Abstract

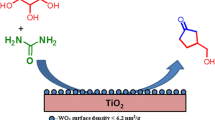

Tungstophosphoric acid supported on TiO2 (TPA/TiO2) and iron modified tungstophosphoric acid supported on TiO2 (Fe0.5TPA/TiO2 and FeTPA/TiO2) were prepared and examined for Friedel–Crafts acylation reactions. The obtained results indicated that FeTPA/TiO2 exhibited excellent catalytic performance on the acylation of m-xylene with benzoyl chloride, but inferior results were obtained in the acylation of anisole with acetic anhydride. However, TPA/TiO2 displayed better catalytic activity than others in the later reaction. All the catalysts were characterized by XRD, FT-IR, NH3-TPD, Py-IR and TGA. The obtained results demonstrated that the Lewis acidity of catalysts presented a significant influence on the reaction with benzoyl chloride as acylating agent while the total acidity of catalysts was more important with acetic anhydride as acylating agent. Finally, the reaction mechanisms with two acylating agents over the above catalysts were discussed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Friedel–Crafts acylation of arenes is one of the most important reactions in the synthesis of aromatic ketones, which are the key intermediates in fine chemicals, agricultural chemicals and pharmaceuticals [1–3]. At present, these reactions are carried out with acid halides or anhydrides as acylating agents, normally catalyzed by Lewis acids (AlCl3, FeCl3) or strong Brönsted acids. However, these catalysts present serious environmental problems, such as disposal of large amounts of waste acid [4]. Therefore, it is a main task to select high efficient and environmental protective heterogeneous catalysts instead of the traditional homogeneous catalysts.

Due to its strong Brönsted acidity and high redox ability, Heteropoly acids (HPAs) as promising catalysts are used for various kinds of reactions, especially in acid-catalyzed reactions and selective oxidation [5–7]. However, these catalysts suffer from some obvious drawbacks: low thermal stability, low surface area and solubility in polar solvents. Therefore, it is an efficient method of solving this problem to supporting them on suitable supports, such as SiO2 [8] or TiO2 [9]. Nowadays, some researchers have reported that TPA/SiO2 could be used for the acylation of anisole but the catalytic activity was low [10]. Furthermore, Heteropoly acid salts, particularly tungstophosphoric acid salts as water tolerant acid catalysts with both Brönsted and Lewis acidities have attracted intensive attention in recent years [11, 12]. However, it is rarely reported that tungstophosphoric acid salts supported on suitable supports have been applied in the acid-catalyzed reactions.

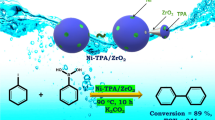

Thus, in this work, tungstophosphoric acid or tungstophosphoric acid salts supported on TiO2 were respectively examined for two different acylation reactions. FeTPA/TiO2 exhibited excellent catalytic performance on the acylation of m-xylene with benzoyl chloride (Scheme 1), but for the acylation of anisole with acetic anhydride, the catalytic performance of TPA/TiO2 is better (Scheme 2). To further investigate the reasons for the obtained results, these catalysts were studied by XRD, FT-IR, NH3-TPD, Py-IR and TGA.

2 Experimental

2.1 Catalyst preparation

Tungstophosphoric acid (TPA), ferric chloride hexahydrate and titania were purchased from Tianjin Guangfu Fine-chemical institute (Tianjin, China). All commercially available reagents were used without further purification.

All the catalysts used in this study were prepared by incipient wetness impregnation method. As an example, Fe0.5TPA/TiO2 (the content of Fe0.5TPA in the catalyst was 30 wt%) was prepared as follows. 1.5 g TPA was dissolved in water (10 mL) and then 0.07 g FeCl3·6H2O was added in the above solution with continuous stirring. After fully dissolved, titania (3.52 g) were added to the mixture. The mixture was stirring for another 3 h and then evaporated to dryness. The obtained catalyst was dried in an air oven at 110 °C for 8 h and then calcined at 300 °C for 2 h.

2.2 Catalytic activity

2.2.1 Acylation of m-xylene with benzoyl chloride

The acylation reaction was carried out in a 50 ml three-necked round bottom flask fitted with a thermometer, reflux condenser and a magnetic stirrer. A mixture of 1.40 g (10 mmol) of benzoyl chloride, 4.24 g (40 mmol) of m-xylene and 0.07 g (5 wt%) of the catalyst in the flask was violently stirred and heated to reflux (130 °C) for 5 h (Scheme 1). The reaction mixture was then filtered and the filtrate was analyzed by gas chromatography (OV-101 capillary column: 30 m × 0.25 mm, 0.33 um film thickness) and the composition of the reaction mixture was confirmed by GC–MS (HP-1 capillary column: 30 m × 0.25 mm, 0.2 um film thickness).

