Abstract

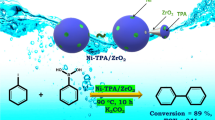

Supported 12-tungstophosphoricacid (12-TPA) and 12-tunstosilicicacid (12-TSA) were used as heterogeneous catalysts for liquid-phase tert-butylation of m-cresol, an industrial important reaction. Alkylation reactions have been carried out with supported 12-TPA by varying different parameters such as % loading of 12-tungstophosphoricacid onto support, mole ratio of alcohol to m-cresol, reaction temperature, amount of the catalyst, reaction time and calcination temperature to optimize the conditions. To see the effect of the acidity on the reaction, the same reaction was studied over supported 12-TSA. Both the catalysts give 100% selectivity for o-isomer with different % conversion. The difference in catalyst performance of both the catalyst was correlated with the value of total acidity as well as Bronsted acidity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In recent years, supported HPAs have been gaining importance as alkylating and acylating catalyst [1–5] as they posses a number of advantages such as high catalytic activity and selectivity, possibility of their repeated use, easy separation from reaction mixture, high surface area, high thermal stability as well as easy disposal of used catalyst, make them economically and environmentally attractive.

Tert-butylation, especially of phenol, is an important industrial reaction as the obtained tert-butylated phenols can be used directly or as intermediates for the synthesis of antioxidants, antiseptics, agrochemicals, resins, UV absorbers and stabilizers for the polymers [6–8]. An extensive research has been carried out on the tert-butylation of phenols over zeolites [9–12], hydrotalcites [12,13], clays [13–15], metal substituted mesoporous silicates [16–19], heteropolyaicds [20–22], the same is very scanty for the tert-butylation of m-cresol [23,24]. Tert-butylation of m-cresol is also a typical Friedel–Crafts reaction which is end up with different products such as 2-tert-butyl 5-methyl phenol (o-isomer), 4-tert-butyl 5-methyl phenol (o-isomer) and ether. These products are the precursors for a number of commercially important antioxidants and light protection agents.

Among supported heteropolyacids, 12-TPA has been widely studied [15,25–30] as it is most stable and strongest acid in the series. Literature survey shows that not much work has been reported on 12-TSA, the next acidic [29,31] and stable [31,32] HPA in the keggin series. Our group is also working on supported heteropolyacids since last 8 years. We have carried out acid catalyzed reactions such as esterification and cyclohexylation of phenol using supported 12-TPA [33–35] and 12-TSA [36–38]. Hence, the obtained results are very promising, it was thought of interest to carry out tert-butylation of m-cresol on which not much study have been carried out using supported HPAs [23,24].

As % conversion of reactant and % selectivity of obtained product depends highly on the acidity-basisity of the employed catalyst in the reaction, it is also interesting to study the effect of acidity of the catalyst systems. In the present work, two different HPAs have been used, 12-TPA and 12-TSA supported onto hydrous zirconia (ZrO2), to study the effect of the acidity.

In the present contribution we are reporting the results of TPA and TSA supported onto ZrO2 for the liquid phase tert-butylation of m-cresol. Alkylation of m-cresol with tert-butyl alcohol was carried out by varying different parameters such as % loading of 12-TPA onto support, temperature, time, mole ratio of m-cresol to alcohol and amount of the catalyst to optimize the conditions. Calcined samples ere also evaluated for the reaction. Tert-butylation of the m-cresol using 12-TSA has been carried out under the optimized conditions. Based on the comparison study, the best catalyst among two has been proposed.

Experimental

Materials

All chemicals used were of A.R. grade. H3PW12O40· n H2O, H4SiW12O40· n H2O (Lobachemie, Mumbai), ZrOCl2 · 8 H2O (SD Fine chemicals, Mumbai) were used as received. m-Cresol and tert-butyl alcohol, was obtained from Merck and used as received.

Synthesis and characterization of the catalyst

Synthesis of the support, ZrO2

Hydrous zirconia was prepared by adding an aqueous ammonia solution to an aqueous solution of ZrOCl2 · 8 H2O up to pH 8.5. The precipitates were aged at 100 °C over a water bath for 1 h, filtered, washed with conductivity water until chloride free water was obtained and dried at 100 °C for 10 h. The obtained material is designated as ZrO2.

