Abstract

This paper reports on recent experimental work to investigate the response of bolted carbon fibre composite joints and structures when subjected to constant dynamic loading rates between 0.1 m/s and 10 m/s. Single fastener joints were tested in both the bearing (shear) and pull-through (normal) loading directions. It was found that the joints exhibited only minor loading rate dependence when loaded in the pull-through direction but there was a significant change in failure mode when the joints were loaded in bearing at or above 1 m/s. Below 1 m/s loading rate the failure mode consisted of initial bolt bearing followed by bolt failure. At a loading rate of 1 m/s and above the bolt failed in a ‘tearing’ mode that absorbed significantly more energy than the low rate tests. A simple composite structure was created to investigate the effect of loading rate on a more complex joint arrangement. The structure was loaded in two different modes and at constant dynamic loading rates between 0.1 m/s and 10 m/s. For the structure investigated and the loading modes considered, only minor loading rate effects were observed, even when the dominant contribution to joint loads came from bearing. It was observed that the load realignment present in the structural tests allowed the joints to fail in a mode that was not bearing dominant, and hence the loading rate sensitivity was not expressed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Composite materials are becoming more commonly used with every generation of aircraft. The Boeing 787 is a prime example, which is set to include 50% composite material by weight [1]. An understanding of the assembly and joining techniques of composite materials is crucial to the design and repair of large scale composite structures.

The low efficiency of fastened joints in composite materials compared with metal structures [2] makes bolts or rivets a less than ideal choice for joining composite parts. Bonded joints offer much greater joining efficiency than bolted joints, but suffer some drawbacks which have limited their use in large scale composite structures. The cost of producing, testing and maintaining a bonded joint is much greater than for the equivalent bolted joint. Limitations of non-destructive inspection techniques mean that bonded structures are difficult to inspect, and there may be no way to determine that the load carrying capacity of a joint has been compromised.

Due to their relative ease of installation, resistance to creep and resistance to environmental degradation, fasteners are commonly used in the assembly of aerospace components. An understanding of the stiffness, strength and failure mode of bolted joints is critical to the efficient design of composite structures. The particular failure mode that is exhibited by a bolted connection is dependent on a number of factors including geometry, layup, and loading direction.

Much effort has been expended testing and categorising the failure of composite pinned and bolted joints experimentally [3–15]. The large number of variables within any joint design makes it difficult and expensive to test even a small range of joints comprehensively. Therefore many attempts have been made to understand and predict the failure of composite joints [8–25] using numerical and analytical methods to reduce the experimental effort required. Most successful joint modelling has been conducted with slow design tools, i.e. detailed finite element models with a large number of elements used to represent the bolt and the surrounding laminates. The analysis is a very difficult one, involving contact, secondary and tertiary bending effects and three-dimensional progressive failure prediction. It is for this reason that success in modelling the failure of composite materials has been slow, and limited to specific joint configurations and loading types.

Most studies of bolted joints have focused on the quasi-static behaviour of the joint. It is an unfortunate consequence of the operating environment of aircraft that many critical load cases involve impact and crash. These loading events are characterised by high loading rates, high kinetic energy and possibly loads well in excess of the static design strengths. The properties of many materials change with loading rate, as does the frictional interaction between surfaces. It is therefore likely that the behaviour of bolted composite joints varies significantly with varied loading rates.

Ger et al. [26] tested a number of carbon and carbon-glass hybrid composite joints dynamically (6–7 m/s) and quasi-statically under pin-loaded, single-lap and double-lap joint configurations. It was found that for all joint configurations the stiffness of the joint increased significantly with loading rate. Contrastingly, the total energy absorption of the joint decreased significantly in the dynamic tests. The variation of peak load carrying capacity with loading rate was more complicated. The pin loaded joints were significantly weaker at higher loading rates while the single lap-joints were not significantly affected. Conversely, the double lap joint configurations carried more load at high loading rates.

Li et al. [27] tested a number of different joint configurations subjected to a bearing load at rates between quasi-static and 8 m/s, and found a number of contradictory results. For the majority of specimens tested, the stiffness and strength of the joint only increased slightly with loading rate. However, there was a significant change in failure mode at higher rates (4–8 m/s) which generally resulted in increased energy absorption. This is in direct contradiction to Ger et al. [26], who found a sharp drop in energy absorption with loading rate.

