Abstract

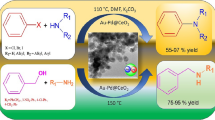

In this research, an efficient procedure for the one-pot four-component synthesis of 2H-indazolo[2,1-b]phthalazine-triones catalyzed by a cobalt-based nanocatalyst (Co/Al2O3 nanocatalyst) is reported. The catalyst was prepared by a co-precipitation method and characterized by BET surface area, SEM, TEM, EDS and XRD analyses. A wide range of various aromatic aldehydes including electron-withdrawing and electron-releasing groups were applied and corresponding products obtained in high yields without any by-product. Moreover, the Co/Al2O3 is recyclable up to 7 consecutive runs by simple filtration.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Phthalazine derivatives are an important class of heterocyclic compounds that has received significant attention from many organic and pharmaceutical chemists due to their broad biological and pharmacological activities such as anticonvulsant, cardiotonic, and vasorelaxant [1, 2]. Phthalazines have been found to be effective for the inhibition of p38 MAP kinase, for selective binding of GABA receptor, and an as anti-anxiety drug and antitumor agent [3, 4]. Moreover, these compounds show unique electrical and optical properties [5].

Various synthetic procedures for the synthesis of 2H-indazolo[2,1-b]phthalazine-triones involving three-component reaction of aldehydes, 1,3-dicarbonyl compounds (dimedone or cyclohexane-1,3-dione) with 2,3-dihydro-1,4-phthalazinedione (phthalhydrazide) and/or one-pot four-component reactions between aldehydes, 1,3-dicarbonyl compounds (dimedone or cyclohexane-1,3-dione), hydrazinium hydroxide and phthalic anhydride have been reported [6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21].

Alumina-supported cobalt catalysts are an important material system in the field of heterogeneous catalysis. It has been reported that metal–support interactions may considerably affect the surface properties and hence catalytic activity [22, 23]. Among these catalysts, Co/Al2O3 catalysts have been studied in various processes several times over the years especially for their activity in CO hydrogenation [24,25,26]. However, to the best of our knowledge, the performance of Co/Al2O3 nanocatalysts as Lewis acids has not investigated over organic synthesis reactions especially for the synthesis of 2H-indazolo[2,1-b]phthalazine-triones.

On the other hand, recently, the practical applications of supported-metallic nanoparticles as the catalysts in organic synthesis have increased due to good activation of adsorbed compounds, reaction rate improvement, easier work-up, recyclability and the eco-friendly reaction conditions. Therefore, in continuation of our studies on the catalytic activity of different nanocatalysts on the organic reactions [27,28,29,30,31,32,33], here, we wish to report the performance of a cobalt-based nanocatalyst (Co/Al2O3 nanocatalyst) as an efficient recyclable catalyst in the synthesis of 2H-indazolo[2,1-b]phthalazine-triones under solvent-free conditions (Scheme 1).

Experimental

Products were characterized by comparison of their spectroscopic data (NMR and IR) and physical properties with those reported in the literature. The NMR spectra were recorded on a Bruker Advance 400 MHz. IR spectra were recorded on a Perkin Elmer 781 Spectrophotometer. Yields refer to isolated pure products. The XRD analysis was performed using an X-ray diffractometer, Cu-Kα monochromatized radiation source and a nickel filter (PANalytical X’Pert-Pro) in order to investigate the structure and crystallinity of the catalyst. The Scherrer equation was used to establish the average crystallite size of the sample. A flame atomic absorption spectrophotometer (GBC 906AA) was applied to determine the amount of cobalt content of the catalyst. The BET surface area of the catalyst was tested by the N2 adsorption–desorption method. The analysis were carried out using an automated gas adsorption analyzer (Tristar 3020; Micromeritics). The sample was purged with nitrogen gas for 3 h at 300 °C by a VacPrep 061 degas system (Micrometrics). The morphology of the prepared catalyst was analyzed by scanning electron microscopy (SEM) using a JEOL JSM-6500F instrument, equipped with an EDS analytical system to study the presence of different components of the catalyst. Transmission electron microscopy (TEM) analysis was also performed using a JEOL JEM-2100 (200 kV) microscope equipped with an EDS analytical system. The size of about 200 cobalt nanoparticles were measured in order to determine their distribution and average particle size.