Supporting of 12-TPA and 12-TSA onto ZrO2

12-TPA was supported on ZrO2 by impregnation method. One gram of ZrO2 was impregnated with an aqueous solution of 12-TPA (0.2 g/ 20 mL of conductivity water) at 100 °C with stirring for 10 h. Material thus obtained was designated as 12-TPA2/ZrO2. Same process was followed for the synthesis of catalyst having 30 and 40% loading of 12-TPA onto ZrO2. The obtained material was designated as 12-TPA3/ZrO2 and 12-TPA4/ZrO2 respectively. The calcination of the best catalyst, 12-TPA3/ZrO2 was carried out at 300, 400 and 500 °C in air for 5 h and designated as 12-TPA33/ZrO2, 12-TPA34/ZrO2 and 12-TPA35/ZrO2 respectively.

Catalyst with 30% loading of 12-TSA has been synthesized by following same method. The synthesized catalyst was designated as 12-TSA3/ZrO2. All the catalysts were well characterized by us earlier [33,35–37].

Ion exchange capacity

Ion exchange capacity was determined by column method using the following formula:

Surface area measurement

Adsorption–desorption isotherms of samples were recorded on a Micromeritics ASAP 2010 Surface area analyser at −196 °C. From the adsorption desorption isotherms specific surface area was calculated using BET method. The samples were degassed under vacuum (5 _ 10–3 mmHg) at 120 °C for 4 h, prior to measurement, to evacuate the physiosorbed moisture.

Acidity measurement

The chemisorptions of ammonia gas (pure) on the surface of the sample was carried out using Micromerities Pulse Chemisorb-2705. The samples, prepared by heating at predetermined temperature (300 °C) were kept in a U-shaped quartz tube and the tube was placed in a split furnace. The sample was first heated in situ at 300 °C in flowing of argon (99.95%) for 2 h to remove the moisture which might have adsorbed during the transfer of sample at various stages. The chemisorptions of pure ammonia on the preheated sample was carried out at 120 °C by repeatedly injecting the pulse of pure ammonia gas onto the sample till the saturation was observed. The amount of ammonia chemisorbed on the sample in every pulse was shown by thermal conductivity detector (TCD) in the form of integrated area of the ammonia peak. From the peak areas, the acidity in terms of mmoles of ammonia chemisorbed per gram of sample was calculated. The temperature 120 °C was selected for adsorption studies to avoid physical adsorption of ammonia.

Catalytic reaction

Tert- butylation of m-cresol

The alkylation reaction was carried out in a 50 mL glass batch reactor provided with a double walled air condenser, magnetic starrier and a guard tube. tert-butyl alcohol (t-BA) to m-cresol was taken in 1:10 (0.95 mL: 10.5 mL) ratio and catalyst was added in the required amount. The resultant mixture was heated at 80 ° C on magnetic stirrer for 1 h. Same reaction was carried out by varying temperature, % loading of the 12-TPA onto ZrO2, t-BA to m-cresol mole ratio, amount of the catalyst and reaction time. Products formed after completion of reactions were analyzed on Gas Chromatograph using SE-30 column and product identification was done by a combined Gas Chromatography–Mass Spectrometry.

Results and discussion

The main characterization of the support as well as catalysts like ion exchange capacity, surface area measurement and total acidity (obtained from temperature program desorption of NH3) are presented in table 1.

Tert-butylation of m-cresol

Alkylation of m-cresol with tert-butyl alcohol is a typical Friedel–Crafts reaction and results in a mixture of three different products: 2-tert-butyl m-cresol (o-isomer), 4- tert-butyl m-cresol (p-isomer) and 2,4-di tert-butyl m-cresol (o,p di-isomer) as shown in scheme 1.