In both cases above, the loading was limited to an ideal tensile load, carried in the shear plane of the joint. Loading of joints is not always ideal and in-plane. Impact of foreign objects or propagation of bending waves through the structure can force the joint to carry significant pull-out loads in addition to the usual bearing loads. This paper extends the study of dynamic joint behaviour to include pull-through loading. For one particular joint configuration, a series of dynamic bearing and pull-through tests were completed up to a rate of 10 m/s.

Single-fastener joint tests do not give a full insight into the behaviour of the joints when built into composite structures. Load in a structure is not always evenly divided between fasteners, especially under impact conditions. A simple composite structure was designed and tested quasi-statically and dynamically to investigate any dynamic effects that may be present when multiple fasteners interact within a joint.

2 Joint Tests

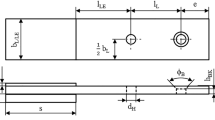

To characterise the stiffness, strength and failure behaviour of composite bolted joints a series of single-fastener joint tests were conducted by Gunnion et al. [28] and Bornschlegel [29]. The method and results of these tests will be summarised here. For consistency, the results shown in this paper are for a single bolt and laminate combination, namely a titanium alloy HiLok 523-8 countersunk head fastener, with a 1/4″ (6.35 mm) nominal diameter and a 100° countersink angle used to join [45,0]4s T300/CYCOM970 carbon fibre epoxy, plain weave fabric laminates of 3.52 mm nominal thickness. In the pull-through tests, the specimen consisted of a 65 × 65 mm square plate with a central bolted hole. The joint geometry for the bearing tests was selected to promote only the bearing type of joint failure. The geometry for the bearing tests is shown in Fig. 1.

Bearing test specimen dimensions [30]

2.1 Quasi-Static Tests

The quasi-static tests were conducted for a range of laminate thicknesses, bolt diameters and bolt head types. Each joint combination was tested in an ideal bearing (shear) loading direction and a pull-through (normal) loading direction. The test geometry and specific loading conditions can be found in Koerber [30]. The experimental rig for the quasi-static pull-through tests is shown in Fig. 2. The specimen was clamped between two steel rings with a 55 mm internal diameter. The test fixture included two LVDTs which measured the displacements of the bolt head and the adjacent laminate. The experimental rig for the quasi-static bearing test is shown in Fig. 3. The rig meets the specifications of ASTM D5961. The specimens were free to move parallel to the loading direction but were restrained from out-of-plane bending.

Quasi-static pull-through test fixture [28]

ASTM D 5961 bearing test fixture [31]

Characteristic load-deflection curves for the pull-through tests are shown in Fig. 4, and can be characterised by the following:

-

Initial linear elastic section

-

Distinct damage initiation point followed by a near linear inelastic plateau

-

Near elastic unloading and reloading with minimal hysteresis losses

-

Material failure with large strength and stiffness reductions

Characteristic load-deflection curves for the bearing tests are shown in Fig. 5, and can be characterised by the following:

-

Small linear elastic section

-

Progressive damage resulting in a near plastic plateau at test completion

-

The unloading was inelastic with the loading approximately non-elastic and significantly more hysteresis losses when compared to the pull-through specimen

-

The joints still carried considerable load at a displacement much greater than the initial damage onset.

2.2 Dynamic Tests

To develop an understanding of the strain rate sensitivity of the bolted joints considered in this paper, additional specimens were tested in a high-rate Instron (model VHS 100/20) at loading rates between 0.1 m/s and 10 m/s.

A small but significant displacement was required for the Instron cross-head to accelerate from rest to the desired constant test velocity. The mass of the rig must also be minimised to reduce the inertial effects that occur at high loading rates. These requirements preclude the use of the ASTM test fixtures for this type of experiment, so specially designed fixtures were developed that captured the main features of the standard testing equipment but still allowed for initial freedom of motion. The dynamic bearing test rig is shown in Fig. 6. The specimen was loaded by a strike plate at the desired dynamic test velocity. The strike plate includes a 55 mm diameter internal hole. The specimen in the dynamic test rig was simply supported around the edges of the hole instead of fully clamped as in the quasi-static tests.

The dynamic bearing test rig is shown in Fig. 7. The specimen is restrained from out-of-plane bending, as was the case for the quasi-static test rig. In the dynamic rig however, both restraint sections are connected to the fixed upper crosshead and do not need to be accelerated by the Instron. The specimen is dynamically loaded via a strike plate which is connected to the moving Instron crosshead.

