Abstract

Transglucosidase from Aspergillus niger was immobilized onto Amberzyme oxirane beads and was used for the production of Isomaltooligosaccharides (IMOs) including panose from maltose. The optimum immobilization parameters and, the stability and activity of the immobilized enzyme were determined. Immobilization resulted in 83–85 % immobilization efficiency. The optimum immobilization conditions were 400 mg of Amberzyme oxirane beads with 20 U of transglucosidase at pH 7.5 for 48 h at 25 °C with agitation at 150 rpm. Both immobilized and free enzyme had maximum activity at pH 4 and 60 °C. The results obtained in this study could be used for production of IMOs from maltose with the repeated use of the immobilized enzyme.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Oligosaccharides are relatively new food ingredients that are drawing interest, because of their potential to improve the quality and nutritional properties of food [1]. A substantial amount of research has been carried out in recent years to understand the fate of oligosaccharides in mammalian metabolic process [2–4]. Isomaltooligosaccharides (IMOs) contain two to five glucose units with one or more α-1-6 linkages. IMOs are gaining interest in the food industry due to their bifidus-stimulating activity [5], low caloric value [6] and low cariogenic properties [7]. Moreover, IMOs are gaining significance due to their high stability in acidic medium, relatively low price and availability of sources [8]. Panose is one such IMO which is non-fermentable by many oral bacteria and has potential use as an anticariogenic sweetener [9]. IMOs with two to six degrees of polymerization are produced from corn starch by a series of reactions with α-amylase, β-amylase and transglucosidase [10]. In the presence of maltose α-transglucosidase from Aspergillus niger catalyzes transglucosylation to the 6-OH of the accepting glucose unit resulting in new 1-6-oligosaccharides including isomaltose, panose and isomaltotriose [1, 11, 12]. However, as the cost of pure transglucosidase is high, it would be very cost effective to be able to reuse the enzyme in several reaction cycles. Immobilizing the enzyme helps achieve this as the recovery of the enzyme in the immobilized form can be far easier than in its free form.

In the recent years immobilized enzymes have been used in the food, pharmaceutical and other biologically important product industries which involve bioreactors and biosensors [13–15]. Enzyme immobilization has become an active research area due to the many benefits associated with immobilized enzyme over the free form of enzyme [16–18]. Various immobilization techniques have been reported in the literature which includes adsorption on to insoluble matrix, entrapment in hydrogels, cross-linking with a bifunctional reagent, immobilization on to magnetic polymer, and immobilization on to insoluble polymer via covalent attachment [13, 19–21]. Immobilization of an enzyme to an insoluble solid surface has several benefits including increased stability, reuse of the enzyme and less contamination of the product with the enzyme. Another advantage of immobilized enzymes over free enzymes is the ability to be used in a continuous processing system [22]. Also, the stability of the immobilized enzyme can be considerably improved by altering the operational conditions [23]. Taking all the above into consideration, immobilization of transglucosidase can render it all the above benefits over the free enzyme. Thus, Amberzyme oxirane beads were selected as a suitable solid support for the immobilization of transglucosidase. Amberzyme oxirane resin/bead is a commercially available resin which allows the covalent attachment of the enzyme to the resin through an oxirane functional group [24]. Figure 1 illustrates the covalent attachment between the polymer bead and the enzyme.

Free enzyme being attached to polymer bead via covalent linkage. The Amberzyme oxirane enzyme immobilization support contains an oxirane functional group which is attacked by the nucleophilic amino groups of the enzyme forming a covalent bond between the bead and the enzyme [24]

Immobilization of transglucosidase into biomimetic polymer–inorganic hybrid capsules for the production of IMOs has been reported in the literature [1]. However, our approach of immobilization was different from this as we focused on covalently attaching the enzyme to a solid support. It was hypothesized that the enzyme transglucosidase can be covalently immobilized to Amberzyme beads. The current research was carried out to develop a novel method for immobilization of transglucosidase for the production of IMO from maltose, optimize the conditions of immobilization, and characterize the immobilized enzyme compared to the free enzyme.

2 Materials and Methods

2.1 Materials

Amberzyme oxirane enzyme immobilization polymeric support (Rohm and Haas Company, USA) (here after referred to as Amberzyme beads) was used as the matrix for immobilization. The enzyme transglucosidase (EC 3.2.1.20) from Aspergillus niger (1,000 U/mL) was obtained from Megazyme (Wicklow, Ireland). Maltose was obtained from Sigma-Aldrich. All other reagents were of analytical grade and were used without further purification.

