. Interestingly, the novel catalyst could be recovered and recycled four times without any significant loss in activity.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Carbon nanotubes including single-walled (SWCNT) and multi-walled (MWCNT) nanotubes have attracted considerable interests due to their remarkable thermal conductivity [1–3], mechanical [4–6], and electrical properties [6, 7]. In addition, their excellent chemical and mechanical stability and large surface area make them an ideal and potentially useful choice for applications in optics [7, 8], electronics [9], catalysis [10, 11], polymer composites [12], and many others [13]. In this context, the deposition of the metal nanoparticles on carbon nanotubes (also referred to as “decoration”) has provided further promising utilities for these materials in a wide range of applications from hydrogen storage, solar cells, sensor devices, energy storage, as well as catalysis [14, 15]. As such, one of the potential areas in which carbon nanotubes may be utilized as an effective solid support is in cross coupling reactions [16–20].

Palladium-catalyzed cross-coupling reactions have been of strategic importance in organic synthesis since their discovery in the 1970s [7–11]. These reactions have evolved into a general technique in preparing biologically active functionalized biphenyls which are important intermediates or products in drug discovery, pharmaceuticals and agricultural compounds [21–27]. Due to their broad applicability for C-C bond formation, enormous interest continues in this area with more focus directed toward developing more efficient and recyclable catalysts that allow for industrial applications within environmentally benign processes. Cross-coupling reactions have typically been performed under homogeneous conditions employing a ligand to enhance the catalytic activity and selectivity for specific reactions [23–27]. However, the issues associated with homogeneous catalysis remain a challenge to pharmaceutical applications of these synthetic tools due to the lack of recyclability and potential contamination from residual metals in the reaction product [28, 29]. One promising solution to address this issue is to employ solid-supported metal nanocatalysts capable of not only efficiently catalyzing the reactions, but also providing a unique opportunity to leverage the reactivity and stability of these materials along with the ease of separation and reusability in subsequent reactions. Thus, numerous efforts have been undertaken in recent years to develop novel metal nanocatalysts for cross coupling reactions in which the metal is fixed on a variety of solid supports such as activated carbon [24, 28], zeolites [32, 33], polymers [34, 35], mesoporous silica [36, 37], inorganic oxides [38, 39], or nanoparticles [40–44]. Among these support systems, carbon nanotubes [16–20] have attracted significant attention due to the high specific surface area, thermal stability, and remarkable structural and electronic features capable of stabilizing the metal nanoparticles. Although heterogeneous supports allow efficient recycling, a decrease in the activity of the immobilized catalysts is frequently observed [45, 46]. Therefore, the development of heterogeneous Pd nanocatalysts that combine high activity, stability, and recyclability is an important goal of nanomaterial research that is likely to have a considerable impact on the chemical and pharmaceutical industries in the future.

Because of these reasons and also as a part of our ongoing research program on the application of catalysts for the development of useful new synthetic methodologies [47–55], herein, we report the synthesis of a heterogeneous palladium nanocatalyst supported on Schiff base-grafted-MWCNTs and its efficiency in the promotion of the Suzuki coupling reactions. The outcomes specified that the steadiness of the catalyst was significantly improved and Schiff base-MWCNTs-Pd was an effective and recyclable catalyst for the Suzuki–Miyaura cross-coupling reactions. Without major losses of catalytic activity, the catalyst can be easily recovered and the suggested procedure has the potential to be a substitute approach for the synthesis of biphenyl compounds.

2 Experimental

2.1 Materials

All the reagents were purchased from Aldrich and Merck and were used without any purification. The pure MWCNTs without functional groups were purchased from Petrol Co. (Tehran, Iran). HCl, H2SO4, HNO3, deionized water, NaH (80%), ethylenediamine, acetonitrile, PdCl2, and N,N-dicyclohexylcarbodiimide (DCC) were obtained from Sigma Aldrich and Merck. The dialdehyde of 2-[2-(2-formylnaphthoxy)ethoxy]-naphthaldehyde was synthesized according our procedure [56].

