Abstract

l-2-Aminobutyric acid (l-ABA) is an unnatural amino acid that is a key intermediate for the synthesis of several important drugs. It can be produced by transaminase or dehydrogenase from α-ketobutyric acid, which can be synthesized enzymatically from the bulk amino acid, l-threonine. Deamination of l-threonine followed by a hydrogenation reaction gave almost the theoretical yield and was estimated to be more cost-effective than the established chemical process. l-Threonine deaminase from Escherichia coli, l-leucine dehydrogenase from Bacillus cereus, and formate dehydrogenase from Pseudomonas sp. were over-expressed in E. coli and used for one-pot production of l-ABA with formate as a co-substrate for NADH regeneration. 30 mol l-threonine were converted to 29.2 mol l-ABA at 97.3 % of theoretical yield and with productivity of 6.37 g l−1 h−1 at 50 l. This process offers a promising approach to fulfil industrial requirements for l-ABA.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

l-2-Aminobutyric acid (l-ABA), an unnatural amino acid, has been used as an important precursor for the synthesis of many chiral drugs, including the anti-tuberculotic ethambutol, brivaracetam, and the anti-epileptic levetiracetam. It is synthesized in an α-transamination reaction starting from l-threonine and l-aspartic acid and has been scaled up to 2,000 l (Zhu et al. 2011). To overcome the typical unfavorable reaction equilibrium catalyzed by α-transaminase, which cannot exceed 50 % without destroying the reaction equilibrium (Taylor et al. 1998), l-aspartate was employed as an amino donor because the resulting oxaloacetic acid underwent spontaneous decarboxylation to pyruvic acid. However, this reaction led to product contamination with l-alanine. Acetolactate synthase has been introduced to remove the pyruvate intermediate, thereby shifting the reaction equilibrium to l-ABA synthesis with transformation yields of 58 % (Fotheringham et al. 1999) and 62 % (Zhu et al. 2011). The process was optimized by the further addition of alanine racemase in combination with d-amino acid oxidase to eliminate the remnant l-alanine, reaching 25.3 g l−1 (0.246 M); a yield of 55 % (Zhu et al. 2011). l-ABA production in a hydrogenation reaction starting from ketobutyric acid, using leucine dehydrogenase (LeuDH) from Thermoactinomyces intermedius in combination with formate dehydrogenase to regenerate NADH, achieved a yield of 88 % and a final titer of 36 g l−1 (0.35 M) (Galkin et al. 1997), which was much higher than the above discussed transamination-based process.

Because α-ketobutyric acid is not commercially available, we developed a hydrogenation reaction-based process starting from the bulk chemical l-threonine in combination with l-threonine deaminase and a NADH-regeneration system and thus successfully solved the problem of low yield from our previously developed α-transamination reaction-based process, which achieved a much higher yield than the previous highest reported yield based on LeuDH from T. intermedius (Galkin et al. 1997). The LeuDH from Bacillus cereus, having a higher specific activity (Ansorge and Kula 2000) than that from T. intermedius, was applied in combination with glucose dehydrogenase or formate dehydrogenase to generate NADH (Fig. 1) in this study.

Materials and methods

Materials

Restriction endonuclease and T4 DNA ligase were purchased from New England Biolabs, Inc. (Beijing, China), and Kod/plus DNA polymerase was obtained from Toyobo (Shanghai, China). The bacterial strains and plasmids used in this study are listed in Supplementary Table 1.

Plasmid construction

The expression vector pET28b-ilvA containing the ilvA gene (Gene ID: 948287), which encodes l-threonine deaminase (TD), was constructed in our previous work (Zhu et al. 2011). The leudh gene (Gene ID: AP009048), encoding l-leucine dehydrogenase (LeuDH), was amplified from the chromosome of B. cereus ATCC 14579 using the primers 5′-CATGCCATGGGAACATTAGAAATCTTC-3′ and 5′-CGGGATCCTTAGCGACGGCTAAT-3′ containing NcoI or BamHI recognition sites, respectively. The NcoI/BamHI double-digested fragment was inserted into the NcoI/BamHI sites of pET28b to create pET28b-leudh. The gdh gene (Gene ID: AL009126.3), encoding glucose dehydrogenase (GDH), was amplified from the chromosome of B. subtilis 168 using the primers 5′-CGGGATCCATGTATCCGGATTTAAAAG-3′ and 5′-CCCAAGCTTTTAACCGCGGCCTGCCTGG-3′ containing BamHI or HindIII sites, respectively. The BamHI/HindIII double digested fragment was inserted into the BamHI/HindIII sites of pET24a to create pET24a-gdh. The fdh gene from Pseudomonas sp. 101 (Tishkov and Popov 2006), encoding formate dehydrogenase (FDH), was synthesized de novo by GeneScript (Nanjing, China) and included NdeI and BamHI sites at either end. This gene was subcloned into NdeI/BamHI-linearized pET24a to create pET24a-fdh. The resulting plasmids were used to transform chemically competent BL21 (DE3) E. coli cells, and all genes were expressed under the control of the T7 promoter. Plasmid constructs were verified by DNA sequencing.

