Abstract

Clinical diagnostics and genomic research often require performing numerous genetic tests. While microfluidic devices provide a low-cost alternative to such demands, integrated microfluidic devices are fabricated using expensive technology not always affordable for single use. However, carryover cross-contamination (CXC) concerns (i.e. either false positive or false negative PCR data) in PCR chips prevent reuse, defying much of the advantages of miniaturized systems developed using expensive MEMS processing. In this work, we present an integrated and reusable PCR–CE glass microfluidic chip capable of multi-chamber PCR and sequential CE, with emphasis on a unique chip reusability approach to avoid CXC. For reliable PCR, the surface of the chamber is re-configured from its virgin hydrophilic (CA < 20°) to hydrophobic (CA > 110°) by silanization. To then extend this silanization method as a chip reusability technique, the silanization coating is ‘stripped and re-silanized’ (SRS) to create a fresh coating prior to each successive PCR run. Experimental confirmation of the effectiveness of SRS method in avoiding the CXC is demonstrated using plasmid DNA and HIV-1 infected DNA samples. We also present passive plug microvalves incorporated in the chip to enable fluid/vapor retention during the PCR and controlled fluid flow from the PCR chamber to the CE section for further analysis.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The polymerase chain reaction (PCR) method for nucleic acid amplification and capillary electrophoresis (CE) technique for the detection and analysis of PCR amplified genes have gained widespread acceptance as a powerful tool for genetic analysis. Integrated PCR–CE devices demand that the nucleic amplification requiring on-chip heating and DNA separation requiring electrical field be performed on the same device. This requirement places important constraints on the choice of material used to fabricate these devices to ensure compatibility of all such processes. In this regard, materials such as polymers (Hong et al. 2001; Prakash et al. 2006), Si (Daniel et al. 1998; Nagai et al. 2001) and glass (Khandurina et al. 2000; Lagally et al. 2004; Waters et al. 1998), have been explored for this purpose. However, polymers, particularly PDMS, suffer from fluid loss during PCR (Li et al. 2006; Prakash et al. 2006; Shin et al. 2003) and means to overcome this by enhanced fabrication strategies hinders rapid prototyping, while bulk Si on the other hand has seldom been used in CE due to incompatibility with EOF and high-voltage artifacts, and its optical opaque property. Alternatively, glass has excellent compatibility with CE (Han and Frazier 2005; Lagally et al. 2004; Ma et al. 2005) (e.g. favorable fluidic, optical and electrical insulating properties), high resistance to fluid and vapor diffusion during PCR, and hence used in most integrated PCR–CE devices (Hong et al. 2001; Khandurina et al. 2000; Lagally et al. 2004; Prakash et al. 2005; Rodriguez et al. 2003; Waters et al. 1998). The main drawback in using glass is its hydrophilicity which causes excessive adsorption of PCR reagents and requires careful tailoring and/or suitable modification of its surface properties (Erill et al. 2003; Giordano et al. 2001a; Obeid et al. 2003).

Although microfluidic devices harness the advantage of low reagent consumption, integrated microfluidic devices are fabricated using expensive technology not always affordable for single use. Furthermore, carryover cross-contamination (CXC) concerns (i.e. either a false positive or a false negative PCR data) in PCR chips prevent reuse, defying much of the advantages of miniaturized systems developed using expensive MEMS processing (Cheng et al. 1996; Curcio and Roeraade 2003; Dorfman et al. 2005; Findlay et al. 1993; Gulliksen et al. 2005; Kuypers et al. 1998; Matsubara et al. 2004). [A false-positive PCR data is the amplification of DNA as a result of the presence of (even a single molecule of) nucleic acid contaminant, particularly from previously amplified DNA; while a false-negative PCR data is a result of an unsuccessful PCR amplification due to the presence of any contaminant from prior runs or inhabitants—in the absence of which the PCR protocol is expected to result in an optimal DNA amplification with high yield.]