2.2 Covalent Grafting of Schiff Base to MWCNTs

First MWCNTs were added to 50 mL HCl (10%) then, after sonication for 15 min, the solution was stirred for 24 h to purification of MWCNTs by remove the metal ions and other impurities adsorbed on it. Then the purified MWCNTs were precipitated and separated using 9000 rpm centrifuging. Then 1000 mg of purified MWCNTs was suspended in 400 mL of concentrated HNO3 and refluxed for 12 h with vigorous stirring. The product (MWCNTs–COOH) was separated by 9000 rpm centrifuging and washed with deionized water to neutral and dried under vacuum at 80 °C for 12 h. In the next step a 1000 mg amount of MWCNTs–COOH was added to 50 mL of ethylenediamine (EDA). After heating and stirring for 5 min, the DCC was added to the solution and refluxed for 48 h. Then the prepared MWCNTS-EDA was separated by centrifuge, washed with ethanol and dried in an oven at 80 °C for 8 h. For the synthesis of Schiff base-MWCNTs, the prepared MWCNTs-EDA was suspended in 25 mL ethanol, and 4 mmol of 2-[2-(2-formylnaphthoxy)ethoxy]-naphthaldehyde was added to the solution. After 12 h stirring at 70 °C, the pure product was separated by centrifugation and washed with ethanol (3 × 10 mL).

2.3 Preparation of the Schiff Base-MWCNTs-Pd

The Schiff base-MWCNTs (500 mg) were dispersed in CH3CN (30 mL) by ultrasonic bath for 30 min. Subsequently, a yellow solution of PdCl2 (20 mg) in 30 mL acetonitrile was added to dispersion of Schiff base-MWCNTs and the mixture was stirred for 10 h at 25 °C. Then, the Schiff base-MWCNTs-Pd(II) was separated by centrifuge and washed by CH3CN, H2O and acetone respectively to remove the unattached substrates. The reduction of Schiff base-MWCNTs-Pd(II) by hydrazine hydrate was performed as follows: 50 mg of Schiff base-MWCNTs-Pd(II) was dispersed in 60 mL of water, and then 100 μL of hydrazine hydrate (80%) was added. The pH of the mixture was adjusted to 10 with 25% ammonium hydroxide and the reaction was carried out at 95 °C for 2 h. The final product Schiff base-MWCNTs-Pd(0) was washed with water and dried in vacuum at 40 °C. Scheme 1 depicted the synthetic procedure of Schiff base-MWCNTs-Pd.

2.4 General Procedure for the Suzuki–Miyaura Reaction

Aryl halide (1 mmol), phenylboronic acid (1.1 mmol), K2CO3 (2 mmol), catalyst (14 mg that contained 0.2 mol% Pd) and water/ethanol (1:1, 2 mL) were added to a 5 mL flask, and the mixture was stirred mechanically at RT or 80 °C (depending on the aryl halide). The progresses of the reactions were monitored by TLC. After completion of the reaction, the catalyst was separated from the reaction mixture by centrifugation and the crude product was extracted using ethyl acetate. The pure products were obtained by column chromatography on silica using the hexane and ethyl acetate as eluent.

3 Results and Discussion

3.1 Characterization of the Schiff Base-MWCNTs-Pd Nanocatalyst

The preparation of the catalyst follows the steps described in Scheme 1. Prior to grafting of Schiff base, CNTs were oxidized with a mixture of HNO3/H2SO4 and successively activated with DCC for amination reaction. Next, aminated-MWCNTs were modified by treatment with the 2-[2-(2-formylnaphthoxy)ethoxy]-naphthaldehyde to afford the Schiff base functionalized onto the carbon surface. Next, palladium nanoparticles were deposited onto the surface of the Schiff base-MWCNTs. The loading of Pd in the obtained material was determined by inductively coupled plasma (ICP) analysis to be 0.15 mmol/g. The thermogravimetric analysis (TGA) in inert atmosphere (N2) was used for the quantification of the Schiff base groups on the surface (Fig. 1). The results showed that solvent loss such as water start at 80–100 °C and carbon tubes and amorphous carbon decompose start at ∼800 °C. The curve shows that several weight losses were observed for Schiff base-MWCNTs-Pd. The first mass loss occurs at temperature range of 80–100 °C that is related to the loss of solvent trap in complex. The second mass loss occurs at temperature range of 240–600 °C that is related to the loss of ligand (Schiff base) in complex and third mass losses occur at ∼700 °C and that related to the decomposition of CNT. The actual weight loss corresponding to the combustion of supported Schiff base was determined 30% by thermogravimetry as the weight loss between 240 and 600 °C at curve. The analysis indicated the stability of catalyst up to a range of 0–10 °C and hence is safe to be used in carrying out the reaction under chosen conditions (room temperature, and 80 °C).

