Abstract

Today ethylene oxide can be produced industrially with ~90 % selectivity through the epoxidation of ethylene over silver catalyst. The past decades there has been a substantial increase in the understanding of the molecular chemistry that leads to high selectivity catalysis. Especially the discovery of an oxometallacycle intermediate that produces ethylene epoxide in competition with acetaldehyde can be considered a major advancement. The state of the surface at reaction conditions causes different reaction paths to compete. At high oxygen coverage also a direct epoxidation channel opens. We will also review recent progress on the understanding of promotion and coverage dependent reactivity. The contributions in our understanding of this reaction from computational catalysis will be emphasized.

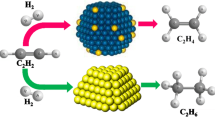

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Partial oxidation of ethylene (C2H4) to ethylene oxide (C2H4O) catalyzed by silver is an important industrial process with a large production capacity. Ethylene oxide (EO) serves as a very useful chemical intermediate from which further products such as plastics, polyester, and glycols can be derived. About 70 % of the world-wide produced EO is converted to ethylene glycol [C2H4(OH)2] (engine antifreeze). The remaining portion is also converted to other end products such as ethoxylates, plastics and higher glycols.

GIA, who announces the release of a comprehensive global report on the EO markets, reported that the global market for EO is projected to exceed 27 million tons by the year 2017 [1]. Thus, due to the global capacity of this process, even slight improvements in the selectivity would have large scale economical benefits.

The EO selectivity of the un-promoted metallic silver is around 50 % [2, 3]. The industrial catalyst consists of silver particles supported on low surface alumina (α-Al2O3), with the addition of alkali compounds as promoters. During the process, chlorine is added in ppm amounts to the feed stream as a promoter in the form of chlorinated hydrocarbons, to enhance the EO selectivity. Today, the EO selectivity of the industrial catalyst lies in the range of 90 % [4], whereas this value was around 70 % in the 70’s [5]. These improvements of the EO selectivity were achieved mainly by trial–error methods [6]. In parallel, important progress on the identification of the mechanism and reaction intermediates was achieved [3, 7]. In the past decade many of these early concepts have been probed on the molecular level. Contributions from computational catalysis have provided a new view on mechanistic steps essential for high selectivity, which is the subject of this review.

There is no consensus on the optimum state of the catalyst surface at reaction conditions. The role of the promoters, as alkali and chlorine that have to be added to obtain high selectivity is also not yet well understood and will be discussed.

Chemical applications of the density functional theory (DFT) supplied a considerable input into our understanding of surface chemistry and catalytic reactions. It is possible and feasible to construct a surface model interacting with the molecules of interest, and reveal the active sites and transition states through simulations. The results of these simulations can further be used to obtain kinetic parameters and thermodynamic relations, such as stability (phase) diagrams. Such an understanding in molecular level fills in the gaps required for further development.

In the following sections we will present a summary of the previous studies, starting with the developments in the ethylene epoxidation mechanism, followed by the question ‘why Ag is the unique catalyst?’ for ethylene epoxidation. After summarizing the contributions for the promoters and promoter effects, we will conclude with the developments in the surface models, and active oxygen species.

2 Epoxidation Mechanism

Following its discovery [8], ethylene epoxidation mechanism was found to follow two parallel paths, both of which are catalyzed by silver [9]. As demonstrated in Scheme 1, selective (k1) and non-selective (k2) parallel reactions take place on the Ag particle, whereas consecutive combustion of EO (k3) was found to be sensitive to the acidity of the catalyst support [10–12]. EO formation is moderately exothermic (−105 kJ/mol), whereas the total oxidations of both ethylene and EO (−1,327 and −1,223 kJ/mol, respectively) are strongly exothermic [13]. Although thermodynamically favored path is the complete combustion, selective production of EO implies that the reaction is kinetically controlled [14].

Initially it was proposed that molecularly adsorbed oxygen (O2,s) was responsible for selective reaction (k1) [15]; whereas atomic surface oxygen (Os) caused non-selective reaction (k2). The interesting consequence of this proposal was that the EO selectivity should be limited to a highest value of 6/7 (87.5 %) [15], according to Eq. 1. This selectivity value was typically observed for promoted catalyst.

Soon after this proposal, EO selectivities higher than 6/7 were reported [16, 17], indicating that a particular atomically adsorbed oxygen atom is responsible for the EO selectivity [18–20]. Consecutive work on the nature of the oxygen species adsorbed on the silver surface [14, 15, 18, 21–49] confirmed this [41]. An outcome of these studies was also that high O coverage is required for high selectivity [3, 32, 41, 48, 50].

Another major outcome of these researches was the identification of two different oxygen species on the surface [3, 24, 25, 27, 43, 45, 49]. A weakly bound (electrophilic, Oδ+) surface oxygen was found to enable selective epoxidation and a strongly bound (nucleophilic, O δ−) surface oxygen to give combustion upon contact with ethylene. Selective ethylene epoxidation was proposed to follow an Eley–Rideal (E–R) mechanism whereas the non-selective combustion follows a Langmuir–Hinshelwood (L–H) mechanism.

According to the direct path proposed for EO (k1) and C–H activation (k2) [40, 45, 48, 49, 51, 52], electron deficient oxygen (Oδ+) attack opens C=C double bond of ethylene, forming the COC ring through O insertion. On the other hand electron rich oxygen (Oδ−) attack to C–H bond removes the H atom from ethylene, creating a radical molecule that ends up in complete combustion. Although the suggested ethylene combustion path (k2) did not include a stable acetaldehyde (AA) intermediate, the EO isomerization to AA (k3) was known [40].

In the 90’s, a major advance was the discovery of an oxometallacycle (OMC) surface intermediate [7, 53] shown in Fig. 1, that decomposed into EO as well as AA (Scheme 2).

One important prospect of OMC mechanism is that, the activation energies towards AA formation are usually found to be lower than that for EO formation. A question arises how this can be reconciled with the high selectivity found for this reaction. Therefore we proposed that also a second reaction channel is present, the direct epoxidation path. In contrast to the OMC intermediated path the direct epoxidation path is only operational at high oxygen coverage. This will be discussed in Sect. 2.2.

