Abstract

The bacterial strain F4, isolated from olive oil-contaminated soil, has been found to produce biosurfactants as confirmed by oil displacement test and the emulsification index results. The identification of the strain F4, by 16S ribosomal RNA gene, showed a close similarity to Bacillus safensis, therefore the strain has been termed Bacillus safensis F4. The Thin Layer Chromatography (TLC) and the High Pressure Liquid Chromatography-Mass Spectrometry (HPLC–MS/MS) demonstrated that the biosurfactant had a lipopeptide structure and was classified as surfactin. The present study showed also that the produced biosurfactant has an important antibacterial activity against several pathogen strains as monitored with minimum inhibitory concentration (MIC) micro-assays. In particular, it presented an interesting anti-planktonic activity with a MIC of 6.25 mg mL−1 and anti-adhesive activity which exceeded 80% against the biofilm-forming Staphylococcus epidermidis S61 strain. Moreover, the produced lipopeptide showed an antitumor activity against T47D breast cancer cells and B16F10 mouse melanoma cells with IC50 of 0.66 mg mL−1 and 1.17 mg mL−1, respectively. Thus, our results demonstrated that Bacillus safensis F4 biosurfactant exhibited a polyvalent activity via a considerable antibiofilm and antitumoral potencies.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Biosurfactants or bioemulsifiers are amphipathic surface-active molecules, which are produced by micro-organisms, composed of hydrophobic (nonpolar) and hydrophilic (polar) moieties. As a consequence, they have the ability to aggregate at interfaces between fluids with different polarities such as oil/water or air/water, reduce the surface and interfacial tensions and form emulsions (Sen et al. 2017). These compounds are characterized as glycolipids, lipopeptides, lipopolysaccharides, fatty acids, phospholipids and neutral lipids (Bezza and Chirwa 2016; Colla et al. 2010). Biosurfactants are produced by a wide variety of bacteria, actinobacteria and fungi with different chemical structures. Some bacterial genera like Bacillus and Arthrobacter are known with their production of lipopeptide biosurfactant (Sriram et al. 2011). Some studies have described the biological activities of the biosurfactants including antimicrobial, anti-adhesive and anti-biofilm properties (Silva et al. 2014; Gudiña et al. 2010a). In fact, the bacterial infections and their biofilm formation abilities causing resistance increase against drugs is getting a serious problem for human health. An urgent need for solving this problem is based on the screening of novel drugs eradicating or inhibiting biofilm formation. The adherence is the first step of the infectious process that requires efficient antagonising molecules. Previous studies reported that based on their amphiphilic structures, the biosurfactants reduce the surface tension and therefore affecting the bacterial adherence (Janek et al. 2013). In this context, the lipopeptide biosurfactant produced by Bacillus subtilis presented antibacterial, anti-adhesive and anti-biofilm activities on uropathogenic bacteria (Moryl et al. 2015). Moreover, a glycolipid biosurfactant, presented cytotoxic activities on cancer cell lines, was produced by a Nocardia farcinica strain (Christova et al. 2015). The biosurfactants, which are selective in nature, act on the surface of liquids and facilitate the action of certain enzymes such as lipases and/or esterases by reducing the surface tension of liquids and/or improving the solubility of water immiscible substrates (Sekhon et al. 2011, 2012).

Lipases are characterized by their ability to synthesize ester bonds in a non-aqueous media (Ülker and Karaoglu 2012) and their production can be associated with several factors including pH, temperature, carbon source and the presence of inducers such as oils and some biosurfactants (Cherif et al. 2011; Colla et al. 2010).

Nowadays, biosurfactants take an important scientific interest with their interesting proprieties such as the high biodegradability, lower toxicity, better environmental compatibility, and important specific activity at extreme conditions of temperature, pH and salinity (Sriram et al. 2011).

In this context, searching for novel biosurfactant producing strains with potential biosurfactant production is required. For that, lipolytic strains could be a possible original source of biosurfactant production (Sekhon et al. 2012). The present study describes the biosurfactant production by a lipolytic strain B. safensis F4 and investigates its antibacterial, anti-adhesive and antitumor activities.

Materials and methods

Bacterial strains

B. safensis F4, B. subtilis, Staphylococcus aureus, Enterococcus faecium, Micrococcus luteus, Agrobacterium tumefaciens, Salmonella enterica, Escherichia coli and Pseudomonas savastanoi were grown in LB (Luria–Bertani) medium. S. epidermidis S61, a biofilm-forming bacterium isolated in our lab from the roof of an old house in Sfax, Tunisia (Jardak et al. 2017), was grown in Tryptic Soy Broth (TSB) medium.

Cell lines and cultures

Breast cancer T47D and mouse melanoma B16F10 cell lines, obtained from the American Type Culture Collection (ATCC), were grown in Dulbecco’s modified Eagle’s medium (DMEM) supplemented with 10% foetal bovine serum, 50 IU/mL penicillin, 50 mg mL−1 streptomycin at 37 °C in a humidified 5% CO2 atmosphere.

Bacterial biosurfactant activity

The oil displacement assay was performed according to Morikawa et al. (1993) using the Petri plate (90 mm diameter) filled with 25 mL of distilled water then 10 µL of a crude oil was added. 10 µL of a cell free culture supernatant was slowly placed on the center of the oil surface. The diameter of the clear halo zone was measured after 30 s of incubation.

