Abstract

Catalytic hydrogenation of m-dinitrobenzene over Pt/TiO2–Al2O3 catalysts was investigated. The effect of the enrichment of TiO2 was analyzed. The results showed that the increase in TiO2 content produced an enhancement in the activity of the catalyst. In these consecutive reactions, both rate constants (k1 and k2) were determined and it whatever the catalyst, k1 is higher than k2. The limiting step of the reaction was the transformation of m-nitroaniline to m-phenylenediamine. This behavior was explained by the modification in the acceptor-donor electron character of the group in the meta position.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Aromatic nitro compounds are constituted by NO2 groups directly attached to the aromatic ring. These represent important chemical intermediates in the manufacture of multiple organic molecules [1]. Their use in the synthesis of aromatics amines for the production of polymers, pigments, herbicides and pharmaceuticals, led to an increase in their industrial interest [2]. The hydrogenation of m-dinitrobenzene (m-DNB) produces m-nitroaniline (m-NA) as intermediate. After this, there is the reduction of the other nitro group to obtain m-phenylenediamine (m-PDA). The hydrogenation to m-nitroaniline to phenylenediamine is difficult due to the presence of a nitro group in meta position [3], which is an electron withdrawing group, and therefore inhibits the desired reaction. This way, there is interest in the development of catalysts with high selectivity to m-PDA.

There are different procedures to synthesize m-phenylenediamine from m-dinitrobenzene: the Bechamp process (reduction with Fe and HCl) and catalytic hydrogenation. The Bechamp process produces a high quantity of inorganic salts as waste, which cannot be recycled [4]. The reduction of organic molecules by catalytic hydrogenation is an ideal example of how catalysis can influence a chemical process. The liquid phase hydrogenation of m-DNB with metallic supported catalysts appeared as an alternative for the conventional process with best activity, selectivity and yield results. Additionally, the catalytic reduction is attractive for the industry due to the high production level, mild conditions of reaction and decrease of environmental pollution [4].

Several researches have performed different active phases and supports in the hydrogenation of m-dinitrobenzene. Generally, the more used catalysts were noble metals supported on active carbon, Al2O3 or other conventional hydrogenation systems as Ni Raney [5]. Recently, we evaluated platinum catalysts supported on several oxides (SiO2, TiO2, Al2O3 and Nb2O5) in the hydrogenation of m-dinitrobenzene at different temperatures of reduction (473 and 773 K). In this research it was found that Pt/TiO2 and Pt/Al2O3 catalysts exhibited the best results of conversion and yield to m-phenylenediamine followed by Pt/SiO2 and Pt/Nb2O5. The authors concluded that the performance was strongly affected by the physical and chemical properties of the supports [6].

There are some advantages in preparing supports with desirable properties. One of the most promising options is to focus on the main characteristics of each oxide constitutive. For example, titanium oxide (titania: TiO2) has large applications as support of catalysts, being a substance with great interest for the industry [7], but it presents the disadvantages of low surface area and poor structural stability when submitted to high temperatures. On the other hand, Al2O3 is used as support because it presents high surface area and resists to abrasion, however, Al2O3 supported catalysts exhibited lower catalytic activity than TiO2 supported catalysts [8]. This way, binary oxides are widely investigated due to their interesting catalytic properties [9]. The presence of a new element in metallic oxides can modify significantly their structural, acid-base, redox and catalytic properties. The final properties can be tuned through the choice of the nature and amount of a new element and preparation method [10]. The grafting method is useful to prepare structurally ordered materials. This method allows to control the properties of the samples, such as porosity and surface area to obtain a homogeneous structure [11].

An example of binary oxide is TiO2–Al2O3. Generally, it is prepared by the powder mixing route, followed by molding and sintering [12]. This method does not produce a homogeneous mixture. Therefore, it is very important to adopt an adequate preparation route. Also, we have shown that in situ reduction is an activation method which easily and efficiently reduces nitro compounds to their corresponding amines [13]. In the case of Pt/TiO2–Al2O3, an excellent regioselectivity was observed for the reduction of a nitro group in the presence of other one [13].