Thus far, Dorfman et al. (2005) demonstrated a high-throughput system combined with reusability using the continuous-flow PCR method by a surfactant and oil emulsion technique. While the concept of high-throughput and reusability for PCR was uniquely accomplished, the addition of surfactants may require tedious reagent titration and often extensive PCR protocol optimization for typical clinical applications (Khandurina et al. 2000; Matsubara et al. 2004; Walsh et al. 2005). Furthermore, in the continuous flow PCR devices, the PCR sample resident time at any segment in the capillary tube is only a few seconds as opposed to many hours in the relatively advantageous (Auroux et al. 2004) chamber PCR approach that is popularly used in integrated systems (particularly with downstream CE analysis). Hence the Dorfman et al. reusability approach introduces the possibility of CXC concerns if adopted in chamber PCR devices, and the approach may not be suitable for reusing microfluidic chips outside the continuous flow PCR domain. Although Giordano et al. (2001b) suggested cleaning with alcohol prior to reuse, only a negative PCR control was demonstrated and lacked rigorous experimentation perhaps since their work was not focused on the concept of reusability.

Addressing the issue of high-throughput and uniquely tackling the topic of chip reusability, we present an integrated ‘array PCR–CE’ microfluidic chip fabricated using the most compatible material for this application—glass, and with capabilities of simultaneous genetic amplification and sequential CE analysis, combined with a unique approach to reuse the PCR chambers avoiding CXC concerns. The reusability feature is realized by first silanizing the surface of the glass PCR chamber to alter the glass surface from its virgin hydrophilic (CA < 20°) to hydrophobic (CA > 110°). To then reuse the PCR chamber, a ‘stripping and re-silanizing’ (SRS) method is implemented where the silanization is stripped from the surface, which exposes the virgin glass surface, and then re-silanized to again form a hydrophobic coating between successive PCR runs. The SRS method ensures a new coating and a clean hydrophobic chamber surface prior to each PCR run thereby avoiding CXC. Furthermore, the hydrophobicity is expected (Giordano et al. 2001a; Shin et al. 2003) to minimize adsorption and consequently enable reliable on-chip PCR in glass devices. The effectiveness of the SRS chip reusability technique for PCR is presented with verified positive control PCR (i.e. PCR protocol with the addition of template DNAs) and negative control PCR (i.e. PCR protocol without the template DNAs) from plasmids and Human Immunodeficiency Virus (HIV) infected DNA containing all parts of the HIV-1 genome (HIVZ6). These experiments, mimicking clinical samples and ranging in their experimental complexity, are intended to demonstrate that the SRS method is not sample specific (e.g. only samples with high PCR yield) and that both false-positive and false-negative PCR data can be avoided in reused glass chips.

In order to implement a practical integrated PCR–CE system, here we also present a simple, efficient and disposable ‘passive plug’ (PP) microvalves fabricated using PDMS that were incorporated in the integrated chip. The PP microvalves enabled fluid/vapor retention during the PCR stage and flow control from the PCR chamber to the CE section prior to downstream CE analysis.

2 Materials and methods

2.1 Microfabrication

The fabrication protocols for the integrated glass microfluidic PCR–CE used in this work is similar to that reported earlier (Taylor et al. 1998) and hence only a brief summary is provided here with emphasis on the modifications to standardized fabrication methods.

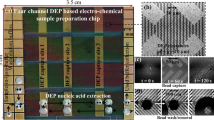

In our fabrication method, the isotropic glass etching using hydrofluoric acid (HF) is accomplished in a two-step process. Initially the entire microfluidic pattern (i.e. the PCR and CE channels) unmasked on a metalized (Cr–Au) 4 in. × 4 in. borofloat glass substrate (1.1 mm thick) is immersed in the HF solution for 20 min to form isotropic 20 μm deep channels. This gives a desired 50 μm wide × 20 μm deep channel suitable for CE. However, deeper etch was desired in the PCR section of the chip to accommodate larger fluid volumes in the PCR chambers. Since the integrated chip layout was such that the CE and PCR sections had distinct boundaries (see Fig. 1), the second step deep isotropic glass etch of the PCR chamber was performed after masking the CE section of the chip with a Teflon tape (Blue Medium Tack, Semiconductor Equipment Corporation, USA). The substrate was again immersed in HF and was etched for a prolonged period of nearly 10 h, so as to give an isotropic etch depth of about 0.7 mm in the PCR chambers, which corresponded to a minimum fluid volume of approximately 3 μl. This deeper etch of the PCR chamber also reduces the thickness of the glass below the chamber and hence is expected to provide more uniform thermal distribution in the chamber during temperature cycling. [Note that the prolonged HF etch caused pin-hole pockets in some areas on the glass protected by the Au–Cr-photoresist mask. However, this did not affect the subsequent processing or the functionality of our fabricated microfluidic chip.]