Further information regarding the testing geometry and procedure can be found in Pearce et al. [32]. Unfortunately due to slight differences between the experimental apparatus for the quasi-static and dynamic tests the results cannot be directly compared in terms of loads and displacements. The general form of the curves, however, can still be compared.

Strain rate (έ) in bolted structures is difficult to characterise due to the complex strain fields that occur in the vicinity of the bolt, and with the multiple material failures that may be occurring simultaneously within the joint. For this paper strain rate magnitudes are not measured or predicted and the rate of dynamic loading shall be defined by the far field velocity of the applied load. Three tests were conducted at each loading rate. The pull-through tests were conducted at loading rates of 0.1, 1, and 5 m/s while the bearing tests were conducted at 0.1, 1, and 10 m/s.

Within the dynamic tests, a loading rate of 0.1 m/s was not considered large enough to induce dynamic material or inertial effects. Therefore, in this discussion, the 0.1 m/s tests will be described as low rate while the 1 m/s and higher tests will be considered high rate.

A set of representative test results for the dynamic bolt pull-through tests are shown in Fig. 8. These results were captured with a high sample rate of 20 kHz, and a moving average filtering technique has been employed to remove very high-frequency signal noise.

The first observation is that there is significant vibration noise on the high rate tests, particularly when the force pulse was measured in the cross-head force transducer. This noise was a real effect and was related to the vibration frequency of the test fixture. A technique was developed to reduce the effect on the force measurement, by attaching a strain gauge to the loadcell bar close to the test specimen in Fig. 7 and by calibrating the axial force to the longitudinal strain. This technique provided good force signals for the tests at 1 m/s and 5 m/s. However, the vibration amplitude was still too large at 10 m/s so the tests were conducted at 5 m/s instead.

It can be seen that the quasi-static (see Fig. 4) and the low and high rate tests (see Fig. 8) all have a very similar form. The initiation of large delamination growth within the specimens, which coincides with the large strength and stiffness reduction on the load-displacment curves, occurred significantly earlier in all 5 m/s tests. The possible reason for this will be addressed later in the discussion. It was also observed that, if the vibration is ignored, the elastic stiffness, failure load and displacement to total failure are nearly identical over the 0.1 to 5 m/s test range.

A typical failed pull-through specimen is shown in Fig. 9. The quasi-isotropic lay-up and the axisymmetric boundary conditions created a nearly isotropic strain field in the specimen relative to the bolt. The outer ply, which experienced the largest strain, had stiff fibres aligned normal to the diagonal direction, so failure initiated and propagated preferentially along these directions. This cross splitting failure mode was present at all loading rates. Small variations exist within the sample sets but there was no general change with loading rate.

A characteristic set of test results for the dynamic bearing tests is shown in Fig. 10. It can be seen that the response of the specimens at different loading rates is very similar during the elastic regime and after the initial onset of damage. The low rate specimens all failed at a displacement of approximately 5 mm, while the high rate specimens continued carrying load and absorbing energy over a much larger displacement.

Analysis of the failed specimens and the high speed test footage reveals that the low-rate specimens experienced the same initial bearing damage as the high rate tests. Near the maximum load, the low rate test failed due to the bolt tail fracturing at the first thread on the pin. In the high rate test this did not occur, and a large amount of bearing damage occurred followed by a final cleavage failure.

A failed low rate and high rate specimen are shown in Fig. 11. The small bearing damage zone and failed bolt are visible in the low rate test specimen while the large damaged zone and eventual cleavage failure are visible in the high rate test specimen.

There was a definite rate sensitivity present under these testing conditions. The major shift between low-rate and high-rate behaviour seems to be in the behaviour of the composite material. This may be due to a reduction in fracture toughness of the epoxy matrix at higher loading rate, and is addressed in the Discussion section of the paper.

3 Structural Testing

Single fastener bolted joints test represent ideal loading conditions. There are significant differences between the conditions of a single fastener test and those experienced by a bolted joint in a composite structure. Firstly, the loads applied to a joint during a bearing or pull-through test are in the two primary loading directions, normal or parallel to the axis of the bolt. In a composite structure, joints may be subjected to a mixture of these two loads, as well as possible moments and prying loads. Secondly, the boundary conditions of single fastener tests do not represent the realistic constraints experienced by joints in structural applications. Thirdly, bolted joints in composite structures include multiple fasteners, which interact with each other.

