Abstract

Objectives

γ-amino butyric acid (GABA) is a non-protein amino acid, considered a potent bioactive compound. This study focused on biosynthesis of food-grade GABA by immobilized glutamate decarboxylase (GAD) from Lactobacillus plantarum in the rice vinegar and monosodium glutamate (MSG) reaction system.

Results

The gene encoding glutamate decarboxylase (GadB) from L. plantarum has been heterologously expressed in Lactococcus lactis and biochemically characterized. Recombinant GadB existed as a homodimer, and displayed maximal activity at 40 °C and pH 5.0. The Km value and catalytic efficiency (kcat/Km) of GadB for L-Glu was 22.33 mM and 62.4 mM−1 min−1, respectively, with a specific activity of 24.97 U/mg protein. Then, purified GadB was encapsulated in gellan gum beads. Compared to the free enzyme, immobilized GadB showed higher operational and storage stability. Finally, 9.82 to 21.48 g/L of GABA have been acquired by regulating the amounts of catalyst microspheres ranging from 0.5 to 0.8 g (wet weight) in 0.8 mL of the designed rice vinegar and MSG reaction system.

Conclusions

The method of production GABA by immobilized GadB microspheres mixed in the rice vinegar and MSG reaction system is introduced herein for the first time. Especially, the results obtained here meet the increased interest in the harnessing of biocatalyst to synthesize food-grade GABA.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

γ-amino butyric acid (GABA), a major inhibitory neurotransmitter in the mammalian central nervous system, has been reported to possess various important biological properties, such as antidiuretic, anti-hypertension, anti-oxidant, anti-fatigue, tranquilizing, and growth-promoting effects (Ngo and Vo 2019). In recent years, GABA has been extensively exploited and applied in the food, nutraceuticals, and pharmaceutical fields (Diana et al. 2014; Ngo and Vo 2019; Park et al. 2020; Misra et al. 2021; Pandey et al. 2021). Thus, development of efficient approaches for the low-cost production of food-grade GABA becomes an important issue to meet its increasing commercial demand (Lyu et al. 2017, 2020).

GABA can be biosynthesized through reversible α-decarboxylation of L-glutamate (L-MSG) by glutamate decarboxylase (GAD, EC 4.1.1.15). A number of methods for the production of GABA by the microbes with high GAD activities or purified native and recombinant GADs have therefore been developed (Lyu et al. 2018; Park et al. 2020; Yogeswara et al. 2020). Despite some achievements in whole cell microbial transformation, the enzymatic conversion could be attractive in terms of the higher GABA yield and its purity (Cui et al. 2020). However, the reusability and operational stability of biocatalyst is a key factor for the efficiency of enzymatic conversion in the practical application process. Consequently, several immobilization strategies have been explored to solve some of these hindrances. However, the immobilized GADs are roughly limited in E. coli one or heterologously expressed in E. coli (Lammens et al. 2009; Lee and Jeon 2014; Matsuura et al. 2020).

To address the above issue, in this work, the GAD gene of Lactobacillus plantarum Yll.03 was amplified and overexpressed in L. lactis NZ9000 by using a nisin-controlled gene expression vector pNZ8148. After purification by Ni2+-NTA resin affinity chromatography, the His-tag fused GadB has been characterized in terms of specific activity, optimum temperature and pH for action. To increase the reusability and operational stability, recombinant GadB was encapsulated in gellan gel beads. In further, immobilized GadB microspheres as the biocatalyst were added to a mixture of rice vinegar and monosodium glutamate, and its advantages on GABA productivity have been determined. Particularly, the source of gadB (L. plantarum), expression host cells (L. lactis), immobilized material (gellan gum) and the reaction system (rice vinegar and monosidum glutamate) are all food-grade forms. Obiviously, the results obtained here meet the increased interest in the harnessing of biocatalyst to produce food-grade GABA.

Materials and methods

Bacterial strains, plasmids, and growth conditions

L. plantarum Yll. 03 was cultured in MRS medium at 30 °C without agitation. L. lactis was grown in M17 broth supplemented with 0.5% glucose (GM17) at 30 °C. E. coli MC1061 was used as the intermediate host. When needed, chloramphenicol was used for plasmid selection and maintenance at the concentration of 30 μg/mL and 10 μg/mL for E. coli and L. lactis, respectively.