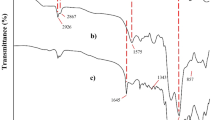

The surface structure of the materials was confirmed using Fourier transform infrared (FTIR) spectroscopy. Figure 2 shows the FT-IR spectra obtained for (a) MWCNTs-NH2, (b) Schiff base-MWCNTs and (c) Schiff base-MWCNTs-Pd. As it is seen in the curve 2a, the absorption band at 1670 cm−1 is attributed to the carbonyl stretching of the amide groups (–CONH–). Also, the bands observed around 2950 cm−1 were assigned to the bending vibration of CH2. The prominent IR bands at ∼3400 and 1579 cm−1 were ascribed to the NH2 stretching vibrations. These results indicated that the ethylenediamine was bonded to the surface of MWCNTs through amidation reaction. In curve 2b the appearance peak at 1650 cm−1 can be assigned to the imine (C=NH) bond of the attached 1,2-bis(2-formyl naphthoxy)-1,2-ethane. These results indicate that the Schiff base reaction is formed on the surface of MWCNTs. Vibrations in the range of ∼1400–1600 cm−1 are attributed to the aromatic rings. The IR scanning patterns of Schiff base-MWCNTs and Schiff base-MWCNTs-Pd samples were almost similar indicated that the structure of Schiff base bonded to MWCNTs was preserved in the process of coordination and reduction. The shift peak observed at curve 2c (C=NH region) from 1650 cm−1 to a lower frequency at 1638 cm−1 displayed the successful formation of a metal–ligand bond.

Another method for assessment of functionalization reaction is Raman spectroscopy [57]. Figure 3 shows the Raman spectra of the samples. Two main peaks in the Raman spectra were appeared in the samples at 1348 and 1581 cm−1 which are known as D and G bonds, respectively. D band is related to disordered carbon atoms of MWCNTs corresponding to sp3 hybridized and G band shows the sp2-hybridized of carbon atoms in the graphene sheets. Area ratio of the D to G bands (ID/IG) can be used to assess the amount of defects in nano particles structure. ID/IG ratio was increased for Schiff base-MWCNTs (ID/IG = 1.20) which approves the successful conversion of MWCNTs to Schiff base-MWCNTs. In the absence of amorphous carbon, the increase of ID is related to increase of carbon containing sp3 hybridized and implies to successful functionalization reaction.

Figure 4 shows transmission electron microscopy (TEM) image of the Schiff base-MWCNTs-Pd nanohybrid. As shown in Fig. 4, TEM confirms that the Schiff base-MWCNTs are decorated successfully with many well-dispersed Pd nanoparticles. Notably, no nanoparticle aggregation is clearly observed on the nanotube surface. The results indicated that Schiff base play an important role to improve the dispersibility of Pd. The particle sizes histogram clearly shows that the average hydrodynamic size of the Pd NPs is in the range of 3–7 nm (Fig. 4, inside).

The morphology of the MWCNTs and Schiff base-MWCNTs-Pd were characterized by field emission scanning electron microscopy (FE-SEM) in Fig. 5. The image of pristine MWCNTs shows that the tube surfaces are clear and smooth (Fig. 5a). However, under the same magnification, the surface of Schiff base-MWCNTs-Pd (Fig. 5b) is distinctly different from the untreated MWCNTs (Fig. 5a). It is observed that in the Schiff base-MWCNTs-Pd, the surface of CNTs uniformly coated, thus clearly indicative of Schiff base units attached to MWCNTs.

EDX analysis confirmed the elemental composition of the synthesized nanocomposite (Fig. 6). The strong peak at ∼3 keV indicated the presence of the elemental Pd nanoparticles as evident from previous observations. Other existing elements revealed by the EDX analysis included carbon, oxygen, and nitrogen which confirmed that the Schiff base present on the surface were responsible for capping and stabilization of the Pd nanoparticles.

The wavelength-dispersive X-ray spectroscopy (WDX)-coupled quantified FESEM mapping of the sample was also investigated (Fig. 7). The wavelength-dispersive X-ray spectroscopy (WDX) can provide qualitative information about the distribution of different chemical elements in the catalyst matrix. Looking at the compositional maps C and Pd, the presence of Pd NPs with good dispersion is clearly distinguished in the composite.