A simple structure was developed and tested to investigate some of these effects. The structure consisted of two rows of single lap shear bolted joints joining three flat composite plates. The structure was loaded transversely by two different impactor types that accentuated non-uniform loading conditions across the joint.

A number of pre-test simulations were conducted to determine the optimum dimensions for the panel that would most heavily load the bolted connections. Manufacturing considerations were also taken into account, so as to make most efficient use of available material. The fasteners and material lay-up were chosen such that they matched the previous dynamic single fastener joint testing [33]. The final selected geometry is shown in Fig. 12. The tabs were optional depending on the test.

3.1 Quasi-Static Tests

A test rig was designed to experimentally replicate a rotationally free boundary condition. Two opposite edges of the specimen were clamped in special brackets which included regions of circular cross-section that allowed the edges to rotate without having translational freedom. The load for the quasi-static tests was applied via a cylindrical section that loaded the plates along a single line perpendicular to their longitudinal direction. A picture of the rig prior to and during testing is shown in Fig. 13. The panels were loaded at 10 mm/min for all quasi-static tests.

Only three fasteners were used for each joint, as the preliminary structure tested with five fasteners per joint did not fail as desired. The joints were too strong and the structure experienced failure under the loading cylinder instead of at the joint. The load-deflection response of the quasi-static three fastener test specimen is shown in Fig. 14. The load and displacement were measured by the crosshead of the Instron test machine.

Distinct load drops were observed prior to final failure. On revision of the photographic evidence post-experiment, it was revealed that these were not due to any failure of the panel, simply a deficiency of the test rig. The friction between the cylindrical rollers and the supports was high enough that the rotation caused the panel to climb the support slightly. The load drops are simply the points where the extra displacement is released and the part drops down to its intended position. This tarnishes the data slightly but it occurred well prior to final failure of the panel so was not considered critical. The slight rounding off of the load-displacement graph prior to failure is due to the bearing damage accumulating in the bolted connection. The failed specimen is shown in Fig. 15. Note that the failure mode is a combination of bearing, pull-through and shear-out.

The joint failure mode was characterised by initial bearing damage and bolt rotation brought about by the high shear forces in the joint. The bolt rotation was apparent in the permanent angular set of the bolts after failure. Under increasing load, the bolt rotation allowed the top and bottom plates to separate significantly. The joint rotation and separation may have a significant effect on the performance of the joint. The separation of the panels removes the effect of friction within the joint. Friction has a positive effect on both the strength and stiffness of the joint [34], and is aided by appropriate clamping forces on the bolts [7,35]. The quasi-static test results indicate that the joint was loaded such that the friction force was removed causing in a significant reduction in the joint performance. The panel finally failed by the bolts pulling from the laminate, with a large section of delaminated composite.

3.2 Line Loaded High-Rate Tests

To investigate the behaviour of the joints under high strain-rate loading, tests were completed at loading rates of 0.1, 1 and 10 m/s. Due to the expense of each part, only one test was conducted at each loading speed. The test rig very similar to that used for the quasi-static tests, but with modifications to allow it to be used in the high strain-rate Instron machine.

The load was applied via a cylindrical impactor and was measured through the load cell in the driving piston of the Instron test machine. The test was filmed with a high-speed camera at 6,000 fps. In the case of the 1 m/s test, failure was forced to occur at the bolted connection by protecting the composite panel with an aluminium plate, as was used in the quasi-static test. The 0.1 and 10 m/s tests were loaded directly by the cylinder onto the panel. The set-up of the test rig in the high-rate Instron is shown in Fig. 16.

The failure mode of the test was very similar to the quasi-static test. A picture of the panel deflection under load is shown in Fig. 17. A large piece of material delaminated and fractured away from the central plate, as shown in Fig. 18. This compares well with the quasi-static failure mode shown in Fig. 15.

The load deflection responses of the quasi-static and 1 m/s test are shown in Fig. 19. The responses of the two tests were very similar, despite the four orders of magnitude difference between the loading rates of the two tests. The peak load and deflection at failure for the two tests only differed by a small margin. The quasi-static response generally has a higher load throughout the test, but it is believed that this was due to the friction effects of the test rig described earlier. This structural test, when considering failure load and failure mode, exhibited no rate effects over the loading rates considered.

There was also no visible variation between the 10 m/s failure and the 0.1 m/s failure. Unfortunately the 10 m/s load data measured at the test machine cross-head transducer had significant machine vibrations as discussed above for the dynamic pull-through specimen tests, so no comparison between low rate and high rate could be made.