Upon completion of the glass etch process, the photoresist and Au–Cr metals were removed by sequentially washing in acetone, Au and Cr metal etchents. Following this, the substrates were subjected to an hour long cleaning in two reactive chemical agents (RCA)—hydrochloric acid, hydrogen peroxide and water (1:1:6), and ammonium hydroxide, hydrogen peroxide and water (1:1:5). This was required to remove any residual metal, since it has been reported (Taylor et al. 1998) that traces of metal, particularly Cr, could potentially inhibit the PCR amplification. Finally, the substrates are immersion cleaned for 30 min in a freshly prepared Piranha solution made-up of hydrogen per-oxide and sulphuric acid (1:3). In the final step, the glass-etched substrate is aligned and bonded to another borofloat glass with drilled holes (diameter = 2 mm) that form access holes to the etched channels in the lower glass substrate. This bonding was achieved by thermal fusion in a programmable furnace enhanced by the hydrophilicity of the two mating surfaces. High quality and reliable bonds were consistently achieved over the entire surfaces of the substrates using this technique. Finally, the bonded substrates were diced along chip boundaries in an automated dicing saw (DAD 321, Disco Hi-Tec America, USA), and the resultant glass-on-glass integrated PCR–CE microfluidic device is shown in Fig. 1. As observed in Fig. 1, to enable high-throughput, 9 PCR chambers (with varying volumes capacity of up to 6 μl) were integrated to a single CE channel to enable performing multiple PCR experiments simultaneously in each of the chambers and then sequentially analyze the PCR product from each chamber by CE.

2.2 Passive plug microvalves

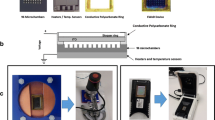

The ‘passive plug’ (PP) microvalves incorporated in the integrated chip conceptually utilizes an airtight plugging mechanism to prevent fluid and vapor loss from open-to-ambient drilled access holes on the upper substrate of the chip. The operation of the PP microvalves in the context of PCR–CE is schematically represented in Fig. 2. As shown, the valves are only required during PCR thermal cycling to enable fluid/vapor retention, and sample transport from the PCR chamber to the CE sample well. The PP microvalves, with the stub and stem components as shown in Fig. 2a, were fabricated of PDMS using a template glass plate with drilled holes identical to those on the upper glass substrate of the chip. A snug and air-tight fit of the PP microvalve in the open-to-ambient access holes on either sides of the PCR chamber (Fig. 2b) in the chip prevents fluid/vapor loss from the chamber during the PCR stage. In addition to the snug fit, application of thrust (e.g. by weight) above the stub of the PP microvalve will also ensure a tight seal inside the access holes.

Overview and functionality of the passive plug (PP) microvalves. a (left) Description of components valves and the PCR section in the integrated chip; (right) photograph of the PP microvalve on the integrated chip. b Air and water tight sealing by the PP microvalve during PCR and c pressure driven fluid flow unloaded from PCR chamber to the CE well is accomplished either by replacing the valve with a short stub valve or by partially lifting the valve

Upon completion of the PCR, to enable fluid transport from the PCR chamber to the CE section for analysis, the channel layout and PP microvalve were designed for controlled fluid flow, as described subsequently. The channel that connects the PCR chamber to the CE channel (Fig. 2a) in the integrated chip is interrupted at the ‘PCR valving and flow control port’ (i.e. the access port to the left of the PCR chamber). In Fig. 2a, this discontinuity in the channel is represented as a ‘flow control elevation’ inside the access port and is achieved by an unetched region in the lower glass substrate. Essentially, this design ensures that pressurized fluid flow from the PCR chamber to the CE section is only achieved by a controlled fluid volume entering the ‘PCR valving and flow control port’ that is sealed by either a short stem PP microvalve or by partially unplugging the snug fit PP microvalve—as shown in Fig. 2c. Although these valves are mechanically robust, they are recommended for single use particularly in genetic analysis experiments that demand contaminant-free components.