The determination of the emulsification index (E24) is carried out according to the following equation (Cooper and Goldenberg 1987). E24 was measured using the cell free culture. Two millilitres of a vegetable oil were added to an equal volume of cell free supernatant and homogenized for 2 min at high speed. The height of emulsion layer was measured after 24 h. All the experiments were done in triplicate.

Surface tension determination

Surface tension of the 24 h culture broth supernatant was measured according to the De Nouy methodology using a tensiometer TD1 (Lauda-K¨onigshofen, Germany). The measurement was performed in triplicate.

Identification of bacterial strain

Strain F4 was identified using the API 20E test Enterobacteriacae (BioMérieux, France) and by sequencing of the 16S rRNA gene. The genomic DNA of the strain F4 was extracted following the protocol detailed by Wilson (1987). The 16S ribosomal DNA of the strain F4 was amplified by PCR (Polymerase chain reaction) using the universal bacterial primers Fd1 and Rd1 (Fd1, 5′-AGAGTTTGATCCTGGCTCAG-3′; Rd1, 5′-AAGGAGG-TGATCCAGCC-3′), and the following program: denaturation at 94 °C for 30 s, annealing at 55 °C for 45 s and extension at 72 °C for 1 min 45 s for a total of 30 cycles.

The PCR products were purified with a Favor Prep GEL/PCR Purification Kit (FAVORGEN) and sequenced using the ABI PRISM, 3100. The obtained sequences were compared with other bacterial sequences in the NCBI database using BLAST program. The phylogenetic tree was constructed using the neighbour-joining method (Naruya and Nei 1987) by MEGA 4.0.

Bacterial biosurfactant production

B. safensis F4 strain was retained as the best local strain producing biosurfactant. The strain was incubated overnight at 30 °C and 160 rpm in 250 mL shaking flasks with 100 mL of LB medium. Two millilitres of culture were used as inoculum and were cultivated in 500 mL shaking flasks containing 200 mL of the medium with 1% olive oil. The culture was incubated for 24 h at 180 rpm and 30 °C to allow maximum biosurfactant production. Cell-free supernatant was obtained by centrifugation at 4 °C during 20 min at 4000×g (ROTANTA 460 RF, Hettich). The obtained supernatant was treated by acidification to pH 2.0 using a 3 M HCl solution and incubated overnight at 4 °C. Then, the acidified supernatant was extracted with ethyl acetate and concentrated with a rotary evaporator (Gargouri et al. 2016).

Thin layer chromatography (TLC)

The extracted biosurfactant in ethyl acetate was analysed by TLC. The sample dissolved in methanol was spotted on silica gel TLC plate (TLC Silica gel 60 F254, Merck Darmstadt, Germany). The plate was developed with a mobile phase of chloroform/methanol/water respectively in the ratio of 65:25:4 (v/v/v). The dried plate was sprayed with a solution of 0.25% ninhydrin in acetone and then, incubated at 105 °C for 5 min (Janek et al. 2010).

Biosurfactant purification and identification

The extracted biosurfactant in ethyl acetate was fractioned using solid-phase extraction (SPE) (Alajlani et al. 2016). C18 Phenomenex strata-X column (silica gel, 10 g) was conditioned by the elution of 3 volumes of acetonitrile. The sample was deposited on the surface of the silica and drawn through the solvent. For the mobile phase, the HPLC (High Pressure Liquid Chromatography) grade acetonitrile (100%—3 volume column) was used in first step, then a binary mixture of HPLC grade dichloromethane/methanol (v/v—3 volume column) was used. The obtained eluates were collected and dried under vacuum. Finally, the acetonitrile fraction was retained.

Two microliters of acetonitrile fraction diluted at 5 mg mL−1 in methanol, were injected in a Dionex Ultimate 3000 UHPLC-HESI HRMS Q-Exactive focus system (Thermo Scientific) connected to Xcalibur software. The chromatographic separation was conducted followed the protocol of Girard et al. (2017) with slight modifications. The Hypersil GOLD C18 column (150 mm × 2.1 mm) with 1.9 µm particle size (Thermo Scientific) and constant flow rate of 0.5 mL min−1. The column oven was set to 50 °C. The water (eluent A) and acetonitrile (eluent B) containing both 0.1% formic acid, were used as mobile phases. A gradient profile was applied, starting with 5% of B and kept constant for 1 min. The percentage of B was linearly increased to 100% in 15 min, and was kept at 100% for 9 min and returned to initial conditions over 1 min. Four minutes of equilibration were followed, giving a total operating time of 30 min. The instrument has been run in the full scan mode with a range of 100 to 1500 m/z equipped with an electrospray interface (ESI). The polarity of the electrospray interface was continuously switched between positive and negative polarity. The LB medium was used as a control subjected to extraction with ethyl acetate. The common peaks between the chromatographs of the samples and the medium were not retained.