3.3 Point Loaded High-Rate Tests

The line loaded rig shown above produced a fairly uniform loading in each of the fasteners and there were minimal edge effects. To investigate the effect of a more complex loading on a structure, a spherical impactor was used to impact the plate and create a double curvature in the panel. The more complex loading gave an insight into the behaviour of the joint when a non-uniform load existed across the bolted connection.

The test rig used was a simply supported frame with the two transverse edges securely clamped. To maintain a flat base to fit the test fixture, the point loaded specimens had 50 mm tabs bonded to the underside of the top panels. A 50 mm diameter ball was used to impact the specimens at 0.1, 1, and 10 m/s. One specimen was tested at each loading speed. A high speed camera filming at 6000 fps was used to collect visual data and the impact load-displacement pulse was recorded directly from the testing machine.

The specimen in the test rig is shown in Fig. 20. All surfaces have been coated in white spray chalk to enhance the light levels for the video recording. The back side of the specimen was filmed during the test as most of the failure was expected on the opposite side to the point of impact.

All three specimens failed in a very similar manner. The failure was characterised by a large damage site with a great deal of delamination and splitting. All of the tests also had a single, large, through-thickness crack that ran in the longitudinal direction of the specimen. A damaged panel is shown in Fig. 21. The large crack, which ran through the whole thickness of the laminate, avoided the stress concentration of the bolt hole, and in some cases deflected around it quite sharply. It is thought that the clamp-up effect of the bolt pretension supported the surrounding laminate and prevented the crack propagating near to the bolt.

The comparison between the high rate and low rate tests is shown in Fig. 22. It can be seen that the two tests exhibited near-identical responses to loading.

The load-displacement response of the ball loaded test was quite similar to the pull-through test specimen and can be characterised by the following:

-

Initial linear elastic section

-

Distinct damage initiation point followed by a near inelastic plateau with local load maxima and minima

-

Material failure with large strength and stiffness reductions

Almost all the damage occurred in the composite panel. The bolted joints did show signs of initial bearing damage but the minor change in overall structural stiffness due to this damage was not considered significant.

The only difference of note between the low and high rate tests was the initiation point of the final material failure, which occurred significantly earlier in the high-rate test, and the load reduction was gradual.

4 Discussion

An investigation of bolted composite joints has been conducted over a range of loading rates up to 10 m/s. These loading rates are representative of low energy impact or crash events that may be experienced by an aircraft or automotive structure, such as a barely survivable vertical crash for a helicopter structure. Even higher energy collisions, such as leading edge bird strike or airliner belly landing will have some joints loaded within this velocity range.

The single fasteners bearing tests revealed that there was a step-change in the failure mode of the composite joints tested between a loading rate of 0.1 and 1 m/s. These tests absorbed significantly more energy when loaded at higher rates. This observation agrees with Li et al. [27], although in that paper the effect was not observed with countersunk fasteners. It was also observed that there were some minor difference between the pull-through tests at varied loading rates. The final material failure initiated earlier in the 5 m/s test that in the lower speed tests, although the peak load and total energy absorption were very similar at all loading rates.

There was no discernable loading rate sensitivity in the load-displacement response or damage for the line loaded structural test. There was a minor loading rate sensitivity in the load-displacement response of the ball loaded structural test, although the damage propagation seemed insensitive to loading rate. The ball loaded stuctural test had many similarities with the pull-through test. The load in both tests was applied transversely to a constrained composite plate. The damage pattern in both tests was similar, as was the load displacement response. The effect of loading rate was also similar, with the final material failure initiating earlier in the faster tests.

It is difficult to attribute one particular phenomena to the rate sensitivity of the bolted joints and structures tested here. There are many complex interaction occuring in a bolted joint, even at quasi-static loading rates.

-

It is generally accepted that fibre dominated failures in carbon fibre composite materials are insensitive to strain rate [36], but matrix dominated properties do vary with loading rate.

-

The large internal energy release and frictional work in the damage zone generates heat which adiabatically heats the damage zone at higher loading rates.

-

At high loading rates, the load is transferred by stress waves and inertial effects become significant.

