Abstract

Here a novel material for methane adsorption was synthesized and studied, which is a graphene-like two-dimensional (2D) carbide (Ti2C, a member of MXenes), formed by exfoliating Ti2AlC powders in a solution of lithium fluoride (LiF) and hydrochloric acid (HCl) at 40 °C for 48 h. Based on first-principles calculation, theoretically perfect Ti2C with O termination has a specific surface area (SSA) of 671 m2 g−1 and methane storage capacity is 22.9 wt%. Experimentally, 2.85 % exfoliated Ti2C with mesopores shown methane capacity of 11.58 cm3 (STP: 0 °C, 1 bar) g−1 (0.82 wt%) under 5 MPa and the SSA was 19.1 m2 g−1. For Ti2C sample intercalated with NH3·H2O, the adsorbed amount was increased to 16.81 cm3 (STP) g−1 at same temperature. At the temperature of 323 K, the adsorbed amount of as-prepared Ti2C was increased to 52.76 cm3 (STP) g−1. For fully exfoliated Ti2C, the methane capacity was supposed to be 28.8 wt% or 1148 V (STP)v−1. Ti2C theoretically has much larger volume methane capacity than current methane storage materials, though its SSA is not very high.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

As the main component of natural gas, methane is a clean fuel with the highest heating value and the least CO2 emissions among all carbon-contained fuels. The extensive use of methane may significantly ease oil crisis. However, like other gas energy sources, the storage and transport of methane is a barrier to constrain its broader commercialization. Gas absorption storage is a promising approach to make the breakthrough and the key of this technology is to develop ideal adsorbents. Activated carbon (Casco et al. 2015; Bagheri and Abedi 2011), carbon materials with nanostructure (Rose et al. 2010; Yushin et al. 2005) and metal–organic framework materials (Song et al. 2015; Duan et al. 2015; Chang et al. 2015) are common used and researched adsorbents. To date, as we know, the best adsorbent is a MOF (MOF-519), which has a high methane volumetric capacity of 200 V (STP) v−1 at 25 °C under 3.5 MPa and 8 MPa (Gandara et al. 2014). Activated carbons exhibit adsorption capacity of 170 V (STP) v−1 at 25 °C and under 5 MPa and 200 V (STP) v−1 under 10 MPa (Casco et al. 2015). Carbide-derived carbon after physical activation has methane storage of 214 mg/g under 8 MPa at 25 °C (Oschatz et al. 2013).

Recently, two dimensional (2D) materials are of interest as novel methane adsorbents (Seyed-Talebi and Neek-Amal 2014; Chouhan et al. 2015; Carrillo et al. 2015), due to their large surface areas and abundant active sites. MXenes, a family of early transition metal carbides and carbonitrides (Naguib et al. 2011), are novel 2D materials, which are synthesized by removing A-site elements from Mn+1AXn phases (Naguib et al. 2011; Ghidiu et al. 2014) (where n = 1, 2, or 3, M is an early transition metal, A is an A-group element, and X represents carbon and/or nitrogen). Due to high surface energy, the surface of MXene made in hydrofluoric acid (HF) solution is always terminated with OH, F and/or O group. As 2D materials, MXenes have the properties such as high specific surface area (SSA), excellent electrical conductivities, etc. (Lukatskaya et al. 2013; Naguib et al. 2012b; Mashtalir et al. 2013; Khazaei et al. 2013). They have important application in the areas such as electrode materials for Li-ion batteries (Tang et al. 2012; Shein and Ivanovskii 2012; Lin et al. 2015; Naguib et al. 2012a) or supercapacitors (Lukatskaya et al. 2013), catalysts (Gao et al. 2014), and lead adsorption materials (Peng et al. 2014). Especially, our group theoretically predicted that MXenes are promising hydrogen storage materials (Hu et al. 2013, 2014). However, as far as we know, there is no report on the methane adsorption of MXenes.

The most extensively researched MXene is Ti3C2 (Mashtalir et al. 2014; Sun et al. 2014; Li et al. 2015; Gao et al. 2015; Yin et al. 2015). It was first synthesized by selective etching Al elements from Ti3AlC2 with HF acid (Naguib et al. 2011). Recently, HF was replaced by HCl and lithium fluoride (LiF) solution to synthesize Ti3C2 (Ghidiu et al. 2014). Compared with HF, HCl and LiF solution is less corrosive and less dangerous, which is a better etchant to synthesize MXenes. Ti2C is another MXene (Come et al. 2012), that is synthesized from Ti2AlC. It is less researched than Ti3C2 because it is less stable than Ti3C2. However, Ti2C, consist of two Ti layers and one C layer, is thinner than Ti3C2, which is consist of three Ti layers and two C layers. Thus the SSA of Ti2C is much larger than Ti3C2, which is very important for the high gas adsorption capacity of materials. Here we synthesized Ti2C from HCl and LiF solution, thereafter, theoretically and experimentally researched its potential as methane adsorption material.