Determination of minimum inhibitory concentration (MIC)

The minimum inhibitory concentration (MIC) for the lipopeptide, produced by B. safensis F4, was defined as the lowest concentration that inhibited the growth of microorganisms after 24 h. The test was performed against several human and plant pathogenic strains (S. aureus, E. faecium, M. luteus, A. tumefaciens, S. enterica, E. coli and P. savastanoi) and B. subtilis. The choice of these strains is justified since we tried to maximize our chance for finding interesting molecules that could be applied to fight against human or plant bacterial infections. The biosurfactant anti-planktonic activity against S. epidermidis S61 was performed with the same test. Each bacterium was grown in LB medium overnight at 30 °C. Bacterial cultures were then adjusted to an optical density of 0.6 at a wavelength of 600 nm. The crude biosurfactant was dissolved in Dimethylsulfoxide (DMSO) and then filtered. Serial dilutions were made to yield volumes of 100 μL per well with final concentrations ranging from 0.0125 to 25 mg mL−1 in LB medium. Twenty microliters of bacterium overnight culture, with appropriate OD, were added to each well and a final volume of 200 μL per well was adjusted with medium. Wells containing just LB medium with inoculum and these containing medium, inoculum and Ampicillin served as controls. The plate was then incubated at 37 °C for 24 h. Twenty microliters of MTT (3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide) solution at 1 mg mL−1 were added to each well.

The determination of the biosurfactant MIC was based on the MTT color change. In fact, the viable bacteria were detected by the change of yellow MTT color to purple. For that, the well devoid of bacterial growth (yellow color) was retained as MIC, which was expressed in mg mL−1. The same test was carried out against Gram-positive and Gram-negative strains.

Anti-adhesive activity

The 96-well flat bottom plates were used for biofilm cultures (Mathur et al. 2006).

Staphylococcus epidermidis S61, a biofilm-forming strain (Jardak et al. 2017), was grown overnight in TSB medium at 30 °C and diluted with fresh medium supplemented with 2.25% (w/v) glucose. One hundred microliters of the bacterial culture dilution was added into each well to obtain a final OD600 nm of 0.1. Then, 100 µL of B. safensis F4 biosurfactant dissolved in TSB, containing 20% (v/v) of DMSO, at various concentrations, were added into wells to reach final concentrations of 0.039, 0.078, 0.156, 0.312, 0.625, 1.25, 2.5, 5 and 10 mg mL−1. Wells containing only TSB medium supplemented with, 2.25% glucose and 20% (v/v) of DMSO, and bacterial suspension were served as controls.

Plates were incubated for 24 h at 30° C under static conditions. After incubation, the wells were emptied into a container by inverting the plates. Each well was gently washed twice with 250 µL of sterile phosphate buffered saline (PBS: 137 mM NaCl, 2.7 mM KCl;10 mM Na2HPO4; 1.76 mM KH2PO4; pH 7.2) in order to remove the planktonic cells (Beenken et al. 2003). After washing, plates were dried at 60 °C for 60 min. Then, wells were stained with 150 µL of crystal violet (0.2%) prepared in 20% ethanol for 15 min at room temperature (Vasudevan et al. 2003). After staining incubation, crystal violet was removed and excess dye was washed three times with sterile water. Finally, 200 µL of glacial acetic acid 33% was added to each well and plates were incubated for 1 h at room temperature. The optical density (OD) was measured at 570 nm using a Varioskan microplate reader (Thermofisher).

The percentage of the adhesion inhibition was calculated by the following formula:

*Control: untreated strain with the extract.

The anti-adhesive activities of the crude biosurfactant and the acetonitrile fraction, against S. epidermidis S61 were confirmed by microscopic observations using the OLYMPUS fluorescent microscope BX50 equipped with a digital camera OLYMPUS DP70. The biofilms were grown on glass pieces (Ø 10 mm) placed in 24-well polystyrene plates treated with the biosurfactant. Non-treated wells, containing TSB supplemented with 10% (v/v) of DMSO, served as controls (Padmavathi and Pandian 2014). The biosurfactant was added at a final concentration of 10 mg mL−1 in TSB with 10% (v/v) of DMSO. The bacterial inoculation was adjusted to an OD600nm of 0.1. Plates were incubated at 30 °C for 24 h. The wells were then carefully emptied with pipetting and glass slides were washed with sterile PBS (1X) before the treatment with 500 µL of acridine orange (0.1%, w/v, dissolved in PBS1X). Visualization was performed through a 40 × objective using U-MWB2 filter with excitation at 460–490 nm and emission at 520 nm.

Cytotoxicity assays

T47D breast cancer and B16F10 mouse melanoma cells were grown in 96-well plates (Orange Scientific) until 40% confluence. The biosurfactant, was added at different concentrations (0.1, 1 and 10 mg mL−1) and incubated for 48 h at 37 °C in a humidified atmosphere containing 5% CO2.

The cell viability was assessed using the MTT assay as previously described by Mosmann (1983). After treatment, the medium was exchanged by a fresh one and 10 µL of MTT solution (5 mg mL−1 in PBS) were added. After incubation for 4 h, 100 µL of 10% SDS (Sodium dodecyl sulfate) solution were added to each well to dissolve the formazan. The optical density was measured at 570 nm using a Varioskan microplate reader (Thermofisher). The growth inhibition was expressed according to the following formula:

A0: control absorbance, AT: treated cells absorbance.

Statistical analysis

All experiments were done in triplicate. The obtained results are expressed as mean values with the standard error. The statistical analyses were performed using Student’s t test to compare the controls and treated samples at a significance level of 5%.

Results and discussion

Selection of biosurfactant producing strain

Morphological and biochemical tests showed that the rod-shaped strain F4 was motile, Gram-positive, catalase-positive and oxidase-positive. Based on the phylogenetic analysis of the 16S rRNA gene sequences, the strain F4 was affiliated to the genus Bacillus with 99% of similarity to Bacillus safensis FO-36bT (AF234854) (Fig. 1) and was termed as B. safensis F4. The 16S rRNA gene sequence, including 1378 nucleotides, was deposited in the GenBank nucleotide database under the accession number MF927780.