2.2.2 Acylation of anisole with acetic anhydride

A mixture of 1.14 g (10 mmol) of acetic anhydride, 5.40 g (50 mmol) of anisole and 0.1 g (10 wt%) of the catalyst was added to the flask with violent stirring and heated to reaction temperature (130 °C) for 5 h (Scheme 2). The reaction mixture was then filtered and the filtrate was analyzed by gas chromatography and the composition of the reaction mixture was confirmed by GC–MS.

2.3 Catalyst characterization

The XRD patterns of these catalysts were recorded on a Rigaka D/max 2500 X-ray diffractomater using Cu-Kα radiation (40 kV, 100 mA) in the range of 5–90°. The FT-IR spectra were recorded using the KBr method on a Nicolet system. Ammmonia temperature programmed desorption (NH3-TPD) was performed on a TP-5000 instrument with a thermal conductivity detector (TCD). The Py-IR spectra were recorded on a Thermo Nicolet Nexus 470 spectrometer equipped with a heatable IR cell containing CaF2 windows. Temperature-gravity properties of these catalysts were measured with a STA 409PC thermo gravimetric (TG) analyzer. The catalysts were heated from room temperature to 800 °C at a rate of 10 °C min−1 in a stream of N2 (40 mL/min).

3 Result and discussion

3.1 Catalyst selection

As mentioned above, tungstophosphoric acid (TPA) supported on suitable supporters have been reported to be efficient heterogeneous catalysts for the acid-catalyzed reactions. As well known, Friedel–Crafts acylation is also typical acid-catalyzed reaction. Therefore, TPA/TiO2, Fe0.5TPA/TiO2, FeTPA/TiO2 catalysts are prepared and evaluated respectively for the acylation of m-xylene with benzoyl chloride and the acylation of anisole with acetic anhydride. The results are summarized in Tables 1 and 2. As shown in Table 1, TPA/TiO2 catalyst exhibits poor catalytic activity for the acylation of m-xylene with benzoyl chloride, but iron modified TPA supported on TiO2 displays better catalytic performance than TPA/TiO2. Moreover, it is apparently found that the conversion of benzoyl chloride and the selectivity of 2,4-dimethylbenzophenone increases with the increase of iron content.

However, the results are completely opposite when these catalysts are also examined for the acylation of anisole with acetic anhydride. It is observed from Table 2 that TPA/TiO2 catalyst exhibits better catalytic performance than other two catalysts. Meanwhile, with the addition of iron, the selectivity of p-MAP and o-MAP decrease but the selectivity of by-product phenol increases. We speculate that the Brönsted and Lewis acidity possibly have different influences on acylation reactions with different acylating agents. To further investigate the obtained results, the catalysts are studied by Py-IR and NH3-TPD.

3.2 Catalyst characterization

3.2.1 XRD

The XRD patterns for TPA/TiO2, Fe0.5TPA/TiO2 and FeTPA/TiO2 are shown in Fig. 1. It is observed that TiO2 patterns are predominant in all of the catalysts and these diffraction lines are designed to the diffraction patterns of anatase structure [13]. These peaks intensity became weaker with the introduction of iron, and it is attributed to the drops of crystallinity with the addition of iron. Moreover, no crystalline peak corresponding to TPA is observed. It is indicated that TPA is finely dispersed on the surface of TiO2.

3.2.2 FT-IR

The FT-IR spectra of the catalysts are described in Fig. 2. TPA/TiO2 and FeTPA/TiO2 catalysts show four characteristic bands in the region of 1100–500 cm−1. The main peaks observed at 1080, 945, 891, 800 cm−1 can be assigned to the stretching vibrations of P–O, W=Ot, W–Oc–W and W–Oe–W, respectively, related to characteristic Keggin ion [14]. Iron modified or unmodified TPA supported on TiO2 catalysts also exhibits these characteristic bands but the intensity of these peaks decreased. The FT-IR results indicate that the Keggin structure of iron modified or unmodified TPA remain unaltered when iron modified or unmodified TPA is supported on TiO2.

