Abstract

Owing to applications in the food and nutraceutical industries, inulinases, fructosyltransferases and sucrases have gained considerable attention in recent times. Twenty-five fungal strains were screened for production of these enzymes on three different media formulated using inulin-rich plant extracts prepared from asparagus root, dahlia tuber and dandelion root extract. Culture filtrates of the fungi were examined for hydrolytic activities. Fungi belonging to genus Aspergillus, A. niger GNCC 2655 (11.3 U/ml), A. awamori MTCC 2879 (8.2 U/ml), A. niger ATCC 26011 (7.9 U/ml) secreted high titers of inulinase followed by Penicillium sp. NFCCI 2768 (2.6 U/ml) and Penicillium citrinum MTCC 1256 (1.1 U/ml). High sucrase activity was noticed in A. niger GNCC 2613 (113 U/ml) and A. awamori MTCC 2879 (107.8 U/ml). Analysis of end products of inulinase action by HPLC revealed that most of the enzymes were exo-inulinases liberating fructose exclusively from inulin. Five fungi, P. citrinum MTCC 1256, Penicillium rugulosum MTCC 3487, Penicillium sp. NFCCI 2768, A. fumigatus GNCC 1351 and A. niger ATCC 26011 however, produced a mixture of endo- and exo-inulinases liberating oligosaccharides (GF3 and GF2) along with fructose. High inulinase/sucrase yielding strains were evaluated for extracellular and intracellular hydrolytic and transfructosylating activities and intracellular enzyme profiles were found to be considerably different in terms of titers and end products.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Inulin serves as a storage polysaccharide in many plants of Compositae and Gramineae, and is accumulated in the underground roots and tubers of several plants including chicory (Cichorium intibus), dahlia (Dahlia pinnata), Jerusalem artichoke (Helianthus tuberosus), asparagus (Asparagus racemosus) and dandelion (Taraxacum officinale). It consists of β-(2 → 1)-d-fructosyl-fructose links terminated by a sucrose residue (Chi et al. 2009; Kango and Jain 2011; Liu et al. 2014). This fructan is a potential substrate for generation of high fructose syrup (HFS) and prebiotic inulooligosaccharides (IOS). These value added products can be produced using microbial inulolytic enzymes. Inulin is acted upon by two types of inulinases i.e. endoinulinase (2,1-β-d-fructanfructanohydrolase, EC 3.2.1.7) and exoinulinase (β-d-fructanfructohydrolase, EC 3.2.1.80). Endoinulinases liberate IOS as the main product (Kango and Jain 2011; Chen et al. 2013; Pouyez et al. 2012) while exoinulinases hydrolyze the terminal linkages to yield fructose as the main product (Mansouri et al. 2013; Altunbas et al. 2013). Sucrase (β-d-fructofuranoside fructohydrolase, EC 3.2.1.26) or invertase hydrolyzes sucrose into glucose and fructose. Fructosyltransferase (FTase; EC 2.4.1.9) is known to hydrolyze sucrose and transfer fructosyl group to an acceptor molecule to generate fructooligosaccharides (FOS) along with glucose and fructose (Ganaie et al. 2013). Major sources of inulolytic enzymes belong to Aspergilli and Penicillia. The details of various inulolytic fungal strains are available in state-of-the-art reviews published previously (Vandamme and Deryke 1983; Chi et al. 2009; Kango and Jain 2011). The pursuit of finding novel enzymes has prompted researchers to explore native strains isolated from different ecological habitats. In the present study it was envisaged that strains from rhizosphere and decaying inulin rich plants would be explored for their inulolytic potential. Recent reports of screening of inulinase producing microorganisms and media formulation indicate their significance (Housseiny 2014). There is immense possibility of finding novel inulinase producers from a variety of ecological niches. Also, it is important to identify the resulting end-products of inulinase action to identify desirable roles in fructan hydrolysis. Inulin stored in a variety of plants can be judiciously exploited for formulating fermentation medium to support inulinase yield (Gern et al. 2001; Paixao et al. 2013; Zhou et al. 2014). The aim of the present work was to screen a variety of such fungal strains and assess their ability to utilize three different inulin containing plant extracts derived from asparagus (5–10 % of fresh weight), dahlia (9–13 % fresh weight) and dandelion (12–15 % fresh weight) for inulinase production (Loo et al. 1995; Kango and Jain 2011; He et al. 2014). Some strains used in the present study were explored for the first time for inulinase production. It is important to find novel strains to suit industrial conditions so that the feasibility of the enzymatic process is realized. Presence of industrially important enzymes, sucrase and FTase, was also examined. End products of enzyme action were analyzed using high performance liquid chromatography (HPLC) to understand their mode of action and liberated biotechnologically important food grade fructose and FOS.

