Abstract

To develop a strain of Saccharomyces cerevisiae that produces ethanol directly from starch, two integrative vectors were constructed to allow the simultaneous multiple integration of the Aspergillus awamori glucoamylase gene (GA1) and the Debaryomyces occidentalis α-amylase gene (AMY) and glucoamylase with debranching activity gene (GAM1) into the chromosomes of an industrial strain of S. cerevisiae. The GA1 and AMY genes were constitutively expressed under the ADC1 promoter in S. cerevisiae using the double δ-integration system. The GAM1 gene was constitutively expressed under the corresponding promoter using the double 18S rDNA-integration system. The recombinant industrial strain secreting biologically active α-amylase, glucoamylase and debranching enzyme was able to ferment starch to ethanol in a single step. The new strain produced 8% (v/v) ethanol (62.8 g l−1) from 20% (w/v) soluble starch after 2 days, fermentation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The conversion of starchy biomass to glucose, which is an important renewable biological resource for industrial and fuel ethanol production, entails liquefaction and saccharification using α-amylase, glucoamylase and debranching enzyme (Janse and Pretorius 1995; Eksteen et al. 2003). Traditionally, ethanol production has been conducted almost exclusively by Saccharomyces cerevisiae because of its high fermentation rate and ethanol tolerance. Unfortunately, S. cerevisiae cannot degrade starch naturally. Manipulation of S. cerevisiae to synthesize and secrete amylolytic enzymes would contribute to the direct conversion of starch-rich materials to ethanol (Marin et al. 2001). Many genes from filamentous fungi and yeasts that encode amylolytic enzymes have been expressed in S. cerevisiae (Kim and Kim 1996; Shigechi et al. 2004). For example, Aspergillus awamori glucoamylase capable of degrading raw starch is widely used to hydrolyze both α-1,4- and α-1,6-glucosidic bonds of starch for saccharification. However this glucoamylase exhibits low debranching activity toward the α-1,6-linkages which could lead to incomplete hydrolysis of starch (Ma et al. 2000).

Of the more than 150 starch-assimilating yeast species, Debaryomyces occidentalis, which secretes both α-amylase and glucoamylase, expresses significant debranching activity as a part of the glucoamylase (Dohmen et al. 1990). Industrial strains of S. cerevisiae that could express the A. awamori glucoamylase gene (GA1), D. occidentalis α-amylase gene (AMY) and glucoamylase with debranching activity gene (GAM1) would be capable of efficiently producing ethanol from starch (Janse and Pretorius 1995). Transformation of industrial S. cerevisiae with GA1, AMY and GAM1 genes can be achieved by their integration into the genome via homologous recombination (Lee and Da Silva 1997; Nieto et al. 1999). In this study, we constructed two linearized integrative vectors to develop an amylolytic industrial strain of S. cerevisiae that expresses high glucoamylase, α-amylase and debranching enzyme activities via δ-integration of the GA1 and AMY genes and 18S rDNA-integration of the GAM1 genes. The growth, substrate utilization and enzyme activity of the recombinant strain were then examined. We also analyzed the fermentative activity of the new strain.

Materials and methods

Strains and plasmids

Escherichia coli DH5α was used for the transformation and plasmid construction. An industrial polyploid strain of S. cerevisiae ATCC 9763 distillery yeast (Ness et al. 1993) was used as the host for the yeast transformation experiment. Plasmid YIpAURG1 and YIpδAURSGδ (Ghang et al. 2005, 2007) were used to clone the GA1 gene and GAM1 gene, respectively. YIpδAURDpSAδ and YIpGB2 (Choi et al. 2002; Lim et al. 2008) served as the backbones of the δ-integrative system and the 18S rDNA-integrative system, respectively.

Media and culture conditions

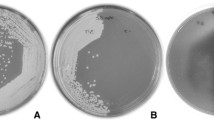

The YPD medium [1% (w/v) yeast extract, 1% (w/v) Bacto-peptone and 2% (w/v) glucose] was used for the propagation of S. cerevisiae. Yeast transformants were grown on YPD plates containing aureobasidin A (1 μg ml−1, TaKaRa) and/or G418 (300 μg ml−1, Sigma) and then transferred onto YPDS3 plates [YPD containing 3% (w/v) soluble starch] and incubated for 4 days at 30°C, after which they were incubated at 4°C for 2 days. Buffered YPS medium (BYPS) containing 2% (w/v) soluble starch and 0.1 M sodium phosphate buffer (pH 6.0) was used to assay the activity of amylase secreted by the yeast transformants. The presence of residual starch was assayed using a starch-iodine reaction to measure the loss of iodine staining capacity (Ghang et al. 2007). The mitotic stability of the AMY or GAM1 gene was determined using the method described by Nieto et al. (1999).