To overcome the limitations, in this study, TiO2–Al2O3 was prepared using the grafting method, and used as a support for platinum catalyst. The hydrogenation of m-dinitrobenzene over Pt/TiO2–Al2O3 catalysts was investigated, and the effect of TiO2 content was addressed.

2 Experimental

2.1 TiO2–Al2O3 Binary Oxide Preparation

TiO2–Al2O3 binary oxides were prepared using the grafting method [14]. A titanium isopropoxide solution (Aldrich, 99.9 %) was added to Al2O3 (SBA 200, Sasol) in a ratio of 1 mmol of titanium isopropoxide per gram of alumina. Then, 300 mL of propanol (JT Baker, 98 %) was added. The resultant mixture was maintained under vigorous stirring in inert atmosphere (N2). Then, the mixture was filtered and washed with distillated water. The resultant solid was dried under vacuum at 423 K. Then, an aliquot called TA1 was taken and the remaining sample was submitted again to the grafting procedure. An aliquot called TA2, was the taken and the grafting procedure was repeated to form TA3 sample. Thus, three supports TiO2/Al2O3 were prepared with a nominal TiO2 content of 4.2, 7.4 and 9.7 wt% (Table 1). Finally, all samples were calcined in air at 673 K for 2 h.

2.2 Platinum Catalysts Preparation

The Pt catalysts supported on TiO2–Al2O3 binary oxides were prepared using the wet impregnation method with 1 wt% of metal. The metallic precursor was H2PtCl6 (Sigma-Aldrich, 99.9 %). The impregnated solids were dried at 343 K and then, the samples were calcined at 673 K for 2 h and reduced under flowing hydrogen (30 mL/min) at 773 K for 2 h.

2.3 Catalysts Characterization

The catalysts were characterized by X-ray diffraction (XRD) in a Philips, PW 1710× diffractometer. The physisorption of Nitrogen at 77 K and hydrogen chemisorption at 298 K were carried out in a Micromeritics ASAP 2020 equipment. TEM studies were performed in a Jeol JEM-1200 EXII microscope. Hydrogen temperature-programmed reduction (H2-TPR) and ammonia temperature-programmed of desorption (NH3–TPD) were carried out in a Micromeritics 2910 (TPD/TPR/TPO) equipment.

2.4 Catalytic Evaluation

All catalytic tests were carried out in a batch reactor. Prior to the reaction, all catalysts were reduced in situ under hydrogen flow of 30 mL/min at temperature of 773 K. The initial conditions were: reaction temperature, 343 K, hydrogen pressure, 0.82 MPa, catalyst weight of 100 mg, 100 mL of a 0.1 M solution of m-dinitrobenzene (Merck 99 %), stirring rate, 1,000 rpm and ethanol (Aldrich) as solvent. The reaction was followed during 7 h. The reagent and products were analyzed using a gas chromatograph (Varian 3400) equipped with a HP5 capillary column (30 m × 2.5 mm × 0.25 μm) and a flame ionization detector (FID). In all reactions, The Weisz–Prater criterion [15] was applied [Eq. (1)] to verify the absence of mass transfer effects.

where r obs is the initial reaction rate per volume (mol/L s), R c is the particle radius (cm), D E is the effective diffusivity (cm2/s) and C DNB is the concentration de m-dinitrobenzene (mol/L).

The values of the Weisz–Prater (CWP) criterion for each catalyst are shown, in Table 2, and the maximum value was of the order of 10−3. These values are well below 0.3, therefore, the results reveal there was not any significant intraphase (internal) mass transfer limitations.