2.1 The OMC Mechanism

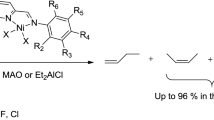

In this section we will review studies that led to the identification of the OMC intermediate and we will discuss its reactivity. The OMC intermediate was identified on the silver surface through experimental studies by the group of Barteau [53–56]. Its formation is proposed to proceed on the catalyst surface through a well defined L–H mechanism with the reaction of Os and C2H4(ads) (Fig. 2). Stable OMC intermediates on the Ag surfaces were obtained either by dosing the silver surfaces with 2 iodoethanol (2I-EthOH) [54–56], the case where only AA formation was observed, or by back adsorbing EO to the surface [53], the case where both AA and EO were observed. Although the formation of OMC intermediate on silver surface was observed at surface science conditions, the catalytic conditions [57] are very different.

Geometries along OMC mechanism on (111) surface. (M: light gray, O: red or dark gray, C: black, H: cyan or gray) Figure adopted from [58]

Nonetheless, these experiments in combination with computational results allow for the conclusion that the OMC is the common precursor for both the parallel reaction channels that produce EO and AA on the un-promoted metallic catalyst. Thus, the product selectivity depends on the relative barriers of the product formations (\(E_{EO}^{a}\) and \(E_{AA}^{a}\)) through the decomposition of the OMC intermediate. Experimentally reported barriers for the EO formation lie in the range of 54–88 kJ/mol [53]. The activation barriers (\(E_{EO}^{a}\) and \(E_{AA}^{a}\)) reported for OMC mechanism on metallic surfaces [2, 7, 58–62] are consistent with ~50 % EO selectivity.

Substitution of hydrogen with deuterium has a rate-decreasing effect on the non-selective path because of the H-transfer reaction, as explained in [63]. Formation of non-selective product, AA, through OMC mechanism is consistent with the increase in the EO selectivity when deuterated ethylene is used [21].

Being closely packed and the most stable surface, the metallic Ag(111) is taken as a model surface in experimental [7, 54–56, 64] and computational [2, 53, 58–63, 65, 66] investigations of OMC. However, at high oxygen coverage surface chemistry may change. High oxygen coverage suppresses ethylene adsorption to Ag. It changes the OMC formation mechanism from Langmuir–Hinshelwood (L–H) to Eley–Rideal (E–R) [58, 62].

The selectivity trends of the OMC intermediate can be related to the binding strength of the surface oxygen [58, 67]. When different metals such as copper, silver and gold are compared the activation barriers differ because of the different stabilities of precursor OMC intermediate, which is in direct relation with the surface oxygen stability [58].

The OMC mechanism was also computationally evaluated for the metallic surfaces of copper [58, 60] and gold [58, 68–70]. On copper surfaces the high stability of the precursor intermediates caused high activation barriers for the product formation, with increasing selectivity towards EO formation. On the other hand gold surfaces showed the smallest activation barriers for the product formations

Starting from 1970’s [31], investigations of highly oxygenated Ag surfaces revealed the formation of complex structures on the catalyst surface, commonly referred as surface oxides. Although the majority of these studies focus on the structure and the properties of these surface-oxides, there are a few computational studies testing the OMC mechanism at higher oxygen coverage. No significant changes in reactivity of the OMC intermediate was reported as long as a surface vacancy is available to stabilize the OMC complex

On the other hand, our studies showed that on the Ag2O(001) oxide surface without such vacancies surface formation of EO follows a direct route (that will be discussed in the next section), since ethylene cannot interact with a surface metal atom [71–74].

However, when there is an oxygen vacancy on the oxide surface, the two Agδ+ ions are exposed to the vacuum. These Ag ions hold larger (+) charge compared to those of the metallic surface [71] due to the subsurface oxygen species. Adsorption of ethylene on an O-vacant site on the oxide surface is more exothermic (−85 kJ/mol) compared to the metal cases.

Figure 3 shows the relative energies of the intermediates and transition states of ethylene reacting on the Ag2O(100) surface. OMC formation follows the ethylene adsorption, which is significantly more stable than the OMC on the metallic surface. On oxide surface, this extra stability is introduced by the stronger ethylene adsorption, unlike oxygen strength on the metallic surfaces. Here again, after its formation decomposition of the OMC produces EO as well as AA, with the lower barrier towards AA formation.

OMC path on an O vacancy of Ag2O(001) surface. Figure adopted from [71]

Also, the oxides of copper and gold with that of silver [72] were computationally compared in the epoxidation reaction. On vacant oxide surfaces, once adsorbed, the ethylene molecule may interact with a neighboring Os to form the OMC intermediate. Formation of OMC proceeds through small barriers on Cu2O and Au2O; and without a barrier on Ag2O.

Compared to the metallic surface, the activation barrier for AA formation through the OMC intermediate is significantly lower on the oxide surfaces.

On reconstructed oxide surfaces a constrained OMC like intermediate [74] can be formed. Ethylene interaction with the non-vacant Ag oxide surface may induce a local reconstruction causing the bridging oxygen atom to shift to a three-fold site. This configuration resembles oxygen ad-atom adsorption on the metallic (111) surfaces or surface-oxide structures [75–77]. This OMC intermediate with a single Ag atom in its ring is much more selective towards EO. This agrees with the earlier observation [65, 67], that only an OMC intermediate that contains two Ag atoms in its ring prefers production of AA.

2.2 Direct Epoxidation

Formation of EO through an E-R type direct mechanism [40, 45, 48, 49, 51, 52] by reaction of gas phase ethylene and surface oxygen was proposed in 80’s. The reaction is of the Mars-van Krevelen type [78]. Recent computational studies have identified such a direct route for EO formation, which is enabled by the electrophilic oxygen on the model Ag2O(001) surface.

