Abstract

Clarity of fruit juices is desirable to maintain an aesthetically pleasing quality and international standards. The most commonly used enzymes in juice industries are pectinases. A partially-purified pectinmethylesterase from tomato was entrapped in calcium alginate beads and used for juice clarification. The activity yield was maximum at 1 % (w/v) CaCl2 and 2.5 % (w/v) alginate. The immobilized enzyme retained ~55 % of its initial activity (5.7 × 10−2 units) after more than ten successive batch reactions. The Km, pH and temperature optima were increased after immobilization. The most effective clarification of fruit juice (%T620 ~60 %) by the immobilized enzyme was at 4 °C with a holding time of 20 min. The viscosity dropped by 56 % and the filterability increased by 260 %. The juice remains clear after 2 months of storage at 4 °C.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Pectic substances are complex colloidal plant carbohydrates and produce a high viscosity and turbidity in fruit juices. They are also responsible for the development of haze and retard the maximum recovery of juices from the fruits. Pectin, which is composed of α-1,4-linked galacturonic acid and its methyl ester are degraded by pectolytic enzymes (Willats et al. 2001) that are widely used in industry for the extraction and clarification of fruit juices and grape musts, maceration of vegetables and fruits, clarification of wine and olive oil extraction (Srivastava et al. 1996). Depectinization using pectinases can clarify fruit juices effectively (Valliant et al. 1999) and can improve processing capacity and economy in the fruit juice and wine industries (Tochi et al. 2009). They increase juice yield, accelerate juice clarification, speed up filtration and prevent storage or post-packaging haze formation. Pectinases are also used as animal feed supplements as they can reduce the feed viscosity by degrading pectins, thereby increasing absorption and liberation of nutrients (Murad and Azzaz 2011).

Pectinmethylesterase (EC 3.1.1.11) is an important constituent of many commercially-available mixtures of pectolytic enzymes. Pectinmethylesterase (PME), also known as pectinesterase, catalyses the de-esterification of carboxyl groups in pectin yielding galactouronic acid and methanol. This catalytic action makes PME an important enzyme in the industrialization and preservation of fruits, juices and other products (Alonso et al. 1997).

Regarding the technological and biological importance of PME, it is desirable to immobilize the enzyme in order to increase its stability, reusability and to make the process more economical. Alginate within a calcium alginate gel is biocompatible and immobilization is inexpensive. The main objective of this work was to evaluate the use of calcium alginate as a support matrix for immobilization of PME (isolated from discarded over-ripe tomatoes) and its possible use in fruit juice clarification.

Materials and methods

Partial purification of pectinmethylesterase (PME)

PME was partially purified from discarded over-ripe tomatoes by homogenizing in distilled water (pH 7.5) containing 10 % (w/v) NaCl, followed by heat inactivation (55 °C for 1 h) and (NH4)2SO4 fractionation (0–60 %).

Determination of pectinmethylesterase activity

Enzyme activity was determined by the method of Hagerman and Austin (1986). The reaction mixture consisted of 2.4 ml distilled water, 0.1 ml 0.5 % (w/v) pectin, 0.4 ml 0.01 % (w/v) Bromothymol Blue and 0.1 ml enzyme preparation. The contents were mixed and change in absorbance at 620 nm for 10 min was determined. One unit of enzyme activity was defined as the amount of enzyme required to release 1 μmol acid equivalent min−1 under standard assay conditions.

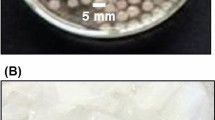

Optimization for immobilization of pectinmethylesterase

For immobilization of pectinmethylesterase in calcium alginate beads, the method of Banerzee et al. (1984 was used. The concentration of sodium alginate and CaCl2 were varied while keeping the other parameters constant. Batch reactions were conducted with the immobilized enzyme and optimum conditions for entrapment were determined. All the entrapment steps were carried out at 25 °C. The percentage of entrapped enzyme activity was calculated from:

Assay of the immobilized enzyme

Activity of the immobilized enzyme was determined by taking ten beads of the enzyme in 2.4 ml distilled water (pH 7.5) containing 10 % (w/v) NaCl. The enzymatic reaction was started by adding 0.1 ml 0.5 % (w/v) pectin, 0.4 ml 0.01 % (w/v) Bromothymol Blue and the reaction was stopped after 20 min by removing the beads.