3 Results and Discussion

The X-ray diffraction patterns of Al2O3 and TiO2 supports and Pt/TiO2–Al2O3 catalysts are shown in Fig. 1. TiO2 displayed the characteristic signals of anatase phase and those of rutile, but with lower intensity [16]. The XRD pattern of Al2O3 was typical of the quite amorphous γ-Al2O3. The XRD patterns of Pt/TiO2–Al2O3 catalysts showed mainly the typical reflections of γ-Al2O3, but some TiO2 related diffraction lines were observed. These signals increased with the increase of titania content, and the Pt/TA3 catalyst showed the higher intensity peaks. The reflections due to anatase were expected due to the calcination temperature, 673 K, in agreement with previous researches [17]. There was not any detection of the platinum diffraction lines.

The nominal Ti content, surface area (BET), total pore volume, pore diameter, H/Pt ratio, metal particle size and surface acidity results are compiled in Table 1. The experimental Ti content was not measured. However as the catalysts were obtained by grafting metal alkoxides on surface hydroxy groups of alumina, it is expected that the most of the titanium alkoxide would be deposited on the Al2O3 surface. Therefore, the surface was slightly modified as is common in this preparation method. Similar behavior was found by Reyes et al. [18] to prepare TiO2/SiO2 catalysts for the unsaturated aldehydes hydrogenation.

The surface area of Pt/TiO2–Al2O3 catalysts slightly increased with the enrichment in TiO2. This behavior has also been found previously when the used Ti precursor was an alkoxide. It is known that the nature of organometallic compounds favors the microporosity in the supports [19, 20]. Thus, a decrease of the pore diameter in the catalyst and a slight decrease in the pore volume in the catalysts supported over binary oxides, lead to a modest enhancement in the surface area. The H/Pt ratio decreased as TiO2 content increased. This could be attributed to a decoration of metallic particles by partially reduced TiO2 species (TiO x ) at temperatures near 773 K, usually called strong metal-support interaction (SMSI) [21].

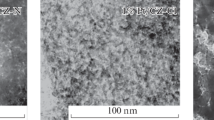

Figure 2 shows bright field TEM micrographs of the Pt/TiO2–Al2O3 catalysts. These systems display a narrow metal particle size distribution, following a Gaussian function. The catalysts showed similar particle sizes (2–3 nm). This result is consistent with X-ray diffraction analysis, as there was not any detection of platinum lines.

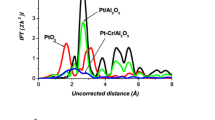

Figure 3 shows the H2-TPR results. The peak centered at 350 K is attributed to the reduction of platinum oxide (PtO2) to metallic platinum (Pt0), whereas the peak at 435 K corresponds to the reduction of a platinum oxychloride surface complex (PtCl x O y ). These species can be formed during the drying and calcination steps, due to presence residual chlorine ions remaining from the preparation procedure [22]. The peak at 580 K is due to partial reduction of TiO2, and it increased with the TiO2 content to the catalyst.

The surface acidity of Pt/TiO2–Al2O3 catalysts was evaluated by NH3 adsorption. The amount of acid centers (weak and strong sites) expressed in NH3 adsorbed molecules per gram of solid is showed in Table 1. For all catalysts, the total acidity decreased as the TiO2 enrichment increased. In addition, the desorption profiles correspond to intermediate acidity strength [23], as most of the ammonia evolved between the 473–673 K temperature range (Fig. 4).

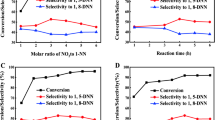

Figure 5 shows the evolution of the conversion of m-DNB with time during the hydrogenation of m-dinitrobenzene. The variation of conversion with the reaction time was compatible with a pseudo first order reaction. An increase in the conversion level with the TiO2 loading could be observed. The Pt/TA3 catalyst displayed the highest conversion of m-dinitrobenzene.