Materials and methods

Materials

Inulin rich substrates used in this study, asparagus roots (AR), dahlia tubers (DT) and dandelion roots (DR) were collected from local agricultural lands and farms. Inulin from chicory, 3,5-dinitrosalicycilc acid (DNS), sucrose, glucose, fructose, 1-kestose (GF2), 1-nystose (GF3) and 1-fructofuranosylnystose (GF4) were obtained from Sigma chemical Co, USA. Other analytical grade chemicals and media ingredients were purchased from Hi-media, Merck, and CDH, India.

Preparation of inulin extracts

For preparation of inulin rich vegetal extracts from asparagus root extract (ARE), dahlia tuber extract (DTE) and dandelion root extract (DRE), tubers or roots were washed in running tap water, air dried and shredded into small pieces. Finally, the pieces were ground in a mill and slurry (20 % w/v) in distilled water was prepared. Hydrothermal extraction of inulin from these sources was done by treating the slurry at 15 lbs pressure at 121 °C for 20 min. The resulting extract was filtered through muslin cloth and suspension thus obtained was used in fermentation medium.

Fungi, culture conditions and maintenance

Twenty three strains of filamentous molds and two yeast strains were examined for production of exo and endoinulinase. Fifteen fungal cultures including two yeasts were obtained from culture collections, Microbial Type Culture Collection (MTCC, Chandigarh, India), National Fungal Culture Collection of India (NFCCI, Pune, India) and American Type Culture Collection (ATCC, USA). Twelve newly isolated molds were obtained from decaying inulin rich vegetal materials like onion peel, garlic peel, asparagus root and rhizospheric soil of dahlia and onion field collected from local area (Sagar, M.P., India). Among the native isolates, Penicillium sp. NFCCI 2768, Arthrinium puccinoides NFCCI 2432 and Fusarium oxysporum NFCCI 2429 were deposited in NFCCI, Pune, while other eleven newly isolated fungal species were deposited in Gour Nodal Culture Collection (GNCC) of Department of Applied Microbiology & Biotechnology, Dr. Harisingh Gour University, Sagar. All the filamentous fungi were grown and maintained on potato dextrose agar (PDA). Yeast strains, Kluyveromyces marxianus MTCC 3999 and Pichia guillermondii MTCC 1311 were grown and maintained on malt extract yeast extract agar medium. The temperature for incubation (72 h) for all the isolates was 28 °C.

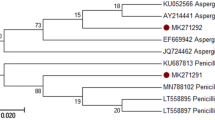

Taxonomic studies

The identity of the newly isolated fungal forms was confirmed on the basis of their colonial and morphological characteristics using available literature (Raper and Thom 1949; Onion et al. 1986).

Enzyme (inulinase, sucrase and FTase) production

Production medium used in this study contained 50 ml of crude inulin extract prepared from plant sources (ARE, DTE, and DRE) as described above and yeast extract (2 % w/v) was used as nitrogen source in all the media throughout study. Erlenmeyer flasks (250 ml) containing 50 ml production medium were autoclaved at 121 °C for 20 min and incubated with two fungal discs (8 mm) obtained from 7 days old cultures of molds and loopful culture of yeast incubated at 28 °C in shaker-incubator at 150 rpm for 72 h. After incubation the content of the flasks was filtered through Whatman filter paper No.1. Screening for transfructosylating activity was done in some fungi showing high hydrolytic (sucrase) activity. For FTase production selected fungi were cultivated on medium containing 20 % (w/v) sucrose and yeast extract 0.5 % (w/v). Cell-free filtrate was used as source of extracellular enzyme without any further purification for inulinase, sucrase and FTase activity in further experiments.