One possible explanation for the loading rate sensitivity observed is the variation of the composite delamination fracture toughness at higher loading rates. There are conflicting reports in the literature as to the effect of crack speed or loading rate on the mode I and II fracture toughness of the epoxy matrix. Due to the large number of epoxy matrix systems available, it is difficult to find specific data about Cycom 970, but a number of researchers have investigated the rate sensitivity of epoxy matrix and adhesive materials. Elder et al. [37] investigated the fracture toughness of FM300 epoxy adhesive in thin bonded joints and found that the fracture toughness drops with increased loading rate. Sun et al. [38] observed a transition from high toughness to low toughness crack behaviour in an epoxy bonded joint at a crack speed of 1 m/s. Sun and Han [39] found that the fracture toughness for Cycom 977-3 was virtually unaffected by loading rate up to crack speeds of 1000 m/s. Huang et al. [40] and Dwivedi and Espinosa [41] discuss a critical crack speed at which the mode II fracture propagation exceeds the Raleigh wave speed of the material and creates a sharp change in the fracture toughness at this speed. Ongoing numerical modelling of the joint failure and structural failure has shown that a reduction in fracture toughness at higher loading rates agrees well with the observed loading rate sensitivity of the ball loaded tests. Further detailed modelling is being conducted for the pull-through and bearing tests to investigate the role that fracture toughness plays in the failure process.

The lack of observed loading rate sensitivity for the line-loaded test can be explained by examining the loads that were applied to the joint and the mode of failure that occurred. In this case, the primary load is carried in bearing, but with significant contributions from pull-through and coupling forces. The approximate free body diagram for the joints during the line loaded structure tests is shown in Fig. 23.

When the bolt began to fail in bearing, the increased hole size allowed the bolt increased freedom to rotate. When a significant amount of hole damage had been reached, the remaining resistance to pull-through was reduced and the bolt pulled from the laminate, delaminating the material on the bearing side of the hole only.

With this damage progression, it was expected that the failure loading rate sensitivity would show the characteristics of bearing failure initially and pull-through failure would dictate the final behaviour. If this was the case, the loading rate dependence would be extremely hard to detect. The initial bearing damage was a rate independent phenomena, while the final pull-through damage, while displaying some rate dependence, was limited to a small displacement range during the tests, and all tests absorbed similar amounts of energy, regardless of the loading rate. Any difference in the failure mode with loading rate would be absorbed within other scatter between the tests.

It is assumed that most unconstrained countersunk fasteners would fail in a similar manner, because load alignment and secondary bending produce significant tensile loads in the bolt. The small initial bearing damage zone for countersunk fasteners allows for more hole elongation and, therefore, reduced resistance to pull-through failure. This would explain why Li et al. [27] did not detect a loading rate dependence for countersunk fasteners.

One further important observation is that the quasi-static joint design was conservative. The dynamic results in all cases tested showed approximately equal or higher values for stiffness, strength, deflection-to-failure and energy absorption relative to the equivalent quasi-static test. The one possible exception to this is the dynamic line-loaded structural test, which seemed to absorb slightly less energy. However, as explained earlier, it is most likely that this was a function of the test rig rather than the structure.

5 Conclusion

A series of single fastener bolted carbon fibre composite joints were tested in the two primary loading modes, pull-through and bearing. The experiments characterised the failure load, failure mode and load-displacement response of a typical bolted joint configuration. A range of tests were then conducted dynamically over a range of loading rates between 0.1 m/s and 10 m/s, to determine the loading rate sensitivity of the joints. The tests have showed varying rate sensitivity depending on the direction of the applied load. Pull-through loaded specimens experienced a mild loading rate sensitivity which did not change the overall strength, damage behaviour or energy absorption. The bearing loaded specimens exhibited a pronounced change in failure mode when loaded at or above 1 m/s. The failure initiation load and ultimate load did not change with rate, but the energy absorption of the specimens increased significantly at higher rates due a change in the residual strength of the specimens post ultimate load.

A simple composite structure was designed and tested to determine whether the single fastener loading rate dependence had any effect on the overall response of a bolted composite structure. The composite structure was tested in two separate configurations which loaded the single lap shear joints in modes that were not pure shear or normal loading, but a mixture. One load case showed no discernable rate sensitivity or change in failure mode, whilst the other showed a mild rate dependence similar to that for the pull-through test specimens.