2 Theoretical method

Firs-principles calculations were carried out by using density function theory (DFT) (Kohn and Sham 1965) and all-electron projected augmented wave (PAW) (Blöchl 1994) method as that were implemented in the Vienna ab initio simulation package (VASP) (Kresse and Furthmüller 1996). A plane-wave cutoff energy of 600 eV and 7 × 7 × 2 Monkhorst–Pack (MP) k-point grid were used during the relaxation to ensure convergence of total energies to 1 meV per primitive cell. For exchange–correlation energy, we use the Perdue–Burke–Ernzerhof (PBE) version of generalized gradient approximation (GGA) (Perdew et al. 1996). To simplify the calculation, only Ti2C terminated with oxygen (Ti2CO2) was considered in this paper. Thus, methane is actually adsorbed on Ti2CO2 surface. Van der Waals interaction was introduced to treat the interaction between methane molecule and the monolayer Ti2CO2, and it is described by Tkatchenko-Scheffler method (Tkatchenko and Scheffler 2009). To avoid the interaction between two sheets, the periodic structure of Ti2CO2 (2 × 2 supercell) was separated by vacuum layers more than 15 Å.

The adsorption energy (\(E_{ads }\)) was calculated by using the following equation:

In this equation, \(E_{{{\text{Ti}}_{{\text{2}}} {\text{CO}}_{{\text{2}}} {\text{ + CH}}_{{\text{4}}} }}, E_{{{\text{CH}}_{{\text{4}}} }} {\text{ and }}E_{{{\text{Ti}}_{{\text{2}}} {\text{CO}}_{{\text{2}}} }}\) are the total energy of monolayer Ti2CO2 adsorbed with CH4 molecule, CH4 molecule, and monolayer Ti2CO2, respectively.

3 Experimental

3.1 Synthesis of Ti2C

Ti2AlC powders were prepared by mixing commercial powders of TiH2 (>99.5 % purity, 200 mesh, Xing Rong Yuan Technology Co., LTD, Beijing, China), Al (>99.5 % purity, 200 mesh, Xing Rong Yuan Technology Co., LTD, Beijing, China), C (>99 % purity, 200 mesh, Hua Xiang Carbon Powder Technology Co., LTD, Henan, China) with a molar ratio of 2:1.1:1 by ball milling for 18 h. The mixture was heated to 1400 °C with a rate of 10 °C/min in a tube furnace under flowing Ar atmosphere. After cooling down to room temperature, the as-synthesized porous product was broken with mortar and pestle, passed through a 500 mesh sieve to produce Ti2AlC powders with particle size ≤38 µm.

Etching solution was made by adding two grams of LiF (>98.5 % purity, 500 mesh, Guangfu Reagent, Tianjin, China) into 40 ml HCl solution (6 M, 36–38 %, Shuangshuang Chemical Co., LTD, Yantai, China). The solution was mixed by sonication for 15 min to dissolve all LiF. Thereafter, 2 g of Ti2AlC powders were immersed in the above solution, stirred for 1 min, and then the mixture was held at 40 °C for 48 h with magnetic stirring. Thereafter the mixture was separated by centrifugation, washed with deionized water and ethanol several times, until the supernatant reached a pH value of ~6. Obtained Ti2C powders were dried in vacuum at 80 °C for 12 h.

In order to get Ti2C with larger layer spacing, as-prepared Ti2C was further exfoliated by intercalation with NH3·H2O (Shuangshuang Chemical Co., LTD, Yantai, China). 0.5 g as-prepared Ti2C powders were mixed with 6 ml NH3·H2O and magnetically stirred for 2 h at room temperature. Then the intercalated Ti2C powders were washed several times by deionized water and dried in vacuum at 80 °C for 12 h.

3.2 Characterization

Composition of as-synthesized Ti2AlC powders and exfoliated Ti2C powders were characterized by a powder X-ray diffractmeter (Bruker AXS Cu, Germany) with Cu Kα radiation. A field emission scanning electron microscopy (FE-SEM, JSM-6330, JEOL, Japan) and transmission electron microscope (TEM, JEOL JEM-2010, Japan) with an accelerating voltage of 200 kV were used to investigate the morphology and microstructures of Ti2C samples. TEM samples were prepared by ultrasonic dispersion of the powder products in ethyl alcohol and then moved on a copper grid. A Laser microscopic confocal Raman spectrometer (Renishaw, INVIA, Britain) was used to obtain Raman spectrum of Ti2C samples.