Optimum pH and temperature

The optimum pH was determined with pectin as a substrate using 50 mM buffers of different pH (histidine.HCl buffer, pH 7.0–7.5; Tris/HCl buffer, pH 8.0–9.0; glycine/NaOH buffer, pH 9.5–10.5) as well as with distilled water of different pH (7.0–9.0). The optimum temperature for pectinmethylesterase was determined from 20 to 75 °C.

Stability of the immobilized enzyme

The pH and temperature stability of enzyme was measured by incubating the enzyme with buffers of different pHs and at different temperatures for 10 min. The residual activity was determined under optimum reaction conditions.

Kinetic parameters of free and immobilized PME

The apparent Km for the hydrolysis of pectin by free and immobilized enzyme was determined by varying the substrate from 0.1 to 3 mg/ml.

Operational stability of immobilized PME

The retention of the immobilized enzyme activity was tested as described in the activity assays of PME. After each reaction run, the enzyme immobilized beads were removed and washed with distilled water of pH 7.5 to remove any residual substrate.

Juice clarification

Three ml extracted, sieved and pasteurized orange juice was treated with 0.5 g beads with immobilized enzyme at 4 °C for 1 h to hydrolyze the pectin. The treated juice was centrifuged at 3,000×g for 5 min and the supernatant was collected. Filterability and clarity were determined in the supernatant.

Filterability

The filterability (s−1) of the treated juice was determined from the reverse of the time taken for filtering 100 ml orange juice using vacuum filtration.

Clarity and viscosity

The clarity of the juice obtained was determined by measuring the absorbance at 620 nm. Distilled water was used as the reference. For processed and unprocessed orange juice, viscosity was measured by a Ostwald viscometer.

Results and discussion

Table 1 shows the effect of varying concentrations of sodium alginate on pectinmethylesterase activity. The entrapped activity was maximal (~115 %) with sodium alginate at 2 % (w/v). At 2.5 % (w/v) or above the entrapped activity was ~100 % but at 2.5 %, the entrapped enzyme could be reused for more than ten cycles, whereas at 2 %, entrapped enzyme could be reused only for six cycles. The decrease in activity may be due to the leakage of enzymes from the beads during washing of beads at the end of each cycle. The loss in activity was insignificant in comparison to its reusability; hence, 2.5 % (w/v) alginate was used in all subsequent experiments. Although approximately the same amount of activity was entrapped with 3 and 3.5 % (w/v) sodium alginate, these concentrations were not used as the beads were not of uniform size due to the high viscosity of the enzyme-bovine serum albumin-sodium alginate mixture. Bovine serum albumin was mixed during the entrapment to prevent the diffusion of the enzyme. Sodium alginate from 2 to 3 % has been used for the immobilization of various enzymes including aminopeptidase B (Bogra et al. 2009) and cathepsin L (Sharma et al. 2007). The effect of varying concentrations of CaCl2 on PME immobilization is shown in Table 1. The activity yield was highest (−115 %) at 1 % (w/v) CaCl2. This increase in activity may be due to the Ca2+ being an activator of PME (Ren and Kermode 2000). Further increases in CaCl2 concentration reduced activity which might be due to the smaller matrix mesh size limiting the substrate diffusion or the higher concentrations of Ca2+ being inhibitory (Ren and Kermode 2000). Therefore, the conditions for immobilization were fixed at 2.5 % (w/v) sodium alginate and 1 % (w/v) CaCl2.

Time course of reaction

Product accumulation with the immobilized enzyme reached a maximum after 60 min. The increase in product formation up to 10 min was slow but more pronounced thereafter (Fig. 1). This suggests that the initial activity is affected by slow diffusion of the substrate into the beads but once sufficient substrate had entered the beads then the apparent activity increased. On the basis of this, the reaction time selected was 20 min. For the free enzyme, the assay time (10 min) was half of the immobilized enzyme.