Bridging Os on the oxide surface causes a totally different epoxidation path compared to the two-step OMC mechanism. As Fig. 4 shows, Os interacts directly with the C=C double bond, resulting in the non-activated formation of EO [78]. This direct reaction path does not include an intermediate such as OMC. Gas phase ethylene reacts with Os where EO(ads) forms directly releasing 174 kJ/mol energy. Subsequent desorption of EO(ads) requires 73 kJ/mol, which gives the overall heat of the epoxidation reaction as −101 kJ/mol.

Relative energies for the direct route on Ag2O(001) surface, and the OMC mechanism on Ag(111) surface. Figure adopted from [71]

From Fig. 4 it can be seen that, the activation energies of the rate controlling steps in both reaction paths (i.e. OMC vs. direct) are similar and agree with experimentally reported values that are around 70 kJ/mol [13, 79]. However, the corresponding reaction steps that go through a barrier are different (i.e. OMC activation versus EO desorption). It should also be noted that, on the oxygen covered oxide surface ethylene cannot directly interact with the silver surface ions, thus no OMC intermediate forms. This prevents C–H bond activation, therefore AA formation.

On the oxide surface, an additional prerequisite for high selectivity is the absence of O-vacancies, where the non-selective reaction takes places through OMC intermediate. Most likely this is the moderating role of Cl that is added to the catalyst as promoter. This will be discussed in the later sections.

These results agree with the previous experimental reports [80] where initial and selective production of EO is followed by AA production as the surface oxygens are consumed. The initial and highly selective production of EO proceeds in an E–R manner and removes the surface oxygens, which causes O-vacancy formation on the surface and enables the L–H path. Ethylene adsorption on the oxygen vacant surface sites opens the non-selective reaction path. Obviously to maintain high EO selectivity rapid silver re-oxidation should occur, while the O-vacancies are being blocked or suppressed.

Although there are different reports on the reaction order of the epoxidation reaction [7, 13], some studies have shown that the kinetics of the epoxidation reaction has a low reaction order in ethylene [81], but a high reaction order in oxygen. The low reaction order of ethylene is consistent with the view that EO desorption is the rate limiting step. The reported increase in EO selectivity with the increasing oxygen coverage [36] is also consistent with the preference for EO formation on an oxidized Ag surface in this manner.

The mechanistic studies that used deuterated ethylene (C2D4 or C2H2D2) revealed that EO can go through two different types of isomerization steps. In the first reaction step, surface adsorbed EO can isomerize to AA through an H-transfer reaction. The experimentally reported activation barrier for this reaction is 59 ± 13 kJ/mol [40]. Studies on the metallic surfaces have not reported a path for this isomerization yet. It is possible that the atomic oxygen on the metallic surfaces, which has a nucleophilic nature, is not strong enough to open the EO ring and activate H-transfer. However, the previously reported activation energy is close to the AA formation through OMC intermediate. Thus, it can be speculated that the adsorption of EO forms OMC intermediate on the surface, which then forms AA. Such a path also explains the EO increase when deuterated ethylene is used [21] due to the increased barrier of H/D-transfer.

On the other hand, in our studies on the oxide surfaces we observed that direct isomerization of EO to AA possible with a relatively large barrier. The right hand side of Fig. 5 shows a comparison of this reaction on different oxide surfaces. It can be concluded that as the binding energy of the surface oxygen increases, EO isomerization gets easier.

Two EO isomerizations on the studied oxide surfaces. Cis–trans isomerization (left) and isomerization to AA (right). Figure adopted from [72]

The second type of isomerization was observed when cis or trans labeled deuterated ethylene was used [29, 82]. Those studies reported the formation of EO with approximately equal amount of cis and trans isomers, although a single type of ethylene isomer was used to begin with. Within the OMC mechanism a possible intermediate for this isomerization has been proposed [7]. In our proposed direct path, the ring opening reaction of EO(ads) to form an ethylenoxy type intermediate, which would isomerise deuterated EO. The energies given in Fig. 5 show that EO desorption competes with EO ring opening, which can lead equal amounts of cis and trans isomers.

2.3 Ag as the Unique Ethylene Epoxidation Catalyst

Silver is the only catalyst with a feasible selectivity for the partial oxidation of ethylene to EO. Other common oxidation catalysts such as Pd, Pt or Ni cause complete combustion [67]. Why other transition metals do not catalyze this reaction is still in debate. Most of the studies directly or indirectly attributed the uniqueness of silver to the special interaction of silver and oxygen. Thus the discussion can be focused on the nature of the active oxygen. There are studies in the literature evaluating two other transition metals, Au and Cu, as possible ethylene epoxidation catalysis [58, 66, 70, 72]. Comparison of Au, Ag and Cu gives good insight in means of epoxidation mechanism. Although different surfaces of studied metals show small changes, the general trend for the metals is that Cu and Au surfaces have a lower selectivity than the Ag surfaces [72].

For the optimum selectivity the metal–oxygen interaction should be strong enough to dissociate O2 molecule and supply the stable atomic oxygen species required for the epoxidation. On the other hand, not too strong to prevent desorption of the formed EO or to cause C–H activation and other side reactions. From this perspective, compared to other metals, the interaction of atomic oxygen and the silver surface lies in an optimum point, which results in the moderate activation barriers and binding of the species.

Silver oxidizes easily in room temperature but silver oxide is not stable at elevated temperatures under atmospheric pressures, due to the weaker Ag–O bonds. Although weaker oxygen binding lowers the thermal stability, it increases the epoxidation activity. This is a special and desired case as weakly bound oxygens on silver surface can activate the C=C double bond, rather than C–H bonds, as discussed in the previous chapters.

On the other hand, O2 dissociation and stable surface atomic oxygen can easily be satisfied in the case of copper. However, strong bound Os prefers to stay on the metallic copper surface, increasing the activation barriers and the desorption energies for the OMC mechanism, making Cu unfeasible for ethylene epoxidation. Furthermore, EO formation is endothermic with respect to pre-oxygenated copper surfaces [58, 60].