Prior to all adsorption measurements, the samples were degassed in vacuum at 353 K for 5 h. Nitrogen adsorption isotherms of Ti2C were measured at 77 K (Quantachrome, Autosorb-iO-MP, USA). The SSA and the pore size distributions were calculated by Brunauer–Emmett–Teller (BET) equation, DFT method, respectively. At relative pressure p/p0 = 0.99, the total pore volume was evaluated. Adsorption of methane of Ti2C was measured by a gas adsorption analyzer (H-Sorb 2600, Gold Corporation, Beijing, China).

4 Results and discussion

4.1 Theoretical prediction on methane adsorption of Ti2CO2

Ti2C made from LiF and HCl solution is always terminated with OH, F and/or O groups. And O group is the most common termination after the Ti2C was kept for some days (Gan et al. 2013; Zhu et al. 2015; Gao et al. 2015). Using the calculating method described in Sect. 2, we obtained the most stable structure of Ti2C terminated with oxygen (Ti2CO2). Three sites on monolayer Ti2CO2 are possible to adsorb CH4. They are (1) top site over O atoms, (2) top sites over Ti atoms, and (3) top sites over C atoms. For these three sites, two types of methane adsorption are established. They are (1) one H atom on Ti2CO2 surface (Ti2CO2 ↔ H–CH3) and (2) three H atoms on Ti2CO2 surface (Ti2CO2 ↔ H3–CH).

The corresponding \(E_{ads }\) of two type adsorption of CH4 molecules on three sites are listed in Table 1. Since all \(E_{ads } s\) are minus, all the sites are possible to adsorb methane molecules. However, No. 4 \(E_{ads }\) (Ti2CO2 ↔ H3–CH, methane molecule directly above Ti) is much larger than others adsorption energies. Therefore, CH4 molecule tends to be adsorbed on the Ti-site with one C-H bond perpendicular to the surface of Ti2CO2 while the other three C-H bonds point to the C atoms. This is the most stable adsorption structures. Figure 1 shows the top views and side view of equilibrium configurations for the adsorption on Ti2CO2. For this configuration, the adsorption energy value is −0.295 eV per CH4 molecule and the CH4-Ti distance is 3.899 Å. Compared with the values of CH4 on graphene in literature (Thierfelder et al. 2011), the energy on Ti2CO2 is very close to the calculated value (0.26–0.32) and larger than experimental value (0.12–0.14). The calculated density of electron shows that there is no electronic exchange between CH4 and Ti2CO2. Thus this is a physical adsorption. For the adsorption with the strongest \(E_{ads }\)(No. 4), per unite cell of Ti2CO2 can adsorb two methane molecules in both sides, and theoretic methane storage capacity is 22.9 wt%.

Finally, the theoretical work can draw two conclusions: (1) CH4 molecules can be adsorbed on the surface of Ti2C terminated with O, and the adsorption is a physical adsorption. (2) The theoretical methane uptake of Ti2C terminated with O is 22.9 wt%. Combined experimental results, these two conclusions will be further discussed in Sect. 4.4.

4.2 Characterization of Ti2C MXene

The XRD patterns of Ti2AlC and Ti2C MXene are shown in Fig. 2. It can be seen that during exfoliation process, most peaks of Ti2AlC disappeared and (002) peak was kept and shifted from 2θ = 12.98° to low angle direction. This suggested Ti2AlC was exfoliated and Ti2C was generated. The (002) peak of new generated Ti2C was divided into two minor peaks (2θ = 6.44° and 7.62°). The separation of this (002) peak means there are two d-spaces for the basal plane of this Ti2C. Calculated from Bragg’s equation, the d for the basal plane of this Ti2C is 2.78 or 2.32 nm, respectively.

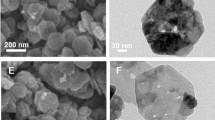

Figure 3a shows the FESEM image of MXene (Ti2C). Inset is partial image with high magnification. From Fig. 3a, layered structure was produced after the sample was treated for 48 h. The Ti2C 2D lamellas are clearly observed, with the thickness of 60 ± 20 nm, and the surface was clean.

TEM image of Ti2C lamellas and the selected area electron diffraction pattern (SAED) are showed in Fig. 3b. The Ti2C lamellas had large area and very small thickness. Their basal plane kept the hexagonal structure of Ti2AlC. From the diffraction pattern, the interplanar spacing in the sample is 2.515, 2.556, 2.571 Å for planes of (\(01\bar{1}0\)), (\(10\bar{1}0\)) and (\(1\bar{1}00\)), respectively.