Effect of pH and temperature on enzyme activity

The optimum pH value of the immobilized PME was shifted from pH 8.0 to 8.5 (Fig. 2a). This might be due to the enzyme being in a negatively-charged alginate matrix attracting positive ions that alter the microenvironment in which the enzyme actually operates and results in basic shift in the optimum pH for the catalytic activity (Grant et al. 1973). The pH optima were obtained with the water of different pHs. This might be due to the fact that buffers may resist the change in pH observed due to PME action. The PME from acerola fruits and immobilized on porous silica had a pH optimum of 8–9 (Assis et al. 2003). The free enzyme was stable between pH 7.5 and 10.5 whereas immobilized pectinmethylesterase was stable from pH 6.5–11 (Fig. 2b). The optimum temperatures for the free and immobilized enzyme were 55 and 60 °C, respectively (Fig. 2c) whereas Assis et al. (2003) reported a decrease in temperature optimum from 90 to 80 °C on immobilization. The immobilized enzyme retained ~60 % of activity at 65 °C whereas the free enzyme retained only ~30 % original activity (Fig. 2d). The stability of the immobilized enzyme is probably due to protection of the enzyme from denaturation. The effect of different incubation time and temperature on enzyme activity is shown in Fig. 3.

Determination of a pH optima of free and immobilized PME. 100 % = 6.5 × 10−2 units for free enzyme and 5.7 × 10−2 units for immobilized enzyme. b pH stability of free and immobilized PME. After exposing the free and immobilized enzymes to various pH values for 10 min, the residual activity was determined at the optimum pH. c Temperature optima of free and immobilized enzyme. 100 % = 6.5 × 10−2 units for free enzyme and 5.7 × 10−2 units for immobilized enzyme. d Thermostability of the free (black diamond suit) and immobilized enzymes (black square). The enzyme was first exposed to different temperatures for 10 min and then immediately cooled to 4 °C. The residual activities were determined at optimal conditions

Determination of kinetic constants

The Km values for free and immobilized enzyme were 0.1 (Supplementary Fig. 1a) and 0.3 mg/ml (Supplementary Fig. 1b), respectively. The Vmax of the free and immobilized enzyme was 125 and 83 U/ml, respectively. Assis et al. (2003) reported a Km value of 1.5 mg/ml for immobilized PME and Assis et al. (2004) reported a Km value of 0.02 and 1.4 g/l for the free and immobilized enzyme, respectively.

Reusability and storage stability

The immobilized enzyme retained ~55 % activity after ten batch reactions with alginate at ≥2.5 % (w/v) (Fig. 4), whereas at lower concentration the enzyme activity decreased. The enzyme immobilized in 2.5 % (w/v) sodium alginate could be used for at least ten batch reactions. Assis et al. (2004) reported that 68 % of PME activity was retained at the end of the second batch reaction. The PME immobilized alginate beads did not lose activity for up to 90 days at 4 °C, but the activity decreased after 90 days as opposed to 60 days for free PME. The decrease in activity is explained as a time-dependent natural loss and this can be prevented to a significant degree by immobilization.

Juice filterability and clarification

Clarity in fruit juices is desirable to make it of international standard. The clarity of juice treated by enzymes depends upon enzyme concentration, incubation time and temperature. Mainly fungal pectinases are used at high temperature in industrial processes for juice clarification (Singh and Gupta 2004). Heat is used commercially to stabilize orange juice against cloudloss (deterioration). Because a temperature near 90 °C is required, processed orange juice always acquires an off-flavor. In the present study, juice clarification was carried out at 4 °C with a holding time of only 20 min. The maximum percentage transmittance (%T620 ~60 %) was after 20 min holding time with free enzyme (5 × 10−2 units) and 1 h with immobilized enzyme (12 × 10−2 units) (Table 2). Singh and Gupta (2004) obtained the maximum percentage transmittance (%T650 ~70 %) at 25 °C after 18 h of holding time.