Unfortunately, available literature does not contain enough data for the evaluation of EO selectivity on the surface-oxide structures. However, in a previous study we compared the epoxidation reaction on the surfaces of Au2O, Ag2O and Cu2O oxides [72]. The bridging oxygens on these oxides surfaces enable the direct path discussed in the previous section. The relative stabilities and the oxygen binding energies of these compounds decrease downwards the periodic table. The Au2O structure is not a stable oxide structure, but having the same crystal structure with Ag2O and Cu2O, its reactivity has been used for comparison. For the three M2O(001) surfaces studied, a direct epoxidation channel has been found to exist with a low or no barrier. As Fig. 6 shows, Os interacts directly with the C=C double bond, resulting in the non-activated formation of EO on the Ag2O(001) surface. This direct reaction path does not include a surface intermediate such as OMC. Os insertion into the C=C double bond forms EO(ads) in a single step reaction.

Direct ethylene epoxidation paths on Ag2O, CU2O, and Au2O oxide surfaces. Figure adopted from [72]

Among these three oxide surfaces, only Ag2O(001) surface enables direct path without a barrier. Au2O cannot regenerate surface oxygen and overall reaction on Cu2O is endothermic. Furthermore, ring opening of EO and subsequent AA formation on Cu2O is more favorable than EO desorption, as shown in Fig. 5. The non-selective AA formation is found to compete with EO formation only on the Cu2O surface. This is essentially due to the relatively weak O–C bond interaction and the high desorption energy of EO.

On all the studied oxide surfaces, the OMC intermediate forms exothermically on O-vacant surface sites. The barrier for AA formation through the OMC intermediate was found to be lower than that of EO formation. The Cu2O(001) surface gave the most exothermic OMC formation and the highest consequent EO and AA barriers, which relates the oxygen binding to OMC selectivity. The Ag2O(001) and Au2O(001) surfaces show more moderate energy values along the OMC mechanism.

On the metallic surfaces of Au, Cu and Ag, the epoxidation mechanism progresses through the OMC mechanism. The stability of the OMC intermediate depends on the oxygen stability [62, 65], which is also effected from the coverage [7]. In this case, Au appears to be a better catalyst than Ag for ethylene epoxidation [58, 70], as the weakly bound Os shows better selectivity for EO than that of AA. Weak binding of Os lowers the activation barriers and the desorption energies. However, metallic or oxide Au is not a realistic catalyst as it fails to dissociate the O2 molecule and to supply the stable surface O species. Apart from the economical feasibility, it can be speculated that if surface atomic oxygens can be supplied on gold surface, such a catalyst may give higher EO selectivities. It is also possible to find recent suggestions on option [83].

Au2O is not a stable structure, and, Cu2O does not favor the EO formation. The intermediate value of Ag2O’s stability and its oxygen bond strength placed between Au2O and Cu2O relate the uniqueness of the silver catalyst for ethylene epoxidation. The interaction of Ag2O(001) surface with molecular oxygen is strong enough to re-oxidize the Ag surface to the oxide, on the other hand weak enough to prevent the ring opening of EO as well as to prevent the activation of the CH bonds.

3 Promotion by Cl and Cesium

Today, industrial EO production operates with a EO selectivity of ~90 % [4] with the addition of halogen (commonly Cl) into the process and alkali (commonly Cs) promoters to the catalyst. Fundamental studies on Cl and Cs promotion have been limited mainly to the metallic silver surfaces [20, 24, 27, 37, 42–44, 84]. Both Cl and Cs are known to increase EO selectivity whereas reducing the overall yield. Thus, their effect on the active sites and/or oxygens is commonly pronounced. The general consensus is that the Cl promotes the active oxygen and the active sites (i.e. block the non-selective sites) and Cs is the structural promoter. Nonetheless, studies taking in account the surface effect of Cs promoter also exist.

3.1 Cl Promotion

Cl is known to be the selectivity promoter for ethylene epoxidation. Addition of ppm levels of chlorinated hydrocarbons to the process deposits Cl on the catalyst surface via the combustion of the hydrocarbon part. Cl accumulation, which poisons the catalyst, is prevented by the Cl removal through a stripping reaction with ethylene. Cl suppresses both of the primary reactions (k1 and k2 in Scheme 1) and increases the EO selectivity with a loss in overall activity [27].

The early mechanistic studies that considered O2 to be the active species [15] proposed Cl promotion to operate through an ensemble effect. As O2,s was considered to be the active species for the selective path (k1) and Os for the non-selective path (k2), Cl was proposed to prevent the O2 dissociation by occupying the neighboring vacant sites. Thus, epoxidation selectivity would be enhanced when molecular oxygen would uniquely give the epoxide upon reaction with ethylene. The non-selective channel would be inhibited [15] as Cl prevents the formation of the atomic surface oxygen.

Later, when atomic surface oxygen was identified as the active species [14, 21–27, 41], Cl was proposed to block the vacant sites next to the active atomic oxygen species, preventing direct interaction of ethylene with the surface, thus suppressing the non-selective channel (k2) that followed a L–H mechanism [18–20]. Site blocking effect of Cl promoter also found later support [42, 47, 49, 74].

Further studies indicated that the effect of the Cl promoter was more complex. A high local surface oxygen concentration and subsurface oxygen (Oss) was previously proposed to be necessary to achieve high EO selectivity [3, 32, 41, 43, 48, 50]. Reports showed that at higher concentrations, Cl diffuses into the sub-surface layers of the catalyst surface [85] and increases the amount of the dissolved (sub-surface) oxygen [24], which has a positive effect on the EO selectivity. One of the mostly supported ideas is that the Cl promoter weakens the Ag–O interaction, which makes the oxygen easier to be transferred to the ethylene [3, 41, 48, 86–91]. This electronic effect was also considered to accelerate the EO isomerization [44]. Unlike previous studies, which investigated the mechanical effect (i.e. site blocking) of the promoter [15, 18–20], recent studies recent studies focus on the electronic effect of Cl neighboring the active O species.

The electronic effect of the Cl promoter within the OMC formalism was also considered. It was suggested that the presence of co-adsorbed halogens significantly decreases the energy barrier from the OMC complex to EO relative to that from the same OMC intermediate to the undesired AA product [91] by changing the electronic structure.