DNA manipulation and yeast transformation

All DNA manipulations and the transformation of E. coli were conducted as described by Sambrook and Russell (2001). Integrative transformation of yeast was carried out using the lithium acetate method described by Gietz et al. (1992).

Construction of integrative plasmids

To construct the double δ system containing the GA1 and AMY genes, a 2.1 kb fragment harboring the GA1 gene was excised from YIpAURG1 and inserted into the SmaI–XbaI sites downstream of the ADC1 promoter (ADC1p) in YIpδAURDpSAδ lacking the phytDc gene, thereby generating YIpδAGSAδ (Fig. 1). A 3.3 kb fragment harboring the ADC1p and GAM1 gene was excised from YIpδAURSGδ and inserted into the SphI–SpeI sites in rDNA-integration vector, YIpGB2, lacking the ADC1p and βAMY gene to obtain YIpSGrD. To construct the double rDNA system, a 1.8 kb 18S rDNA fragment was ligated with the linearized YIpSGrD that had been treated with SpeI, thereby generating YIpSG2rD (Fig. 1).

Real-time PCR and enzyme assays

Real-time PCR was performed on the Roter-Gene 3000 System (Corbett Research) using a mixture of D. occidentalis genomic DNA or S. cerevisiae transformant genomic DNA as the template DNA, GAM1 or AMY, β-actin primers and the reagents in a SYBR Green PCR Master Mix Reagent Kit (Qiagen). The primers used were as follows: GAM1, 5′-AACATGCAAGGTGACTCCGA-3′ and 5′-GCCCAATCAGCAGTGTTGTC-3′; AMY, 5′-CGATCTGGATCTCCCCAGTT-3′ and 5′-TTGAACCATCTCCGTTCCAA-3′; β-actin, 5′-GATCTGGCACCACACCTTCT-3′ and 5′-GGGGTGTTGAAGGTCTCAAA-3′. The glucoamylase and α-amylase activities were quantified at pH 5.5 and 40°C using the PGO/ODAD assay (Sigma) and dinitrosalicylic acid method, respectively (Ghang et al. 2007). All assays were repeated three times and the means were calculated. The enzymatic reaction products were analyzed by TLC using silica gel plates (Merck). SDS-PAGE was conducted on 10% (w/v) gels and the proteins were visualized by Coomassie Blue staining.

Ethanol fermentation and assay

The evaluation of ethanol production via fermentation was conducted using the method described by Ma et al. (2000). Briefly, a single colony of S. cerevisiae transformant was inoculated and aerobically grown in 10 ml of YPS medium at 30°C in a shaking incubator at 200 rpm for 24 h. The culture was inoculated into 100 ml of YPS containing 2% (w/v) yeast extract, 2% (w/v) Bacto-peptone and 5–30% (w/v) soluble starch (Difco) and then incubated at 30°C for 7 days. The culture was also inoculated into 100 ml of corresponding medium in a closed bottle equipped with a bubbling CO2 outlet at 30°C for 7 days. The supernatants were assayed for ethanol content using a QuantiChrom ethanol assay kit (BioAssay Systems). Conversions: 1% (v/v) ethanol is equivalent to 7.85 g l−1 or 170 mM.

Results and discussion

Integration of the GA1, AMY and GAM1 genes into S. cerevisiae

To enable multiple-copy stable integration of the GA1 and AMY genes into the chromosomes of S. cerevisiae, YIpδAGSAδ was linearized by digesting δ sequences with XhoI (Fig. 1) and the unneeded sequences related to bacterial DNA and ampicillin resistance marker (2.8 kb) were removed to produce a smaller linear vector prior to transformation. These resulting fragments (8.2 kb) containing the ADC1p-GA1 and ADC1p-AMY gene cassettes flanked by δ sequences could be integrated into δ sequences dispersed throughout the S. cerevisiae genome to produce multicopy integrants (Ghang et al. 2007; Lim et al. 2008). The GAM1 gene was separately introduced into S. cerevisiae targeted to the rDNA sequences since δ-integrative system containing GA1, AMY and GAM1 gene cassettes (13 kb) could exhibit lower amylolytic activity and mitotic stability, possibly because of low copy integrations by long integrating constructs (data not shown). YIpSG2rD was linearized by digesting 18S rDNA sequences with NheI (Fig. 1) and the unnecessary URA3 and bacterial DNA sequences except for the G418 resistance marker (5.0 kb) were excised prior to transformation. These resulting fragments (8.1 kb), containing the ADC1p-GAM1 cassette flanked by 18S rDNA sequences, could be integrated into the rDNA cluster on chromosome XII via homologous recombination to introduce multiple copies of the GAM1 gene into the integrants (Nieto et al. 1999). Real-time PCR reactions were conducted using two primers specific for the AMY gene or two primers specific for the GAM1 gene and genomic DNAs from D. occidentalis and S. cerevisiae transformants exhibiting high AMY and GAM1 activities as a template. The AMY and GAM1 DNAs from one S. cerevisiae transformant were increased 46-fold and 12-fold relative to D. occidentalis, respectively. It was assumed that these increases were due to the presence of multiple copies of the AMY and GAM1 genes integrated at the δ sequences and rDNA locus of S. cerevisiae. No amplified AMY or GAM1 genes were detected from the wild-type S. cerevisiae ATCC 9763.