Construction of plasmids and strains

For expression of GadB in L. lactis NZ9000, the gadB was amplified from the genomic DNA of strain L. plantarum Yll. 03 by polymerase chain reaction (PCR) with primers F (CATGCCATGGGCCATCATCATCATCATCATATGGCAATGTTATACGGT) and R (CTAGTCTAGATTAGTGTGTGAATCCGTATTTCTTAG). The PCR product was ligated into pNZ8148 and subsequently transformed into the intermediate host E. coli MC1061. Recombinant pNZ8148-gadB was confirmed by DNA sequencing, and then transformed into L. lactis NZ9000 by electroporation as described previously (Lyu et al. 2020).

Expression and purification of the recombinant GadB in L. lactis

Overnight culture of L. lactis NZ9000/pNZ8148-gadB was inoculated into fresh GM17 medium with a dilution of 1:100, grown to an optical density (OD600) of 0.4 and induced with 5.0 ng nisin/mL. After 7 h of incubation, the cells were harvested by centrifugation at 6000×g for 10 min, and then resuspended in 0.05 M PBS buffer (pH 7.8). Enzyme was released by sonication in an ice-water bath (400 W, 200 × 3 s pulse with 6 s rest in between). The cell debris was removed by centrifugation at 10,000×g for 40 min at 4 °C.

Recombinant GadB was purified by Ni2+-affinity chromatography. Samples were washed with 0.9% (w/v) NaCl and concentrated by filtration over a 30 kDa centrifugal filter device (Merck millipore) via centrifugation at 13,500×g for 30 min at 4 °C. Moreover, the molecular weight distribution of GadB was determined by HPLC gel filtration with a TSK gel G-3000 SWXL column (5 μm, 300 mm × 7.8 I.D.; Tosoh Corp., Japan) (Lyu et al. 2020).

Encapsulation of GadB

The gellan gum was selected an efficient support matrix for GAD immobilization. Briefly, 1 g of gellan gum was dissolved in 90 mL of deionized distilled water with magnetic stirrer. Subsequently, 10 mL of diluted enzyme suspension (6.12 mg/mL) was added to the carrier solution. The immobilized GAD was formed by extruding the mixture through a 20 mL glass syringe with the 25 G hypodermic needle into 0.2 M CaCl2 and letting it harden for 1 h.

Biochemical properties of free and immobilized GAD

To investigate the effect of temperature on GAD activity, free and immobilized enzymes were incubated with 100 mM L-Glu and 0.01 mM PLP in 0.2 M sodium acetate-acetic acid buffer (pH 4.8) for 15 min at different temperatures (25–60 °C), and the GABA concentrations were determined as described below. The effect of pH on activities of free and immobilized GadB preparations was assayed at 40 °C in different buffers (0.2 M sodium acetate buffers of pH 3.6–5.6, 0.1 M sodium phosphate buffers of pH 6.0–7.0). To document the storage stability, the free and immobilized enzymes were stored in the 2-mL sterile plastic tubes and kept in a refrigerator at 4 °C, and then their stabilities were analyzed by measuring the remained GAD activities of small amounts of samples taken after scheduled times.

GAD activity assay

The GAD activity was determined by detecting the amount of GABA produced from L-Glu. Briefly, free enzyme (20 µL) and immobilized enzyme (wet weight, 0.5 g) were added to the above reaction mixtures (0.8 mL) and incubated at the designed pH and temperature for 15 min. Then, 0.1 mL reaction product was mixed with 0.9 mL NaHCO3 (0.2 M, pH 9.8) to terminate the reaction. After derivatization with dansyl chloride (DNS-Cl), the GABA concentrations of samples were analyzed by RP-HPLC method (Marquez et al. 1986). One unit of free or immobilized GAD activity (U) was defined as the amount of free enzyme or immobilized enzyme (dry weight) that produced 1 μM of GABA per minute under the assay conditions.