These ideas agree with the proposals on the weakly bound (electrophilic) and the strongly bound (nucleophilic) oxygens being responsible for the selective and non-selective and reactions, respectively [10, 11, 32, 41, 48, 52, 92]. Within this concept, the larger number of electron acceptors (i.e. oxygens and Cl) on the surface and in the sub-surface layers would leave less charge for active oxygen, making them electron deficient and more reactive towards the epoxidation reaction.

In parallel with these proposals our previous studies on silver oxide surface concluded that Cl promotes EO selectivity by blocking the O-vacant sites, therefore preventing OMC formation, which is responsible for the non-selective reaction. In addition, Cl also competes with the surface oxygens for the electronic charge, reducing the charge on the surface oxygens and making them more electrophilic [73]. Furthermore, molecular adsorption energies of O2 and C2H4 on the vacant site of Ag2O(100) surface are −20 and −85 kJ/mol respectively. The dissociative adsorption energy of O2 on the O-vacant surface depends on Os coverage and varies between −32 and −62 kJ/mol [72]. However, the adsorption of a Cl atom on the same vacancy is exothermic by −185 kJ/mol [73]. Selective adsorption of Cl into the vacant sites increases EO selectivity by suppressing the non-selective channels. This is different from the role of Cl proposed on a metallic surface [91] which suggested an electronic effect of Cl, that would change the selectivity of OMC decomposition.

Furthermore, our study [74] also revealed that Cl prevents the local reconstructions on the silver oxide surface and sustains the well ordered oxide structure due to the stronger bonding of the Ag–Cl. Therefore, electrophilic oxygen species that are active for epoxidation does not change their nature by shifting to three-fold sites. Cl can act on the surface or in the sub-surface layers as previously proposed [24, 27, 37]. However subsurface diffusion of Cl destabilizes the surface oxygen atoms, creating more vacant sites for the non-selective reaction. However, surface adsorbed Cl, especially in combination with Cs, has a positive effect on the direct epoxidation mechanism.

3.2 Cs promotion

Cesium is the commonly used alkali metal promoter added during catalyst preparation. In practice Cs is proposed not to affect the primary reactions (k1 and k2 in Scheme 1) but to inhibit the EO isomerization (k3) [40, 44, 93–95]. However, addition of Cs to the metallic catalyst is known to reduce the yield while increasing the selectivity [47, 51, 96].

The promoter activity of Cs is not as well understood as Cl. However, it was shown that among other alkali elements, the least amount of Cs is required as the promoter amount required to achieve the optimum promotion is inversely proportional with the elements radius [97]. Two different proposals on the Cs effect consider its activity on either on the support material or on the catalyst surface. The studies assigning Cs to act on the support material propose that it reduces the EO combustion by suppressing the acidic sites of the Al2O3 support [93–95]. It is also in common view that Cs acts on the support [98] and gives better Ag dispersion [99].

On the other hand, studies investigating the Cs effect on the active catalyst surface produced several conclusions [24, 43, 100]. Those studies that were conducted on single crystal surfaces showed that dosing the surface with Cs makes the metallic surface less active but more selective for epoxidation [96]. Cs and surface oxygen combine together to form CsO x complexes that enhances the thermal stability of both Cs and O on Ag surface [51, 74, 96], which agrees with the studies proposing that Cs acts as an electron donor to the surface [101] and makes the electrophilic oxygen adsorption stronger [99]. Cs was also proposed to maintain the high surface coverage of Cl [47]. On the other hand, studies suggesting that the Cs reduces the combustion by stabilizing the electrophilic oxygen and reducing the nucleophilic oxygen concentration [11] did not find much support.

A recent study [84] proposed that, on the metallic silver catalyst Cs blocks the stepped surfaces, which were proposed to have lower EO selectivity than the flat Ag(111) surface. On the other hand, a set of studies [59, 61] experimentally showed that Ag(100) and Ag(110) surfaces are more selective for EO compared to Ag(111) surface. Furthermore, increased ethylene combustion was previously reported for the Cs only promotion [43].

In the computational studies of the OMC mechanism on flat metallic surfaces, Cs was proposed to stabilize the transition state of EO and to affect the activation energies for the competing parallel reactions on the metallic silver surface in favor of EO [102].

In agreement with the previous reports on the surface effect of Cs, the conclusions of our previous study investigating the promoter effect on the model Ag2O(001) surface [74] were in line with the above proposals and conclusions about the Cs effect on the catalyst surface. When introduced to the Ag2O surface, Cs interacts with the surface and subsurface oxygen atoms creating CsO x type complexes. The adsorption energies of the Cs bound oxygens increase as observed previously [40, 51, 99, 101]. Compared to the non-promoted oxide surface, oxygen atoms that are not interacting with Cs show no change in their activity towards epoxidation. Previously defined direct epoxidation channel is still available. In the absence of Cl, increased oxygen vacancy concentration by Cs introduction implies that in the case of Cs only promotion the EO selectivity of the system would reduce considerably due to the increased possibility for OMC formation. This explains the reduced EO selectivity observed for Cs only promotion [103].

4 The State of the Silver Surface

The nature of the active (selective) oxygen species, therefore selectivity, is directly related to the nature of the surface and surface state, which affects the strength of the oxygen binding [7, 39]. This can be clearly seen in the studies investigating the particle shape and size [2, 10, 61]. After the active oxygen species was identified as the atomically adsorbed oxygen (more detail in [3]), further studies revealed two types of oxygen as electrophilic (Oδ+) and nucleophilic (Oδ−), present in the system [50, 86, 87, 104–106], usually considered each to be responsible for selective and/or non-selective paths [104, 106–108]. Furthermore, sub-surface oxygen was reported be necessary [3, 21, 31, 32, 41, 47, 48] for the epoxidation reaction as it increases the surface activity [109]. Although high reaction temperatures lower oxygen stability and concentration, high oxygen pressures in the reactor compensates for th.