The detected products were m-nitroaniline (m-NA) and m-phenylenediamine (m-PDA) confirming that the hydrogenation of polynitro compounds are consecutive reactions [24]. m-Nitrosobenzene and m-oxiaminonitrobenzene, the intermediates due to the hydrogenation of m-dinitrobenzene were expected, but only the product formed from the hydrogenation of m-dinitrobenzene, m-nitroaniline, was detected in a significant extent. The products generated from the corresponding consecutive hydrogenation reactions of m-nitroaniline were m-aminonitrobenzene, m-aminoaminobenzene and m-phenylenediamine. However, they were detected low amount and they were neglected in the evaluation of the rate constants.

Figure 6 shows the product formation in the m-dinitrobenzene hydrogenation for one representative catalyst, Pt/TA3. The evolution of the m-DNB concentration and the other reaction products follow the expected trend: the m-DNB concentration decreased through a first-order law, leading to m-nitroaniline. A maximum of m-nitroaniline concentration was obtained around 120 min. Longer reaction times to reach a maximum m-nitroaniline concentration were observed for Pt/TA2 and Pt/TA3, 180 and 270 min respectively (not shown). In all cases, the presence of over-hydrogenated products, hydrogenation of the aromatic ring was not observed, and the evolution of the m-phenylenediamine concentrations follows the expected sigmoid curve, characteristic of final products of consecutive reactions. Thus, the reaction pathway may be represented by irreversible and consecutive reactions. If it is assumed that the intermediate products were present in very small amounts and they could be neglected. This way, only two reaction steps were considered: The hydrogenation of m-dinitrobenzene to m-nitroaniline (k1) and hydrogenation m-nitroaniline to m-phenylenediamine (k2).

Table 2 compiles the obtained rate constants in the hydrogenation of m-dinitrobenzene. There was an enhancement in both rate constants with the increase in the TiO2 loading. A modification of the active sites by the presence of Ptδ+ species generated by the interaction between the Pt and the partially reduced support (TiO2–x ) could also improve the catalytic behavior [25]. This was more important for higher TiO2 loading, influenced by the presence of reduced PtO x species and intermediate acidity of the supports. The presence of this phenomenon contributed to the reduction of nitro aromatics compounds, as suggested by Corma et al. [26] in the case of Au/TiO2 catalysts in the hydrogenation of 3-nitroestirene and nitrobenzene. The m-DNB conversion and m-PDA yield also were also affected by acid-base characteristics of the support. The total acidity results indicated that the Pt/TiO2–Al2O3 catalysts exhibited a higher acidity, compared to Pt/TiO2 and Pt/Al2O3 reported in the literature [6]. This fact is in agreement with a study carried out by Shimizu et al. [27], who pointed out that a cooperation of the acid-base pair site of the support is required for this reaction.

On the other hand, for the three studied catalysts, k1 values are approximately three times higher than k2. First, this is related to the presence of two possible nitro-groups for hydrogenation in the first step. Additionally, there is an influence of the nature of the substituent in the meta position [28]. Hammett suggested a relation between the rate constants and the electron donor character of a given substituent group in meta or para position [29, 30]. Thus, m-dinitrobenzene can be considered as an aromatic compound in which one −NO2 is in meta position in respect to the other −NO2 group. This group is well known for its high ability to attract electrons. As this capacity decreases, in the rate constant should also decreases. Thus, the hydrogenation to the −NH2 group involves changes in the electrophilicity of the substituent group and therefore a decrease in the rate constant should be expected. Similarly, in the hydrogenation of the remaining −NO2 group to the final m-phenylenediamine, a decrease in the rate constant should be expected. This mechanism may also account for the small amounts of intermediates such as m-aminonitrobenzene, m-aminoaminobenzene detected. Reactant activation on the catalyst generates a negatively charged intermediate, consistent with a nucleophilic mechanism. The presence of an electron-donating substituent decreases the NO2 reduction rate.