2.2 Methods

2.2.1 Immobilization Procedure

Enzyme immobilization was carried out according to the method described in Amberzyme oxirane enzyme immobilization polymeric support product data sheet with some modifications [24]. Immobilization of transglucosidase (20 U) was carried out in a beaker by reacting with Amberzyme beads (400 mg) with potassium phosphate buffer (10 mL, 1 M, pH 7.5) at 25 °C with shaking (150 rpm) for 48 h. The enzyme immobilized Amberzyme beads were filtered and washed with deionized distilled water (50 mL, pH 6) on a sintered glass filter. The immobilized enzyme obtained was stored in refrigerator with potassium phosphate buffer (10 mL, 1 M, pH 7.5) at 4 °C. It was washed with distilled water (pH 6) before use in reactions.

2.2.2 Optimization of Immobilization Conditions

Optimum immobilization conditions were determined by individually varying the conditions: buffer pH from 4.5 to 8.5; buffer concentration from 0.2 to 1.2 M; amount of Amberzyme from 200 to 1,200 mg; coupling time from 24 to 120 h. During optimization the parameters not being tested were kept constant at conditions stated above in immobilization procedure.

2.2.3 Determination of Activity

Maltose (10 mL, 10 % w/v) in sodium acetate buffer (25 mM, pH 5.4) was reacted with free (20 U) or immobilized enzyme at 40 °C for three hours in a water bath with continuous shaking at 150 rpm. Then the reaction was terminated by adding 50 μL of the reaction mixture to 4,950 μL of distilled water and boiling for 10 min. The resulting reaction mixture was analyzed using high performance anion exchange chromatography with pulsed amperometric detection (Dionex, Sunnyvale, CA) and a CarboPac PA-100 column. The flow rate was 1.0 mL/min with a gradient of eluent A (100 mM sodium hydroxide) and eluent B (100 mM sodium hydroxide and 300 mM sodium nitrate). The gradient rates were as follows: 0–5 min, 99 % A and 1 % B; then 5–30 min a linear gradient to 8 % B [25]. The final reaction mixture included glucose, isomaltotriose, isomaltose, maltose and panose. Panose was the main product of the reaction. The amount of panose produced was used to quantify the reaction.

2.2.4 Determination of Optimum Temperature, pH and Kinetic Parameters

Activity assay conditions were changed individually to determine the Michaelis constant (K m), maximum reaction velocity (V max), optimum temperature and pH. Temperature was changed from 30 to 80 °C and pH from 3.0 to 8.0. (3–5: 25 mM sodium acetate buffer, 6–8: 25 mM imidazole buffer). Initial velocities of kinetic parameters were determined by carrying out the reaction for eight minutes with varying maltose concentrations using 20 U of immobilized and free enzyme (assuming 400 mg of enzyme immobilized Amberzyme beads contain 20 U of enzyme). The reaction was stopped by adding NaOH (4 M). The kinetic data was fitted to the Michaelis–Menten equation and Lineweaver–Burk plot was constructed. K m and V max values for free and immobilized enzyme were calculated from the plot.

2.2.5 pH Stability of the Enzyme

Free and immobilized enzyme was incubated in different buffers with pH ranging from 3.0 to 8.0. (3–5: 25 mM sodium acetate buffer, 6 to 8: 25 mM imidazole buffer). Incubation was carried out for 1 h at 40 °C with continuous shaking at 150 rpm. Then the remaining enzyme activity of the free and immobilized enzyme was measured.

2.2.6 Thermal Stability of the Enzyme

The free and immobilized enzyme was incubated at different temperatures (30–80 °C) in sodium acetate buffer (25 mM, pH 5.4) for 1 h with continuous shaking at 150 rpm. Then the remaining enzyme activity of the free and immobilized enzyme was measured.

2.2.7 Operational and Storage Stability of Immobilized Enzyme

After measuring the enzyme activity of the immobilized enzyme (20 U) with maltose (10 mL, 10 % w/v) for 3 h at 40 °C in a water bath with continuous shaking at 150 rpm, the amount of panose produced in reaction mixture was measured. The immobilized enzyme was washed with distilled water (pH 6) and stored in sodium acetate buffer (25 mM, pH 5.4) in refrigerator (4 °C). The same immobilized enzyme was used repeatedly in 10 activity assay cycles, washing with distilled water (pH 6) after each cycle. The 10 activity assay reaction cycles were carried out over a period of 30 days. The amount of panose produced was determined after each cycle.