Studies on the structure of the active Ag/O phase using experimental and theoretical methods [33, 35, 39, 77, 89, 90, 110–114] showed that, after a relatively low surface coverage of Os is achieved, oxygen diffuses into sub-surface layers [35, 39], forming surface-oxide structures through morphological changes [15, 28, 50, 75, 77, 86, 87, 89, 90, 110, 111, 115–125]. More recent studies of this type investigate the nature and the stability of these structures forming under high oxygen regimes, and the activity of oxygen in these structures. Comparisons for these structures at different, temperatures, pressures and coverage are carried out by building temperature–pressure phase diagrams, based on ab initio thermodynamics [6, 90, 112, 113]. An important finding of these studies is that under high oxygen pressure regimes, oxide like species found to be more stable compared monolayer oxygen adsorption on metallic surfaces [86, 87]. Although these studies have shown that the actual catalyst is far from a simple adsorption system, the structure of the catalyst surface under high oxygen regimes is still controversial [90, 123].

Along the surface-oxide formations on the Ag(111) surfaces, recent studies suggest formation of Ag2O (or like) oxide phase Ag(100) and similar corrugated surfaces [112, 113]. Moreover, the activity of the 2-fold in bridge positions, which are available on oxide surfaces was emphasized [92]. The surface structural studies have not resulted in a definitive description of silver-oxide over layer structures.

As it was discussed in the previous sections, the main challenge to the possible existence of the direct epoxidation mechanism is the stability of the oxide surface that supplies electrophilic oxygen without the oxygen vacancies under reaction conditions. Bulk Ag2O decomposes at the relatively high reaction temperatures (200–300 °C) the adsorbed oxygen over layer it will create oxygen vacant sites on the surface, which reduce the EO selectivity. On the other hand, the high oxygen (partial) pressure within the reactor favors the surface and the subsurface oxygen species formation and its stability.

The presence of Cs and Cl co-adsorbates on the catalyst surface was shown to have an important effect on the stability on the on-surface oxygen layer [51, 74, 96]. Figure 7 shows the equilibrium curves of surfaces and structures in equilibrium with the gas phase oxygen, as investigated in our previous studies [74]. As the figure shows, un-promoted Ag2O(001) surface is not stable under the reaction conditions, which transforms to a metallic nature [58, 73, 74] by losing the weakly bound surface oxygens. Furthermore, Cs only and Cl only promotion does not significantly alter the relative stability of the surface oxide over layer under reaction conditions. However, with the combined effect of Cs and Cl, the Ag–O bond strength increases such that a stable surface oxide layer can be achieved.

The calculated equilibrium diagram for the un-promoted and promoted Ag2O(001) surfaces. Adopted from [74]

These results give insight on the necessary state of the silver surface to give high selectivity at reaction conditions. The high EO selectivity of the industrial catalyst requires the Cs promotion in the presence of co-adsorbed Cl to stabilize the non-vacant oxidic surface over layer. Introduction of Cl into the system blocks the non-selective vacant oxygen sites generated by Cs. Cs promotion increases the temperature stability of the oxide over layer without converting surface oxygen atoms to non-selective nucleophilic oxygen.

5 Summary (Conclusion)

Silver catalyzed ethylene epoxidation has long been an interesting topic for the heterogeneous catalysis. Although it is the simplest kinetically controlled reaction [14], mechanism of this reaction is still under debate. Recent developments and contributions from the computational studies made a significant contribution in our understanding. In this paper we summarized the most recent developments in the identification of the active catalyst surface, effect of the promoters, and the reflection of these developments in the understanding of the mechanism.

It is almost clear that the active catalyst under applied conditions is not metallic silver, and more than a simple adsorption system. However, discussion continues on the state of the catalyst surface and the nature of the active oxygen species.

One major development of the last decade is the identification of the OMC intermediate and related mechanism for the competitive production of ethylene oxide (EO) and acetaldehyde (AA). Although discussions on explaining the high EO selectivity of the industrial application with OMC mechanism continues, it is the first conclusive model to explain the non-selective AA formation and the ~50 % EO selectivity of the un-promoted metallic silver.

On the other hand, our recent contributions focus on the oxidized silver surface that enables the direct epoxidation mechanism. Such a direct route enabled by the oxidized surface agrees with the previous reports on the necessity of the high oxygen coverage, electrophilic oxygen being the active species, as well as with the selective channel proceeding in an E–R manner.

We have also shown that the non-selective AA formation proceeded through OMC intermediate forming on the oxygen vacant sites. Thus, Cl and Cs promoters have an important role for the stability of the active oxygen species under high reaction temperatures as well as blocking the oxygen vacancies and inhibiting the non-selective channel.

Further developments in the computational methods would make it feasible to study the complete system including all the reactants, products, catalyst surface, support and the promoters, and their interactions and affects. Under the light of such studies the exact state of the surface and the exact mechanism can be identified. Practical applicati ons are sure to benefit from such a molecular level knowledge.

References

Ethylene Oxide (EO) (Complete Report), A Global Strategic Business Report Global Industry Analysts Inc, 2011, pp. 346

Christopher P, Linic S (2008) J Am Chem Soc 130:11264–11265

Van Santen RA, Kuipers HPCE (1987) The mechanism of ethylene epoxidation. In: Pines H, Eley DD, Weisz PB (eds), Advances in Catalysis, Academic Press, New York, pp. 265–321

SHELL, Ethylene oxide/ethylene glycol (EO/EG) processes, SHELL, 2010

Zomerdijk JC, Hall MW (1981) Catal Rev 23:163–185

Michaelides M-LBaA (2006) Exploring the catalytic activity of a noble metal: the Ag catalyzed ethylene epoxidation reaction, In: Rosei PGeWHF (ed) Physics of single molecules on crystal surfaces. Imperial College Press, London, pp. 389–424

Linic S, Barteau MA (2003) J Catal 214:200–212

Lefort ET (1935) Process for the production of ethylene oxide, Catalyse. Generalisee FR. DE. SA, United States

Voge HH, Adams CR (1967) Catalytic oxidation of olefins. In: Pines H, Eley DD, Weisz PB (eds) Advances in catalysis. Academic Press, New York, pp. 151–221

Bulushev DA, Paukshtis EA, Nogin YN, Bal’zhinimaev BS (1995) Appl Catal. A 123:301–322