3.2.3 NH3-TPD and Py-IR

In the present investigation, NH3-TPD studies are performed to compare the acidity distinction of TPA/TiO2, Fe0.5TPA/TiO2 and FeTPA/TiO2. The results are described in Fig. 3. FeTPA/TiO2 catalyst exhibits both the weak (120–391 °C) and strong acid site peaks (above 400 °C). But for Fe0.5TPA/TiO2 and TPA/TiO2, only the weak acid site peaks are observed. Therefore, It is obvious that with the addition of iron, the desorption temperature on the weak acid sites decreases but that on the strong acid sites increases.

During NH3-TPD measurement, the samples have exactly the same weight, so the areas of a specific peak are used to estimate the amount of ammonia desorbed from the catalyst [15]. As listed in Table 3, it can be found that the total acidity decrease from 0.39 mmol NH3/g in curve (a) to 0.16 mmol NH3/g in curve (c). It is indicated that the addition of iron on the catalysts decreases the total acidity of TPA/TiO2. Moreover, this result also explains why this catalyst has better catalytic activity in the acylation of anisole with acetic anhydride as displayed in Table 2. Furthermore, it is clearly that the addition of iron decreases the weak acidity but increases the strong acidity. As listed in Table 2, with the increase of iron content, the selectivity of MAP decreases from 92.49 to 87.25 % while the selectivity of phenol increases from 7.51 to 12.75 %. Therefore, it can be concluded that the existence of the strong acidic sites is favorable for the demethylation of anisole.

Moreover, although the total acidity of FeTPA/TiO2 is weaker than that of other catalysts, the conversion of benzoyl chloride over FeTPA/TiO2 is higher as shown in Table 1. We speculate that the Lewis acidity has the main effect on the acylation of m-xylene with benzoyl chloride. To further verify our speculation, Py-IR spectra is performed and the result is displayed in Fig. 4. It is observed that the band at 1540 and 1450 cm−1 are attributed to the pyridine adsorbed on the Brönsted and Lewis acid sites, respectively [16]. Meanwhile, the integrated areas for Brönsted and Lewis acid sites are obtained and the calculated L/B ratio is shown in Table 4. It can be discovered that FeTPA/TiO2 exhibits excellent Lewis acid strength, which might be the main reason that FeTPA/TiO2 exhibits better catalytic performance than other catalysts in the acylation of m-xylene with benzoyl chloride (Table 1). Thus, it can be concluded that Lewis acidity became the main factor in the acylation of m-xylene with benzoyl chloride.

3.2.4 TGA

Figure 5 represents the TGA and DTG patterns of the three catalysts, respectively. The TGA curve of TPA/TiO2 shows three weight losses. The initial weight loss below 100 °C is due to the desorption of physical adsorbed water. The second weight loss up to 250 °C corresponds to the loss of crystal water and then the last significant weight loss in the range of 400–750 °C may be due to the decomposition of TPA. The result is consistent with DTG curve. However, Fe0.5TPA/TiO2 and FeTPA/TiO2 show only two main weight losses in the regions of 25–250 and 400–750 °C, corresponding to the removal of water and the decomposition of Fe0.5TPA or FeTPA. Moreover, as the iron content increase, the weight loss of the catalysts is inhibited and their thermal stability increases. Due to the salt formation of TPA with Fe3+, FeTPA/TiO2 and Fe0.5TPA/TiO2 are more stable than TPA/TiO2. In fact, for all the catalysts, the major weight losses occur before 250 °C, which are related to the elimination of absorbed and crystal water [17]. The weight loss decreases with increasing Fe content, which is attributed to the degree of hydration. The similar conclusion is presented in the TG analysis of DTP/K-10 and Cs-DTP/K-10 [18].

3.3 Reaction mechanism

As well known, Friedel–Craft acylation is a typical electrophilic aromatic substitution. In this reaction, the π-complex is firstly formed through a π-dipole interaction between the electrophile and the π-electrons of the aromatic ring, and then transformed into σ-complex. Finally, product is obtained by losing a proton from σ-complex. Therefore, for the acylations with different acylating agents, the acylium ion could be formed by different ways. The generation mechanism of electrophilic cations from acylating agents are studied. As shown in Fig. 6, the benzoyl cation is generated by capturing chloride ion of benzoyl chloride over FeTPA/TiO2. Therefore, Lewis acid sites on the catalyst enhance the acylation of m-xylene with benzoyl chloride. Although the complex is formed when the catalyst combines with oxygen atom of acetic anhydride, it is difficult to the formation of the acetyl cation by removing acetate ion compared with the generation of the benzoyl cation. Therefore, FeTPA/TiO2 exhibits excellent catalytic performance on the acylation with benzoyl chloride as acylating agent, but it has worse catalytic performance on the acylation with acetic anhydride as acylating agent.