2.3 Statistical Analysis

All the experiments were done in duplicates or in triplicates. A least significant difference (LSD) with a 5 % significance level was used to declare differences. All statistics was performed using the Statistical Analysis System Software 9.1 (SAS Institute, Cary, NC).

3 Results and Discussion

3.1 Optimization of Immobilization Procedure

3.1.1 Effect of Immobilization Buffer pH on Immobilization Efficiency

The optimum conditions for immobilization were determined by comparing the immobilization efficiency percentage of panose produced under each condition. The immobilization efficiency percentage was defined as the percentage ratio between the amounts of panose produced by the immobilized enzyme to the amount of panose produced by the free enzyme, under the same conditions. Table 1 gives the immobilization efficiencies for reactions at different pH. There was no significant difference between reactions at pH 4.5, 6.5, 7.5 and 8.5. However pH 7.5 was closest to the pH specified for immobilization of enzymes by the manufactures of Amberzyme beads [24]. Thus, this pH was selected as the optimum pH for the reaction.

3.1.2 Effect of Immobilization Buffer Concentration

The effect of buffer concentration was evaluated by varying the molar strength of the immobilization buffer. There was no significant difference in immobilization efficiency between different molarities of the immobilization buffer used in the range of 0.2–1.2 M. However nucleophiles such as ammonium ions in the enzyme preparation can also affect the immobilization efficiency [26]. For the purpose of this research, the 1 M potassium phosphate buffer concentration was chosen as the optimum conditions. The results obtained are summarized in Table 2.

3.1.3 Effect of Amount of Amberzyme Beads

The immobilization was carried out using 200–1,200 mg Amberzyme beads. The optimal immobilization efficiency was obtained with 400 mg of Amberzyme beads (Table 3). As the amount of Amberzyme beads increased, the immobilization efficiency decreased. This may be due to the reaction of epoxy groups on the Amberzyme beads with the active site of the enzyme and/or reaction with groups of enzyme responsible for maintaining the tertiary structure of the enzyme. Either of these reactions will affect the activity of the enzyme and lead to reduced immobilization efficiency [27]. Similar results were seen by Martin et al. [26] with the immobilization of cyclodextrin glucosyltransferase onto Eupergit C. However they have further concluded that as the amount of solid support increases, the amount of enzyme attached increases, but the activity of the enzyme decreases. They suggested this to be a result of changed conformation and also diffusional restrictions of the substrate to reach the active site of the enzyme [26].

3.1.4 Effect of Coupling Duration

The duration allowed for coupling of the enzyme to the support to occur also affects the immobilization process [28]. The results obtained for different coupling times are given in Table 4. There was no significant difference between the 24–96 h of coupling time. 120 h of coupling time gave the highest immobilization efficiency; however it was not significantly higher than 24, 48 or 72 h. Thus, the 48 h of coupling time was selected as the optimum time for coupling for this experiment.

3.2 Characterization of Immobilized Enzyme

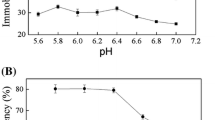

The immobilized enzyme was characterized based on the relative activity of the enzyme. The percent relative activity of the enzyme was determined as the percentage ratio of the enzyme activity to the highest enzyme activity within the same experiment series. The effect of pH on the free and immobilized enzyme was evaluated and both the free and immobilized enzyme showed an optimum pH of 4.0. However the immobilized enzyme had a better application range over the pH range of 5.0–8.0 than the free enzyme. The immobilized enzyme showed above 90 % of its maximum activity in the range of pH 4–6. Overall, it can be implied that the immobilization has stabilized the enzyme for an improved retained activity from pH 4–8. The results obtained are shown in Fig. 2.

The effect of temperature on the free and immobilized enzyme was also investigated. The results are shown in Fig. 3. The optimum activity was determined to be 60 °C for both free and immobilized enzyme. The immobilized enzyme retained 80 % or more of its maximum activity over the temperature range of 30–50 °C. However, both the free and immobilized enzyme followed similar paths of retained activity over the temperature range of 30–80 °C. Also, the immobilized enzyme had better stability over the free enzyme at both lower (30–50 °C) and higher (70–80 °C) temperatures. The improved pH and thermal stability of the immobilized enzyme indicates its potential in commercial applications for the production of IMO.