The filtration of the juice may be the critical parameter for scale-up and the quality of the end product. During the enzymatic treatment, pectinases break down pectin leading to a decrease in water-holding capacity and viscosity. This facilitates filtration. A viscosity drop of 55 % and an increase of 264 % in filterability were observed in present study. Lee et al. (2006) also observed an increase of filterability on treatment of banana juice by pectinase. The clarified juice did not show any haze development after 2 months of storage at 4 °C.

The immobilization increased the thermostability as well as pH stability of enzyme. The immobilized enzyme with improved stability along with juice clarification ability could also find its potential application in wine clarification and oil extraction industries.

References

Alonso J, Howell N, Canet W (1997) Purification and characterization of two pectinmethylesterase from persimmon (Diospyros kaki). J Sci Food Agric 75(352–358):8

Assis SAD, Trevisan HC, Mascarenhas OM, Oliveira F (2003) Immobilization of pectinmethylesterase from acerola (Malpighia glabra L.) in porous silica. Biotechnol Lett 25:869–872

Assis SAD, Fernandes P, Ferreira BS, Cabral JM, Oliveira OMMF (2004) Screening of supports for the immobilization of pectinmethylesterase from acerola (Malpighia glabra L). J Chem Technol Biotechnol 79:277–280

Banerjee M, Chakarvarty A, Mjumdar SK (1984) Characteristics of yeast β-galactosidase immobilized on calcium alginate gels. Appl Microbiol Biotechnol 20:271–274

Bogra P, Singh J, Singh H (2009) Immobilization of goat brain aminopeptidase B in calcium alginate beads. Biocat Biotrans 27:96–101

Grant GT, Morris EF, Rees DA, Smith PJG, Thomas D (1973) Biological interaction between polysaccharides and divalent cation: the egg box model. FEBS Lett 32:195–200

Hagerman AE, Austin PJ (1986) Continuous spectrophotometric assay for plant pectin methylesterase. J Agri Food Chem 34:440–444

Lee WC, Yusof S, Hamid NSA, Baharin BS (2006) Optimizing conditions for enzymatic clarification of banana juice using response surface methodology. J Food Eng 73:55–63

Murad HA, Azzaz HH (2011) Microbial pectinases and ruminant nutrition. Res J Microbiol 6:246–269

Ren C, Kermode AR (2000) An increase in pectinmethylesterase activity accompanies dormancy breakage and germination of yellow cedar seeds. Plant Physiol 124:231–242

Sharma S, Mittal A, Sharma R, Gupta VK, Singh H (2007) Stabilization of immobilized cathepsin L in non-aqueous medium. Biocat Biotrans 25:65–71

Singh S, Gupta R (2004) Apple juice clarification using fungal pectinolytic enzyme and gelatin. Indian J Biotechnol 3:573–576

Srivastava S, Nighojkar A, Kumar A (1996) Demethoxylation of pectin using immobilized Cuscuta reflexa pectinmethylesterase. Genet Eng Biotechnol 16:73–80

Tochi BN, Wang Z, Xu SY, Zhang W (2009) The influence of a pectinase and pectinase/hemicellulases enzyme preparations on percentage pineapple juice recovery, particulates and sensory attributes. Pak J Nutr 8:1184–1189

Valliant F, Millan P, O’Brien G, Dornier M, Decloux M, Reynes M (1999) Crossflow microfiltration of passion fruit juice after partial enzymatic liquefaction. J Food Eng 42:215–224

Willats WG, McCartney L, Mackie W, Knox JP (2001) Pectin: cell biology and prospects for functional analysis. Plant Mol Biol 47:9–27

Acknowledgments

The authors wish to thank the Chairman and the Director, JMIT, Radaur, Haryana, India, for providing funding and facilities necessary for the research work.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Bogra, P., Kumar, A., Kuhar, K. et al. Immobilization of tomato (Lycopersicon esculentum) pectinmethylesterase in calcium alginate beads and its application in fruit juice clarification. Biotechnol Lett 35, 1895–1900 (2013). https://doi.org/10.1007/s10529-013-1278-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-013-1278-3