Moreover, the generation mechanisms of acyl cation from different acylating agents over TPA/TiO2 are shown in Fig. 7. TPA/TiO2 presents stronger total acidity, especially Brönsted acidity, enhances the protonation of acetic anhydride and leads to form acyl cation. So, TPA/TiO2 exhibits excellent catalytic performance on the acylation with acetic anhydride as acylating agent. Moreover, although this catalyst can also protonate benzoyl chloride, but it is hard to form acyl cation. Therefore, for the acylation with benzoyl chloride as acylating agent, the catalytic activity is low. Therefore, the total acidity of TPA/TiO2 had a significant influence on the acylation of anisole with acetic anhydride. Furthermore, although the total acidity decreased with the addition of iron on catalysts, the strong acidity increased. Meanwhile, the strong acid site of the catalyst was favorable for protonating the anisole so the demethylation of anisole happened.

4 Conclusion

In summary, two acylations of m-xylene with benzoyl chloride and anisole with acetic anhydride were studied over iron modified or unmodified TPA supported on TiO2, respectively. The obtained results indicated that FeTPA/TiO2 exhibited excellent catalytic performance on the acylation of m-xylene with benzoyl chloride. But for the acylation of anisole with acetic anhydride, the catalytic activity of TPA/TiO2 was much better than others. The catalysts were characterized and the results showed that the Lewis acidity of catalysts presented a significant influence on the reaction with benzoyl chloride as acylating agent while the total acidity of catalysts was more important with acetic anhydride as acylating agent. Based on the experimental results above, the reaction mechanisms with two acylating agents over the above catalysts were discussed.

References

G. A. Olah, Friedel–Crafts and Related Reactions, vols. I, II, and III (Wiley, New York, 1964)

H.G. Franck, J.W. Stadelhofer, Industrial Aromatic Chemistry (Springer, Berlin, 1988)

S. Gmouh, H. Yang, M. Vaultier, Org. Lett. 5, 2219 (2003)

J. Ross, J. Xiao, Green Chem. 4, 129 (2002)

I.V. Kozhevnikov, Chem. Rev. 98, 171 (1998)

I.V. Kozhevnikov, Appl. Catal. A: Gen. 256, 3 (2003)

K. Na, T. Okuhara, M. Misono, J. Catal. 170, 96 (1997)

S.-H. Chai, H.-P. Wang, Y. Liang, Green Chem. 10, 1087 (2008)

K.-M. Su, Z.-H. Li, B.-W. Cheng, Fuel Process. Technol. 92, 2011 (2011)

B.B. Baeza, J.A. Anderson, J. Catal. 228, 225 (2004)

C.R. Kumar, K.V. Rao, P.S. Sai Prasad, J. Mol. Catal. A: Chem. 337, 17 (2011)

L. Méndez, R. Torviso, L. Pizzio, Catal. Today 173, 32 (2011)

M. Balaraju, V. Rekha, B.L.A. Prabhavathi Devi, Appl. Catal. A: Gen. 384, 107 (2010)

C.R. Kumar, P.S. Sai Prasad, N. Lingaiah, Appl. Catal. A: Gen. 384, 101 (2010)

D. Ma, W.P. Zhang, Y.Y. Shu, X.M. Liu, Y.D. Xu, X.H. Bao, Catal. Lett. 66, 155 (2000)

K. Rhee, U. Rao, J. Stencel, G. Melson, J. Crawford, Zeolites 3, 337 (1983)

T. Okuhara, N. Mizuno, M. Misono, Adv. Catal. 41, 113–252 (1996)

M.S. Tiwari, G.D. Yadav, Chem. Eng. Sci. 266, 64–73 (2015)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mu, M., Chen, L. & Wang, S. A comparative study on iron modified or unmodified tungstophosphoric acid supported on titania for Friedel–Crafts acylation. J Porous Mater 22, 1137–1143 (2015). https://doi.org/10.1007/s10934-015-9989-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-015-9989-6