The phase structure of the nanocatalyst was revealed through powder XRD. The XRD pattern acquired for Schiff base-MWCNTs-Pd nanocatalyst is shown in Fig. 8. The diffraction peaks at 26.2° and 42.5° are attributed to (0 0 2) and (1 0 0) planes of hexagonal graphite and appearance of these peaks after functionalization, signifies that functionalization of MWCNTs with Schiff base did not destroy or alter the original structure of MWCNTs. The well-defined peaks around 39°, 47° and 67° can be assigned to (111), (200) and (220) crystallographic planes of face-centered cubic (fcc) palladium [14]. Thus the XRD results indicate efficient immobilization of fcc structured Pd nanoparticles on Schiff base-MWCNTs.

3.2 Evaluation of the Catalytic Activity of Schiff Base-MWCNTs-Pd Through the Suzuki Coupling Reaction

The prepared Schiff base-MWCNTs-Pd heterogeneous nanocatalyst was then evaluated in the C–C bond formation reaction of aryl halides with phenyl boronic acid by Suzuki–Miyaura cross coupling reaction. For initial assessment of the reaction, the Suzuki coupling reaction of 4-bromotoluene with phenyl boronic acid was chosen as a model for optimizing reaction parameters such as the solvent, base and the amount of the catalyst at room temperature. Optimization conditions studies are summarized in Table 1. As expected, no target product could be detected in the absence of the catalyst (Table 1, entry 11). However, addition of the catalyst to the mixture has rapidly increased the synthesis of product in high yields. The reactions were conducted using H2O/EtOH (1:1) as the best solvent. Among the bases evaluated, K2CO3 was found to be the most effective. The effect of catalyst loading was investigated employing several quantities of the catalyst ranging from 0.1 to 0.3 mol% (Table 1, entries 7, 8 and 9). The best yield was obtained with 0.014 g (0.2 mol%) of the catalyst (Table 1, entry 8). The higher content of Pd (0.3 mol% in compare with 0.2 mol%) in the reaction mixture provides low yield of homo-coupling product as by-product.

Under the optimized reaction conditions, the reactions of structurally different aryl iodides, bromides and chlorides with phenylboronic acid were studied in the presence of the catalyst (Table 2). The results indicate that aryl iodides and aryl bromides that contain electron-donating and electron-withdrawing groups with phenylboronic acid proceeded satisfactorily, and the corresponding coupling products were obtained in high to excellent yields (Table 1, entries 4, 5, 7, 8, 10–15). Moreover, reactions of unsubstituted iodobenzene and bromobenzene proceed efficiently and afford the corresponding products (Table 1, entries 1, 2). The reaction of 2-iodothiophene and 2-bromothiophene as heterocyclic aryl halides with phenylboronic acid gave the coupling product in 96% and 90% yields, respectively (Table 2, entries 16 and 17). Substituted aryl chlorides are less expensive than aryl iodides and bromides, and more accessible for Pd-catalyzed cross-coupling reactions. However, the reactions of aryl chlorides under the optimized reaction conditions at room temperature were sluggish; therefore, the reaction temperature was increased to 80 °C. Under these reaction conditions, the Suzuki–Miyaura reaction was efficient, and the desired cross-coupling products were obtained in high to excellent yields (Table 1, entries 3, 6, 9).

It was found that the catalyst Schiff base-MWCNTs-Pd could be separated conveniently by centrifugation and reused at least 4 times with the yield of 96, 96, 96, 90 and 82% for the Suzuki coupling reaction between phenylboronic acid and 4-bromotoluene in the presence of K2CO3 (Fig. 9). After completion of the reaction, catalyst was separated by centrifugation from the reaction mixture and washed several times with deionized water and ethanol. Then, it was dried in an oven at 50 °C and the recycled catalyst was saved for the next reaction. To investigate the leaching of Pd nanoparticles, the samples of the filtrate plus washings obtained from the above standard reactions were subjected to ICP analysis that showed the concentrations of Pd were less than 3.0 ppm in each measurement. In addition, the standard reaction was conducted with the recovered filtrate, but no product could be isolated. The results suggested that the supported Pd catalysts, rather than the leached Pd catalysts, provide the high catalytic performance. Based on these evidences, a reaction mechanism for Suzuki coupling with the prepared nanocatalyst was proposed (Scheme 2).