The Raman spectra of Ti2C and Ti2AlC are shown in Fig. 4. The peaks at ω1, ω2 and ω4, according to previous literature (Spanier et al. 2005), are due to vibrations of the Al atoms in Ti2AlC. The most of these peaks are disappeared in the spectrum of Ti2C, which suggested the removing of Al layers from Ti2AlC. It is noticed that two new weak peaks, ω7 at ~1345 cm−1 and ω8 at ~1579 cm−1, appear in the spectrum of Ti2C. These two peaks are the characteristic peaks of carbon with the name of D band and G band (Ferrari and Robertson 2004; Mapelli et al. 1999). This indicates to the presence of amorphous carbon in the synthesized Ti2C.

4.3 Surface area and porosity analysis of Ti2C MXene

The nitrogen adsorption–desorption isotherm at 77 K of Ti2C is showed in Fig. 5a. According to IUPAC classification, the isotherm is of type IV and exhibit a clear hysteresis loop, indicating the existence of mesopores in Ti2C MXene.

The corresponding pore size distribution calculated by DFT theory is shown in Fig. 5b. Most pores in this sample are mesopores with the pore size distributed between 2 to 20 nm. There is a sharp peak in the distribution curve, which corresponds to the pore size of 2.77 nm. The pore shape in the DFT theory was assumed to be slit-like. Thus the pore size (2.77 nm) is the distance between two walls of a pore. It is very close to the d (2.78 or 2.32 nm) of basal plane calculated from the XRD results in Fig. 2. The agreement between the pore width and d-space suggests that some Ti2C was really exfoliated to 2D structure and the interspace between Ti2C layers play a very important role in the gas adsorption of Ti2C. Therefore, gas adsorption and XRD result verify each other in this work.

BET SSA of this sample was calculated to be 19.1 m2 g−1, which are close to previous reported SSA of Ti3C2 and Ti2C(Liang et al. 2015; Naguib et al. 2012a). The total pore volume of this Ti2C sample was obtained to be 0.0732 cm3 g−1 at the relative pressure p/p 0 = 0.99. If all Ti2CO2 are exfoliated to be only single layer, the theoretical SSA of Ti2CO2 is 671 m2 g−1 calculated from surface area and mass of Ti2CO2 unit cell. For this fully exfoliated Ti2CO2, if pore width is still 2.77 nm as shown in Fig. 5 b, which is the distance between two basal planes, theoretical pore volume can be calculated from unit cell mass and surface area to be 1.86 cm3 g−1. From the ratio of experimental SSA to theoretical SSA, it can be concluded that only 2.85 % Ti2C layers are fully exfoliated. Thus, the SSA and/or pore volume of Ti2C can be much further increased with better synthesize method.

4.4 Adsorptive properties of MXene

Methane sorption isotherm of Ti2C is shown in Fig. 6. Langmuir isothermal adsorption theory was used to calculate the adsorption quantity. Four curves in Fig. 6a, b are represented the methane sorption of MXene under the different conditions. (a) For as-prepared MXene, the methane adsorbed amount at 25, 40 and 50 °C under 5 MPa are 11.58, 18.18 and 52.76 cm3 (STP) g−1, respectively. It can be found that the adsorption quantity increases with temperature. (b) For MXene after the intercalation, the methane adsorbed amount at 25 °C under 5 MPa is 16.81 cm3 (STP) g−1, which is close to that of as-prepared MXene at 40 °C (18.18 cm3 (STP) g−1). The XRD pattern of intercalated MXene is shown in the inset of Fig. 6b. From the comparison of Fig. 2 and the inset of Fig. 6b, it can be seen that the two minor peaks disappeared after intercalated and the new peak of Ti2C at low angle (2θ = 6.23°) appeared. It suggested that, after intercalation with NH3·H2O, the Ti2C was further exfoliated and space between MXene layers become larger. This kind of MXene has obviously larger methane adsorbed amount than as-prepared MXene.