References

Badders, D.: Dreamliner 101: All about the Boeing 787. 2007 [cited 2008 May 23rd]; Available from: http://seattlepi.nwsource.com/boeing/787/787primer.asp

McCarthy, M.: BOJCAS: bolted joints in composite aircraft structures. Air Space Eur. 3(3–4), 139–142 (2001)

Khashaba, U.A., Sallam, H.E.M., Al-Shorbagy, A.E., Seif, M.A.: Effect of washer size and tightening torque on the performance of bolted joints in composite structures. Compos. Struct. 73(3), 310–317 (2006)

McCarthy, M.A., Lawlor, V.P., Stanley, W.F., McCarthy, C.T.: Bolt-Hole clearance effects and strength criteria in single-bolt, single-lap, composite bolted joints. Compos. Sci. Tech. 62, 1415–1431 (2002)

Lawlor, V.P., McCarthy, M.A., Stanley, W.F.: Experimental study on effects of clearance on single bolt, single shear, composite bolted joints. Plast. Rubber Compos. 31, 405–411 (2002)

Lawlor, V.P., McCarthy, M.A., Stanley, W.F.: An experimental study of bolt-hole clearance effects in double-lap, multi-bolt composite joints. Compos. Struct. 71(2), 176–190 (2005)

Park, H.-J.: Effects of stacking sequence and clamping force on the bearing strengths of mechanically fastened joints in composite laminates. Compos. Struct. 53(2), 213–221 (2001)

Kelly, G.: Quasi-static strength and fatigue life of hybrid (bonded/bolted) composite single-lap joints. Compos. Struct. 72(1), 119–129 (2006)

Icten, B.M., Karakuzu, R.: Progressive failure analysis of pin-loaded carbon-epoxy woven composite plates. Compos. Sci. Tech. 62(9), 1259–1271 (2002)

Icten, B.M., Karakuzu, R., Toygar, M.E.: Failure analysis of woven kevlar fiber reinforced epoxy composites pinned joints. Compos. Struct. 73(4), 443–450 (2006)

Kelly, G., Hallström, S.: Bearing strength of carbon fibre/epoxy laminates: effects of bolt-hole clearance. Compos. B Eng. 35(4), 331–343 (2004)

Okutan, B.: The effects of geometric parameters on the failure strength for pin-loaded multi-directional fiber-glass reinforced epoxy laminate. Compos. B Eng. 33(8), 567–578 (2002)

Okutan, B., Karakuzu, R.: The strength of pinned joints in laminated composites. Compos. Sci. Tech. 63(6), 893–905 (2003)

Camanho, P.P., Matthews, F.L.: A progressive damage model for mechanically fastened joints in composite laminates. J. Compos. Mater. 33(24), 2248–2280 (1999)

Wu, T.J., Hahn, H.T.: The bearing strength of e-glass/vinyl-ester composites fabricated by vartm. Compos. Sci. Tech. 58(9), 1519–1529 (1998)

Dano, M.-L., Gendron, G., Picard, A.: Stress and failure analysis of mechanically fastened joints in composite laminates. Compos. Struct. 50(3), 287–296 (2000)

Dano, M.-L., Kamal, E., Gendron, G.: Analysis of bolted joints in composite laminates: Strains and bearing stiffness predictions. Compos. Struct. 79(4), 562–570 (2007)

Echavarría, C., Haller, P., Salenikovich, A.: Analytical study of a pin-loaded hole in elastic orthotropic plates. Compos. Struct. 79(1), 107–112 (2007)

Karakuzu, R., Gulem, T., Icten, B.M.: Failure analysis of woven laminated glass-vinylester composites with pin-loaded hole. Compos. Struct. 72(1), 27–32 (2006)

Kradinov, V., Madenci, E., Ambur, D.R.: Application of genetic algorithm for optimum design of bolted composite lap joints. Compos. Struct. 77(2), 148–159 (2007)

Kradinov, V., Madenci, E., Ambur, D.R.: Combined in-plane and through-the-thickness analysis for failure prediction of bolted composite joints. Compos. Struct. 77(2), 127–147 (2007)

McCarthy, M.A., McCarthy, C.T.: Finite element analysis of effects of clearance on single shear composite bolted joints. Plast Rubber Compos 32, 65–70 (2003)

McCarthy, M.A., McCarthy, C.T., Lawlor, V.P., Stanley, W.F.: Three-dimensional finite element analysis of single-bolt, single-lap composite bolted joints: part I–model development and validation. Compos. Struct. 71(2), 140–158 (2005)

McCarthy, C.T., McCarthy, M.A.: Three-dimensional finite element analysis of single-bolt, single-lap composite bolted joints: Part II–effects of bolt-hole clearance. Compos. Struct. 71(2), 159–175 (2005)