Results and discussion

Heterologous expression and purification of recombinant GadB in L. lactis

The strain L. plantarum Yll.03 was isolated from naturally pickled vegetables and identified by morphology observation (Supplementary Fig. 1a), physiological and biochemical tests (Supplementary Table 1) as well as 16S rDNA sequence analysis (Supplementary Fig. 1b). The potential gadB was amplified from its genomic DNA and incorporated into the pNZ8148 vector, and then overexpressed in L. lactis NZ9000 (Supplementary Fig. 2). The results indicate that the gadB (MN661347.1) consists of 1,410 bases, which encode a protein of 469 amino acid residues with the predicted molecular mass of 53.56 kDa (Supplementary Fig. 3). As expected, recombinant GadB has an apparent molecular mass of approximately 55 kDa as revealed by SDS-PAGE (Fig. 1a), and elutes as a 109.14 kDa species as measured by gel filtration chromatography (Fig. 1b). Our results indicate that the GadB exists as a homodimer under the native conditions.

a SDS-PAGE analysis of recombinant GadB. Lanes: (M) protein marker, (1) uninduced cells, (2) nisin-induced cells, (3) and (4) recombinant GadB purified by Ni2+-NTA agarose column. b Determination of molecular mass of recombinant GadB. Gel filtration chromatography of GadB was performed on a TSK gel G-3000 SWXL column. Molecular weight markers shown in the inset (a–g) are thyroglobulin (669 kDa), ferritin (440 kDa), myosin (200 kDa), aldolase (158 kDa), bovine serum albumin (67 kDa), ovalbumin (45 kDa) and bovine carbonic anhydrase (29 kDa)

Biochemical properties of recombinant GadB

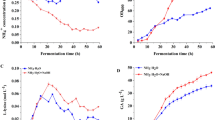

To facilitate characterization of GadB, temperature and pH dependences on enzymatic activity were investigated. The effect of temperature on GAD activity was assessed in the temperatures range 25–60 °C, with maximum activity being observed at 40 °C, above which the relative activity decreased markedly (Fig. 2a). Similar to the GADs from other LAB species (Supplementary Table 2), a narrow optimum pH range was observed from pH 4.4 to 5.2, with the maximum activity observed at pH 5.0 (Fig. 2b). Moreover, the Km value and specific activity of GadB estimated using 10–100 mM of L-Glu as substrate (pH 5.0 and 40 °C) were 22.33 mM and 24.97 U/mg (Supplementary Fig. 4), respectively. The catalytic efficiency (kcat/Km) for L-Glu was 62.4 mM−1 min−1.

Immobilization of GadB in Gellan gum beads

Gellan gum, a high molecular weight anionic linear polysaccharide, extensively used in foods and cosmetics industries owing its special gelling property and rheological behavior of its aqueous solution (Giavasis et al. 2000). Recently, gellan gum has been regarded as a versatile materials for encapsulation of various enzymes with sufficient porosity. Particularly, the gellan gum beads was found to be stable over a wide range of pH values (2.0 to 10.0) and temperatures (4.0 to 90 °C), alternative to agar, alginate and κ-carrageenan (Giavasis et al. 2000). To favour the reusability and operational stability, the gellan gel was selected as the carrier for encapsulation of GadB in this work.

The immobilization process was performed as described in materials and methods. After immobilization, the average particle size of blank gellan gum microspheres and GadB loaded gellan gum microspheres was measured and found within the range of 1.64 ± 0.13 mm and 1.47 ± 0.16 mm, respectively (Fig. 3a, b). By magnified scanning electron microscope (SEM) observation, the surface of the beads was rough and wrinkled which was possibly caused by partial collapsing of the polymeric network upon loss of water (Fig. 3c, d). Overall, there were no obvious differences in size and morphology between blank gellan gum beads and immobilized GadB beads. The amount of GadB immobilized in the gellan gum was estimated as 4.08 mg/g support (dry weight). Furthermore, the effects of temperature and pH on the activity of immobilized GadB were also investigated. The optimum temperature and pH for immobilized GadB were found to be 42 °C and 4.7, respectively. Remarkably, the immobilized GadB was endowed with lower pH-sensitivity and higher resistance to heat than that of free enzyme, as shown in Fig. 4. In addition, the Km value and specific activity of the immobilized GadB reached 40.19 mM and 19.05 U/mg, respectively.