Catalyst preparation

The Co/Al2O3 nanocatalyst was prepared by a co-precipitation process. An aqueous solution of 0.5 M NaOH was added into a mixture of 0.5 M cobalt nitrate and aluminium nitrate under vigorous stirring at 50 °C. The obtained solution was aged at pH of 9 for 1 h, then filtered and washed with deionized water to remove the interfering ions. The sample was dried overnight at 100 °C and then calcined in air at 450 °C for 4 h. Also, a batch of the Al2O3 support without Co content was prepared by the same method for the supplementary analysis.

General procedure for the synthesis of 2H-indazolo[2,1-b]phthalazine-triones

A mixture of dimedone (1 mmol), aromatic aldehyde (1 mmol), hydrazinium hydroxide (1.2 mmol) and phthalic anhydride (1 mmol) in the presence of CO/Al2O3 nanocatalyst (0.05 g), heated in an oil bath at 100 °C for appropriate times. After reaction completion (monitored by TLC), the mixture was cooled to room temperature, hot ethanol was added and the catalyst was separated. Evaporation of the solvent from the resulting solution and recrystallization of the solid residue from hot ethanol afforded the pure products in high yields.

Results and discussion

Catalyst characterization results

From XRD analysis (Fig. 1), the Co/Al2O3 nanocatalyst shows diffraction peaks at 2θ = 37.60°, 45.79°, 66.76° and 85.02°, which are attributed to the [110], [111], [211] and [300] planes, respectively, of γ-Al2O3 [code No. 01-1303]. The diffraction peaks at 19.04°, 31.35°, 36.94°, 44.92°, 59.51°, 65.41° and 77.56° respectively correspond to [111], [220], [311], [400], [511], [440] and [533] planes of cubic Co3O4 (code No. 01-074-1657). Moreover, the XRD pattern of the cobalt nanocatalyst shows a distinct peak at 94.38° which is attributed to the [731] plane of CoAl2O4 (code No. 03-0896). This peak indicates the incorporation of Co species into the structure of the Al2O3 support at calcination temperatures as high as 450 °C. The average crystallite size of Co oxide in the Co/Al2O3 nanocatalyst, calculated by the Debye–Scherrer equation, is about 11.1 nm.

Table 1 shows the structural properties of the samples. The amount of Co content in the catalyst analyzed by atomic absorption spectroscopy is 9.6 wt%. The alumina support has a high BET surface area of about 270 m2 g−1; however, after incorporation of Co content, the BET is decreased to about 252 m2 g−1.

Figure 2 shows the N2 adsorption/desorption profiles of the catalysts. The results show that the alumina support and the Co nanocatalyst exhibit adsorption/desorption isotherm profiles with hysteresis loops between p/p 0 = 0.45–0.9. Based upon the IUPAC classification, this type of isotherm is categorized as type IV, and ascribed to mesoporous structures. While the alumina support adsorption profile shows a H3 type hysterisis loop, which can demonstrate aggregates of nonuniform narrow slit-like pores of plate-like and/or cubic nanoparticles, the Co/Al2O3 sample shows a H2 hysterisis loop which is common for mesoporous carriers and catalysts. This type of hysterisis loop is attributed to aggregates and agglomerates of spheroidal particles with nonuniform sized and shaped pores [34, 35]. As exhibited in Fig. 2, the alumina support and the cobalt nanocatalyst display narrow pore size distributions with a maximum at 3 and 4 nm, respectively.

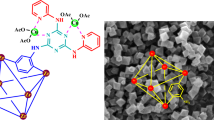

Figure 3 displays the SEM images and the EDS results of the Co/Al2O3 nanocatalyst. The SEM analysis shows a uniform aggregation of nanoparticles with a diameter of about 21 nm. This result is in accordance with the type IV hysterisis H2 isotherm shown by the N2 adsorption/desorption test.

As shown in Fig. 3, cobalt nanoparticles are dispersed on the alumina support with a particle size distribution between 3 and 13 nm, and an average size of about 6.5 nm. The HRTEM image of the catalyst (Fig. 4) exhibits reflections with d-spacing values of about 0.24 nm which correspond to the Co3O4 (311) lattice plane.