2.3 ‘Stripping and re-silanizing’ (SRS) protocol for chip reuse

It is well known (Shin et al. 2003; Yoon et al. 2002) that hydrophobic surfaces elude problems associated with adsorption of PCR reagents and DNA. Earlier studies by Giordano et al. (2001a) and Shoffner et al. (1996) on surface coatings to enable the PCR in chips conclusively deemed it necessary to apply coatings for reliable amplification. For the silanization coating used in this work, a single step alcohol-based non-hazard glass silanizing chemical (SafetyCoat™, lot # A10707, J. T. Baker, USA) was utilized and the virgin hydrophilic glass surface of the PCR chamber was configured to be hydrophobic. This was achieved by completely filling the PCR chamber with the silanizing solution and sealing the chamber air-tight with the PP microvalves. After 30 min of incubation, the silanizing solution was unloaded from the chamber and the chip was left to air-dry for at least 4 h to ensure complete drying of any residual silanizing solution. Applying either positive or negative air pressure to the PCR chamber was also seen to quicken the residual drying process. The chamber was then rinsed with ‘DNAs and RNAs free’ water (Fluka, Sigma Aldrich Chemie GmbH, Switzerland) for a minimum of five rinses.

To further extend this method as a unique chip reusability technique we implement our ‘stripping and re-silanizing’ (SRS) method as follows. First we strip the silanization coating by treating with 10% NaOH for 30 min and then flushing with coupes quantities of ‘DNAs and RNAs free’ water to dilute and remove any residual NaOH; we observed that the remains of NaOH prevent reliable re-silanization and could also inhibit the PCR. This dilute NaOH treatment breaks down the silane monolayer and hence strips the monolayer coating, which re-exposes the clean (virgin) hydrophilic glass surface in the PCR chamber. To then reuse the PCR chamber, the chamber is again silanized, which imparts a fresh hydrophobic surface coating prior to the proceeding PCR run. It should be noted that prolonged exposure to higher concentration of NaOH during the stripping process could cause microscopic pitting on the glass resulting in improper re-silanization and hence to be avoided (Cras et al. 1999). This unique SRS process can be repeated for as many times between PCR experiments and as demonstrated subsequently, avoids PCR CXC since it imparts a fresh coating prior to each PCR experiment.

2.4 PCR protocols

Two different template DNAs were selected for the PCR experiments performed on SRS implemented reused chips—purified plasmid DNA and HIV infected DNA. For PCR experiments with the plasmid DNA (ROC/ENE), the templates were used to amplify a genetic sequence in the DNA using the M13 forward and reverse primer as follows. A forward primer comprised of 22 bases, 5′-GCC AGG GTT TTC CCA GTC ACG A-3′, and a universal reverse primer, with 17 bases, 5′-CAG GAA ACA GCT ATG AC-3′, commonly used for sequencing any vector containing the N-terminus of b-galactosidase (catg. # N530-02, Invitrogen, USA), were utilized to yield a 500 basepair (bp) PCR product. Both the primers were purchased from Applied Biosystems, CA, USA, and the forward primer was labeled with the fluorophore VIC. A PCR master mix of 25 μl was prepared, of which approximately 3 μl was loaded in the PCR chamber and the remaining was used as a control run performed on a conventional 0.2 ml PCR tube. The protocol for the PCR reaction master mix was as follows: 1 μl of each primer (1 pM/μl), 2.5 μl of 10× PCR buffer [Tris HCl 200 mM (pH 8.5)], 2 μl of MgCl2 (25 mM), 1 μl of dNTPs (10 mM), 1 μl of Taq DNA Polymerase (5 U/μl), 14.5 μl of molecular biology water (BioChemika, Fluka, Sigma-Aldrich, Switzerland) and 2 μl of template DNA at a concentration of 50 ng/μl in the case of a positive control PCR experiment, or another 2 μl of molecular biology water in the case of a negative control PCR experiment. The PCR temperature cycling parameters for this experiment consisted of an initial denaturation at 94°C for 2 min, followed by 30 cycles of denaturation (94°C), annealing (60°C), and extension (72°C) temperatures with a dwell time of 30 s at each temperature.