Storage stability of immobilized GadB

In order to estimate the storage stability of immobilized GadB, the GAD activity was monitored during storage at 4 °C at different time intervals. As shown in Fig. 5a, after 4 days and 5 days storage, the free enzyme retained only 37.2% and 13.7% of its original activity, respectively. Meanwhile, the immobilized enzyme still retained approximately 92.48%, 60.2% and 49.8% of its initial activity after 5 days, 15 days and 30 days of storage, respectively (Fig. 5b). That means the GadB immobilized in the gellan gum beads is a stable biocatalyst, which may have practical applications for food-grade GABA synthesis.

Production of food-grade GABA by immobilized GadB in the mixture of MSG and rice vinegar

In recent years, GABA-enriched foods have been actively promoted owing their health benefits (Pandey and Mishra 2020). To document the potential applications of immobilized GadB microspheres, a rice vinegar and MSG reaction system has been developed. Roughly, 1.5 g of MSG powder (99%) was dissolved in the 20 mL of rice vinegar with an approximate pH value of 4.7, and then varying amounts of beads were added to 0.8 mL of the above mixture. After incubation in a static condition for 30 min at 37 °C, the resulting reaction mixtures were subjected to HPLC analysis. As expected, 9.82 g/L to 21.48 g/L of food-grade GABA have been obtained when the immobilized GadB beads were added to the designed reaction systems (0.8 mL) at the amounts ranging from 0.5 to 0.8 g (wet weight) (Fig. 6). As proven by the data gathered above, the GABA productivity in the present system (42.96 g/L/h) was relatively higher than that of the immobilized GADs from L. fermentum YS2 (3.09 g/L/h), E. coli (6.03 g/L/h) and L. plantarum WCFS1 (41.7 g/L/h) (Lin et al. 2017).

The effects of the amount of immobilized GadB beads on the biosynthesis of GABA in the MSG and rice vinegar reaction system. The 1.5 g of MSG powder (99%, Zhejiang Westlake Monosodium Glutamate Group Co. Ltd., Hangzhou, China) was dissolved in the 20 mL of rice vinegar (Zhejiang Wuweihe Food Co. Ltd., Huzhou, China) with an approximate pH value of 4.7, and then varying amounts of beads were added to 0.8 mL of the reaction mixture

Currently, the generic doses of GABA used in the supplements range from 50 to 500 mg per capsule. As expected, several milliliters of reaction soution would actually satisfy the daily needs. Herein, for the first time, the immobilized GadB gelllan gum beads is introduced as a biocatalyst for the synthesis of food-grade GABA in the designed rice vinegar and MSG reaction system.

Conclusion

In this work, the gadB from L. plantarum has been heterologously expressed in L. lactis NZ9000 based on pNZ8148. After purification by Ni2+-affinity chromatography, recombinant GadB has been characterized in terms of kinetic parameters, temperature and pH dependence. Subsequently, the GadB has been encapsulated in gellan gum beads. As expected, the immobilized GadB showed better storage stability than the free enzyme. After 30 days of storage at 4 °C, the immobilized GadB still retained 49.8% of its initial activity. Finally, up to 21.48 g/L of food-grade GABA has been obtained when 0.8 g (wet weight) of immobilized GadB microspheres were added into 0.8 mL of the designed rice vinegar and MSG reaction system. Overall, our results meet the increased interest in the harnessing of biocatalyst to produce food-grade GABA.

References

Cui YH, Miao K, Niyaphorn S, Qu XJ (2020) Production of gamma-aminobutyric acid from lactic acid bacteria: a systematic review. Int J Mol Sci 21(3):995. https://doi.org/10.3390/ijms21030995

Diana M, Quilez J, Rafecas M (2014) Gamma-aminobutyric acid as a bioactive compound in foods: a review. J Funct Foods 10:407–420. https://doi.org/10.1016/j.jff.2014.07.004

Giavasis I, Harvey LM, McNeil B (2000) Gellan gum. Crit Rev Biotechnol 20(3):177–211. https://doi.org/10.1080/07388550008984169

Lammens TM, Biase DD, Franssen MCR, Scott EL, Sanders JPM (2009) The application of glutamic acid α-decarboxylase for the valorization of glutamic acid. Green Chem 11(10):1562–1567. https://doi.org/10.1039/b913741f

Lee JY, Jeon SJ (2014) Characterization and immobilization on nickel-chelated sepharose of a glutamate decarboxylase a from Lactobacillus brevis BH2 and its application for production of GABA. Biosci Biotechnol Biochem 78(10):1656–1661. https://doi.org/10.1080/09168451.2014.936347