Intracellular enzyme extraction

Some potential fungal forms producing high titers of extracellular inulinase were studied for presence of intracellular hydrolytic enzymes. For this, a fixed packed cell volume (5 ml) was collected in Falcon tubes by centrifugation at 8,000×g for 15 min. The biomass thus obtained was washed with sodium acetate buffer (pH 5.0) and homogenized by ultrasonication. The slurry was centrifuged at 10,000×g for 15 min at 4 °C and the clear supernatant was used as enzyme source (Ganaie and Gupta 2014).

Hydrolytic enzyme (inulinase and sucrase) assay

Appropriately diluted enzyme (0.2 ml) was added to 1.8 ml of inulin (0.5 % w/v dissolved in 200 mM sodium acetate buffer, pH 5.0) and incubated at 50 °C for 15 min. After incubation, total reducing sugars liberated from inulin were measured by adding 3 ml DNS reagent and boiling in a water bath for 5 min (Miller 1959). Samples were allowed to cool and their absorbance was read at 540 nm. Invertase activity was measured using sucrose solution (1 % w/v dissolved in 200 mM sodium acetate buffer, pH 5.0). One inulinase/invertase unit was defined as the amount of enzyme which produced 1 μmol of fructose/glucose per second under the assay conditions as described above. Total protein content and inulinase specific activity (U/mg) was estimated using Folin-Lowry method (Lowry et al. 1951). Temperature and pH relationships of inulinase of some promising inulinase producing strains was determined as described earlier (Kango 2008).

FTase assasy

Screening for transfructosylating activity was done in some fungi showing high hydrolytic (sucrase) activity. The FTase activity was determined by incubating 100 µl culture filtrate with 400 µl of sucrose (20 % w/v in 0.1 M sodium acetate buffer pH 5.0) at 50 °C for 1 h in water bath. The reaction was stopped by boiling the mixture in a water bath at 100 °C for 10 min. FTase activity was estimated by taking 10 µl of appropriately diluted reaction mixture and mixing it with 1 ml test reagent (Glucose oxidase–peroxidase, GOPOD kit, Sigma). The glucose released was measured at 505 nm. One unit of FTase was defined as the amount of enzyme required to produce 1 µmol of glucose per minute under the assay conditions (Ganaie et al. 2014).

End products analysis

Hydrolysis of pure chicory inulin (5 % w/v) and sucrose (20 % w/v) dissolved in sodium acetate buffer (pH 5.0) was studied by incubating 1 ml undiluted culture filtrate with 4 ml of substrate for period of 24 h at 50 °C under mild shaking conditions in shaking water bath. End products of inulin hydrolysis, sucrose hydrolysis and transfructosylation were analyzed using HPLC. The amount of liberated sugars was analyzed using HPLC, Waters, with sugar pak column (6.5 × 300 mm) and refractive index (RI) differential detector (RI 2414). Samples (2 ml each) were filtered by using 0.45 µm Millipore filter paper before injecting into 20 µl valve. Column temperature was maintained 70 °C by oven column (Dyna, Mumbai). Fructose (F), glucose (G), sucrose (GF), kestose (GF2), nystose (GF3) and fructofuranosylnystose (GF4) and inulin (Sigma chemical, co. USA) were used as standards for chromatographic analysis. Calculation and analysis were analyzed using Empower-2 software Build 2154, Waters (Ganaie et al. 2014).