Goncharova SN, Paukshtis EA, Bal’zhinimaev BS (1995) Appl Catal. A 126:67–84

Tan SA, Grant RB, Lambert RM (1987) Appl Catal 31:159–177

Kestenbaum H, Lange de Oliveira A, Schmidt W, Schüth F, Ehrfeld W, Gebauer K, Löwe H, Richter T, Lebiedz D, Untiedt I, Züchner H (2002) Ind Eng Chem Res 41:710–719

Campbell CT (1984) J Vac Sci Technol. A 2:1024–1027

Kilty PA, Sachtler WMH (1974) Catal Rev Sci Eng 10:1–16

Bryce-Smith D, BET, Griffe de Martinez B (1983) Chem Ind 18

Park DM, Ghazali S, Gau G (1983) Appl Catal 6:175–193

Force EL, Bell AT (1975) J Catal 38:440–460

Force EL, Bell AT (1975) J Catal 40:356–371

Force EL, Bell AT (1976) J Catal 44:175–182

Grant RB, Lambert RM (1985) J Catal 92:364–375

Grant RB, Lambert RM (1983) J Chem Soc, Chem Commun (12):662–663

Grant RB, Lambert RM (1984) Surf Sci 146:256–268

Campbell CT (1986) J Catal 99:28–38

Campbell CT (1985) J Catal 94:436–444

Campbell CT, Daube KA (1987) J Catal 106:301–306

Campbell CT, Koel BE (1985) J Catal 92:272–283

Rovida G, Pratesi F, Maglietta M, Ferroni E (1972) J Vac Sci Technol. A 9:796–799

Cant NW, Hall WK (1978) J Catal 52:81–94

Barteau MA, Madix RJ (1980) Surf Sci 97:101–110

Rovida G, Pratesi F, Ferroni E (1980) Appl Surf Sci 5:121–132

Backx C, Moolhuysen J, Geenen P, van Santen RA (1981) J Catal 72:364–368

Kitson M, Lambert RM (1981) Surf Sci 109:60–74

Backx C, De Groot CPM, Biloen P (1981) Surf Sci 104:300–317

Campbell CT, Paffett MT (1984) Surf Sci 143:517–535

Akella LM, Lee HH (1984) J Catal 86:465–472

Campbell CT, Paffett MT (1984) Appl Surf Sci 19:28–42

Campbell CT, Paffett MT (1984) Surf Sci 139:396–416

Campbell CT (1985) Surf Sci 157:43–60

Grant RB, Lambert RM (1985) J Catal 93:92–99

van Santen RA, de Groot CPM (1986) J Catal 98:530–539

Tan SA, Grant RB, Lambert RM (1986) J Catal 100:383–391

Grant RB, Harbach CAJ, Lambert RM, Tan SA (1987) J Chem Soc Faraday Trans 1(83):2035–2046

Tan SA, Grant RB, Lambert RM (1987) J Catal 106:54–64

Carter EA, Goddard WA (1988) J Catal 112:80–92

Dean M, Bowker M (1988) Appl Surf Sci 35:27–40

Santen RAv (1988) The active site of promoted ethylene-epoxidation catalysts In: Phillips MJ, Ternan M, (eds) Catalysis: theory to practice, Proceedings of characterization and metal catalysts, Ottawa Canada, pp 1152–1158

Van den Hoek PJ, Baerends EJ, Van Santen RA (1989) J Phys Chem 93:6469–6475

Carter EA, Goddard WA III (1989) Surf Sci 209:243–289

Su DS, Jacob T, Hansen TW, Wang D, Schlögl R, Freitag B, Kujawa S (2008) Angew Chem 120:5083–5086

Grant RB, Lambert RM (1985) Langmuir 1:29–33

van Santen RA (1997) Handbook of heterogeneous catalysis. Wiley-VCH, Weinheim

Linic S, Barteau MA (2001) J Am Chem Soc 124:310–317

Jones GS, Mavrikakis M, Barteau MA, Vohs JM (1998) J Am Chem Soc 120:3196–3204

Wu G, Stacchiola D, Kaltchev M, Tysoe WT (2000) Surf Sci 463:81–92

Linic S, Medlin JW, Barteau MA (2002) Langmuir 18:5197–5204

Stacchiola D, Wu G, Kaltchev M, Tysoe WT (2001) Surf Sci 486:9–23

Ozbek MO, Onal I, Santen RA (2012) Top Catal 55:710–717

Lukaski A, Barteau M (2009) Catal Lett 128:9–17

Torres D, Lopez N, Illas F, Lambert RM (2005) J Am Chem Soc 127:10774–10775

Christopher P, Linic S (2010) ChemCatChem 2:78–83

Kokalj A, Gava P, de Gironcoli S, Baroni S (2008) J Phys Chem C 112:1019–1027

Linic S, Barteau MA (2003) J Am Chem Soc 125:4034–4035

Linic S, Barteau MA (2008) Heterogeneous catalysis of alkene epoxidation. In: Ertl G, Knözinger H, Schüth F, Weitkamp J (eds) Handbook of heterogeneous catalysis. Wiley-VCH, Weinheim

Medlin JW, Barteau MA (2001) J Phys Chem B 105:10054–10061

Torres D, Lopez N, Illas F (2006) J Catal 243:404–409

Mavrikakis M, Doren DJ, Barteau MA (1998) J Phys Chem B 102:394–399

Nakatsuji H, Hu Z-M, Nakai H, Ikeda K (1997) Surf Sci 387:328–341

Chen H-T, Chang J-G, Ju S-P, Chen H-L (2010) J Phys Chem Lett 1:739–742

Torres D, Illas F (2006) J Phys Chem B 110:13310–13313

Özbek MO, Önal I, van Santen RA (2011) ChemCatChem 3:150–153

Ozbek MO, Onal I, van Santen RA (2011) J Catal 284:230–235

Ozbek MO, Onal I, Santen RAV (2011) J Phys Condens Matter 23:404202

Ozbek MO, Onal I, Santen RAv (2012) ChemCatChem. doi:10.1002/cctc.201200690

Bocquet ML, Michaelides A, Sautet P, King DA (2003) Phys Rev B 68:075413

Bocquet M-L, Loffreda D (2005) J Am Chem Soc 127:17207–17215

Schnadt J, Michaelides A, Knudsen J, Vang RT, Reuter K, Laegsgaard E, Scheffler M, Besenbacher F (2006) Phys Rev Lett 96:146101