According to the value of total acidity (0.64), ZrO2 should be active for tert-butylation, but the reaction carried out over support shows that the support is inactive for the tert-butylation of m-cresol. This controversy can be explained by considering the fact that alkylation reaction required strong acidity, while the acidity of ZrO2 must not be strong enough to catalyze the reaction. In other words the acidity of ZrO2 contributes to the weak acidic sites. Thus the active species which is responsible for the reaction is HPAs only.

Optimization of parameters

Effect of temperature

Tert-butylation of m-cresol was carried out at mole ratio of tert-butyl alcohol to m-cresol in 1:10, with 0.5 g of 12-TPA3/ZrO2 for 6 h at two temperature; ambient temperature and 80 °C. At ambient temperature, the % conversion is found to be zero where as at 80 °C temperature, the % conversion of tert-butyl alcohol is found to the 96%.

Effect of % loading of 12-TPA onto ZrO2

The tert-butylation of m-cresol was carried out over 12-TPA2/ZrO2, 12-TPA3/ZrO2 and 12-TPA4/ZrO2. The conditions were: mole ratio of tert-butyl alcohol to m-cresol is 1:10, temperature 80 °C and reaction time 6 h, amount of the catalyst is 0.5 g. Results of the experiment are shown in figure 1.

It is seen from the figure that the % conversion is increases on increases the % loading of 12-TPA form 20 to 30% on to ZrO2. Even though the surface area of 12-TPA2/ZrO2 is greater than 12-TPA2/ZrO3, it gives less % conversion as compared to that of 12-TPA2/ZrO3. This may be explained on the bases of the acid strength of both the catalysts. As seen from the table 1, the total acidity as well as Ion exchange capacity (Measurement of Bronsted acidity) for 12-TPA2/ZrO3 is more than that of 12-TPA2/ZrO2.

Further, on increasing the % loading form 30 to 40, the % conversion is observed to be increase but not that much appreciable. From table 1, it is seen that the surface area is decreases form 12-TPA3/ZrO2 to 12-TPA4/ZrO2 and hence the catalytic activity should decreases. But obtained results again show controversy and can be correlated with the total acidity as well as ion exchange capacity value. As there is not much difference in the value of total acidity as well as ion exchange capacity, not appreciable change in activity is expected. The obtained results are in good agreement with the same.

As the 30% loading of 12-TPA onto ZrO2 shows better activity, detail study was carried out over 12-TPA3/ZrO2.

Effect of mole ratio of tert-butyl alcohol to m-cresol

The reaction was carried out by varying mole ratio of tert butyl alcohol to m-cresol with 0.5 g of the 12-TPA3/ZrO2 for 6 h at 80 °C and the obtained results are shown in table 2. It is seen from the table that with increase the concentration of tert-butyl alcohol, there is drastic change in the % conversion with change in % selectivity of the products. The decrease in % conversion may be due to the steric hindrance of tert-butyl alcohol. It is known that the alkylating molecules compete with the reactant (m-cresol) to adsorb on the adsorption sites. On increasing tert-butyl alcohol in the reaction mixture, majority of the adsorption sites of the catalyst surface are occupied by bulky tert-butyl alcohol molecules. Hence fewer sites remain available for the reactant (m-cresol). As the alkylating agent and reactant can not come closer enough, reaction will not be takes place.

It is seen from the table that, 100% selectivity is obtained at the 1:10 mole ratio of tert butyl alcohol to m-cresol. As in case of m-cresol, the 2nd position (o-isomer) and 4th position (p-isomer) is not favourable for the substitution because of the bulk of the tert-butyl molecule as well as because of the electronic repulsion. In this case, substitution will take place on 6th position (o-isomer) only as seen from the scheme 1. Hence the results obtained for 1:10 mole ratio of alcohol to m-cresol are as expected.

As with the increases in the mole ratio, other products have also been formed. This is because of the higher concentration of the alkylating agent in the reaction medium. Because of the higher concentration of the tert-butyl alcohol, more tert-butyl alcohol cation is available for reaction with m-cresol which results in the p-isomer as well as o,p di-isomer. The maximum % conversion to tert-butyl m-cresol is 96% and the products selectivity to o-isomer is 100% was observed at a mole ratio of 1:10 with 0.25 g of the catalyst.