Fermentation

Flask fermentation was performed as follows: The BL21 (DE3) strains containing pET28b-ilvA, pET28b-leudh, pET24a-gdh and pET24a-fdh were grown overnight at 37 °C with shaking at 220 rpm in 5 ml LB medium plus kanamycin (100 μg ml−1). These cultures were then inoculated into 100 ml Terrific broth (TB) plus kanamycin (100 μg ml−1) and grown to an OD600 of 5–6 at 37 °C with shaking at 220 rpm. The cultures were then induced with 0.2 mM IPTG and incubated overnight at 28 °C. The cells were then recovered by centrifugation at 10,000×g for 15 min, washed in 50 mM Tris/HCl buffer (pH 7.5) and re-centrifuged. The cell pellets were frozen for SDS-PAGE or activity analysis.

The 50-l scale fermentations were performed as follows: The BL21 (DE3) strains containing pET28b-ilvA, pET28b-leudh, and pET24a-gdh were grown for 16 h with shaking at 220 rpm at 37 °C in 4 ml of LB medium plus kanamycin (100 μg ml−1). These cultures were then inoculated into 5-l flasks containing 750 ml LB medium plus kanamycin (100 μg ml−1) at 37 °C with shaking at 220 rpm for 5 h. Then, the cultures were inoculated at 5 % (v/v) into 30 l TB medium in a 50 l fermentor (08-F33, Baoxing Bio-Engineering Equipment Co., Ltd., Shanghai, China) and cultured at 37 °C with agitation at 600 rpm and aeration at 1.25 vvm for 1 h. The cultures were then induced with 10 g lactose l−1 for 1 h at 25 °C followed by feeding 5 g lactose l−1 and further culture for 24 h.

The BL21 (DE3) strain containing pET24a-fdh was grown for 16 h at 37 °C with agitation at 220 rpm in 4 ml LB medium plus kanamycin (100 μg ml−1). These cultures were then inoculated into 5 l flasks containing 750 ml LB medium kanamycin (100 μg ml−1) at 37 °C with agitation at 220 rpm for 5 h. Then, the cultures were inoculated at 5 % (v/v) into 30 l TY medium (8 g yeast extract l−1; 12 g tryptone l−1; 4.02 g K3PO4 l−1; 3 g NaCl l−1; 2.1 g citric acid monohydrate l−1; 0.3 g ferric ammonium citrate l−1; 10 g glycerol l−1; 2.5 g (NH4)2SO4 l−1; 0.5 g MgSO4·7H2O l−1) in the 50 l fermentor and cultured at 37 °C with agitation at 300 rpm, aeration at 1 vvm. The agitation was increased steadily up to a maximum of 800 rpm to reach 20 % dissolved oxygen (DO). When the DO further increased above 60 %, 400 g glycerol l−1; 50 g yeast extract l−1, and 25 g tryptone l−1 were fed into the medium to control the DO >10 % with 1 vvm aeration, 800 rpm agitation. 0.2 mM IPTG was added to the medium when the OD600 reached 20, and the cells were cultured at 28 °C for 20 h. The cells were then recovered by centrifugation at ~11,000×g for 15 min.

Enzyme analysis

Cells from 3 ml culture were harvested after overnight induction by centrifugation at 1,500×g for 10 min at 4 °C and resuspended in 1.2 ml lysis buffer (100 mM Tris/HCl, pH 7.5). The cell suspensions were lysed by sonication for 2 min in 30 s pulses on ice. The 1.2 ml cell lysis was divided into three portions. One portion was subjected to SDS-PAGE analysis as the whole cellular protein extract. The soluble and insoluble protein extracts were prepared by centrifugation of the lysates at 15,000×g for 10 min at 4 °C followed by mixture of the supernatant or precipitant fraction (resuspended in 400 μl water), respectively, with 5 × SDS sampling buffer for SDS-PAGE analysis. Protein solubility was estimated by scanning Coomassie Blue-stained gels and comparing the protein bands to that of a reference protein. The soluble proteins were all used for activity measurement. Protein concentrations were determined by the Bradford method using bovine serum albumin for calibration. TD activity was measured by determining the decrease in threonine levels (see Umbarger and Brown 1957). The amounts of threonine were determined by HPLC. LeuDH activity was measured by the method of Ansorge and Kula (2000). Formate dehydrogenase activity was assayed by the method of Berrios-Rivera et al. (2002). GDH was assayed by the method of Fujita et al. (1977).

