Abstract

The catalytic performance of highly active cobalt(II) supported on mesoporous SBA-15 materials for the Pechmann reaction was investigated. SBA-15 supported cobalt(II) nanocatalyst was found to be efficient and easily recoverable in the Pechmann reaction of phenols and β-ketoesters to their corresponding coumarin derivatives under solvent-free conditions. The supported cobalt catalyst could be easily recovered after reaction completion and reused twelve times with an excellent durability and without any noticeable loss in activity.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The development of greener synthetic organic processes based on the principles of green chemistry stimulated scientists to design innovative alternative protocols to traditional wasteful, time and resource-consuming and energy intensive protocols [1]. Heterogeneous catalysis provided a number of suitable possibilities in organic synthesis in the production of relevant compounds with various activities. Among important synthetic products in organic chemistry, coumarins preparation attracted a significant deal of attention in recent years due to their wide range of applications. Coumarins are compounds exhibiting various biological activities including antibacterial, anticoagulant, hypothermal, anti-helminthic [2–4] as well as different applications as food additives, perfumes and cosmetics [5]. Importantly, a large number of natural products with significant biological activities and unique physical properties also contain coumarin moieties in their chemical structure [2]. Coumarin compounds have extensively been synthesized using a number of known organic reactions including Wittig [6], Perkin [7], Knoevenagel [8] and Pechmann [9] type of chemistries. Among them, Pechmann condensation processes can offer a significant advantage for coumarin synthesis due to the simplicity of the protocol, the utilization of widely available and relatively inexpensive reagents and well known reaction mechanism via acid-catalysis [9].

Pechmann condensations generally involve the reaction of phenolic compounds with a carboxylic acid or an ester containing a β-carbonyl group to generate an intermediate that undergoes dehydration to the final coumarin product. Several protocols have extensively covered the synthesis of coumarin derivatives via Pechmann condensation, mostly catalysed by homogeneous acidic catalysts including H2SO4, P2O5 [10], trifluoroacetic acid [11] as well as different metal salts such as FeCl3, TiCl4, InCl3, ZrCl4 [12–15], Bi(NO3)3·5(H2O) [16] and Cu(CH3CN)4PF6 [17]. The use of homogeneous acid catalysts possesses inherent corrosion, separation, product isolation and purification and catalyst recycling issues, highly detrimental from the practical point of view. Comparatively, the development of efficient and environmentally benign solid acid catalysts could provide advantages in the proposed coumarin synthesis in terms of separation, product purification and catalyst recycling. Alumina supported MoO3 [18], Keggin‐type heteropoly compounds [19] and silica sulfuric acid [20] have therefore been explored as solid acid catalysts for a greener synthesis of coumarins. In spite of clear advantages of the reported heterogeneous solid acids utilized for coumarin synthesis, most of the reported protocols still entail long reaction times, high catalyst loadings, high reaction temperatures and relatively poor reusable catalysts [18]. A major challenge in the field deals with the design of highly active, stable and reusable environmentally friendly catalysts able to work under mild reaction conditions.

In continuation with research efforts from our groups directed towards the design and development of advanced nanocatalytic materials for fine chemicals production [21–23], this contribution discloses an efficient, greener and mild catalytic protocol for the synthesis of coumarin derivatives using a previously reported and extensively investigated Co/SBA-15 solid acid nanocatalyst. Excellent yields to coumarins could be obtained using the Co/SBA-15 system under solvent-free conditions.