For the second set of experiments with HIV DNA, the PCR reagents were obtained from the commercially available GeneAmp® HIV-1 control reagent and core reagent kit (Applied Biosystems, CA, USA). With this sample, a 115 bp PCR product was amplified from the gag region of the HIV-1 genome (AppliedBiosystemsUSA 2003–2004; Goodenow et al. 1989; Ou et al. 1988) using sequence-specific forwards and reverse primers, SK38 (5′-ATAATCCACCTATCCCAGTAGGAGAAAT-3′) and SK39 (5′-TTTGGTCCTTGTCTTATGTCCAGAATGC-3′), respectively. The primers were also purchased from Applied Biosystems, and the forward primer was labeled with the fluorophore VIC. A PCR master mix of 100 μl was prepared and about 3 μl was loaded in the PCR chamber while the remaining was utilized for a control run on a conventional 0.2 ml PCR tube. The PCR protocol was as follows: 2 μl of each primer (1 pM/μl), 10 μl of 10× PCR buffer, 10 μl of MgCl2 (25 mM), 16 μl of dNTPs mix (200 μM of each dNTP), 0.5 μl of Taq DNA Polymerase (5 U/μl), 49.5 μl of molecular biology water (BioChemika, Fluka, Sigma-Aldrich, Switzerland) and 10 μl of HIV-1 template DNA (103 copies/μl) in the case of a positive control PCR experiment, or an added 10 μl of molecular biology water in the case of a negative control PCR experiment. The PCR temperature cycling protocol for this experiment included an initial denaturation at 95°C for 60 s followed by 35 cycles between 95 and 60°C with dwell times of 60 s at each temperature. Thermal cycling for all the PCR experiments was performed on the Thermo Electron P×2 instrument (MA, USA).

To demonstrate the feasibility of performing PCR in reusable chambers, all the positive and negative control PCRs were repeatedly performed in only one of the nine PCR chamber in the integrated chip (i.e. repeatedly reusing a single chamber) and the SRS method was implemented in that chamber prior to each run. The order of PCR experiments was as follows. A first set of PCR with positive control plasmid DNA (expected PCR amplification of 500 bp) followed by a negative control (no expected PCR amplification), which will verify the absence of any residual DNA between runs and consequently demonstrate avoiding false-positive data. For a second set of PCR to verify the absence of false-negative data, positive control HIV-1 DNA (expected amplification of 115 bp) was performed followed by a negative control (no expected PCR amplification).

2.5 CE protocol

The CE section on the integrated microfluidic chip (Fig. 1) is constituted by a cross-channel design (Crabtree et al. 2001) in which the sample and sample waste, and buffer and buffer waste wells are connected by two intersecting channels. The channels in the CE section were loaded with a sieving medium (GeneScan polymer, Applied Biosystems, CA, USA) using a syringe. The sample waste, buffer and buffer waste wells were filled with 3 μl of 1× TBE (lot # 994B82, OmniPur, USA) running buffer and the sample well filled with 2.7 μl of 0.1× TBE running buffer. A portion of the PCR product from the PCR chamber was then driven from the PCR chamber (as described earlier, Fig. 2) to the CE sample well. Although the PCR volume in the chip was about 3 μl, typically 0.3 μl of the PCR product is sufficient for the CE analysis. Given the current limitations in accurately dispensing pressure driven fluid into the sample well, care was taken to estimate a volume of the PCR product that would be comparable to the typical requirement of about 0.3 μl when pressure driving the PCR product into the CE sample well. Finally, the high voltage electrophoretic separation by CE and laser induced fluorescence (LIF) detection of the primers and DNA in the PCR product was performed using the Microfluidic Tool Kit (μTk, Micralyne, Edmonton, Canada) as described in prior work (Prakash et al. 2006).

3 Results and discussion

3.1 SRS method to reconfigure surfaces

To confirm the reusability of the chip through surface modification, we employed contact angle (CA) measurements of di-ionized (DI) sessile water drops dispensed (approx. 5 μl) from a micropipette onto the coated and uncoated glass surface, as shown in Fig. 3. The CA measurements, performed at various points in the process confirm that the surface of the glass can be reversibly configured between its virgin hydrophilic to a silanized hydrophobic state. The contact angle of the DI water droplet on an uncoated glass surface is 14° (Fig. 3a) and this extreme hydrophilicity causes undesirable adsorption of PCR reagents. However, once silanized the surface turns hydrophobic with a contact angle of 116° as seen in Fig. 3b. At this stage the PCR experiment can be performed in the silanized chamber. To then reuse the chamber, first the silanization coating is stripped using NaOH as described before and the contact angle measurement in Fig. 3c suggests a hydrophilic surface (CA 16°), implying re-exposure of the virgin glass surface. Now the surface is re-silanized to form a fresh hydrophobic coating (Fig. 3d, CA 112°) prior to performing another PCR in the chamber. As observed in Table 1, this SRS method can be repeated many times to create a freshly coated surface prior to each PCR experiment. Subsequently we experimentally demonstrate that either a false-positive or false-negative PCR data can be avoided in reused chips subjected to the SRS method.