The heat of CH4 in this paper is calculated from the data measured in the pressure range from 0–5 MPa (313 and 323 K) by a method described in references (Rowsell and Yaghi 2006; Dong et al. 2015). In brief, the heat is calculated from:

where Q st is the heat of adsorption and R is the universal gas constant (R = 8.314); a 0 through a m were the virial coefficients, which were obtained by fitting experimental data in Fig. 6 a with a virial-type expression (R2 > 0.99). From this calculation, Q sts at 313 and 323 K were found to be 38.5 and 19.7 kJ mol−1, respectively. In generally, the heat of adsorption (Q st) for physical adsorption is less than 40 kJ mol−1. The calculated adsorption heats are in this range. Thus, methane adsorption of MXene is a physical adsorption, which agree with the theoretical calculation in Sect. 4.1. Compared with other adsorption heats, these values are close to the heats of methane adsorption of active carbons, which are in the range of 16–21 kJ mol−1 (Himeno et al. 2005).

Then a conclusion can be drawn that Ti2C with termination made in our lab can really adsorb methane at room temperature, as illustrated in Fig. 6a. This agrees with the theoretic work in Sect. 4.1. The total methane adsorbed amount of this sample is 11.58 cm3 (STP) g−1 (0.82 wt%) at 25 °C under 5 MPa. If the sample was further exfoliated, the adsorbed amount increased to 16.81 cm3 (STP) g−1, and if temperature increased to 323 K, the adsorbed amount increased to 52.76 cm3 (STP) g−1.

For 2.85 % exfoliated Ti2C with SSA of 19.1 m2 g−1, the methane uptake is 0.82 wt%. If Ti2C can be 100 % exfoliated and achieve a theoretic SSA of 671 m2 g−1, its methane uptake can be 28.8 wt%. The theoretic uptake in Sect. 4.1 is 22.9 wt%. Considering the errors in measurement and the approximation in theoretical work, the divergence of these two values is acceptable. The measured uptake and calculated uptake agree well with each other.

Adsorbed density of as-prepared MXene can be calculated from adsorbed amount (0.82 wt% or 0.0082 g g−1) and total pore volume (0.0732 cm3 g−1). That gives a density for the methane adsorbed of approximately 0.11 g cm−3, which is similar or lower to the values presented by other adsorbents such as carbon materials. For carbon materials, this value varies between 0.1 and 0.2 g cm−3. And the theoretical adsorbed density of fully exfoliated MXene also can be calculated from adsorbed amount (28.8 wt% or 0.288 g g−1) and total pore volume (1.86 cm3 g−1). It is 0.155 g cm−3. This value is in the range of methane adsorbed density of carbon materials. Thus it is a reasonable value. The super high adsorption value of MXene is not because of high adsorbed density. It is because of the large adsorption surface area due to the structure of MXene.

Furthermore, the methane adsorption performance of Ti2CO2 may be greatly improved in the future with the improvement of Ti2C synthesis. More importantly, the density of Ti2CO2 is much higher than porous carbon normally used as methane adsorbent (pack density = 0.5–0.7 g cm−3) (Yeon et al. 2009). The apparent density of Ti2CO2 discs compacted under pressure of 10 MPa is 1.79 g cm−3. If the unit of methane uptake is changed from gravimetric uptake (per g) to volumetric uptake (per cm3), which can be calculated from the adsorbed amount value in Fig. 5 divided by density of absorbent, the methane volumetric uptake can be as high as 32.7 V (STP)v−1 for 2.85 % exfoliated Ti2C. And for fully exfoliated Ti2C, the theoretic volumetric uptake can be 1148 V (STP)v−1. Compared with 279 V (STP) v−1 for MOF-519 with SSA of 2400 m2 g−1 (Gandara et al. 2014), 214 mg g−1 for CDC with SSA of 3100 m2 g−1 (Oschatz et al. 2013), and 170 V (STP) v−1 for activated carbon with SSA of 2700 m2 g−1 (Casco et al. 2015), the theoretic uptake can be very huge if fully exfoliated single layer Ti2C is made, though the first report value for 2.85 % exfoliated Ti2C in this paper is not very high. This very high volumetric uptake means methane can be stored in a tank with very small volume. This is important for applications that require small dimensions, such as portable fuel storage, adsorption of gas from landfills, etc. Therefore, this work suggests that MXenes theoretically have very high volumetric methane uptake, though their SSA is not so high. We are working to synthesize MXene with higher methane uptake and wish to achieve the theoretic value in the future.