Expression and secretion of GA1, AMY and GAM1 in an industrial strain of S. cerevisiae

Industrial S. cerevisiae ATCC 9763 distillery yeast was transformed with YIpδAGSAδ, generating ATCC 9763/YIpδAGSAδ expressing the GA1 and AMY genes. To obtain S. cerevisiae transformants expressing the GA1, AMY and GAM1 genes, YIpSG2rD was integrated into ATCC 9763/YIpδAGSAδ, thereby generating ATCC 9763/YIpδAGSAδ/YIpSG2rD. Both S. cerevisiae transformants could utilize starch in the medium whereas the parental wild-type could not. SDS-PAGE revealed that the recombinant GA1 band (83 kDa), α-amylase band (55 kDa) and GAM1 band (145 kDa) were present in the culture supernatant of ATCC 9763/YIpδAGSAδ/YIpSG2rD (data not shown). The α-amylase and glucoamylase activities were examined in culture supernatants from transformants grown in the BYPS media. The clones showing the highest activities among the transformants were selected for further analysis.

As shown in Table 1, the activities of the α-amylase and glucoamylase produced by ATCC 9763/YIpδAGSAδ/YIpSG2rD were 7.6-times and 4.1-times higher than those of D. occidentalis (Ghang et al. 2007). The multicopy integration of the AMY, GA1 and GAM1 genes may be correlated with the high-level expression of the corresponding genes (Lee and Da Silva 1997; Nieto et al. 1999). Moreover, the glucoamylase activity of ATCC 9763/YIpδAGSAδ/YIpSG2rD, which expressed both the GA1 and GAM1 genes, was 1.8-times higher than that of ATCC 9763/YIpδAGSAδ, which only expressed the GA1. The increase in glucoamylase activity was likely due to a synergistic effect of the sequential δ-GA1 integration and rDNA-GAM1 integration (Choi et al. 2002).

As shown in Table 2, the GAM1 of ATCC 9763/YIpδAGSAδ/YIpSG2rD could hydrolyze isomaltose and pullulan to glucose whereas the GA1 of ATCC 9763/YIpδAGSAδ could not. This result was confirmed by the analysis of enzymatic reaction products using TLC (Fig. 2). Ma et al. (2000) reported that the GA1-encoded glucoamylase has limited α-1,6 activity. The co-expression of GAM1 with significant debranching activity (α-1,6 activity) leads to the complete hydrolysis of starch for the production of more ethanol (Janse and Pretorius 1995). Time course analyses of the α-amylase and glucoamylase activities and cell growth for ATCC 9763/YIpδAGSAδ/YIpSG2rD over 5 days are shown in Fig. 3.

Thin-layer chromatography of the enzymatic products from soluble starch, isomaltose and pullulan by glucoamylases from S. cerevisiae transformants. Substrates: St soluble starch, Is isomaltose, Pu pullulan. Lanes: S standards (G1: glucose, G2: maltose, G3: maltotriose); 1–3 GA1 from ATCC 9763/YIpδAGSAδ; 4–6 GA1 and GAM1 from ATCC 9763/YIpδAGSAδ/YIpSG2rD

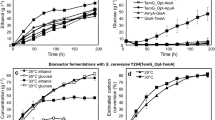

Growth curve, time courses of starch hydrolysis and extracellular glucoamylase activities and α-amylase activities produced by ATCC 9763/YIpδAGSAδ/YIpSG2rD in the BYPS medium. Growth was measured on different days based on the cell dry weight and glucoamylase and α-amylase activities were measured in the culture supernatants. The remaining starch results were presented as percentages taking the starch in the uninoculated medium as 100%. Each point represents the means of three independent measurements with a standard deviation of ±5%. Filled triangle, mg ml−1 cell mass; filled square, U ml−1 α-amylase activities; open square, U ml−1 glucoamylase activities; filled circle, % residual starch