In fact, B. safensis F4 was retained after laboratory screening of lipolytic strains for their ability to produce biosurfactant during growth on olive oil. The oil displacement assay showed that the selected strain presented the highest clear halo zone (about 21.08 ± 1.46 cm2). The emulsification activity of the selected strain against sunflower oil was 74.99%. Previous results showed that Bacillus cereus NK1 biosurfactant presented a clear halo zone of 2.95 cm2 and 62% in the oil displacement test and emulsification activity against n-hexadecane, respectively (Sriram et al. 2011). Ibrahim (2018) claimed that biosurfactant produced by Ochrobactrum anthropi HM-1 culture showed a clear halo zone 38.5 cm2, while 33.17 cm2 was presented by Citrobacter freundii HM-2 biosurfactant. The cell-free culture broths of HM-1 and HM-2 strains successfully emulsified sunflower oil with approximately 70% and 60%, respectively.

Surface tension determination

Surface tension is a key parameter for the evaluation of biosurfactant production. In fact, a microorganism is considered as a promising biosurfactant producer, if it could reduce the surface tension to less than 40 mN m−1 (Shete et al. 2006). The obtained results showed that our biosurfactant is able to reduce surface tension until 30.73 mN m−1 ± 0.48 which is lower than results obtained by Ghazala et al. (2017) during the characterization of an anionic lipopeptide produced by Bacillus mojavensis I4 where the surface tension of the culture supernatant was 31.5 ± 0.8 mN m−1. Moreover, our results are very close to those obtained by Jemil et al. (2016) which showed that the best result in decreasing surface tension was observed with Bacillus methylotrophicus DCS1 strain (31 mN m−1). Likewise, other study showed that biosurfactants produced by O. anthropi HM-1 and C. freundii HM-2 were able to reduce surface tension until 30.8 ± 0.6 and 32.5 ± 1.3 mN m−1, respectively (Ibrahim 2018). While, compared to surface tensions of some chemical surfactants studied by Ghazala et al. (2017), B. safensis F4 cell free broth showed lower surface tension than SDS (34.8 ± 1.3 mN m−1) and Triton X-100 (32 ± 0.9 mN m−1).

Characterization of B. safensis F4 biosurfactant

TLC analysis showed that B. safensis F4 biosurfactant is a lipopeptide. The relative front (Rf) value was 0.56 (Fig. 2) which confirmed that the biosurfactant extract is a lipopeptide as reported by similar previous studies (Fernandes et al. 2007).

In order to identify our biosurfactant, the acetonitrile fraction was collected, and then analysed by LC–MS (Liquid chromatography–mass spectrometry) (Fig. 3). The details of the obtained masses have been identified according to previous reported studies. Results showed the presence of two surfactin derivates (M+H+= 1022.6668 and 1008.6513/M−H+=1020.6579 and 1006.6436, respectively) at retention time of 15.98 min with the presence of adducts (M+Na) (Table 1). The presence of surfactin was confirmed by the positive and negative ionization mode (Jasim et al. 2016). At the same retention time of 15.98 min, the two compounds were identified as Leu/Ile-7, C14 surfactin and Leu/Ile-7, C13 surfactin with different masses of 1021.66 m/z and 1007.65 m/z (Price et al. 2007). Another peak at 9.20 min has been depicted (M−H+ = 329.2328), which could correspond to pinellic acid. According to literature, pinellic acid is mainly known with its anti-allergic (Arulselvan et al. 2016) and anti-inflammatory (Nagai et al. 2004) activities.

ESI-MS chromatogram of biosurfactants produced by Bacillus safensis F4. The blue arrows correspond to two surfactin derivates were identified as Leu/Ile-7, C14 surfactin and Leu/Ile-7, C13 surfactin with different masses of 1021.66 m/z and 1007.65 m/z, respectively, at the same retention time of 15.98 min

Determination of minimum inhibitory concentration (MIC)

Das et al. (2008) reported that some types of biosurfactants produced by many Bacillus species present antimicrobial activity against many bacteria including pathogenic strains.

Our lipopeptide showed limited activity against Gram-negative bacteria compared to that obtained against the Gram-positive tested strains. The tested biosurfactant has a MIC of 0.78 mg mL−1 against B. subtilis and 1.56 mg mL−1 against S. aureus, E. faecium and M. luteus. However, it presented a MIC value of 3.125 mg mL−1 against A. tumefaciens, S. enterica, E. coli and 1.56 mg mL−1 against P. savastanoi (Table 2). Moreover, Singh and Cameotra (2004) reported that the lipopeptide produced by B. subtilis C1 was found to be active against several Gram-positive bacteria.

In another study, biosurfactant produced by the Lactobacillus paracasei ssp. paracasei A20 showed significant antimicrobial activities against pathogenic E. coli, S. aureus with MIC higher values ranging between 25 and 50 mg mL−1 comparing with our results (Gudiña et al. 2010b). Likewise, a high level of growth inhibition was observed against different pathogens with a biosurfactant produced by Lactobacillus helveticus at a concentration of 25 mg mL−1 (Sharma and Saharan 2016). Furthermore, many lipopetides produced by Bacillus licheniformis, (Yakimov et al. 2007; Fiechteer 1992) and B. subtilis (Vollenbroich et al. 1997) were known by their important antimicrobial activities. In other studies, the crude biosurfactant produced by Lactobacillus jensenii presented approximately 100% activity against E. coli, and S. aureus with a MIC of 50 mg mL−1 which are higher than our MIC values (Sambanthamoorthy et al. 2014).