4 Conclusions

The hydrogenation of m-dinitrobenzene to m-phenylenediamine in liquid phase is affected by the presence of Ptδ+ species and acidity of the supports. This reaction could be modeled as two-step consecutive reaction, in which the rate constant for the first step (k1) was higher than k2, the rate constant for the second step. The limiting step of the reaction is the transformation of m-nitroaniline to m-phenylenediamine. This may be explained by the modification in the acceptor-donor electron character exhibited by the group in the meta position as the hydrogenation takes place. The addition of TiO2 to Al2O3 caused an interaction between the Pt particles and the TiO2 and consequently an enhancement in the rate constants.

References

Figueras F, Coq B (2001) J Mol Catal A 173:223

Downing R, Kunkeler P, Van Bekkum J (1997) Catal Today 37:121

Telkar M, Nadgeri J, Rode C, Chaudhari R (2005) Appl Catal A Gen 295:23

Wegener G, Brandt M, Duda L, Hofmann J, Klesczewski B, Koch D, Kumpf R, Orzesek H, Pirkl H, Six C, Steinlein C, Weisbeck M (2001) Appl Catal A Gen 221:303

Yingxin L, Jixiang C, Jiyan Z Chin (2007) J Chem Eng 15: 63

Rojas H, Borda G, Reyes P, Brijaldo M, Valencia J (2011) J Chil Chem Soc 56:793

Borda G, Rojas H, Murcia J, Fierro JLG, Reyes P, Oportus M (2007) React Kinet Catal Lett 92:369

Medvedovski E (2002) J Am Ceram Soc Bull 81:27

Seo J, Youn M, Song I (2007) J Mol Catal A 268:9

Seo J, Youn M, Song I (2007) J Power Sources 168:251

Qi H, Fan Y, Xing W, Winnubst L (2010) J Eur Ceram Soc 30:1317

Zawrah MF, Schneider J, Zum KH (2002) Mater Sci Eng A 332:167

Rojas H, Cubillos J, Martínez J, Guerrero D, Reyes P (2012) Curr Org Chem 16:2770

Hoffmann H, Staudt P, Costa T, Moro C, Benvenutti E (2002) Surf Interface Anal 33:631

Fogler HS (1999) Elements of chemical reaction engineering. Prentice Hall, New Jersey

Rodriguez V, Zanella R, Angel G, Gomez R (2008) J Mol Catal A 281:93

Montes F, Getton P, Vong W, Sermon A (1997) J Sol Gel Sci Technol 8:131

Reyes P, Rojas H, Borda G, Martínez JJ, Valencia J (2008) J Mol Catal A Chem 286:70

Choi J, Kim J, Sang K, Gyu T (2008) Powder Technol 181:83

Li J, Zhu Y, Ke R, Hao J (2008) Appl Catal B Environmental 80:202

Reyes P, Rojas H, Fierro JLG (2003) Appl Catal A Gen 248:59

Passos F, Aranda D, Soares R, Schmal M (1998) Catal Today 43:3

Valdez R, Pawelec B, Quintana J, Olivas A (2013) Fuel 105:668

Rojas H, Borda G, Brijaldo M, Reyes P, Valencia J (2012) Reac Kinet Mech Cat 105:271

Reyes P, Salinas D, Campos C, Oportus M, Murcia J, Rojas H, Borda G, Fierro JLG (2010) Qui Nova 33:777

Corma A, Serna P, Concepción P, Calvino J (2008) J Am Chem Soc 130:8748

Shimizu K, Miyamoto Y, Kawasaki T, Tanji T, Tai Y, Satsuma A (2009) J Phys Chem C 113:17803

Campos CH, Torres C, Oportus M, Peña MA, Fierro JLG, Reyes P (2013) Catal Today 213:93

Hammett LP (1937) J Am Chem Soc 59:96

Jaffé HH (1953) Chem Rev 53:191

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Brijaldo, M.H., Passos, F.B., Rojas, H.A. et al. Hydrogenation of m-Dinitrobenzene Over Pt Supported Catalysts on TiO2–Al2O3 Binary Oxides. Catal Lett 144, 860–866 (2014). https://doi.org/10.1007/s10562-014-1218-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-014-1218-4