5 Conclusions

Ti2C MXene was successfully synthesized by exfoliating Ti2AlC powders in the solution of LiF and hydrochloric acid (HCl) at 40 °C for 48 h. Characteristic peaks of carbon (D bond and G bond) was detected in Raman spectrum of Ti2C, which indicates to the presence of amorphous carbon in synthesized Ti2C. The pore width of Ti2C with maximum distribution obtained from N2 adsorption isothermal agree well with d space of basal plane of Ti2C obtained from XRD. The methane adsorption properties of Ti2C were theoretically and experimentally researched. From theoretical calculations, the methane adsorption of Ti2C with O termination is physical adsorption. The most stable adsorption structure was CH4 molecules on the site directly above Ti atoms. At high pressure and room temperature, 2.85 % exfoliated Ti2C with SSA of 19.1 m2 g−1 made in this paper has a methane uptake of 11.58 cm3 (STP) g−1 (0.82 wt%). For fully exfoliated Ti2C, the capacity was supposed to be 28.8 wt% or 1148 V (STP) v−1. For Ti2C sample after NH3·H2O intercalation, the adsorbed amount increased to 16.81 cm3 (STP) g−1. At the temperature of 323 K, the adsorbed amount increased to 52.76 cm3 (STP) g−1. Based on their theoretical high surface area, high pack density, good pore size distribution and absorptivity, Ti2C MXene is a promising candidate for adsorbent of methane storage.

References

Bagheri, N., Abedi, J.: Adsorption of methane on corn cobs based activated carbon. Chem. Eng. Res. Des. 89(10), 2038–2043 (2011)

Blöchl, P.E.: Projector augmented-wave method. Phys. Rev. B 50(24), 17953–17979 (1994)

Carrillo, I., Ramírez, J., Magaña, L.: Adsorption of carbon monoxide, carbon dioxide and methane on hexagonal boron nitride with high titanium coverage. Surf. Sci. 637, 48–52 (2015)

Casco, M.E., Martínez-Escandell, M., Kaneko, K., Silvestre-Albero, J., Rodríguez-Reinoso, F.: Very high methane uptake on activated carbons prepared from mesophase pitch: a compromise between microporosity and bulk density. Carbon 93, 11–21 (2015)

Chang, G., Li, B., Wang, H., Bao, Z., Yildirim, T., Yao, Z., Xiang, S., Zhou, W., Chen, B.: A microporous metal–organic framework with polarized trifluoromethyl groups for high methane storage. Chem. Commun. 51(79), 14789–14792 (2015)

Chouhan, R.K., Ulman, K., Narasimhan, S.: Graphene Oxide as an Optimal Candidate Material for Methane Storage. J. Chem. Phys. 143(4), 044704 (2015)

Come, J., Naguib, M., Rozier, P., Barsoum, M.W., Gogotsi, Y., Taberna, P.L., Morcrette, M., Simon, P.: A non-aqueous asymmetric cell with a Ti2C-based two-dimensional negative electrode. J. Electrochem. Soc. 159(8), A1368–A1373 (2012)

Dong, B., Zhang, S., Liu, W., Wu, Y., Ge, J., Song, L., Teng, Y.: Gas storage and separation in a water-stable [Cu I 5 BTT 3] 4− anion framework comprising a giant multi-prismatic nanoscale cage. Chem. Commun. 51(26), 5691–5694 (2015)

Duan, X., Wu, C., Xiang, S., Zhou, W., Yildirim, T., Cui, Y., Yang, Y., Chen, B., Qian, G.: Novel microporous metal-organic framework exhibiting high acetylene and methane storage capacities. Inorg. Chem. 54(9), 4377–4381 (2015)

Ferrari, A.C., Robertson, J.: Raman spectroscopy of amorphous, nanostructured, diamond–like carbon, and nanodiamond. Philos. Trans. R. Soc. London Ser. A 362(1824), 2477–2512 (2004)

Gan, L.-Y., Huang, D., Schwingenschlögl, U.: Oxygen adsorption and dissociation during the oxidation of monolayer Ti 2 C. J. Mater. Chem. A 1(43), 13672–13678 (2013)

Gandara, F., Furukawa, H., Lee, S., Yaghi, O.M.: High methane storage capacity in aluminum metal-organic frameworks. J. Am. Chem. Soc. 136(14), 5271–5274 (2014)

Gao, Y., Wang, L., Li, Z., Zhou, A., Hu, Q., Cao, X.: Preparation of MXene-Cu2O nanocomposite and effect on thermal decomposition of ammonium perchlorate. Solid State Sci. 35, 62–65 (2014)

Gao, Y., Wang, L., Zhou, A., Li, Z., Chen, J., Bala, H., Hu, Q., Cao, X.: Hydrothermal synthesis of TiO2/Ti3C2 nanocomposites with enhanced photocatalytic activity. Mater. Lett. 150, 62–64 (2015)

Ghidiu, M., Lukatskaya, M.R., Zhao, M.Q., Gogotsi, Y., Barsoum, M.W.: Conductive two-dimensional titanium carbide ‘clay’ with high volumetric capacitance. Nature 516(7529), 78–81 (2014)