Tserpes, K.I., Labeas, G., Papanikos, P., Kermanidis, T.: Strength prediction of bolted joints in graphite/epoxy composite laminates. Compos. B Eng. 33(7), 521–529 (2002)

Ger, G.S., Kawata, K., Itabashi, M.: Dynamic tensile strength of composite laminate joints fastened mechanically. Theor. Appl. Fract. Mech. 24(2), 147–155 (1996)

Li, Q.M., Mines, R.A.W., Birch, R.S.: Static and dynamic behaviour of composite riveted joints in tension. Int. J. Mech. Sci. 43(7), 1591–1610 (2001)

Gunnion, A., Koerber, H., Elder, D., Thomson, R.: Development of Fastener Models for Impact Simulation of Composite Structures, in 25th Congress of the International Council of Aeronautical Sciences ICAS. Hamburg, Germany (2006)

Bornschlegel, T.: DLR, Private Communication—Experimentelle Untersuchung von Nieten in Verbundstrukturen unter Hochgeschwindigkeitsbelastungen (2007)

Koerber, H.: Pull-out and shear failure of bolted single lap joints in composite laminates, in Institut fur Flugzeugbau. Stuttgart University: Stuttgart, Germany (2006)

ASTM International, ASTM D 5961 / D 5961 M - 05—Standard Test Method for Bearing Response of Polymer Matrix Composite Laminates (2005)

Pearce, G.M., Johnson, A.F., Thomson, R.S., Kelly, D.W.: High strain-rate response of fastened carbon fibre composite joints in composite structures, in ECCOMAS Thematic Conference on Mechanical Response of Composites. Porto, Portugal (2007)

Bornschegel, T.: In preparation—Experimentelle Untersuchung von Nieten in Verbundstrukturen unter Hochgeschwindigkeitsbelastungen (2007)

Crews, J.H. Jr.: Bolt-bearing fatigue of a carbon/epoxy laminate. In: Kedward, K.T. (ed.) Joining of Composite Materials, p. 131–144. American Society for Testing and Materials (1981)

Collins, T.A.: The strength of bolted joints in multidirectional CFRP laminates. Composites 8, 43–55 (1977)

Zhou, Y., Jiang, D., Xia, Y.: Tensile mechanical behavior of T300 and M40J fiber bundles at different strain rate. J. Mater. Sci. 36(4), 919–922 (2001)

Elder, D., Dorsamy, Y., Rheinfurth, M.: Failure of composite bonded joints at elevated strain rates, in Thirteenth Australian Aeronautical Conference. Melbourne (2009)

Sun, C., Thouless, M.D., Waas, A.M., Schroeder, J.A., Zavattieri, P.D.: Ductile-brittle transitions in the fracture of plastically-deforming, adhesively-bonded structures. Part I: experimental studies. Int. J. Solids Struct. 45(10), 3059–3073 (2008)

Sun, C.T., Han, C.: A method for testing interlaminar dynamic fracture toughness of polymeric composites. Compos. B Eng. 35(6–8), 647–655 (2004)

Huang, Y., Wang, W., Liu, C., Rosakis, A.J.: Analysis of intersonic crack growth in unidirectional fiber-reinforced composites. J. Mech. Phys. Solid 47(9), 1893–1916 (1999)

Dwivedi, S.K., Espinosa, H.D.: Modeling dynamic crack propagation in fiber reinforced composites including frictional effects. Mech. Mater. 35(3–6), 481–509 (2003)

Acknowledgements

This research was conducted as part of cooperation between the German Aerospace Centre (DLR) and the Cooperative Research Centre for Advanced Composite Structures (CRC-ACS). Financial support was provided by the Australian Federal Government International Science Linkages Grant CG100184, which facilitated the primary author’s secondment to the DLR.

The primary author would like to thank the Australian Government for ongoing financial support through the Australian Postgraduate Award (APA) and the International Science Linkages scheme; the CRC-ACS for their ongoing financial and in-kind support of this research program and the author; and the staff at DLR, specifically Harald Kraft, for providing technical and experimental support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pearce, G.M., Johnson, A.F., Thomson, R.S. et al. Experimental Investigation of Dynamically Loaded Bolted Joints in Carbon Fibre Composite Structures. Appl Compos Mater 17, 271–291 (2010). https://doi.org/10.1007/s10443-009-9120-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-009-9120-8