Microscope images of the contact angle of di-ionized sessile water drops on silanized and unsilanized glass surface. a Hydrophilic glass (CA 14°) causes adsorption and undesired for PCR. b Hence the glass is configured to hydrophobic (CA 116°) by silanization coating and PCR performed. c, d To then reuse the chip without contamination concerns, the silanization is stripped (CA 16°) and re-silanized (CA 112°) between successive PCR runs to result in a fresh coating prior to each experiment. Contact angle measurements are within a 10% measurement error

3.2 Silinization: mechanism and advantages

Silanization is a process whereby free OH-groups on the surface of a material are substituted by aprotic organic groups. Since the affinity of protic liquids (e.g. water) onto a surface is primarily controlled by the density of OH-groups on the surface, the fewer the free OH groups, lower will be the surface wettability by water (i.e. higher contact angle—hydrophobic) (Felbel et al. 2004). The reaction of free OH-groups with trimethylchrolosilane (TMCS, the primary silane in SafetyCoat™) results in a silanization (or covalent endcapping) of the hydrophobic trimethylesilane onto the surface, as shown in the equation below (Zhao and Lu 1998).

Prior to selecting the SafetyCoat™ silanizing chemical used here, dimethyldichlorosilane (DMDCS) (Obeid et al. 2003; Shoffner et al. 1996), a commonly used PCR chip silanizing chemical was also considered, however, with the following shortcomings: required special equipment (i.e. a desiccator)(Obeid et al. 2003) to safely apply the coating, it was a hazardous chemical, required additional gases (e.g. chloroform) to enable silanization reaction, sometimes inhibited the PCR amplification, could not be easily stripped once applied, and is not reliably reproducible. However, TMCS (silane in SafetyCoat™) is known (Sundberg et al. 2003) to impart the most reproducible silanization results, possibly because (Sundberg et al. 2003) unlike di- and trichlorosilanes, the TMCS cannot form dimmers/polymers; however with the other popular silanes (e.g. DMDCS, octadecyltrichlorosilane, Sigmacoat®), such products might be formed if sufficient care is not taken to eliminate contaminating water/humidity from the reagent or surface. The dimer/polymer may then be adsorbed on top of the covalently bounded silane monomers to various extents thus resulting in poor reproducibility and repeatability (Sundberg et al., 2003). Furthermore, the TMCS is the smallest available monochlorosilane and hence facilitates its accessibility to surface silanol groups that are sometimes difficult to reach due to steric hindrance from alkyl chains (Rodriguez and Colon 1999). Assuming a dominance of the TMCS silane in SafetyCoat™ and a similar surface silanization effect to earlier studies (Felbel et al. 2004; Zhao and Lu 1998), silanization coverage of up to 85% of the surface can be expected, which correlates well with our hydrophobic contact angle measurements.

Unlike other silanes, the SafetyCoat™ silanizing chemical used in this work always showed good reproducibility, reliability in coating integrity, consistent PCR compatibility and more importantly it could be easily stripped-off the coated surface (by the method described earlier).

3.3 PCR–CE data from reused chip

Figure 4 shows the Electropherograms, a plot of Relative Fluorescence Intensity (RFU) versus Time, of all the positive and negative control PCR experiments performed on the integrated chip as an additional confirmation to contact angle measurements on the SRS reuse method to avoid CXC. The size of the resulting PCR products is either verified by the arrival time of the fluorescence peak as compared with the separation of commercially available size standards, GeneScan 500 (Applied Biosystems, CA, USA), on the chip as shown in Fig. 4a, d, or by comparison with λHindIII–φX174HaeIII sizers as separated on a 1% agarose gel with ethidium bromide on a conventional slab gel electrophoresis system. Figure 4b shows the CE analysis of the first positive control PCR performed with the plasmid DNA in a silanized PCR chamber. A weak primer peak was seen at ∼185 s and a stronger product peak corresponding to about 500 bp was seen at ∼233 s indicating successful amplification. This is followed by the analysis of the negative control run for the prior plasmid amplification. As expected, Fig. 4c only shows a strong primer peak at ∼185 s—confirming the absence of amplification due to the lack of residual DNA from the prior positive control run, thus verifying the avoidance of false-positive data.