2 Experimental

2.1 Catalyst Synthesis

Co/SBA-15 was synthesized as previously reported [21]. Briefly, salicylaldehyde (2 mmol, 0.244 g) was added to an excess of absolute MeOH, to which 3-aminopropyl(trimethoxy)silane (2 mmol, 0.352 g) was subsequently added. The solution instantly became yellow due to imine formation. After 3 h, cobalt(II) acetate, Co(OAc)2·2H2O (1 mmol, 0.248 g) was added to the solution, and the mixture further stirred for 3 h to allow the new ligands to complex the cobalt. A color change from pink to olive green is observed. Mesoporous silica (average pore diameter 60 Å, 3 g) was activated by refluxing in concentrated hydrochloric acid (6 M) and then washed thoroughly with the deionized water and dried before undergoing chemical surface modification. This activation treatment readily hydrolyses the siloxane Si–O–Si bonds to Si–OH species which will be key to anchor the cobalt complex. The complex and the activated silica were then mixed and the mixture stirred overnight. The solvent is removed using a rotary evaporator, and the resulting olive green solid dried at 80 °C overnight. The final product was washed with MeOH and water (to remove all physisorbed metal species) until the washings were colourless. Further drying of the solid product was carried out in an oven at 80 °C for 8 h.

2.2 Pechmann Reactions

To a mixture of phenol (1 mmol) and β-ketoester (1 mmol), Co/SBA-15 (0.001 mmol) was added at 100 °C. The mixture was stirred for 3 h (Table 2). The progress of the reaction was monitored by thin layer chromatography (TLC). After the complete conversion of the starting materials, as indicated by TLC, ethanol (10 mL) was added to the reaction mixture was filtered and the solid residual catalyst was washed with ethyl acetate (2 × 10 mL) and then dried at 50 °C. After this, it could be used for the next run. The filtrate was recrystallised from ethanol to get the pure product. The products were characterized according to their 1H and 13CNMR, IR, and melting point data.

3 Results and Discussion

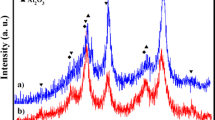

Full characterization details of Co/SBA-15 have been previously reported [21]. Typically, cobalt loading was around 0.3 mmol g−1 and surface and textural properties of Co/SBA-15 provided a surface area of 450 m2 g−1, with a pore size of 3.6 nm and 0.77 cm3 g−1 mesoporous pore volume, with an excellent homogeneous dispersion of cobalt oxide species on the SBA-15 support. The catalytic activity of the catalyst was tested in the Pechmann reaction. Resorcinol and ethylacetoacetate were selected for the model reaction to optimize reaction conditions. Firstly, the effect of the addition of a solvent on yields was thoroughly investigated and summarized in Table 1. A moderate amount of product (4-methyl-8-hydroxy coumarin) could be obtained when dichloromethane was used as solvent (Table 1, entry 4). The conversion of resorcinol to the corresponding product progressively increased between 82 and 95 % using polar protic solvents (Table 1, entries 1–3). Noteworthy, solvent free conditions proved to be very effective for the model reaction (Table 1, entry 5). The effect of the amount of catalyst, temperature and time of reaction were subsequently investigated under solvent-free conditions. Reducing the amount of catalyst decreased the product yield at 120 °C (Table 1, entry 6). These results showed the significant effect of the catalyst amount and temperature in the reaction (Table 1, entries 7–11). Optimum conditions were found to be the addition of 0.1 mol% catalyst at 110 °C for 3 h reaction (Table 1, entry 9).

In order to ensure the heterogeneous nature of the catalyst the model reaction of resorcinol and ethylacetoacetate was tested in a hot filtration test. The reaction was stopped at the halfway and the filtrate was allowed to continue for additional time but didn’t react more significantly. Furthermore, no detectable Co traces in solution were determined by the AA analysis of the final solution phase upon catalyst filtration after the end of the reaction mixture.

Since the recycling of the catalyst is an important issue in heterogeneous catalysis, the catalyst was filtered upon reaction completion, washed with ethyl acetate and dried overnight prior to its reuse in another reaction cycle (Fig. 1). The supported cobalt catalyst showed excellent recoverability and reusability over twelve successive runs under identical conditions to those of the first run, indicating a high activity and stability under the investigated conditions.