Kinetic parameters of the free and immobilized enzyme were also determined using Lineweaver–Burk plot. The K m values for free and immobilized enzyme were 52 and 65 mM maltose respectively. The V max values for free and immobilized enzyme were 19.9 and 12.7 mM panose/min/20 U of enzyme, respectively. The K m value for the immobilized enzyme was increased by about 1.2-fold compared to the free enzyme. This implies a decrease in the affinity of the enzyme towards the substrate upon immobilization to Amberzyme beads via covalent attachment [13]. The V max of the immobilized enzyme was decreased by about 1.5-fold compared to the free enzyme. When an enzyme is immobilized, the change in its kinetic parameters with respect to its free form implies that the immobilized enzyme has altered affinity towards the substrate. Also, changes in kinetic parameters indicate that the reaction rate is changed upon using immobilized enzyme. These changes can be attributed to factors such as protein conformational changes induced by the support, steric hindrances and diffusional effects which might act independently or collectively to change the microenvironment around the immobilized enzyme [13]. From the kinetic data the immobilization efficiency factor, the ratio of the V max of the immobilized enzyme over V max of the free enzyme was calculated. Thus efficiency factor of the immobilized enzyme was 0.63. This value was lower than the immobilization efficiency values of the experiment. Catalytic efficiency, which is the ratio of V max over K m was calculated to be 0.38 min−1 for the free enzyme and 0.20 min−1 for the immobilized enzyme. This implies that the catalytic efficiency of the enzyme decreases about twofold upon immobilization.

3.2.1 pH Stability of the Enzyme

The pH stability of the immobilized enzyme was compared with that of the free enzyme. The immobilized enzyme was shown to be more stable than the free enzyme over the same pH range. The results obtained are shown in Fig. 4. The free and immobilized enzyme retained above 50 % of each of its maximum activity over the pH range of 3–8.

3.2.2 Thermal Stability of the Enzyme

The immobilized enzyme was shown to be more stable than the free enzyme at 30, 60 and 70 °C. At 60 °C the immobilized enzyme showed 96 % of maximum activity while the free enzyme only showed 78 % of its maximum activity. However the immobilized enzyme retained some activity even at 70 °C, while the free enzyme showed no activity at 70 or 80 °C. This implies that immobilization provides stability to the enzyme over a wide range of reaction temperatures. The immobilized enzyme showed 11 % of its maximum activity at 70 °C with no activity at 80 °C. This may be due to the presence of maltose substrate which was present at the time of incubation. The presence of substrate also helps to stabilize the enzyme [29]. The results obtained for thermal stability of free and immobilized enzyme are shown in Fig. 5.

3.3 Operational and Storage Stability of Immobilized Enzyme

Operational and storage stability of the enzyme is vital, especially in an industrial aspect. The stability of the immobilized enzyme was determined by repeatedly using the immobilized enzyme in 10 reaction cycles and measuring its activity. The enzyme was shown to give immobilization efficiency in the range of 60–90 % (Fig. 6) through the 10 reaction cycles. Considering all the above results it is clear that the immobilization has stabilizes the enzyme as expected for any immobilized enzyme. Also, the immobilized enzyme was able to display >50 % immobilization efficiency over the repeated use in 10 reaction cycles. At the end of 10 reaction cycles, the immobilized enzyme only lost <25 % of its original activity. Considering the cost of the enzyme, it is highly economical to use this immobilized enzyme which can be used in repeated reaction cycles to produce IMOs from maltose.

4 Conclusion

In conclusion it can be assumed that immobilized transglucosidase is covalently bound to the Amberzyme beads. The method is an efficient novel method for production of panose from maltose with the repeated use of enzyme without drastic loss of catalytic activity of the enzyme. The immobilization improves the pH and thermal stability of the enzyme over the free enzyme and it has improved activity over free enzyme at different temperatures and pH. In general, continuous reactions of immobilized enzymes should be carried out in temperatures above 55 °C to avoid microbial growth [30]. Thus, transglucosidase immobilized according to the procedures in this paper can be a feasible industrial application since the immobilized enzyme shows optimal activity above 55 °C and has 96 % of activity retained at 60 °C. Moreover the immobilized transglucosidase is a suitable method for production of IMOs from maltose and can be considered a potential approach for commercial production of IMOs including panose. As maltose is a readily available substrate and is relatively cheap, it is a good source to produce IMOs. Further purification of panose from the resulting mixture is possible. Panose is gaining interest due to its beneficial health effects. The market for panose is already growing and more cost effective means of producing it will surely benefit the industry. Due to the low cost of the overall process, the immobilized transglucosidase has potential to be used in a continuous reaction column for the production of IMOs.