Effect of amount of the catalyst

To study the effect of amount of the catalyst on % conversion and % selectivity, reaction was carried out using different amount of the catalyst with mole ratio of alcohol to m-cresol, 1:10 for 6 h at 80 °C. The % conversion and % selectivity of different products is reported in figure 2.

It is proved that the activity increases with an increase in the amount of the supported heteropolyaicds. In the present study, with increases in the amount of the catalyst, there is also increase in the % conversion, with same % selectivity of the products. The obtained results are in good agreement with the earlier reported [39,40]. A total of 96% conversion and 100% selectivity for o-isomer was found at a mole ratio of 1:10 with 0.25 g catalyst at 80 °C.

Effect of reaction time

Tert-butylation of m-cresol was carried out at different reaction time at a mole ratio of 1:10 using 0.25 g catalyst. The results are presented in figure 3.

It is seen from the figure that with increase in reaction time, the % conversion also increases. In beginning, the conversion of tert-butyl alcohol is fast, but after 6 h, it become in equilibrium. This is because of the fact that as tert-butyl alcohol molecules consume in the reaction, less molecules are left in the reaction medium and more time is required to get adsorb on to the support surface. It is also seen from the figure that the catalyst give same % conversion and % selectivity after 10 h also. This indicates that the catalyst is stable and can be use for 10 h without any loss of activity.

The optimum conditions for maximum conversion of tert-butyl alcohol and maximum % selectivity towards 2-tert-butyl m-cresol (o-isomer) with 12-TPA3/ZrO2 are as follows.

% loading of the 12-TPA = | 30% |

Mole ratio of tert-butyl alcohol to m-cresol = | 1:10 |

Amount of the catalyst = | 0.25 g |

Temperature = | 80 °C |

Reaction time = | 6 h |

Effect of calcinations on catalyst

Tert-butylation of m-cresol has been carried out with the calcined samples under the optimized conditions and the results are presented in table 3.

It is seen from the table that on calcination at 300 °C, catalytic activity of the catalyst is decreases to some extent than after it remains constant up to 500 °C. On heating at high temperature, some Bronsted acidity may be loss in terms of water molecules from the catalyst. As the catalyst has enough strong acidity, change observed is not that much appreciable.

Test for heterogeneity

For the rigorous proof of heterogeneity, a test [41] was carried out by filtering catalyst from the reaction mixture at 80 °C after 1 h and allowed the filtrate to react further up to 6 h, i.e. completion of the reaction. The reaction mixture of 1 h and filtrate was analysed for Gas Chromatogram. No change in the % conversion as well as % selectivity was found indicating the present catalyst fall into category C. On the basis of these results, it can be concluded that there is no any leaching of the 12-TPA from the support and the present catalysts are truly heterogeneous in nature.

Recycling of the catalyst

The catalyst was recycled in order to test its activity as well as stability. The recycling was carried out after separating it from reaction mixture only by filtration, washing with conductivity water, drying at 100 °C and treating at 300 °C. Reaction carried out with the recycled catalyst did not show any appreciable change in catalytic activity. A total of 92% conversion with 100% selectivity for the o-isomer was obtained with the recycled catalyst.

Tert-butylation with 12-TSA supported onto ZrO2

Tert-butylation of the m-cresol has been carried out under optimized conditions using 12-TSA supported onto the ZrO2. Results are shown in table 4. Results of tert-butylation of m-cresol over 12-TPA3/ZrO2 under optimized conditions are also presented in table 4. It is seen from the table 4 that 12-TPA3/ZrO2 is more active than 12-TSA3/ZrO2.

It is known that [29,41] that the catalytic activity of heteropolyacids, both in homogeneous and heterogeneous systems, usually parallels to their acid strength i.e. H3[PW12O40] > H4[SiW12O40] > H3[PMo12O40] > H4[SiMo12O40]. It is also known that the difference in the activity is not much appreciable as the acidity is also depends on the addenda atom. Since in the present case, the addenda atom is the same, not appreciable difference in the activity should observed. The obtained results are in good agreement with the above trend.