α-Amylase and glucoamylase were growth-associated and reached maximal activities after 4 days of growth. ATCC 9763/YIpδAGSAδ/YIpSG2rD utilized 100% of the soluble starch in a culture medium that contained 2% (w/v) soluble starch during 24 h growth. To examine the mitotic stability, ATCC 9763/YIpδAGSAδ and ATCC 9763/YIpSG2rD were cultivated in non-selective YPD media for 50 generations. On the YPS plate, 100% of the integrant colonies still exhibited halos. These results suggest that the δ-integrated GA1 and AMY genes and rDNA-integrated GAM1 gene were stably maintained in the chromosomes of the integrants (Nieto et al. 1999; Ghang et al. 2007).

Ethanol production from starch

The ability of S. cerevisiae ATCC 9763 and ATCC 9763/YIpδAGSAδ/YIpSG2rD to produce ethanol directly via the fermentation of 20% (w/v) soluble starch was examined (Fig. 4). As expected, the wild-type S. cerevisiae ATCC 9763 could not produce any ethanol, whereas ATCC 9763/YIpδAGSAδ/YIpSG2rD fermented starch to ethanol directly. After 2 days of fermentation, 8% (v/v) ethanol (62.8 g l−1) was produced, and the maximum ethanol concentration was attained after 7 days. Additionally, the starch content decreased drastically during fermentation as the ethanol concentration increased to 9.5% (v/v) (74.6 g l−1). The residual starch was 0.16% (w/v) after 7 days of fermentation indicating that the starch was almost completely degraded and converted to ethanol (Shigechi et al. 2004). Kim and Kim (1996) reported that an industrial S. cerevisiae strain secreting S. diastaticus glucoamylase and mouse salivary α-amylase produced 7.5% (v/v) ethanol in 20% (w/v) starch-containing medium after 8 days of fermentation, and the residual starch content after fermentation was 1.68% (w/v). These results indicate that the introduction of GA1 and GAM1 with α-1,4 and α-1,6 activity resulted in increased starch hydrolysis rates and ethanol production when compared to S. diastaticus glucoamylase with α-1,4 activity (Janse and Pretorius 1995; Ma et al. 1999).

Time courses of direct ethanol production via fermentation from starch by S. cerevisiae ATCC 9763 and ATCC 9763/YIpδAGSAδ/YIpSG2rD. Each point represents the means of three independent measurements with a standard deviation of ±5%. Filled triangle, ethanol concentration in S. cerevisiae ATCC 9763; open triangle, ethanol concentration in ATCC 9763/YIpδAGSAδ/YIpSG2rD; filled square, residual starch concentration in S. cerevisiae ATCC 9763; open square, residual starch concentration in ATCC 9763/YIpδAGSAδ/YIpSG2rD

When ethanol production in YPS medium containing soluble starch of over 5% (w/v) was examined, the final concentration of ethanol produced by this strain after 7 days of fermentation was 5.9% (v/v) (46.3 g l−1) and 10.2% (v/v) (80.1 g l−1) in medium containing 10% (w/v) and 30% (w/v) starch, respectively. In the present study, ethanol production increased gradually as the starch concentration of the medium increased although the yield of ethanol produced per gram of starch did not increase in proportion to starch concentration due to exhaustion of other nutrient components. Birol et al. (1998) reported that a haploid laboratory strain of S. cerevisiae strain secreting A. awamori glucoamylase and Bacillus subtilis α-amylase produced 43.8 g ethanol l−1 in 10% (w/v) starch-containing medium. However, the haploid laboratory strain does not have fermentation characteristics as good as the industrial strain due to its genetic instability (Kim and Kim 1996). In this study, a direct and efficient starch-fermenting industrial polyploid yeast strain was produced by multiple integrations of the GA1, AMY and GAM1 genes. The results presented here may lead to the development of various industrial strains of S. cerevisiae for the production of commercially important products, including ethanol, from starch in a one-step process (Lin et al. 1998; Eksteen et al. 2002; Shigechi et al. 2004).