Concerning the anti-planktonic activity, the crude biosurfactant and the acetonitrile fraction were tested against S. epidermidis S61. Results showed that the crude biosurfactant and acetonitrile fraction effectively inhibited its growth with MIC of 12.5 mg mL−1 and 6.25 mg mL−1, respectively. However, biosurfactant produced by L. helveticus showed a high percentage of growth inhibition (98.4%) against S. epidermidis with a concentration of 25 mg mL−1 (Sharma and Saharan 2016).

Anti-adhesive activity

The ability of the crude biosurfactant and the acetonitrile fraction to inhibit the early biofilm formation at various concentrations was carried out against S. epidermidis S61. According to the Fig. 4, the crude biosurfactant and the tested fraction significantly (P < 0.001) inhibited the biofilm formation with approximately the same percentages of 90% and 80% at the concentrations of 10 and 5 mg mL−1, respectively. However, at the concentration of 2.5 mg mL−1, the acetonitrile fraction, containing the surfactin, showed higher anti-adherence activity with a percentage of inhibition of 64% against 53% of the crude biosurfactant. Comparing with our results, the purified biosurfactant produced by B. cereus NK1 presented lower percentages of biofilm inhibition of S. epidermidis at the raison of 33.55% and 26.46% at concentrations of 10 and 5 mg mL−1, respectively (Sriram et al. 2011). In similar studies, the anti-adhesive activity of B. methylotrophicus DCS1 crude lipopeptide was evaluated against different strains using biosurfactant pre-treated polystyrene surfaces. Results showed that the highest anti-adhesive effect was observed against C. albicans with an inhibition percentage of about 89.3% when biosurfactant was applied at a concentration of 1 mg mL−1 (Jemil et al. 2017). In another study, the crude biosurfactant isolated from L. paracasei ssp. paracasei A20 inhibited the adherence of S. epidermidis at the concentration of 50 mg mL−1 with a percentage of 72.9% (Gudiña et al. 2010b) compared to 90 and 80% at 10 and 5 mg mL−1 respectively of our present biosurfactant.

Moreover, biosurfactant produced by L. helveticus showed a potential anti adhesive activity against S. epidermidis with a percentage of 85% which is similar to our results but at higher concentration of 25 mg mL−1 (Sharma and Saharan 2016). Furthermore, biosurfactants produced by L. jensenii and L. rhamnosus presented anti-adhesive and anti-biofilm activities against the pathogen strains A. baumannii, E. coli, and S. aureus at concentrations ranging between 25 and 50 mg mL−1 (Sambanthamoorthy et al. 2014).

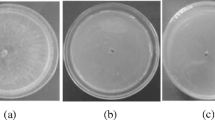

The anti-adherence activity of the two extracts was confirmed by fluorescence microscopy. The images of the acridine orange staining treated slides with extracts showed the reduction in the biofilm covered surface compared to the control (Fig. 5). Lipopeptides are able to decrease biofilm surface and interfacial tension (Zhao et al. 2017). Previous studies demonstrated that biosurfactants had the ability to alter the surface characteristics of bacterial cells and reduce their adhesive properties. In fact, the application of biosurfactant to a substratum surface can decrease its hydrophobicity, interfere with the microbial adhesion and microorganisms adsorption process (Rodrigues et al. 2006a).

Cytotoxicity assays

The cytotoxicity assay of the crude biosurfactant and the acetonitrile fraction was performed against T47D breast cancer cells and B16F10 mouse melanoma cells.

Figure 6 showed that the crude biosurfactant and the acetonitrile fraction showed high inhibition against T47D and B16F10 cells at 10 mg mL−1 (P < 0.001). Furthermore, at the concentration of 1 mg mL−1, the acetonitrile fraction was more toxic against B16F10 cells with a survival of 59.75% than T47D cells, whereas, at concentration of the 0.1 mg mL−1, both tested samples did not show any toxicity against both cell lines.

The acetonitrile fraction inhibited significantly cancer cell growth at almost all the tested concentrations (P < 0.01). It presented an IC50 of 1.17 mg mL−1 and 0.66 mg mL−1 against B16F10 cells and T47D cells, respectively (Fig. 7).

These results can be correlated with the composition of the acetonitrile fraction, which mainly consists of surfactin, belonging to lipopeptides. According to literature, lipopeptides can act as antitumor agents (Rodrigues et al. 2006b).

Previous studies reported that a biosurfactant extracted from Lactobacillus casei showed anti-proliferative potencies against an epithelial cell line with an IC50 (The half-maximal inhibitory concentration) ranging from 109.1 ± 0.84 mg mL−1 to 129.7 ± 0.52 mg mL−1 (Merghni et al. 2017) which are higher than the IC50 values obtained by our biosurfactant.

Moreover, it was previously demonstrated that surfactin could disrupt the membrane structure via two main mechanisms which are insertion into lipid bilayers, modification of membrane permeabilization via channel formation or diffusion of ions across the membrane barrier and membrane solubilization by a detergent-like mechanism (Deleu et al. 2013; Wu et al. 2017). Interestingly, Gudiña et al. (2016) reported that the surfactin anticancer activity is in relation with its hydrophobic nature. In fact, the fatty acid moiety of surfactin strongly interacts with the acyl chain of the phospholipids in order to penetrate the outer sheet of lipid bilayer, while the peptide moiety interacts with the polar head group of the lipids in cancer cells.