Himeno, S., Komatsu, T., Fujita, S.: High-pressure adsorption equilibria of methane and carbon dioxide on several activated carbons. J. Chem. Eng. Data 50(2), 369–376 (2005)

Hu, Q., Sun, D., Wu, Q., Wang, H., Wang, L., Liu, B., Zhou, A., He, J.: MXene: a new family of promising hydrogen storage medium. J. Phys. Chem. A 117(51), 14253–14260 (2013)

Hu, Q., Wang, H., Wu, Q., Ye, X., Zhou, A., Sun, D., Wang, L., Liu, B., He, J.: Two-dimensional Sc2C: a reversible and high-capacity hydrogen storage material predicted by first-principles calculations. Int. J. Hydrog. Energy 39(20), 10606–10612 (2014)

Khazaei, M., Arai, M., Sasaki, T., Chung, C.-Y., Venkataramanan, N.S., Estili, M., Sakka, Y., Kawazoe, Y.: Novel electronic and magnetic properties of two-dimensional transition metal carbides and nitrides. Adv. Funct. Mater. 23(17), 2185–2192 (2013)

Kohn, W., Sham, L.: Density function theory. J. Phys. Rev. 140, A1133–A1138 (1965)

Kresse, G., Furthmüller, J.: Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54(16), 11169–11186 (1996)

Li, Z., Wang, L., Sun, D., Zhang, Y., Liu, B., Hu, Q., Zhou, A.: Synthesis and thermal stability of two-dimensional carbide MXene Ti3C2. Mater. Sci. Eng. B 191, 33–40 (2015)

Liang, X., Garsuch, A., Nazar, L.F.: Sulfur cathodes based on conductive MXene nanosheets for high-performance lithium-sulfur batteries. Angew. Chem. Int. Ed. 54(13), 3907–3911 (2015)

Lin, Z., Sun, D., Huang, Q., Yang, J., Barsoum, M.W., Yan, X.: Carbon nanofibers bridged two-dimensional titanium carbide as a superior anode in lithium-ion battery. J. Mater. Chem. A 3(27), 14096–14100 (2015)

Lukatskaya, M.R., Mashtalir, O., Ren, C.E., Dall’Agnese, Y., Rozier, P., Taberna, P.L., Naguib, M., Simon, P., Barsoum, M.W., Gogotsi, Y.: Cation intercalation and high volumetric capacitance of two-dimensional titanium carbide. Science 341(6153), 1502–1505 (2013)

Mapelli, C., Castiglioni, C., Meroni, E., Zerbi, G.: Graphite and graphitic compounds: vibrational spectra from oligomers to real materials. J. Mol. Struct. 480, 615–620 (1999)

Mashtalir, O., Cook, K., Mochalin, V., Crowe, M., Barsoum, M., Gogotsi, Y.: Dye adsorption and decomposition on two-dimensional titanium carbide in aqueous media. J. Mater. Chem. A 2(35), 14334–14338 (2014)

Mashtalir, O., Naguib, M., Mochalin, V.N., Dall’Agnese, Y., Heon, M., Barsoum, M.W., Gogotsi, Y.: Intercalation and delamination of layered carbides and carbonitrides. Nat. Commun. 4, 1716 (2013)

Naguib, M., Come, J., Dyatkin, B., Presser, V., Taberna, P.-L., Simon, P., Barsoum, M.W., Gogotsi, Y.: MXene: a promising transition metal carbide anode for lithium-ion batteries. Electrochem. Commun. 16(1), 61–64 (2012a)

Naguib, M., Kurtoglu, M., Presser, V., Lu, J., Niu, J., Heon, M., Hultman, L., Gogotsi, Y., Barsoum, M.W.: Two-Dimensional Nanocrystals Produced by Exfoliation of Ti3AlC2. Adv. Mater. 23(37), 4248–4253 (2011)

Naguib, M., Mashtalir, O., Carle, J., Presser, V., Lu, J., Hultman, L., Gogotsi, Y., Barsoum, M.W.: Two-dimensional transition metal carbides. ACS Nano 6(2), 1322–1331 (2012b)

Oschatz, M., Borchardt, L., Senkovska, I., Klein, N., Leistner, M., Kaskel, S.: Carbon dioxide activated carbide-derived carbon monoliths as high performance adsorbents. Carbon 56, 139–145 (2013)

Peng, Q., Guo, J., Zhang, Q., Xiang, J., Liu, B., Zhou, A., Liu, R., Tian, Y.: Unique lead adsorption behavior of activated hydroxyl group in two-dimensional titanium carbide. J. Am. Chem. Soc. 136(11), 4113–4116 (2014)