It is also seen from table 1 that 12-TSA supported on to ZrO2 poses large surface area as compared to that of 12-TPA3/ZrO2. So 12-TSA3/ZrO2 is supposed to be more active than 12-TPA3/ZrO2. But it is seen from the table 4 that the activity of 12-TPA3/ZrO2 is more than that of 12-TSA3/ZrO2, in good agreement with the value of total acidity (0.82 and 0.72 for 12-TPA3/ZrO2 and 12-TSA3/ZrO2 respectively) and ion exchange capacity value (0.62 and 0.45 for 12-TPA3/ZrO2 and 12-TSA3/ZrO2 respectively). Thus, increase with increase in the acidic strength of the catalyst.

Table 5 highlights the unique and best performance of the present catalysts for tert-butylation of m-cresol in comparison with other reported catalysts. The superiority of the present catalysts lies in obtaining more than 90% conversion and 100% selectivity for o-isomer.

Alkylation reactions, especially where more than one product is possible required tedious work up procedure to separate them. All other work carried out on tert-butylation of m-cresol, reactions were end up with two or more than two products but in present work single product is obtained under optimized conditions. Literature survey shows that in reported tert-butylation reactions, o-isomer was obtained as a major product. The % conversion is 25.6 and 34.8% conversion and % selectivity for the mentioned product is 96.1 and 91.3% at 250 °C with 0.5 g of catalyst. Here % selectivity obtained was good but because of incomplete conversion of m-cresol, it required extra work up process to separate the reactant form reaction mixture to reuse. Further, 70% conversion was obtained with HPW/MCM-41 catalytic system, but % selectivity for desired product is very less.

As a view point of green and sustainable chemistry, catalyst and catalytic process which gives high % conversion with higher selectivity for desired product is in demand. In this reported work, reaction was carried out at 80 °C, with 0.25 g of reusable catalyst which provides economical advantages over other methods. Further reaction was carried out without using any solvent, with 96% conversion of one of the reactant and end up with a single desired product. The catalysts were recyclable without significant loss of catalytic activity. The catalyst is not only selective but is a very good option against the conventional solid and liquid acid catalyst.

Conclusion

The present paper reports, non aqueous liquid phase tert-butylation of m-cresol at low temperature which provides remarkable economical advantage. The results are unique in terms of % conversion as well as % selectivity. This method gives 96% conversion and end up with a single desired product which is also one of the most important advantages of supported heteropolyacid catalysts. In addition more expensive cresols can be separated by simple distillation from the reaction mixture and can be reused. Moreover, removal of the catalyst as well as the products consists of the single filtration. The catalysts can be reused after a simple workup.

References

Molnar A., Keresszegi C., Torok B. (1999) Appl. Catal. A. 189:217

Hu C., Zhang Y., Xu L., Peng G. (1999) Appl. Catal. A. 177:237

Salinas E.L., Cortez J.G.H., Schifter I., Gavcia E.T., Navarrete J., Carrillo A.G., Lopez T., Lottiei P.P., Bersani D. (2000) Appl. Catal. A. 193:215

Zhang J., Zhu Z., Li C., Wen L., Min E. (2003) J. Mol. Catal. A. 198:359

Kumar J., Grittin K., Harrison B., Kozhevnikov I.V. (2002) J. Catal. 208:448

Knop A., Pilato L.A. (1985) In: Norbert Platzer (eds) Phenolic resins, Chemistry, Applications and Performance-Future Directions. Springer-Verlag, Berlin

Pospisil J. (1988) Polym. Degrad. Stab. 20:181

Murphy J. (2001) Additives for Plastics Handbook, 2nd ed. Elsevier, Amsterdam

Zhang K., Huang C., Xiang S., Liu S., Xu D., Li H. (1998) Appl. Catal. A. 166:89

Zhang K., Zhang H., Xu G., Xiang S., Xu D., Liu S., Li H. (2001) Appl. Catal. A. 207:183