Enzyme transformation

The cells were then recovered by centrifugation at ~11,000×g for 15 min and resuspended in a double volume of water. The cell lysates were prepared using a French Press at 60 MPa.

For the large-scale study, a 30 l reaction was carried out in a 50 l jar fermentor. The cultivation mixture contained 39 mol l-threonine, 40 mol glucose, 2.5 × 104 U TD l−1, 2.5 × 104 U GDH l−1, 7.5 × 103 U LeuDH l−1, and 0.6 g NAD. The pH was controlled with 15 % NH4OH at pH 7.5, and incubation continued until the titer of l-ABA ceased to increase. Samples were taken during the transformation and the cells were removed by centrifugation. The resulting supernatant was diluted 100-fold and subjected to analysis by HPLC.

When using FDH in the 30-l cultivation, the initial mixture contained 30 mol l-threonine, 30 mol ammonium formate, 2.5 × 104 U TD l−1, 1.25 × 104 U FDH l−1, 1.25 × 104 LeuDH l−1 and 0.9 g NAD. 0.3 g NAD was then fed into the mixture at 3 and 6 h. The pH was controlled with 20 % (v/v) formic acid at pH 7.5, and incubation continued until the titer of l-ABA ceased to increase.

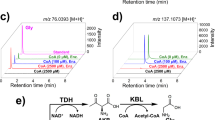

HPLC analysis of amino acids

The amino acids were derivatized with OPA/BOC-Cys and analyzed by HPLC using a LC-18DB column (5 μm, 4.6 × 250 mm, Agilent). The gradient elution profile, at 1 ml/min, was as follows: 100 % A at 0–17 min, 40 % A and 60 % B at 17–18.1 min, 100 % B at 18.1–25 min (A = 0.02 M sodium acetate, with 180 μl triethylamine l−1 and 3 ml tetrahydrofuran l−1, pH 7.2; B = 0.02 M sodium acetate/acetonitrile/MeOH (1:2:2, by vol), pH 7.2). Detection was at 338 nm.

Isolation and purification of l-ABA

The reaction mixture was heated to 100 °C and 0.5 % activated charcoal was added. The precipitate was removed by composite filtration, and the liquid was then vacuum concentrated to approx. 33 % of its original volume. Three volumes of ethanol were then added for crystallization. The l-ABA crystals were collected by composite filtration, and two vol. 95 % (v/v) ethanol were then added for crystallization. The final l-ABA crystal was heat-dried for analysis.

Results

Expression of cloned genes

The genes, ilvA, leudh, fdh, and gdh, were over-expressed in flask fermentation and compromised 35–57 % of the total E. coli proteins and 68–90 % of the soluble fraction (Fig. 2a). The total enzyme activities were calculated as 134 ± 17, 16.9 ± 0.8, and 118 ± 3 U ml−1 for TD, LeuDH, and GDH, respectively. However, FDH showed low activity relative to the other dehydrogenases (<3 U ml−1), and therefore the process was optimized by switching to fed-batch fermentation in TY medium with glycerol as the carbon source. The final OD reached approx. 20 and the total FDH activity increased to 26 ± 3 U ml−1 (Fig. 2b).

SDS-PAGE analysis of the recombinant E. coli BL21(DE3) lysate (a) and relative enzyme activities calculated by U ml−1 broth in dark black at the end of fermentation (b). The insoluble fraction (lane 1, 4, 7, 10), soluble fraction (lane 2, 5, 8, 11), and whole cellular protein extract (lane 3, 6, 9, 12) of BL21 (DE3)/pET28b-leudh, BL21 (DE3)/pET24a-fdh, BL21 (DE3)/pET28b-ilvA, and BL21 (DE3)/pET24a-gdh induced by IPTG. Lane 13 low molecular protein marker (Pharmacia)

Large-scale preparation of l-ABA catalyzed by TD, LeuDH, and GDH

Two NADH regeneration systems, catalyzed by either GDH or FDH with glucose or formate as co-substrates, respectively, were studied. The titer of L-ABA produced by 25000 U TD l−1, 7500 U LeuDH l−1, and 25000 U GDH l−1 from 39 mol l-threonine, 40 mol glucose, and 0.6 g NAD in 30 l was 36.3 mol (124.8 g l−1) in 15 h, achieving 93 % of the theoretical yield and a productivity of 8.32 g l−1 h−1.