Conclusion

In the present study, the best producing biosurfactant strain has been screened and selected. Termed B. safensis F4, it is a lipolytic bacterial strain that has the propriety to produce surfactin with important surface-active properties. Crude and purified biosurfactant showed important antibacterial activity under planktonic conditions, preventing also bacterial adherence through inhibiting early stage biofilm formation. Interestingly, surfactin from Bacillus sp. F4 has potent cytotoxic activity against cancer cell lines, T47D breast cancer cells and B16F10 mouse melanoma cells. These findings make this studied surfactin a good candidate for potential applications in preventing infectious diseases and treating cancer.

References

Alajlani M, Shiekh A, Hasnain S, Brantner A (2016) Purification of Bioactive Lipopeptides Produced by Bacillus subtilis Strain BIA. Chromatographia 79:1527–1532. https://doi.org/10.1007/s10337-016-3164-3

Arulselvan P, Fard MT, Tan WS, Gothai S, Fakurazi S, Norhaizan ME, Kumar SS (2016) Role of antioxidants and natural products in inflammation. Oxid Med Cell Longev. https://doi.org/10.1155/2016/5276130

Beenken KE, Blevins JS, Smeltzer MS (2003) Mutation of sarA in Staphylococcus aureus limits biofilm formation. Infect Immun 71:4206–4211. https://doi.org/10.1128/IAI.71.7.4206-4211.2003

Bezza FA, Chirwa EMN (2016) Pyrene biodegradation enhancement potential of lipopeptidebiosurfactant produced by Paenibacillus dendritiformis CN5 Strain. J Hazard Mater. https://doi.org/10.1016/j.jhazmat.2016.08.035

Cherif S, Mnif S, Hadrich F, Abdelkafi S, Sayadi S (2011) Strategy for improving extracellular lipolytic activities by a novel thermotolerant Staphylococcus sp. strain. Lipids Health Dis 10:209–216. https://doi.org/10.1186/1476-511X-10-209

Christova N, Lang S, Wray V, Kaloyanov K, Konstantinov S, Stoineva I (2015) Production, structural elucidation, and in vitro antitumor activity of trehalose lipid biosurfactant from Nocardia farcinica strain. J Microbiol Biotechnol 25:439–447. https://doi.org/10.4014/jmb.1406.06025

Colla LM, Rizzardi J, Pinto MH, Reinehr CO, Bertolin TE, Costa JA (2010) Simultaneous production of lipases and biosurfactants by submerged and solid-state bioprocesses. Bioresour Technol 101:8308–8314. https://doi.org/10.1016/j.biortech.2010.05.086

Cooper DG, Goldenberg BG (1987) Surface-active agents from two Bacillus species. Appl Environ Microb 53:224–229

Das P, Mukherjee S, Sen R (2008) Antimicrobial potential of a lipopeptide biosurfactant derived from a marine B. circulans. J Appl Microbiol 104:1675–1684. https://doi.org/10.1111/j.1365-2672.2007.03701.x

Deleu M, Lorent J, Lins L, Brasseur R, Braun N, El Kirat K, Nylander T, Dufrêne YF, Mingeot-Leclercq M-P (2013) Effects of surfactin on membrane models displaying lipid phase separation. BBA—Biomembranes 1828:801–815. https://doi.org/10.1016/j.bbamem.2012.11.007

Fernandes PA, Arruda IR, Santos AFA, Araújo AA, Maior AMS, Ximenes EA (2007) Antimicrobial activity of surfactants produced by Bacillus subtilis R14 against multidrug-resistant bacteria. Braz J Microbiol 38:704–709. https://doi.org/10.1590/S1517-83822007000400022

Fiechteer A (1992) Biosurfactants: moving towards industrial application. Trends Biotechnol 10:208–217. https://doi.org/10.1016/0167-7799(92)90215-H

Gargouri B, Contreras MM, Ammar S, Segura-Carretero A, Bouaziz M (2016) Biosurfactant production by the crude oil degrading Stenotrophomonas sp. B-2: chemical characterization, biological activities and environmental applications. Environ Sci Pollut Res 24:3769–3779. https://doi.org/10.1007/s11356-016-8064-4

Ghazala I, Bouassida M, Krichen F, Benito JM, Ellouz-Chaabouni S, Haddar A (2017) Anionic lipopeptides from Bacillus mojavensis I4 as effective antihypertensive agents: Production, characterization, and identification. Eng Life Sci. https://doi.org/10.1002/elsc.201700020

Girard L, Blanchet É, Intertaglia L, Baudart J, Stien D, Suzuki M, Lebaron P, Lami R (2017) Characterization of N-acyl homoserine lactones in Vibrio tasmaniensis LGP32 by a biosensor-based UHPLC-HRMS/MS method. Sensors 17:906–918. https://doi.org/10.3390/s17040906

Gudiña EJ, Teixeira JA, Rodrigue LR (2010a) Isolation and functional characterization of a biosurfactant produced by Lactobacillus paracasei. Colloid Surface B 76:298–304. https://doi.org/10.1016/j.colsurfb.2009.11.008