Results

Enzyme production

All the fungi were grown on three different media containing extracts and studied for the production of inulinase and sucrase hydrolytic activities. Maximum inulinase activity (12.2 U/ml) was noticed in Aspergillus niger GNCC 2655 culture filtrate grown on DTE. Following this Aspergillus awamori MTCC 2879 produced (8.21 U/ml) inulinase on medium containing ARE. Other fungal strains producing relatively higher inulinase titers were A. niger GNCC 2613 (5.97 U/ml), Aspergillus ficuum MTCC 7591 (5.27 U/ml), Aspergillus sp. GNCC 2531 (5.63 U/ml), Penicillium sp. NFCCI 2768 (3.89 U/ml) and Arthrinium pucciniodes NFCCI 2432 (2.27 U/ml), Penicillium citrinum MTCC 1256 (1.19 U/ml). Yeasts, K. marxianus MTCC 3995 and P. guillermondii MTCC 1311, showed maximum inulinase activity on DTE (1.49 U/ml) and ARE (0.54 U/ml) respectively. Interestingly, considerable variation in inulinase production by the test fungi was noticed on the three media (Table 1). While most of the fungi showed higher inulinase titers on ARE and DTE, considerable amount of enzyme was also noticed in DRE medium. Results indicated possible use of asparagus root, dahlia tuber and dandelion root in formulating media for inulinase production as they make suitable alternatives to costly commercial inulin. In the present study A. niger GNCC 2655 produced high inulinase titers on DTE (12.2 U/ml), ARE (11.3 U/ml) and DRE (6.47 U/ml). A. ficuum MTCC 7591 and A. awamori MTCC 2789 showed highest inulinase titers in ARE medium. Some of the interesting fungi observed as inulinase producers for the first time include native isolates, A. pucciniodes NFCCI 2432 (2.27 U/ml, DTE), Aspergillus ochraceous GNCC 1423 (0.85 U/ml, ARE), F. oxysporum NFCCI 2429 (0.83 U/ml, ARE) and Aspergillus flavus NFCCI 2364 (0.77 U/ml, DTE). Penicillium sp NFCCI 2768 isolated from rhizosphere soil of dahlia plant produced 3.89 U/ml inulinase activity on DTE. A. niger GNCC 2613 and A. awamori MTCC 2879 were high sucrase producers elaborating 113 and 107 U/ml on ARE medium, however, much lower yields of this enzyme (4–23 U/ml) were noticed on DTE and DRE medium. Inulinase/sucrase (I/S) ratio was lower than 0.5 in most cultivations indicating relatively higher sucrase activity. I/S ratio of individual fungi also varied considerably on the three substrates indicating variation in induction of I/S activity with respect to the composition of vegetal infusions. The I/S ratio is a very important criterion in understanding the hydrolytic properties/characteristics of the enzyme preparation. Reducing sugars content of the purified chicory inulin itself shows masking effects and hence the assays were made at lower inulin concentration of 0.5 % (w/v). Also, recent reports present hydrolytic activity using sucrose as substrate (Kango 2008; Mansouri et al. 2013). Aspergillus fischeri MTCC 150 and A. pucciniodes NFCCI 2432 showed I/S ratio of more than 1.0 (Table 1) when grown on DRE medium. The study revealed the possibility and effects of using crude plant extracts for inducing inulinase activity and the potential of screened fungi for the purpose.

pH and temperature relationship

pH optima of most inulinases was between 5.0 and 6.0 while 50 and 55 °C were common temperature optima A. fumigatus GNCC 1351 inulinase had maximum temperature optimum at 60 °C and was stable at 65 °C up to 90 min. Inulinase from P. rugulosum MTCC 3487 and A. niger GNCC 2655 showed better thermostability and remained fully active for more than 2 h at 65 °C.

End product profiles of inulinase action

HPLC analysis of end products of inulinase action showed that most of the fungal strains (22) produced fructose as the predominating end product indicating exoinulinase activity. The maximum yield of fructose was achieved with A. awamori MTCC 2879 (F-96.8 % w/w) by using chicory inulin as substrate (5 % w/v) (Fig. 1a). Some of the other promising strains producing fructose efficiently as their end product were Aspergillus niger GNCC 2613 (F-75.2 % w/w), A. niger GNCC 2655 (F-64.9 % w/w) (Fig. 1b; Suppl Fig.). The remaining fungal strains and yeasts produced fructose in the range of 3–55 % (w/w). Relatively low inulinase activity was noticed in these FOS producing strains as compared to those producing exoinulinase. This may be attributed to lack of generation of reducing equivalents in the case of FOS producing strains. Production of FOS (GF2 and GF3) along-with glucose and fructose was seen in Aspergillus fumigatus GNCC 1351 (GF3-0.34, GF2-1.32, GF-2.16, G-12.3, F-7.99 % w/w), P. citrinum MTCC 1256 (GF3-0.59, GF2-5.57, GF-23.9, G-34.4, F-26.7 % w/w), and Penicillium sp. NFCCI 2768 (GF3-3.57, GF2-8.32, GF-14.26, G-29.34, F-13.9 % w/w) indicating production of a mixture of endo and exo-inulinases (Fig. 1c, d; Table 2). The sugar profile produced by inulinase/sucrase activity of fungi is presented in supplementary material.