Mars P, van Krevelen DW (1954) Chem Eng Sci 3:41–59

Larrabee AL, Kuczkowski RL (1978) J Catal 52:72–80

Frondelius P, Häkkinen H, Honkala K (2010) Angew Chem Int Ed 49:7913–7916

Klugherz PD, Harriott P (1971) AIChE J 17:856–866

Richey WF (1972) J Phys Chem 76:213–216

Cusumano JA (1976) Olefin oxidation process. In: U.S. Patent (ed) Exxon Research and Engineering Company, 1976

Atkins M, Couves J, Hague M, Sakakini BH, Waugh KC (2005) J Catal 235:103–113

Bowker M, Waugh KC (1983) Surf Sci 134:639–664

Nagy AJ, Mestl G, Herein D, Weinberg G, Kitzelmann E, Schlögl R (1999) J Catal 182:417–429

Savinova ER, Zemlyanov D, Pettinger B, Scheybal A, Schlögl R, Doblhofer K (2000) Electrochim Acta 46:175–183

Saravanan C, Salazar MR, Kress JD, Redondo A (2000) J Phys Chem B 104:8685–8691

Li W-X, Stampfl C, Scheffler M (2003) Phys Rev B 67:045408

Michaelides A, Reuter K, Scheffler M (2005) J Vac Sci Technol. A 23:1487–1497

Torres D, Illas F, Lambert RM (2008) J Catal 260:380–383

Wang C-B, Deo G, Wachs IE (1999) J Phys Chem B 103:5645–5656

Macleod N, Keel JM, Lambert RM (2003) Catal Lett 86:51–56

Jung K-H, Chung K-H, Kim M-Y, Kim J-H, Seo G (1999) Korean J Chem Eng 16:396–400

Mao C-F, Albert Vannice M (1995) Appl Catal. A 122:61–76

Campbell CT (1985) J Phys Chem 89:5789–5795

Kapran A, Orlik S (2005) Theor Exp Chem 41:377–381

Ayame A, Uchida Y, Ono H, Miyamoto M, Sato T, Hayasaka H (2003) Appl Catal. A 244:59–70

Amorim de Carvalho MCN, Passos FB, Schmal M (2007) J Catal 248:124–129

Bukhtiyarov VI, Prosvirin IP, Kvon RI, Bal’zhinimaev BS, Podgornov EA (1997) Appl Surf Sci 115:135–143

Wang J, Ellis PD (1991) J Am Chem Soc 113:9675–9676

Linic S, Barteau MA (2004) J Am Chem Soc 126:8086–8087

Santen RAv (1988) Catalysis: theory to practice; Characterization and metal catalysts, Ottawa, Canada. Proceedings 3:7.

Bukhtiyarov VI, Hävecker M, Kaichev VV, Knop-Gericke A, Mayer RW, Schlögl R (2001) Catal Lett 74:121–125

Bukhtiyarov VI, Hävecker M, Kaichev VV, Knop-Gericke A, Mayer RW, Schlögl R (2003) Phys Rev B 67:235422

Kaichev VV, Bukhtiyarov VI, Hävecker M, Knop-Gercke A, Mayer RW, Schlögl R (2003) Kinet Catal 44:432–440

Bukhtiyarov VI, Boronin AI, Savchenko VI (1990) Surf Sci 232:L205–L209

Bal’zhinimaev BS, Sadovskaya EM, Suknev AP (2009) Chem Eng J (Lausanne) 154:2–8

Xu Y, Greeley J, Mavrikakis M (2005) J Am Chem Soc 127:12823–12827

Li W-X, Stampfl C, Scheffler M (2002) Phys Rev B 65:075407

Schmid M, Reicho A, Stierle A, Costina I, Klikovits J, Kostelnik P, Dubay O, Kresse G, Gustafson J, Lundgren E, Andersen JN, Dosch H, Varga P (2006) Phys Rev Lett 96:146102

Gajdos M, Eichler A, Hafner J (2003) Surf Sci 531:272–286

Buatier de Mongeot F, Cupolillo A, Rocca M, Valbusa U (1999) Chem Phys Lett 302:302–306

Goddard PJ, Lambert RM (1981) Surf Sci 107:519–532

Michaelides A, Bocquet ML, Sautet P, Alavi A, King DA (2003) Chem Phys Lett 367:344–350

Reuter K, Scheffler M (2001) Phys Rev B 65:035406

Reuter K, Scheffler M (2004) Appl Phys A 78:793–798

Bocquet M-L, Michaelides A, Loffreda D, Sautet P, Alavi A, King DA (2003) J Am Chem Soc 125:5620–5621

Bocquet M-L, Sautet P, Cerda J, Carlisle CI, Webb MJ, King DA (2003) J Am Chem Soc 125:3119–3125

Carlisle CI, King DA, Bocquet ML, Cerd J, Sautet P (2000) Phys Rev Lett 84:3899

Schnadt J, Knudsen J, Hu XL, Michaelides A, Vang RT, Reuter K, Li Z, Laegsgaard E, Scheffler M, Besenbacher F (2009) Phys Rev B 80:075424

Gao W, Zhao M, Jiang Q (2007) J Phys Chem C 111:4042–4046

Carlisle CI, Fujimoto T, Sim WS, King DA (2000) Surf Sci 470:15–31

Bare SR, Griffiths K, Lennard WN, Tang HT (1995) Surf Sci 342:185–198

Li W-X, Stampfl C, Scheffler M (2003) Phys Rev B 68:165412

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Özbek, M.O., van Santen, R.A. The Mechanism of Ethylene Epoxidation Catalysis. Catal Lett 143, 131–141 (2013). https://doi.org/10.1007/s10562-012-0957-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-012-0957-3