To show the importance of the Schiff base in the activation and stabilization of Pd NPs, a similar catalyst without ligand was synthesized. Pd absorbed physically on the surface of MWCNTs was tested in the model reaction under the optimized reaction conditions. However, the results showed that reaction achieved only 70% yield in 24 h and the catalyst loosed its catalytic activity in next run. This result confirms the key role of Schiff base for the stabilization of Pd NPs in the catalyst structure. In addition, SEM and TEM (Fig. 10) images of the catalyst after the fourth run showed that the nanostructure of the catalyst was preserved and the Pd nanoparticles were not aggregated.

A comparison of the activity of various Pd catalysts with Schiff base-MWCNTs-Pd in the Suzuki coupling reaction published in the literature is listed in Table 3. From Table 3, it can be seen that present catalyst exhibited higher conversions and yields compared to the other reported system.

4 Conclusions

In conclusion, a novel and recyclable palladium catalyst supported on Schiff base modified multi walled carbon nanotubes (MWCNTs) was fabricated for the first time. The synthesized catalyst was confirmed by XRD, FT-IR, TEM, TGA, FESEM, WDX, ICP and EDX techniques. The results indicated that the stability of the catalyst was much improved and Schiff base-MWCNTs-Pd was an efficient and recyclable catalyst for the Suzuki–Miyaura cross-coupling reactions. The catalyst can be readily recovered and reused without significant loss of its catalytic activity. The proposed method can be a promising alternative approach for the preparation of biphenyl compounds.

References

Han Z, Fina A (2011) Prog Polym Sci 36:914

Sun K, Stroscio MA, Dutta M (2009) J Appl Phy 105:1

Che J, Cagin T, Goddard WA III, (2000) Nanotechnology 11:65

Martinez-Hernandez AL, Velasco-Santos C, Castano VM (2010) Nanoscience 6:12

Miyagawa H, Misra M, Mohanty AK (2005) J Nanosci Nanotech 5:1593

Popoy V (2004) Mat Sci Eng R Reports R43:61

Kramberger C, Pichler T, Adv Carbon Nanomaterials 131

Liu K, Deslippe J, Xiao F, Capaz RB, Hong X, Aloni S, Zettl A, Wang W, Bai X, Louie SG, Wang E, Wang F (2012) Nat Nano 7:325

Biswas C, Lee YH (2011) Adv Func Mat 21:3806

Serp P, Corrias M, Kalck P (2003) Appl Cat A General 253:337

Serp P, Castillejos E (2010) Chem Cat Chem 2:41

Moniruzzaman M, Winey KI (2006) Macromolecules 39:5194

Baughman RH, Zakhidov AA, de Heer WA (2002) Science 297:787

Wildgoose GG, Banks CE, Compton RG (2006) Small 2:182

Georgakilas V, Gournis D, Tzitzios V, Pasquato L, Guldi DM, Prato M (2007) J Mat Chem 17:2679

Veisi H, Khazaei A, Safaei M, Kordestani D (2014) J Mol Catal A Chem 382:106

Sullivan JA, Flanagan KA, Hain H (2009) Catal Today 145:108

Turkenburg DH, Antipov AA, Thathager MB, Rothenberg G, Sukhorukov GB, Eiser E (2005) Phys Chem Chem Phys 7:2237

Ghorbani-Vaghei R, Hemmati S, Hashemi M, Veisi H (2015) C R Chimie 18:636

Zhang PP, Zhang XX, Sun HX, Liu RH, Wang B, Lin YH (2009) Tetrahedron Lett 50:4455

Vanderbilt D (1990) Phys Rev B 41:7892–7895

Perdew JP, Burke K, Ernzerhof M (1996) Phys Rev Lett 77:3865–3868

Monkhorst HJ, Pack JD (1976) Phys Rev B 13:5188–5192

Zanti G, Peeters D (2009) Eur J Inorg Chem, 3904–3911

Rana S, Maddila S, Yalagala K, Jonnalagadda SB (2015) Applied Catalysis A General 505:539

Das P, Linert W (2016) Coord Chem Rev 311:1–23

Adib M, karimi Nami R, Veisi H (2016) New J Chem 40:4945

Yan J-A, Chou MY (2010) Phys Rev B 82:125403

Wang L-L, Johnson DD (2007) J Am Chem Soc 129:3658–3664

Ravon U, Chaplais G, Chizallet C, Seyyedi B, Bonino F, Bordiga S, Bats N, Farrusseng D (2010) Chem Cat Chem 2(10):1235–8