Perdew, J.P., Burke, K., Ernzerhof, M.: Generalized gradient approximation made simple. Phys. Rev. Lett. 77(18), 3865 (1996)

Rose, M., Kockrick, E., Senkovska, I., Kaskel, S.: High surface area carbide-derived carbon fibers produced by electrospinning of polycarbosilane precursors. Carbon 48(2), 403–407 (2010)

Rowsell, J.L., Yaghi, O.M.: Effects of functionalization, catenation, and variation of the metal oxide and organic linking units on the low-pressure hydrogen adsorption properties of metal-organic frameworks. J. Am. Chem. Soc. 128(4), 1304–1315 (2006)

Seyed-Talebi, S.M., Neek-Amal, M.: The different adsorption mechanism of methane molecule onto a boron nitride and a graphene flakes. J. Appl. Phys. 116(15), 153507 (2014)

Shein, I.R., Ivanovskii, A.L.: Graphene-like titanium carbides and nitrides Tin+1Cn, Tin+1Nn (n = 1, 2, and 3) from de-intercalated MAX phases: first-principles probing of their structural, electronic properties and relative stability. Comput. Mater. Sci. 65, 104–114 (2012)

Song, C., Ling, Y., Feng, Y., Zhou, W., Yildirim, T., He, Y.: A NbO-type metal–organic framework exhibiting high deliverable capacity for methane storage. Chem. Commun. 51(40), 8508–8511 (2015)

Spanier, J.E., Gupta, S., Amer, M., Barsoum, M.W.: Vibrational behavior of the Mn+1AXn phases from first-order Raman scattering(M = Ti,V,Cr,A = Si,X = C,N). Phys. Rev. B 71(1), 012103 (2005)

Sun, D., Wang, M., Li, Z., Fan, G., Fan, L.-Z., Zhou, A.: Two-dimensional Ti3C2 as anode material for Li-ion batteries. Electrochem. Commun. 47, 80–83 (2014)

Tang, Q., Zhou, Z., Shen, P.: Are MXenes Promising Anode Materials for Li Ion Batteries? Computational Studies on Electronic Properties and Li Storage Capability of Ti3C2 and Ti3C2X2 (X = F, OH) Monolayer. J. Am. Chem. Soc. 134(40), 16909–16916 (2012)

Thierfelder, C., Witte, M., Blankenburg, S., Rauls, E., Schmidt, W.: Methane adsorption on graphene from first principles including dispersion interaction. Surf. Sci. 605(7), 746–749 (2011)

Tkatchenko, A., Scheffler, M.: Accurate molecular van der Waals interactions from ground-state electron density and free-atom reference data. Phys. Rev. Lett. 102(7), 073005 (2009)

Yeon, S.-H., Osswald, S., Gogotsi, Y., Singer, J.P., Simmons, J.M., Fischer, J.E., Lillo-Ródenas, M.A., Linares-Solano, Á.: Enhanced methane storage of chemically and physically activated carbide-derived carbon. J. Power Sources 191(2), 560–567 (2009)

Yin, H., Zhu, J., Guan, X., Yang, Z., Zhu, Y., Zhao, H., Zhang, Z., Zhou, A., Zhang, X., Feng, C.: Effect of MXene (nano-Ti 3 C 2) on early-age hydration of cement paste. J. Nanomater. 2015, 147 (2015)

Yushin, G.N., Hoffman, E.N., Nikitin, A., Ye, H., Barsoum, M.W., Gogotsi, Y.: Synthesis of nanoporous carbide-derived carbon by chlorination of titanium silicon carbide. Carbon 43(10), 2075–2082 (2005)

Zhu, Y., Zhou, A., Ji, Y., Jia, J., Wang, L., Wu, B., Zan, Q.: Tribological properties of Ti3SiC2 coupled with different counterfaces. Ceram. Inter. 41(5), 6950–6955 (2015)

Acknowledgments

This work was supported by National Nature Science Foundation of China (51472075, 51205111), Program for Innovative Research Team (in Science and Technology) in the University of Henan Province (No. 16IRTSTHN005), Plan for Scientific Innovation Talent of Henan Province (134100510008), Program for Innovative Research Team of Henan Polytechnic University (T2013-4), Fundamental Research Funds for the Universities of Henan Province (NSFRF140401, 140601).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Liu, F., Zhou, A., Chen, J. et al. Preparation and methane adsorption of two-dimensional carbide Ti2C. Adsorption 22, 915–922 (2016). https://doi.org/10.1007/s10450-016-9795-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10450-016-9795-8