After determining the optimum Pechmann condensation reaction conditions, the scope and limitations of the reaction and efficiency of the catalytic system were further evaluated by reacting a variety of phenols with β-ketoesters. Results summarized in Table 2 under optimized reaction conditions demonstrate that excellent yields (similar between ethyl and methyl acetoacetate) were obtained in both cases. Generally, the catalyst exhibited prominent activity for phenols bearing electron-donating and bulky substituents.

4 Conclusion

We have reported a simple, efficient and green approach for the synthesis of substituted coumarins by a one-pot reaction of phenols with β-ketoesters in the presence of catalytic amounts of low-loaded Co-containing SBA-15 under solvent-free condition. The supported Co/SBA-15 nanocatalyst could be easily removed from the reaction mixture by simple filtration and reused twelve times without any significant loss in activity. No metal leaching was observed during the reaction which also demonstrates the potential of the catalyst in greener organic reactions. Clean reaction conditions and high selectivity (affording exclusively coumarins in high yields) as well as the use of a green and recyclable heterogeneous catalyst are key advantages of the proposed protocol. These results expand the stability and capability of the supported catalyst and further progress is underway in our research group.

References

Clark J, Sheldon R, Raston C, Poliakoff M, Leitner W (2014) Green Chem 16:18

Ahadi S, Zolghadr M, Khavasi HR, Bazgir A (2013) Org Biomol Chem 11:279

Nofal ZM, El-Masry H, Fahmy HH, Sarhan I (1997) Egypt J Pharm Sci 38:1

Nofal ZM, El-Zahar MI, Abd-El-Karim SS (2000) Molecules 5:99

Romanelli GP, Bennardi D, Ruiz DM, Baronetti G, Thomas HJ, Autino JC (2004) Tetrahedron Lett 45:8935

Yavari I, Hekmat-Shoar R, Zonouzi A (1998) Tetrahedron Lett 39:2391

Donnelly BJ, Donnelly DMX, O’Sullivan AM (1968) Tetrahedron 24:2617

Bigi F, Chesini L, Maggi R, Sartori G (1999) J Org Chem 64:1033

Sethna SM, Phadke R (1953) Org React 7:1

Canter FW, Curd FH, Robertson A (1931) J Chem Soc 1245

Woods LL, Sapp J (1962) J Org Chem 27:3703

Niharika P, Ramulu BV, Satyanarayana G (2014) Org Biomol Chem 12:4347

Valizadeh H, Shockravi A (2005) Tetrahedron Lett 46:3501

Subhas Bose D, Rudradas AP, Hari Babu M (2002) Tetrahedron Lett 43:9195

Smitha G, Sanjeeva Reddy CH (2004) Synthetic Commun 34:3997

Alexander VM, Bhat RP, Samant SD (2005) Tetrahedron Lett 46:6957

Soleimani E, Khodaei MM, Batooie N, Samadi S (2012) J Heterocyclic Chem 49:409

Singhal S, Jain SL, Sain B (2008) Heterocycles 75:1205

Rafiee E, Fakhri A, Joshaghani M (2013) J Heterocyclic Chem 50:1121

Dabiri M, Salehi P, Zolfigol MA, Baghbanzadeh M (2007) Heterocycles 71:677

Rajabi F, Luque R, Clark JH, Karimi B, Macquarrie DJ (2011) Catal Commun 12:510

Rajabi F, Luque R, Serrano-Ruiz JC (2012) Chem Biodivers 9:1823

Rajabi F, Nourian S, Ghiassian S, Balu AM, Saidi MR, Serrano-Ruiz JC, Luque R (2011) Green Chem 13:3282

Acknowledgments

Fatemeh Rajabi is grateful to Payame Noor University for support of this work. Afsaneh Feiz gratefully acknowledges financial support from Research Council of Shahid Beheshti University for a research visit to Universidad de Cordoba (Spain).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rajabi, F., Feiz, A. & Luque, R. An Efficient Synthesis of Coumarin Derivatives Using a SBA-15 Supported Cobalt(II) Nanocatalyst. Catal Lett 145, 1621–1625 (2015). https://doi.org/10.1007/s10562-015-1544-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-015-1544-1