HPLC chromatograms of hydrolysis products using selected fungal strains (incubation time: 24 h, pH 5.0, Temp. 50 °C) Inulin (5 % w/v) hydrolysis showing exclusive generation of fructose: a Aspergillus awamori MTCC 2879 b Aspergillus niger GNCC 2655; production of IOSs: c Penicillium citrinum MTCC 1256 d Aspergillus fumigatus GNCC 1351; Sucrose (20 % w/v) hydrolysis by sucrase showing exclusive generation of high fructose and glucose: e Aspergillus ficuum MTCC 7591 f Aspergillus niger GNCC 2613 and FTase activity generating FOS from sucrose (20 % w/v): g Penicillium citrinum MTCC 1256 h Penicillium rugulosum MTCC 3487. F-Fructose, G-Glucose, GF-Sucrose, GF2-Kestose, GF3-Nystose, GFn or S-Fructan or Inulin

Intracellular hydrolytic activities

The intracellular hydrolytic activities of some of the high inulolytic strains were examined. In order to see the distribution and the nature of enzymes, the end products of intracellular preparation were also analyzed. The nature of the enzyme was considerably different in most cases and also the amounts and types of end products varied differed significantly (Table 3). This also suggests that after separating extracellular inulinase, the mycelial mass can be exploited for intracellular inulin and sucrose hydrolyzing enzymes. A. awamori MTCC 2879 showed highest intracellular exoinulinase activity and released high amount of fructose (98.4 % w/w). Intracellular extract of A. niger GNCC 2655, and A. niger GNCC 2613 showed generation of above 90 % (w/w) fructose while A. ficuum MTCC 7591 intracellular inulinase liberated (73.2 % w/w) of fructose. In the case of P. citrinum MTCC 1256, mixed action of intracellular exo and endoinulinases lead to production of GF3 (11.23 % w/w), GF2 (5.81 % w/w), GF (24.7 % w/w), G (39.14 % w/w) and F (31.7 % w/w). Penicillium sp NFCCI 2768 intracellular study showed the liberation of GF4 (0.14 % w/w), GF3 (0.18 % w/w), GF2 (4.61 % w/w), GF (9.64 % w/w), G (28.16 % w/w) and F (17.3 % w/w) whereas GF4 was not detected in case of extracellular preparation (Fig. 1 c–f; Table 3; Suppl Fig.).

Fungi exhibiting higher sucrase activity were further examined for FTase activity. FTase activity as evidenced by formation of FOS (GF4, GF3 and GF2) was seen in two strains. Only hydrolytic activity without any trace of transfructosylation was noticed in the case of A. niger GNCC 2655 and A. ficuum MTCC 7591 strains. Significant amounts of GF3 (1.12 % w/w) and GF2 (11.64 % w/w) was produced by A. niger ATCC 26011. P. rugulosum MTCC 3487 produced only GF2 (7.59 % w/w) intracellularly but in extracellular study it produced GF2 (1.24 % w/w) in lesser amount. P. citrinum MTCC 1256 intracellular study showed the liberation of GF3 (1.99 % w/w), GF2 (19.22 % w/w), GF (28.19 % w/w), G (12.45 % w/w) and F (9.80 % w/w) in comparisons with extracellular study of same species produced GF3 (0.21 % w/w), GF2 (3.59 % w/w), GF (9.37 % w/w) G (29.4 % w/w) and F (22.4 % w/w). The present study revealed presence of sucrase and FTase which can be used for formation of FOS (Table 4; Fig. 1g, h; Suppl Fig.).