Large-scale preparation of l-ABA catalyzed by TD, LeuDH, and FDH

As the cost of FDH fermentation was higher than that of GDH, the addition of FDH activity was reduced to half that of GDH. However, l-ABA production by 25000 U TD l−1, 7500 U LeuDH l−1, and 12500 U FDH l−1 from 1 M l-threonine, 1 mol ammonium formate and 20 mg NAD+ l−1 yielded only 45.3 g l-ABA l−1 in a 1 l reaction in 9 h (Fig. 3a). As the second hydrogenation step was catalyzed by LeuDH and FDH with NAD+ as a cofactor, and the addition of the FDH activity was limited by its cost, we increased LeuDH activity and/or NAD+ concentration. The l-ABA titer only increased by 15.6 % (52.3 g l−1) in 9 h when the LeuDH activity was doubled to 12,500 U l−1. We then increased NAD+ from 20 to 30 mg l−1, and the l-ABA titer further increased by 30 % from 52.3 to 68.4 g l−1 in 15 h, which was 70.8 % of the theoretical yield. This indicates that the concentration of NAD+ was the rate-limiting step. When 10 mg NAD+ l−1 was fed into an reaction mixture at 3 h and 6 h, with the initial concentration of 30 mg l−1, l-ABA was 94.7 g l−1, achieving 98.4 % of the theoretical yield (Fig. 3a). From 1 l of reaction mixture, 94.7 g l-ABA was produced and, after purification and crystallization, 81.7 g l-ABA with purity of 99.1 % was obtained (ee > 99.5 %). The process was then used for one-pot production of l-ABA with formate as co-substrate for NADH regeneration in a scale-up of the process. With 30 l reaction in a 50 l fermentor, 30 mol l-threonine was converted to 29.2 mol l-ABA at 97.3 % of theoretical yield and with a productivity of 6.9 g l−1 h−1 (Fig. 3b).

The titer (solid column) and yield (blank column) of l-ABA catalyzed by combinations of recombinant TD, FDH, LeuDH cell extract and NAD (a), and the time courses (b) catalyzed by recombinant 25000 U TD l−1, 12500 U FDH l−1, 12500 U LeuDH l−1 cell extract and NAD+ initial concentration = 30 mg l−1, 10 mg l−1 being fed at 3 h and 6 h from 30 mol l-theronine at 30 l scale

Discussion

This is the first report of dehydrogenase-based biotransformation to produce l-ABA from the bulk chemical, l-threonine, through a process coupled with a NADH regeneration system. l-ABA production in a hydrogenation reaction starting from α-ketobutyric acid and catalyzed by LeuDH from T. intermedius in combination with formate dehydrogenase to regenerate NADH reached a yield of 88 % and a final titer of 0.35 M (Galkin et al. 1997). However, the combination of deamination with a hydrogenation reaction starting from l-threonine was made due to the expectation of a high yield (97.3 %), which would approach the theoretical yield, in the scale-up of this process in this study and was thus in commercialization by local companies. The original commercial chemical-based process from propionaldehyde and NaCN to generate 5-ethyl hydantoin followed by hydrolysis and chiral separation (Wang 2011) was replaced by the newly-developed process in this study. Anti-epileptic drug, levetiracetam, is synthesized from the l-ABA derivative, l-aminobutanamide, which can be directly synthesized chemically without generating l-ABA (Jiang et al. 2012). Based on current domestic chemical prices (July, 2013: http://www.qrx.cn/), the above mentioned l-aminobutanamide synthesis process was calculated to have a substrate cost of US$ 3.4 (Supplementary Fig. 1b), while the bioprocess established in the present study was US$ 3.9 kg−1 (Supplementary Fig. 1a). The small differences in the theoretical substrate costs between the two routes will result in competition with regard to the cost of process development.

There are several strategies that may further increase the economic advantage of the established dehydrogenase-based bioprocess. One strategy is to reuse the enzymes in the immobilized form or a membrane reactor to increase the total turnover number. One example would be the use of PEG-covalent technology and membrane reactors as previously reported in the production of l-tert-leucine (Kragl et al. 1996). Another strategy is to increase the activity of the enzymes, in particular that of FDH, by rational design or random mutagenesis, as previously reviewed (Tishkov and Popov 2006). The recently-reported ω-transaminase-based reaction with benzylamine (Park et al. 2010; Seo et al. 2012) or even cheaper isopropylamine (Park et al. 2013) as amino donor permit thermodynamically unrestricted asymmetric synthesis of l-ABA at over 99 % yield. This offers another promising biochemical synthesis route of l-ABA.