Lin Q, Li DN, Qin HZ (2017) Molecular cloning, expression and immobilization of glutamate decarboxylase from Lactobacillus fermentum YS2. Electron J Biotechnol 27:8–13. https://doi.org/10.1016/j.ejbt.2017.03.002

Lyu CJ, Zhao WR, Hu S et al (2017) Physiology-oriented engineering strategy to improve gamma-aminobutyrate production in Lactobacillus brevis. J Agric Food Chem 65(4):858–866. https://doi.org/10.1021/acs.jafc.6b04442

Lyu CJ, Zhao WR, Peng CL et al (2018) Exploring the contributions of two glutamate decarboxylase isozymes in Lactobacillus brevis to acid resistance and γ-aminobutyric acid production. Microb Cell Fact 17:180. https://doi.org/10.1186/s12934-018-1029-1

Lyu CJ, Fei JY, Yan JP et al (2020) Improvement of γ-aminobutyrate biosynthesis by genetically engineered Lactococcus lactis. Biochem Eng J 157:107525. https://doi.org/10.1016/j.bej.2020.107525

Marquez FJ, Quesada AR, Sanchez-Jimenez F, Castro IND (1986) Determination of 27 dansyl amino acid derivatives in biological fluids by reversed-phase high-performance liquid chromatography. J Chromatogr B 380(2):275–283. https://doi.org/10.1016/S0378-4347(00)83656-7

Matsuura SI, Ikeda T, Chiba M, Yamamoto K (2020) Efficient production of γ-aminobutyric acid by glutamate decarboxylase immobilized on an amphiphilic organic-inorganic hybrid porous material. J Biosci Bioeng 131(3):250–255. https://doi.org/10.1016/j.jbiosc.2020.10.012

Misra S, Pandey P, Mishra HN (2021) Novel approaches for co-encapsulation of probiotic bacteria with bioactive compounds, their health benefits and functional food product development: a review. Trends Food Sci Technol 109:340–351. https://doi.org/10.1016/j.tifs.2021.01.039

Ngo DH, Vo TS (2019) An updated review on pharmaceutical properties of gamma-aminobutyric acid. Molecules 24(15):2678–2700. https://doi.org/10.3390/molecules24152678

Pandey P, Mishra HN (2020) Co-microencapsulation of γ-aminobutyric acid (GABA) and probiotic bacteria in thermostable and biocompatible exopolysaccharides matrix. LWT-Food Sci Technol 136:110293. https://doi.org/10.1016/j.lwt.2020.110293

Pandey P, Mettu S, Mishra HN, Ashokkumar M, Martin G (2021) Multilayer co-encapsulation of probiotics and γ-amino butyric acid (GABA) using ultrasound for functional food applications. LWT-Food Sci Technol 146(5):111432. https://doi.org/10.1016/j.lwt.2021.111432

Park SJ, Kin DH, Kang HJ et al (2020) Enhanced production of γ-aminobutyric acid (GABA) using Lactobacillus plantarum EJ2014 with simple medium composition. LWT-Food Sci Technol 137:110443. https://doi.org/10.1016/j.lwt.2020.110443

Yogeswara IBA, Maneerat S, Haltrich D (2020) Glutamate decarboxylase from lactic acid bacteria-A key enzyme in GABA synthesis. Microorganisms 8(12):1923. https://doi.org/10.3390/microorganisms8121923

Acknowledgements

This work was supported by China Postdoctoral Science Foundation (2020M671337), Postgraduate Innovation Science Research Project, Heilongjiang Bayi Agricultural University (YJSCX2021-Y110), Postdoctoral Foundation of Jiangsu Province (2020Z074), National Natural Science Foundation of China (Nos. 31670804, 31971372) and Ningbo “Scientific and Technological Innovation 2025” Key Project (No. 2020YZCXYD180178).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Yao, LL., Cao, JR., Lyu, CJ. et al. Food-grade γ-aminobutyric acid production by immobilized glutamate decarboxylase from Lactobacillus plantarum in rice vinegar and monosodium glutamate system. Biotechnol Lett 43, 2027–2034 (2021). https://doi.org/10.1007/s10529-021-03164-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-021-03164-4