Discussion

We have screened twenty five fungal strains including twelve species of predominantly inulolytic Aspergillus and three species of Penicillium on inulin rich vegetal infusion prepared from low cost plant sources. The inulinase and sucrase levels were found comparable to those reported before (Mansouri et al. 2013; Kango 2008). A. puccinoides NFCCI 2432, native isolate obtained from rhizospheric soil of dahlia has been reported to produce inulinase for the first time (Table 1). We have observed that crude vegetal infusion extract media also supported efficient production of sucrase, however, this lead to a low I/S ratio (<0.50) in most cases. Mansouri et al. (2013) reported use of pure inulin for better induction of inulinase than Jerusalem artichoke preparation; however, our premise of using cheaper inulin rich extract is intended to make the process more cost effective. Inulinase sourced from twenty three strains produced fructose exclusively with A. awamori MTCC 2879, A. niger GNCC 2613 producing more than 70 % (w/w) fructose from inulin (Table 2; Fig. 1a, b). This clearly indicated high incidence of exoinulinase in fungi as reported earlier (Jain et al. 2012; Chen et al. 2013; Mansouri et al. 2013). Three fungal species, A. fumigatus GNCC 1351, P. citrinum MTCC 1256 and Penicillium sp NFCCI 2768 showed production of IOS (GF3, GF2) indicating occurrence of endoinulinase (Table 2; Fig. 1c, d). Gill et al. (2006) have reported production of exoinulinase in A. fumigatus in contrast to our findings. Recently, Chen et al. (2014) reported cloning and characterization of endoinulinase from A. fumigatus Cl 1 which showed similar end product profile to A. fumigatus GNCC 1351 used in the present study. Penicillium sp. TN-88 endoinulinase liberated inulotriose as main product by hydrolyzing inulin up to 70 % (Nakamura et al. 1997). Recently, Gallegos et al. (2014) proposed the exoinulinase action of P. citrinum and its use in generating fructose syrup efficiently. Sirisansaneeyakul et al. (2007) have reported production of fructose syrup by using inulinases of A. niger TISTR 3570 and Candida guilliermondii TISTR 5844. A. niger inulinase liberated 37.5 g/l fructose from 100 g/l inulin while C. guilliermondii inulinase produced 35.3 g/l of fructose under similar conditions. Various reports indicating efforts to establish low cost media have lead to the identification of novel potential substrates for production of commercial enzymes. Several strains of Aspergillus have been reported to be efficient inulinase producers and utilize a variety of inulin rich extracts such as dandelion (Kango 2008), kuth root (Viswanathan and Kulkarni 1996), Carob pulp, figs, cherries, plums, peaches and Jerusalem artichoke (Paixao et al. 2013), sunflower tubers and lettuce roots (Housseiny 2014). With regard to industrial conditions higher thermal stability is a desirable feature. In the present study P. rugulosum MTCC 3487 and A. niger GNCC 2655 were identified as sources of thermostable inulinases (Table 5).

We have compared the distribution of inulinase in intracellular compartment of six fungi showing high extracellular inulinase activity. Interestingly, in most cases the intracellular activity was observed to be comparable or slightly more than extracellular inulinase activity. However, the nature of enzyme (exoinulinase) producing fructose exclusively remained same. In case of fungi producing endoinulinase, P. citrinum MTCC 1256 and Penicillium NFCCI 2768, again higher titers of inulinase were observed intracellularly. Also, the HPLC analysis showed slight differences in product profile where presence of GF3 and GF2 was observed in the case of both fungi (Suppl Figs. 3, 4).