References

Zhang L, Jiang Y, Jiang Z, Sun X, Shi J, Cheng W, Sun Q (2009) Biochem Eng J 46:186

Yamase H, Zhao L, Liu HW (2000) J Am Chem Soc 122:12397

Dube DH, Bertozzi CR (2003) Curr Opin Chem Biol 7:616

Campbell CT, Sampathkumar SG, Yarema KJ (2007) Mol Biol Syst 3:187

Thitaram SN, Chung CH, Day DF, Hinton A, Bailey JS, Siragusa GR (2005) Poult Sci 84:998

Mussatto SI, Mancilha IM (2007) Carbohydr Polym 68:587

Koga T, Horikoshi T, Fujiwara T, Hamada S (1988) Microbiol Immunol 32:25

Sheu DC, Huang CI, Duan KJ (1997) Biotechnol Tech 11:287–291

Miyake T, Yoshida M, Takeuchi K. (1985) US Patent 4,518,581

Crittenden RG, Playne MJ (1996) Trends Food Sci Technol 7:353

Pazur JH, Tominaga Y, DeBrosse CW, Jackman LM (1978) Carbohydr Res 61:279

Pazur JH, French D (1982) J Biol Chem 196:265

Bayramoglu G, Tunali Y, Arica MY (2007) Catal Commun 8:1094

Scheller F, Renneberg R (1983) Anal Chim Acta 152:265

Bayramoglu G, Akgol S, Bulut A, Denizli A, Arica MY (2003) Biochem Eng J 14:117

Bayramoglu G, Yilmaz M, Arica MY (2004) Food Chem 84:591

Betancor L, Fuentes M, Dellamora-Ortiz G, Lopez-Gallego F, Hidalgo A, Alonso-Morales N, Mateo C, Guisan JM, Fernandez-Lafuente R (2005) J Mol Catal B Enzym 32:97

Kang K, Kan C, Yeung A, Liu D (2006) Mater Sci Eng C 26:664

Amaya-Delgado L, Hidalgo-Lara ME, Montes-Horcasitas MC (2006) Food Chem 99:299

Deng HT, Xu ZK, Liu ZM, Wu J, Ye P (2004) Enzym Microb Technol 35:437

Sanjay G, Sugunan S (2005) Catal Commun 6:525

Carpio C, Batista-Viera F, Ruales J (2011) Food Bioprocess Technol 4:1186

Carpio C, Escobar F, Batista-Viera F, Ruales J (2011) Food Bioprocess Technol 4:566

Amberzyme Oxirane Enzyme Immobilization Polymeric Support (2005) Rohm and Haas Company (online source)

Ao Z, Simsek S, Zhang G, Venkatachalam M, Reuhs BL, Hamaker BR (2007) J Agric Food Chem 55:4540

Martin MT, Plou FJ, Alcalde M, Ballesteros A (2003) J Mol Catal B Enzym 21:299

Katchalski-Katzir E, Kraemer DM (2000) J Mol Catal B Enzym 10:157

Boller T, Meier C, Menzler S (2002) Org Process Res Dev 6:509

Lejeune A, Vanhove M, Lamotte-Brasseur J, Pain RH, Frere JM, Matagne A (2001) Chem Biol 8:831

Kuriki T, Tsuda M, Imanaka T (1992) J Ferment Bioeng 73:198

Acknowledgments

We would like to thank Kristin Whitney and Dr. Steven Meinhardt for technical support and valuable input. This research (in part) was supported by National Science Foundation Grant # HRD-0811239 to the NDSU Advance FORWARD program and North Dakota State University Agricultural Experiment Station.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mendis, M., Mendoza, B.R. & Simsek, S. Covalent Immobilization of Transglucosidase onto Polymer Beads for Production of Isomaltooligosaccharides. Catal Lett 142, 1107–1113 (2012). https://doi.org/10.1007/s10562-012-0866-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-012-0866-5