Pickard CJ, Mauri F (2001) Phys Rev B 63:245101

Hummers WS Jr, Offeman RE (1958) J Am Chem Soc 80:1339–1339

Liao K-H, Mittal A, Bose S, Leighton C, Khoyan KA, Macosko CW (2011) ACS Nano 5:1253–1258

Niedermann K, Welch JM, Koller R, CvengrošSantschi JN, Battaglia P, Togni A (2010) Tetrahedron 66:5753–5761

Santra S, Dhara K, Ranjan P, Bera P, Dash J, Mandal SK (2011) Green Chem 13:3238–3247

Xu C, Yin L, Huang B, Liu H, Cai M (2016) Tetrahedron 72:2065

El Hankari S, El Kadib A, Finiels A, Bouhaouss A, Moreau JJE, Crudden CM, Brunel D, Hesemann P (2011) Chem Eur J 17:8984

Shuai Z, Melanie J, Veinot JGC (2010) Chem Commun 46:2411

Formo E, Yavuz MS, Lee EP, Lane L, Xia Y (2009) J Mat Chem 19:3878

Santra S, Ranjan P, Bera P, Ghosh P, Mandal SK (2012) RSC Adv 2:7523–7533

Ganesan M, Freemantle RG, Obare SO (2007) Chem Mater 19:3464–3471

Yeh T-F, Syu J-M, Cheng C, Chang T-H, Teng H (2010) Adv Funct Mater 20:2255–2262

Diallo AK, Ornelas C, Salmon L, Ruiz Aranzaes J, Astruc D (2007) Angew Chem Int Ed Engl 46:8644

Shen J, Hu Y, Shi M, Li N, Ma H, Ye M (2010) J Phys Chem C 114:1498–1503

Carey JS, Laffan D, Thomson C, Williams MT (2006) Org Biomol Chem 4:2337–2347

Matheron ME, Porchas M (2004) Plant Dis 88:665–668

Capan A, Veisi H, Goren AC, Ozturk T (2012) Macromolecules 45:8228–8236

Pirhayati M, Veisi H, Kakanejadifard A (2016) RSC Adv, 6:27252

Veisi H, Hamelian M, Hemmati S (2014) J Mol Catal A 395:25

Veisi H, Masti R, Kordestani D, Safaei M, Shahin O (2014) J Mol Catal A 385:61

Veisi H, Kordestani D, Faraji AR (2014) J Porous Mater 21:141

Veisi H, Morakabati N (2015) New J Chem 39:2901

Veisi H, Sedrpoushan A, Maleki B, Hekmati M, Heidari M, Hemmati S (2015) Apply Organomet Chem 29:834

Veisi H, Rashtiani A, Barjasteh V (2016) Appl Organometal Chem 30:231

Veisi H, Ghadermazi M, Naderi A (2016) Appl Organometal Chem 30:341

Azadbakht R, Parviz M, Tamari E, Keypour H, Golbedaghi R (2011) Spectrochim Acta A 82:200–204

Rosca ID, Watari F, Uo M, Akasaka T (2005) Oxidation of multiwalled carbon nanotubes by nitric acid. Carbon 43:3124–3131

Fortea-Pérez FR, Schlegel I, Julve M, Armentano D, De Munno G, Stiriba SE (2013) J Organomet Chem 743:102

Liu QX, Zhang W, Zhao XJ, Zhao ZX, Shi MC, Wang XG (2013) Eur J Org Chem 2013:1253

Ghiaci M, Zargani M, Moeinpour F, khojastehnezhad A (2014) Appl Organometal Chem 28:589

de Paula VI, Sato CA, Buffon R (2012) J Braz Chem Soc 23:258

Shakil Hussain SM, Ibrahim MB, Fazal A, Suleiman R, Fettouhi M, El Ali B (2014) Polyhedron 70:39

Sobhani S, Ghasemzadeh MS, Honarmand M, Zarifi F (2014) RSC Adv 4:44166

Sobhani S, Zarifi F (2015) Chinese J. Catal 555

Acknowledgements

We are thankful to Payame Noor University for partial support of this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Veisi, H., Azadbakht, R., Saeidifar, F. et al. Schiff Base-Functionalized Multi Walled Carbon Nano Tubes to Immobilization of Palladium Nanoparticles as Heterogeneous and Recyclable Nanocatalyst for Suzuki Reaction in Aqueous Media Under Mild Conditions. Catal Lett 147, 976–986 (2017). https://doi.org/10.1007/s10562-016-1963-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-016-1963-7