Intracellular study suggested the possibility of deriving inulinase, sucrase and FTase by cell lysis of some strains. When the results obtained for the intracellular and extracellular activities and their end products were compared, significant differences were observed. Some fungal inulinase producers are reported to secrete a mixture of exo and endoinulinases. A. niger NK-126 produced a mixture of exo and endoinulinases on dandelion root extract medium and produced of fructose, inulobiose (F2) and IOS (Kango 2008). Results of this experiment highlighted the presence of intracellular inulinase which can be possibly leached out using surfactants in the medium. Wenling et al. (1999) reported the HFS (85 % w/w) production by using Kluyveromyces sp. Y-85 intracellular inulinase by utilizing Jerusalem artichoke tuber extract. We have detected FTase activity in P. citrinum MTCC 1256, P. rugulosum MTCC 3487 and A. niger ATCC 26011 and the major products of transfructosylation were GF2 and GF3. Silva et al. (2013) reported production of FOS from sucrose and inulin, using free and immobilized inulinase from A. niger. Ganaie et al. (2013) have screened out twenty microorganisms for the production of FTase and to generate FOS from sucrose. Our results clearly suggested that sonication disrupted fungal cells resulting in the effective release of intracellular enzymes. Inulinase, sucrase and FTase activity observed after cell disruption by sonication was suitable for combined action of extracellular and intracellular enzyme released after microbial cell disruption (Vargas et al.2004). The present study describes a comprehensive analysis of hydrolytic and transfructosylating activity of some fungi, enzyme distribution and product profile obtained from different media.

References

Altunbas C, Uygun M, Uygun DA, Akgol S, Denizli A (2013) Immobilization of inulinase on concanavalin A-attached super macroporous crygel for production of high fructose syrup. Appl Biochem Biotechnol 170:1909–1921

Chen XM, Xu XM, Jin ZY, Chen HQ (2013) Expression of an endoinulinase gene from Aspergillus ficuum in Escherichia coli and its characterization. Carb Pol 92:1984–1990

Chen M, Lei X, Chen C, Zhang S, Xie J, Wei D (2014) Cloning, overexpression, and characterization of a highly active endoinulinase gene from Aspergillus fumigatus Cl1 for production of inulo-oligosaccharides. Appl Biochem Biotechnol. doi:10.1007/s12010-014-1296-1

Chi Z, Chi Z, Zhang T, Liu G, Yue L (2009) Inulinase-expressing microorganisms and applications of inulinases. Appl Microbiol Biotechnol 82:211–220

Gallegos ACF, Chavez JAM, Aguilar CN, Riutort M, Herrera RR (2014) Gene encoding inulinase isolated from Penicillium citrinum ESS and its molecular phylogeny. Appl Biochem Biotechnol. doi:10.1007/s120-014-1280-9

Ganaie MA, Gupta US (2014) Recycling of cell culture and efficient release of intracellular fructosyltransferase by ultrasonication for the production of fructooligosaccharides. Carb Pol 110:253–258

Ganaie MA, Gupta US, Kango N (2013) Screening of biocatalysts for transformation of sucrose to fructooligosaccharides. J Mol Cata B: Enzym 97:12–17

Ganaie MA, Rawat HK, Wani OA, Gupta US, Kango N (2014) Immobilization of fructosyltransferase by chitosan and alginate for efficient production of fructooligosaccharides. Proc Biochem 49:840–844

Gern RM, Furlan SA, Ninow JL, Jonas R (2001) Screening for microorganisms that produce only endo-inulinase. Appl Microbiol Biotechnol 55:632–635

Gill PK, Manhas RK, Singh P (2006) Purification and properties of a heat stable exoinulinase isoform from Aspergillus fumigates. Bioresour Technol 97:894–902

He M, Wu D, Wu J, Chen J (2014) Enhanced expression of endoinulinase from Aspergillus niger by codon optimization in Pichia pastoris and its application in inulo-oligosaccharide production. J Ind Microbiol Biotechnol 41:105–114

Housseiny MM (2014) Production of an endoinulinase from Aspergillus niger AUMC 9375, by solid state fermentation of agricultural waste, with purification and characterization of the free and immobilized enzyme. J Microbiol 52:389–398

Jain SC, Jain PC, Kango N (2012) Production of inulinase from Kluyveromyces marxianus using dahlia tuber extract. Braz J Microbiol 43:62–69

Kango N (2008) Production of inulinase using tap roots of dandelion (Taraxacum officinale) by Aspergillus niger. J Food Eng 85:473–478

Kango N, Jain SC (2011) Production and properties of microbial inulinases: recent advances. Food Biotechnol 4:165–212

Liu GL, Fu GY, Chi Z, Chi ZM (2014) Enhanced expression of the codon optimized exo-inulinase gene from the yeast Meyerozyma guilliermondii in Saccharomyces sp. W0 and bioethanol production from inulin. Appl Microbiol Biotechnol 98:9129–9138