Dumitriu E., Hulea V. (2003) J. Catal. 218:249

Anand R., Maheswari R., Gore K.U., Tope B.B. (2003) J. Mol. Catal. A. 193:251

Yadav G.D., Doshi N.S. (2002) Appl. Catal. A. 236:129

Shinde A.B., Shrigadi N.B., Samant S.D. (2004) Appl. Catal. A. 276:5

Devessy B.M., Shanbhag G.V., Lefbvre F., Halligudi S.B. (2004) J. Mol. Catal. A 210:125

Karthik M., Tripathi A.K., Gupta N.M., Vinu A., Hartmann M., Palanichamy M., Murugsan V. (2004) Appl. Catal A 268:139

Selvam P., Dapurkar S.E. (2004) Catal Today 96:135

Dapurkar S.E., Selvam P. (2004) J. Catal. 224:178

Vinu A., Nandhini K.U., Murugesan V., Bohlmann W., Umamaheswari V., Poppl A., Hartmann M. (2004) Appl. Catal. A 265:1

Devessy B.M., Shanbhag G.V., Mirajkar S.P., Bohringer W., Fletcher J., Halligudi S.B. (2005) J. Mol. Catal. A. 233:141

Nandhini K.U., Arabindoo B., Palanichamy M., Murugesan V. (2004) J. Mol. Catal. A. 223:201

Badamali S.K., Sakthivel S., Selvam P. (2000) Catal. Today 63:291

Kamalakar G., Komura K., Sugi Y. (2006) Appl. Catal. A 310:155

Karthik M., Vinu A., Tripathi A.K., Gupta N.M., Palanichamy M., Murugesan V. (2004) Micropor. Mesopor. Mater. 70:15

Angelis A.D., Amarilli S., Berti D., Montunari L., Perego C. (1999) J. Mol. Catal. A 146:37

Mao J., Kamiya Y., Okuhara T. (2003) Appl. Catal. A 255:337

Izumi Y., Hisano K., Hidu T. (1999) Appl. Catal. A 181:277

Kozhevnikov I.V., Sinnema A., Janse R.J., Pamin K., Bekkum H.V. (1995) Catal. Lett. 30:241

Kozhevnikov I.V. (1998) Chem. Rev 98:171

Kozhevnikov I.V. (2002) Catalysts for the fine chemicals Catalysis by polyoxometalates, Vol 2. Wiley, Chichester

Mizuno N., Misono M. (1998) Chem. Rev 98:199

J.B. Moffat, The surface and catalytic properties of heteropoly oxometalate: From Fundamental and applied catalysis. Eds M.V. Twigg and M.S. Spencer, (Kluwer, 2001).

Patel S., Purohit N., Patel A. (2003) J. Mol. Catal. A 192:195

Sharma P., Vyas S., Patel A. (2004) Mol. Catal. A 214:281

Sharma P., Patel A. (2006) Bull. Mater. Sci. 29:439

Bhatt N., Patel A. (2005) J. Mol. Catal. A, 238:223

Bhatt N., Patel A. (2007) J. Mol. Catal. A, 264:214

N. Bhatt and A. Patel, Catal. Lett. In Press (2007)

Mastikhin V.M., Tersskih V.V., Timofeeva M.N., Krivoruchko O.P. (1995) J. Mol. Catal. A 95:135

Izumi Y., Natsume N., Takamine H., Tamaoki I., Urabe K. (1989) Bull. Chem. Soc. Jpn 62:2159

Sheldon A., Walau M., Arends I.W.C.E., Schuchurdt U. (1998) Acc. Chem. Res. 31:485

Acknowledgments

We are thankful to Dr. R.V. Jasra, CSMCRI, Bhavnagar for surface area analysis. One of the authors, Mr. Nikunj Bhatt, is thankful to Department of Science and Technolgy, New Delhi, for the financial assistance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bhatt, N., Shah, C. & Patel, A. 12-tungstophosphoric and 12-tungstosilicicacid supported onto hydrous zirconia for liquid phase tert-butylation of m-cresol. Catal Lett 117, 146–152 (2007). https://doi.org/10.1007/s10562-007-9126-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-007-9126-5