The EDS analysis shows a cobalt content of about 15.4 wt% on the surface of the catalyst. The higher Co loading in comparison to the nominal Co loading (10 wt%) could be due to the procedure of the synthesis of the catalyst. By considering the higher Ksp number of Co(OH)2, 3 × 10−16, in comparison to the Ksp of Al(OH)3, 3 × 10−34, it can be suggested that, with a gradual increase of the pH of solution during the co-precipitation procedure, the Co clusters tend to precipitate at higher pH values, which results in an increase in the amount of Co content on the surface of the Co/Al2O3 nanocatalyst.

Catalytic performance

To find the best reaction conditions, the one-pot four-component reaction of benzaldehyde with hydrazinium hydroxide, phthalic anhydride and dimedone was selected as a model and its behavior was studied under a variety of conditions. Several reaction conditions were examined and the yield and reaction times were monitored in the presence of different amounts of Co/Al2O3 nanocatalyst.

The obtained results are summarized in Table 2. To study the effect of reaction temperature, the reaction was carried out at different temperatures. At room temperature, the reaction rate was found to be slow, and it was improved at higher temperatures. The best result was found at 80 °C, and further increases in temperature did not show any improvement. The model reaction was studied in the presence of different amounta of Co/Al2O3 nanocatalyst. It was found that using 0.05 g of the Co/Al2O3 nanocatalyst was sufficient for the reaction to complete. When the amount of the catalyst was lower, the time increased and the yield of the product reduced. Moreover, various solvents were examined and solvent-free conditions were found to be the most optimum in terms of yield of product and reaction rate. Consequently, the best result was achieved by carrying out the reaction in the presence of 0.05 g of the Co/Al2O3 nanocatalyst under solvent-free condition at 80 °C.

In the next step, the extent and efficiency of this process was investigated under the optimized reaction conditions. Therefore, a various range of aromatic aldehydes were condensed with phthalic anhydride, hydrazinium hydroxide and dimedone in the presence of the Co/Al2O3 nanocatalyst under solvent-free condition.

As shown in Table 3, aromatic aldehydes having electron-withdrawing groups reacted at a faster rate compared with aromatic aldehydes substituted with electron-donating groups. All substrates were efficiently converted to their corresponding products in high yields and short reaction times without the formation of any by-product. The corresponding products were isolated by simple filtration and easily recrystallized in hot ethanol. Moreover, the products were characterized by spectroscopic data (1HNMR, 13CNMR and IR) and by comparison with the spectral data reported in the literature. A plausible mechanism of the reaction is shown in Scheme 2, with the reaction occurring via initial formation of the phthalhydrazide by nucleophilic addition of hydrazinium hydroxide to phthalic anhydride activated(by the Co/Al2O3 nanocatalyst, followed by dehydration. The second step involves Knoevenagel condensation between dimedone and aldehyde activated by the Co/Al2O3 nanocatalyst. Subsequent Michael-type addition of the phthalhydrazide followed by cyclization affords the corresponding product.

To investigate the recyclability of the catalyst, the reaction of benzaldehyde, dimedone, phthalic anhydride, and hydrazinium hydroxide under solvent-free conditions at 80 °C was studied. After reaction completion, the catalyst was washed with hot ethanol, dried and stored for another consecutive reaction run. The recovered catalyst was reused 7 times without any significant loss of activity (Table 4).

Conclusion

In conclusion, an efficient cobalt-based nanocatalyst (Co/Al2O3 nanocatalyst) was prepared, characterized and used for the one-pot four-component synthesis of 2H-indazolo[2,1-b]phthalazine-triones under solvent-free condition. The catalyst is stable and easily synthesized. It can promote the yields and reaction times over 7 runs with comparable activity. Moreover, heterogeneous reaction conditions, operational simplicity, enhanced rates and high isolated yields of pure products are major advantages will make this procedure a useful addition to the available methods.

References

F.W. Lichtenthaler, Acc. Chem. Res. 35, 728 (2002)

V.P. Litvinov, Russ. Chem. Rev. 72, 69 (2003)

J.S. Kim, H.J. Lee, M.E. Suh, H.Y.P. Choo, S.K. Lee, H.J. Park, C. Kim, S.W. Park, C.O. Lee, Bioorg. Med. Chem. 12, 368 (2004)

Y. Imamura, A. Noda, T. Imamura, Y. Ono, T. Okawara, H. Noda, Life Sci. 74, 29 (2003)

Y. Xu, Q.X. Guo, Heterocycles 63, 903 (2004)

H.R. Shaterian, F. Rigi, Res. Chem. Intermed. 40, 1989 (2014)