Loo JV, Coussement P, Leenheer L, Hoebregs H, Smits G (1995) On the presence of Inulin and oligofructose as natural ingredients in the western diet. Crit Rev Food Sci Nutr 35:525–552

Lowry OH, Rosenbrough NJ, Farr AL, Randall RJ (1951) Protein measurement with the folin-phenol reagent. Biol Chem 193:265–275

Mansouri M, Houbraken J, Samson RA, Frisvad JC, Christensen M, Tuthill DE, Koutaniemi S, Hatakka A, Lankinen P (2013) Penicillium subrubescens, a new species efficiently producing inulinase. Antonie Van Leeuwenhoek 103:1343–1357

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugars. Anal Chem 3:14–26

Nakamura T, Shitara A, Matsuda S, Matsuo T, Suiko M, Ohta K (1997) Production, purification and properties of endoinulinase of Penicillium sp. TN-88 that liberates inulotrioses. J Ferment Bioeng 84:313–318

Onion AH, Allsopp D, Eggins HOW (1986) Smith’s introduction to industrial mycology, 2nd edn. Edward Arnold, London, pp 217–226

Paixao SM, Teixeira PD, Silva TP, Teixeira AV, Alves L (2013) Screening of novel yeast inulinases and further application to bioprocesses. New Biotechnol 30:598–606

Pouyez J, Mayard A, Vandamme AM, Roussel G, Perpète EA, Wouters J, Housen I, Michaux C (2012) First crystal structure of an endo-inulinase, INU2, from Aspergillus ficuum: discovery of an extra-pocket in the catalytic domain responsible for its endo-activity. Biochimie 94:2423–2430

Raper KB, Thom C (1949) Manual of the Penicillia. Williams & Wilkins, Baltimore

Silva MF, Rigo D, Mossi V, Golunski S, Kuhn GDO, Luccio MD, Dallago R, Oliveira DD, Oliveira JV, Treichel H (2013) Enzymatic synthesis of fructooligosaccharides by inulinases from Aspergillus niger and Kluyeromyces marxianus NRRL Y-7571 in aqueous-organic medium. Food Chem 138:148–153

Sirisansaneeyakul S, Worawuthiyanan N, Vanichsriratana W, Srinophakun P, Chisti Y (2007) Production of fructose from inulin using mixed inulinases from Aspergillus niger and Candida guilliermondii. World J Microbiol Biochnol 23:543–552

Vandamme EJ, Deryke DG (1983) Microbial inulinases: Fermentation process, properties and applications. Adv Appl Microbiol 29:139–176

Vargas LHM, Piao ACS, Domingos RN, Carmona EC (2004) Ultrasound effects on invertase from Aspergillus niger. World J Microbiol Biotechnol 20:137–142

Viswanathan P, Kulkarni PR (1996) Inulinase producing fungi and actinomycetes from dahlia rhizosphere. Indian J Microbiol 36:117–118

Wenling W, Huiying WWL, Shiyuan W (1999) Continuous preparation of fructose syrups from Jerusalem artichoke tuber using immobilized intracellular inulinase from Kluyveromyces sp. Y-85. Proc Biochem 34:643–646

Zhou J, Lu Q, Peng M, Zhang R, Mo M, Tang X, Li J, Xu B, Ding J, Huang Z (2014) Cold active and NaCl-tolerant exo-inulinase from a cold adapted Arthrobacter sp. MN8 and its potential for use in the production of fructose at low temperatures. Biosci Bioeng. doi:10.1016/jbiosc2014-08.003

Acknowledgments

Authors are thankful to Madhya Pradesh Biotechnology Council (MPBC), Bhopal, India major research project-(PA-23/656) for financial assistance.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Rawat, H.K., Ganaie, M.A. & Kango, N. Production of inulinase, fructosyltransferase and sucrase from fungi on low-value inulin-rich substrates and their use in generation of fructose and fructo-oligosaccharides. Antonie van Leeuwenhoek 107, 799–811 (2015). https://doi.org/10.1007/s10482-014-0373-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10482-014-0373-3