References

Birol G, Onsan ZI, Kirdar B, Oliver SG (1998) Ethanol production and fermentation characteristics of recombinant Saccharomyces cerevisiae strains grown on starch. Enzym Microb Technol 22:672–677

Choi EY, Park JN, Kim HO, Shin DJ, Im SY, Lee HB, Chun SB, Bai S (2002) Construction of an industrial polyploid strain of Saccharomyces cerevisiae containing Saprolegnia ferax β-amylase gene and secreting β-amylase. Biotechnol Lett 24:1785–1790

Dohmen RJ, Strasser AWM, Dahlems UM, Hollenberg CP (1990) Cloning of the Schwanniomyces occidentalis glucoamylase gene (GAM1) and its expression in Saccharomyces cerevisiae. Gene 95:111–121

Eksteen JM, van Renseburg P, Cordero Otero RR, Pretorius IS (2003) Starch fermentation by recombinant Saccharomyces cerevisiae strains expressing the α-amylase and glucoamylase genes from Lipomyces kononenkoae and Saccharomycopsis fibuligera. Biotechnol Bioeng 84:639–646

Ghang DM, Lee SA, Chun YH, Chin JE, Ko HM, Lee HB, Bai S (2005) Expression of Aspergillus awamori glucoamylase gene in an industrial strain of Saccharomyces cerevisiae. Korean J Microbiol 41:146–151

Ghang DM, Yu L, Lim MH, Ko HM, Im SY, Lee HB, Bai S (2007) Efficient one-step starch utilization by industrial strains of Saccharomyces cerevisiae expressing the glucoamylase and α-amylase genes from Debaryomyces occidentalis. Biotechnol Lett 29:1203–1208

Gietz D, St. Jean A, Woods R, Schiestl RH (1992) Improved method for high efficiency transformation of intact yeast cells. Nucleic Acids Res 20:1425

Janse BJ, Pretorius IS (1995) One-step enzymatic hydrolysis of starch using a recombinant strain of Saccharomyces cerevisiae producing α-amylase, glucoamylase and pullulanase. Appl Microbiol Biotechnol 42:876–883

Kim TG, Kim K (1996) The construction of a stable starch-fermenting yeast strain using genetic engineering and rare-mating. Appl Biochem Biotechnol 59:39–51

Lee FWF, Da Silva NA (1997) Improved efficiency and stability of multiple cloned gene insertions at the δ sequences of Saccharomyces cerevisiae. Appl Microbiol Biotechnol 48:339–345

Lim MH, Lee OH, Chin JE, Ko HM, Kim IC, Lee HB, Im SY, Bai S (2008) Simultaneous degradation of phytic acid and starch by an industrial strain of Saccharomyces cerevisiae producing phytase and α-amylase. Biotechnol Lett 30:2125–2130

Lin LL, Ma YJ, Chien HR, Hsu WH (1998) Construction of an amylolytic yeast by multiple integration of the Aspergillus awamori glucoamylase gene into a Saccharomyces cerevisiae chromosome. Enzym Microb Technol 23:360–365

Ma Y, Lin LL, Chien HR, Hsu WH (2000) Efficient utilization of starch by a recombinant strain of Saccharomyces cerevisiae producing glucoamylase and isoamylase. Biotechnol Appl Biochem 31:55–59

Ness F, Lavallee F, Dubourdieu D, Aigle M, Dulau L (1993) Identification of yeast strains using the polymerase chain reaction. J Sci Food Agric 62:89–94

Nieto A, Prieto JA, Sanz P (1999) Stable high-copy number integration of Aspergillus orizae α-amylase cDNA in an industrial baker’s yeast strain. Biotechnol Prog 15:459–466

Sambrook J, Russell DW (2001) Molecular cloning: a laboratory manual. Cold Spring Harbor Laboratory Press, NY

Shigechi H, Koh J, Fujita Y, Matsumoto T, Bito Y, Ueda M, Satoh E, Fukuda H, Kondo A (2004) Direct production of ethanol from raw corn starch via fermentation by use of a novel surface-engineered yeast strain codisplaying glucoamylase and α-amylase. Appl Environ Microbiol 70:5037–5040

Acknowledgments

This work was supported in part by a grant from the Ministry of Agriculture of Korea and in part by a grant of the Korea Ministry of Education, Science and Technology (The Regional Core Research Program/Biohousing Research Institute). Ji-Hye Kim and Ha-Ram Kim were supported by the second stage of the Brain Korea 21 project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, JH., Kim, HR., Lim, MH. et al. Construction of a direct starch-fermenting industrial strain of Saccharomyces cerevisiae producing glucoamylase, α-amylase and debranching enzyme. Biotechnol Lett 32, 713–719 (2010). https://doi.org/10.1007/s10529-010-0212-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-010-0212-1