M.V. Reddy, G.C.S. Reddy, Y.T. Jeong, Tetrahedron 68, 6820 (2012)

R. Tayebee, M. Fattahi Abdizadeh, B. Maleki, E. Shahri, J. Mol. Liq. 241, 447 (2017)

A. Hashemzadeh, M.M. Amini, R. Tayebee, A. Sadeghian, L.J. Durndell, M.A. Isaacs, A. Osatiashtiani, C.M.A. Parlett, A.F. Lee, Mol. Catal. 440, 96 (2017)

A.V. Chate, P.K. Bhadke, M.A. Khande, J.N. Sangshetti, C.H. Gill, Chin. Chem. 28, 1577 (2017)

M. Abedini, F. Shirini, J.M.A. Omran, J. Mol. Liq. 212, 405 (2015)

E. Mosaddegh, A. Hassankhani, Catal. Commun. 71, 65 (2015)

F. Shirini, M.S.N. Langarudi, O. Goli-Jolodar, Dys Pig. 123, 186 (2015)

A.B. Atar, S.D. Lee, B.G. Cho, D.W. Cho, Y.T. Jeong, Res. Chem. Intermed. 42, 1707 (2016)

E. Mosaddegh, A. Hassankhani, Tetrahedron Lett. 52, 488 (2011)

A. Hasaninejed, M. Rasekhi Kazerooni, A. Zare, Catal. Today 196, 148 (2012)

B. Atashkar, A. Rostami, H. Golami, B. Tahmasbi, Res. Chem. Intermed. 41, 3675 (2015)

H.-J. Wang, X.N. Zhang, Z.H. Zhang, Monatshefte Chem. 141, 425 (2010)

M. Esmaeilpour, J. Javidi, F. Dehghani, J. Iran. Chem. Soc. 13, 655 (2016)

X.-N. Zhao, G.-F. Hu, M. Tang, T.-T. Shi, X.-L. Guo, T.-T. Li, Z.-H. Zhang, RSC Adv. 4, 51089 (2014)

B. Dam, M. Saha, R. Jamatia, A.K. Pal, RSC Adv. 6, 54768 (2016)

L. Ji, J. Lin, H.C. Zeng, J. Phys. Chem. B. 104, 1783 (2000)

E. Iglesia, Appl. Catal. A Gen. 161, 59 (1997)

S. Storsaeter, Ø. Borg, E.A. Blekkan, B. Tødal, A. Holmen, Catal. Today 100, 343 (2005)

M. Lu, N. Fatah, A.Y. Khodakov, Y. Gu, Green Chem. 14, 2091 (2012)

J. Zhang, J. Chen, J. Ren, Y. Li, Y. Sun, Fuel 82, 581 (2003)

J. Albadi, A. Alihoseinzadeh, A. Razeghi, Catal. Commun. 49, 1 (2014)

J. Albadi, A. Alihoseinzadeh, M. Jalali, M. Shahrezaei, A. Mansournezhad, Mol. Catal. 440, 133 (2017)

J. Albadi, A. Mansournezhad, S. Salehnasab, Res. Chem. Intermed. 41, 5713 (2015)

J. Albadi, J. Abbasi Shiran, A. Mansournezhad, J. Chem. Sci. 126, 147 (2014)

J. Albadi, M. Keshavarz, F. Shirini, M. Vafaie-nezhad, Catal. Commun. 27, 17 (2012)

J. Albadi, A. Mansournezhad, T. Sadeghi, Res. Chem. Intermed. 41, 8317 (2015)

J. Albadi, A. Mansournezhad, Res. Chem. Intermed. 42, 5739 (2016)

R.A. Sheldon, Catal. Today 1, 351 (1987)

G. Leofanti, M. Padovan, G. Tozzola, B. Venturelli, Catal. Today 41, 207 (1998)

Acknowledgements

We are grateful to the Shahrekord University for the support of this work.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Albadi, J., Jalali, M. & Momeni, A. Cobalt-based nanocatalyst catalyzed one-pot four-component synthesis 2H-indazolo[2,1-b]phthalazine-triones under solvent-free condition. Res Chem Intermed 44, 2395–2404 (2018). https://doi.org/10.1007/s11164-017-3236-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-017-3236-5