Gudiña EJ, Rocha V, Teixeira JA, Rodrigues LR (2010b) Antimicrobial and antiadhesive properties of a biosurfactant isolated from Lactobacillus paracasei ssp. paracasei A20. Lett Appl Microbiol 50:419–424. https://doi.org/10.1111/j.1472-765X.2010.02818.x

Gudiña EJ, Teixeira JA, Rodrigues LR (2016) Biosurfactants produced by marine microorganisms with therapeutic applications. Mar Drugs 14:38–52. https://doi.org/10.3390/md14020038

Ibrahim HMM (2018) Characterization of biosurfactants produced by novel strains of Ochrobactrum anthropi HM-1 and Citrobacter freundii HM-2 from used engine oil-contaminated soil. Egyptian J Pet 27:21–29. https://doi.org/10.1016/j.ejpe.2016.12.005

Janek T, Łukaszewicz M, Rezanka T, Krasowska A (2010) Isolation and characterization of two new lipopeptide biosurfactants produced by Pseudomonas fluorescens BD5 isolated from water from the Arctic Archipelago of Svalbard. Bioresource Technol 101:6118–6123. https://doi.org/10.1016/j.biortech.2010.02.109

Janek T, Łukaszewicz M, Krasowska A (2013) Identification and characterization of biosurfactants produced by the Arctic bacterium Pseudomonas putida BD2. Colloid Surface B 110:379–386. https://doi.org/10.1016/j.colsurfb.2013.05.008

Jardak M, Abdelli F, Laadhar R, Lami R, Stien D, Aifa S, Mnif S (2017) Evaluation of biofilm-forming ability of bacterial strains isolated from the roof of an old house. J Gen Appl Microbiol 63:186–194. https://doi.org/10.2323/jgam.2016.10.005

Jasim B, Sreelakshmi KS, Mathew J, Radhakrishnan EK (2016) Surfactin, iturin, and fengycin biosynthesis by endophytic Bacillus sp. from Bacopa monnieri. Microb Ecol 72:106–119. https://doi.org/10.1007/s00248-016-0753-5

Jemil N, Ben Ayed H, Hmidet N, Nasri M (2016) Characterization and properties of biosurfactants produced by a newly isolated strain Bacillus methylotrophicus DCS1 and their applications in enhancing solubility of hydrocarbon. World J Microbiol Biotechnol 32:175–187. https://doi.org/10.1007/s11274-016-2132-2

Jemil N, Ben Ayed H, Manresa A, Nasri M, Hmidet N (2017) Antioxidant properties, antimicrobial and anti-adhesive activities of DCS1 lipopeptides from Bacillus methylotrophicus DCS1. BMC Microbiol 17:144–154. https://doi.org/10.1186/s12866-017-1050-2

Mathur T, Singhal S, Khan S, Upadhyay DJ, Fatma T, Rattan A (2006) Detection of biofilm formation among the clinical isolates of staphylococci: an evaluation of three different screening methods. Indian J Med Microbiol 24:25–29. https://doi.org/10.4103/0255-0857.19890

Merghni A, Dallel I, Noumi E, Kadmi Y, Hentati H, Tobji S, Ben Amor A, Mastouri M (2017) Antioxidant and anti proliferative potential of biosurfactants isolated from Lactobacillus casei and their anti-biofilm effect in oral Staphylococcus aureus strains. Microb Pathog 104:84–89. https://doi.org/10.1016/j.micpath.2017.01.017

Morikawa M, Daido H, Takao T, Murata S, Shimonishi Y, Imanaka T (1993) A new lipopeptide biosurfactant produced by Arthrobacter sp. strain MIS38. J Bacteriol 175:6459–6466. https://doi.org/10.1128/jb.175.20.6459-6466.1993

Moryl M, Spętana M, Dziubek K, Paraszkiewicz K, Różalska S, Płaza GA, Różalski A (2015) Antimicrobial, antiadhesive and antibiofilm potential of lipopeptides synthesised by Bacillus subtilis, on uropathogenic bacteria. Acta Biochim Pol 62:725–732. https://doi.org/10.18388/abp.2015_1120

Mosmann T (1983) Rapid colorimetric assay for cellular growth and survival: application to proliferation and cytotoxicity assays. J Immunol Methods 65:55–63. https://doi.org/10.1016/0022-1759(83)90303-4

Nagai T, Arai Y, Emori M, Nunome S, Yabe T, Takeda T, Yamada H (2004) Anti-allergic activity of a Kampo (Japanese herbal) medicine ‘‘Sho-seiryu-to (Xiao-Qing-Long-Tang)’’ on airway inflammation in a mouse model. Int Immunopharmacol 4:1353–1365. https://doi.org/10.1016/j.intimp.2004.05.021

Naruya S, Nei M (1987) The neighbor-joining method: a new method for reconstructing phylogenetic trees. Mol Biol Evol 4:406–425. https://doi.org/10.1093/oxfordjournals.molbev.a040454

Padmavathi AR, Pandian SK (2014) Antibiofilm activity of biosurfactant producing coral associated bacteria isolated from Gulf of Mannar. Indian J Microbiol 54:376–382. https://doi.org/10.1007/s12088-014-0474-8

Price NPJ, Rooney AP, Swezey JL, Perry E, Cohan FM (2007) Mass spectrometric analysis of lipopeptides from Bacillus strains isolated from diverse geographical locations. FEMS Microbiol Lett 271:83–89. https://doi.org/10.1111/j.1574-6968.2007.00702.x