References

Ansorge MB, Kula MR (2000) Production of recombinant l-leucine dehydrogenase from Bacillus cereus in pilot scale using the runaway replication system E. coli[pIET98]. Biotechnol Bioeng 68:557–562

Berrios-Rivera SJ, Bennett GN, San KY (2002) Metabolic engineering of Escherichia coli: increase of NADH availability by overexpressing an NAD(+)-dependent formate dehydrogenase. Metab Eng 4:217–229

Fotheringham IG, Grinter N, Pantaleone DP, Senkpeil RF, Taylor PP (1999) Engineering of a novel biochemical pathway for the biosynthesis of L-2-aminobutyric acid in Escherichia coli K12. Bioorg Med Chem 7:2209–2213

Fujita Y, Ramaley R, Freese E (1977) Location and properties of glucose dehydrogenase in sporulating cells and spores of Bacillus subtilis. J Bacteriol 132:282–293

Galkin A, Kulakova L, Yoshimura T, Soda K, Esaki N (1997) Synthesis of optically active amino acids from α-keto acids with Escherichia coli cells expressing heterologous genes. Appl Environ Microbiol 63:4651–4656

Jiang Y, Que L, Cai T. (2012) Chinese patent: 102584622 A

Kragl U, Vasic-Racki D, Wandrey C (1996) Continuous production of l-tert-leucine in series of two enzyme membrane reactors. Bioprocess Eng 14:291–297

Park E, Kim M, Shin JS (2010) One-pot conversion of l-threonine into l-homoalanine: biocatalytic production of an unnatural amino acid from a natural one. Adv Synth Catal 352:3391–3398

Park E, Dong J, Shin JS (2013) ω-Transaminase-catalyzed asymmetric synthesis of unnatural amino acids using isopropylamine as an amino donor. Org Biomol Chem 11:6929–6933

Seo YM, Mathew S, Bea HS, Khang YH, Lee SH, Kim BG, Yun H (2012) Deracemization of unnatural amino acid: homoalanine using d-amino acid oxidase and ω-transaminase. Org Biomol Chem 10:2482–2485

Taylor PP, Pantaleone DP, Senkpeil RF, Fotheringham IG (1998) Novel biosynthetic approaches to the production of unnatural amino acids using transaminases. Trends Biotechnol 16:412–418

Tishkov VI, Popov VO (2006) Protein engineering of formate dehydrogenase. Biomol Eng 23:89–110

Umbarger HE, Brown B (1957) Threonine deamination in Escherichia coli. II. Evidence for two l-threonine deaminases. J Bacteriol 73:105–112

Wang B (2011) Chinese patent: 102050750

Zhu L, Tao R, Wang Y, Jiang Y, Lin X, Yang Y, Zheng H, Jiang W, Yang S (2011) Removal of l-alanine from the production of l-2-aminobutyric acid by introduction of alanine racemase and d-amino acid oxidase. Appl Microbiol Biotechnol 90:903–910

Acknowledgments

This work was supported by the Knowledge Innovation Program of the Chinese Academy of Sciences (KSCX2-EW-G-7-1), Hi-Tech industrialized seed fund projects by Pudong New Area and Chinese Academy of Sciences (No. PKC2010-03), and Zhejiang province biocatalytic Engineering Technology Research Center Project (2011E10025). This work was also supported in part by National Basic Research Program of China (973: 2007CB707803, 2011CBA00806), Academy-Locality cooperation program of Chinese Academy of Sciences (DBSH-2011-046), and “365” Outstanding Scientific and Technological Innovation Team of Huzhou (2010KC01). We thanks for the exhaustive discussion with Dr. Bo Wang from gyrochem.

Author information

Authors and Affiliations

Corresponding author

Additional information

Rongsheng Tao and Yu Jiang have contributed equally to this work.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Tao, R., Jiang, Y., Zhu, F. et al. A one-pot system for production of l-2-aminobutyric acid from l-threonine by l-threonine deaminase and a NADH-regeneration system based on l-leucine dehydrogenase and formate dehydrogenase. Biotechnol Lett 36, 835–841 (2014). https://doi.org/10.1007/s10529-013-1424-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-013-1424-y