Rodrigues L, Banat IM, Vandermis HC, Teixeira JA, Oliveira R (2006a) Interference in adhesion of bacteria and yeasts isolated from explanted voice prostheses to silicone rubber by rhamnolipid biosurfactants. J Appl Microbiol 100:470–480. https://doi.org/10.1111/j.1365-2672.2005.02826.x

Rodrigues L, Banat IM, Teixeira J, Oliveira R (2006b) Biosurfactants: potential applications in medicine. J Antimicrob Chemother 57:609–618. https://doi.org/10.1093/jac/dkl024

Sambanthamoorthy K, Feng X, Patel R, Patel S, Paranavitana C (2014) Antimicrobial and antibiofilm potential of biosurfactants isolated from lactobacilli against multi drug resistant pathogens. BMC Microbiol 14:197–205. https://doi.org/10.1186/1471-2180-14-197

Sekhon KK, Khanna S, Cameotra SS (2011) Enhanced biosurfactant production through cloning of three genes and role of esterase in biosurfactant release. Microb Cell Fact 10:49–58. https://doi.org/10.1186/1475-2859-10-49

Sekhon KK, Khanna S, Cameotra SS (2012) Biosurfactant production and potential correlation with esterase activity. J Pet Environ Biotechnol 3:7–16. https://doi.org/10.4172/2157-7463.1000133

Sen S, Borah SN, Bora A, Deka S (2017) Production, characterization, and antifungal activity of a biosurfactant produced by Rhodotorula babjevae YS3. Microb Cell Fact 16:95–108. https://doi.org/10.1186/s12934-017-0711-z

Sharma D, Saharan BS (2016) Functional characterization of biomedical potential of biosurfactant produced by Lactobacillus helveticus. Biotechnol Rep 11:27–35. https://doi.org/10.1016/j.btre.2016.05.001

Shete AM, Wadhawa G, Banat IM, Chopade BA (2006) Mapping of patents on bioemulsifier and biosurfactant: a review. J Sci Ind Res 65:91–115

Silva NRA, Luna MAC, Santiago ALCMA, Franco LO, Silva GKB, Souza PM, Okada K, Albuquerque CDC, Silva CAA, Takaki GMC (2014) Biosurfactant-and-bioemulsifier produced by a promising Cunninghamella echinulata isolated from Caatinga soil in the northeast of Brazil. Int J Mol Sci 15:15377–15395. https://doi.org/10.3390/ijms150915377

Singh P, Cameotra SS (2004) Potential applications of microbial surfactants in biomedical sciences. Trends Biotechnol 22:142–146. https://doi.org/10.1016/j.tibtech.2004.01.010

Sriram MI, Kalishwaralal K, Deepak V, Gracerosepat R, Srisakthi K, Gurunathan S (2011) Biofilm inhibition and antimicrobial action of lipopeptide biosurfactant produced by heavy metal tolerant strain Bacillus cereus NK1. Colloid Surf B 85:174–181. https://doi.org/10.1016/j.colsurfb.2011.02.026

Ülker S, Karaoglu SA (2012) Purification and characterization of an extracellular lipase from Mucor hiemalis f. corticola isolated from soil. J Biosci Bioeng 114:385–390. https://doi.org/10.1016/j.jbiosc.2012.04.023

Vasudevan P, Nair MK, Annamalai T, Venkitanarayanan KS (2003) Phenotypic and genotypic characterization of bovine mastitis isolates of Staphylococcus aureus for biofilm formation. Vet Microbiol 92:179–185. https://doi.org/10.1016/S0378-1135(02)00360-7

Vollenbroich D, Pauli G, Ozel M, Vater J (1997) Antimycoplasma properties and application in cell culture of surfactin, a lipopeptide antibiotic from Bacillus subtilis. Appl Environ Microb 63:44–49

Wilson K (1987) Preparation of genomic DNA from bacteria. In: Ausubel FM, Brent R, Kingston RE, Moore DD, Seidman JG, Smith JA, Struhl K (eds) Current protocols in molecular biology. Wiley, New York, 2003, pp 2.4.1–2.4.2

Wu YS, Ngai SC, Goh BH, Chan KG, Lee LH, Chuah LH (2017) Anticancer activities of surfactin and potential application of nanotechnology assisted surfactin delivery. Front Pharmacol 8:761. https://doi.org/10.3389/fphar.2017.00761

Yakimov MM, Timmis KN, Golyshin PN (2007) Obligate oil-degrading marine bacteria. Curr Opin Biotechnol 18:257–266. https://doi.org/10.1016/j.copbio.2007.04.006

Zhao H, Shao D, Jiang C, Shi J, Li Q, Huang Q, Rajoka MSR, Yang H, Jin M (2017) Biological activity of lipopeptides from Bacillus. Appl Microbiol Biotechnol 101:5951–5960. https://doi.org/10.1007/s00253-017-8396-0

Acknowledgements

The authors are grateful to Dr. Dorra Driss for her valuable critical reading of the manuscript. This work was funded by the Tunisian Ministry of Higher Education and Scientific Research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Abdelli, F., Jardak, M., Elloumi, J. et al. Antibacterial, anti-adherent and cytotoxic activities of surfactin(s) from a lipolytic strain Bacillus safensis F4. Biodegradation 30, 287–300 (2019). https://doi.org/10.1007/s10532-018-09865-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10532-018-09865-4