Electropherograms from CE analysis of PCR data on the integrated chip. A single PCR chamber is reused implementing the SRS method prior to each run. a, d Separation of DNA size standards (GeneScan 500 Tamra) for comparison to estimate the size of the PCR products. b, c First set of positive and negative control plasmid DNA PCR performed subsequent to each other in a reused chamber. e, f Second set of positive and negative control PCR with HIV-1 DNA performed in the same chamber as earlier experiments, again implementing the SRS method between runs. As expected, all positive controls showed successful amplification and all negative controls showed lack of amplification. The effectiveness of the SRS method to avoid PCR CXC is experimentally verified

Figure 4e, f shows analysis of the second set of positive and negative control PCR performed in the same SRS reused chamber; however, now with HIV-1 DNA samples. For the positive control (Fig. 4e), a product peak is seen at ∼202 s preceded by a primer peak at ∼192 s, clearly suggesting that the false-negative data can also be avoided with the SRS method. Finally the analysis of the negative control for the HIV-1 PCR in Fig. 4f again verifies avoiding false-positive data. The size of all the resulting PCR products was confirmed to be of expected length from conventional control experiments (data not shown) performed in 0.2 ml tubes and was also verified from literature (AppliedBiosystemsUSA 2003–2004; Goodenow et al. 1989; Ou et al. 1988).

To establish the robustness of the SRS reuse method, all positive and negative control PCR experiments were repeated at least thrice more than the data presented here with the earlier samples and an additional siRNA vector sample in the same experimental sequence previously described. Figure 5 represents 20 such randomized sets of positive and negative control experiments that repeatedly confirmed the absence of either false-positive or false negative PCR data (i.e. CXC) with this SRS reuse method. As seen in Fig. 5, the three selected DNA samples include both strong-positive PCR amplification (i.e. a high replication of DNA even with small initial copy numbers) and weak-positive PCR amplification (i.e. a comparatively lower replication of DNA with about the same initial copy number) characterized by peak fluorescence intensity of the PCR product. For strong-positive amplification sample even a small residue of previously amplified material (i.e. contamination) might be sufficient to yield detectable false-positive PCR amplification on a consecutive negative control PCR run. However, with weak-positive amplification samples a comparatively larger residue may be required to yield detectable false-positive PCR amplification. The chosen samples cover a range of experimental complexity (i.e. varied PCR yield), ideally suited to verify the feasibility of on-chip PCR enhanced by the SRS reuse technique.

Experimental verification of PCR repeatability without false-positive or false-negative data in reused chips implementing the SRS method prior to each PCR run. The graph represents experiment history performed sequentially with three different samples (Plasmids, siRNA, HIV-1 DNAs) versus the obtained normalized RFU at an expected PCR product location during CE analysis. As expected, each positive control experiment showed amplification (represented by a numerical RFU on y-axis rounded to the nearest 0.5 U) with resulting PCR product (500 bp for plasmids, 340 bp for siRNA or 115 bp for HIV-1) and each of the consecutive negative control experiments for the same sample showed no amplification (represented by null RFU on y-axis)

4 Conclusion

Unlike the CE channels which can be repeatedly reused (Ma et al. 2005) without much concern of false-positive data, since comparatively many magnitudes of larger contaminant samples will be required for a detectable false-positive signal, the same is not the case with PCR chambers. In PCR, even a single molecule of nucleic acid contaminant, particularly from a previously amplified DNA, is sufficient to produce false-positive data, and thereby PCR chambers are seldom reused.

Here, we demonstrated an integrated microfluidic PCR–CE chip with a unique reusability method. Our reusability method ensures a fresh chamber surface prior to each PCR experiment and this was implemented by the SRS method. The SRS reuse method utilized a silanizing chemical to alter the surface of the glass PCR chamber from its virgin hydrophilic (CA < 20°) to a hydrophobic surface (CA > 110°), and a fresh silanization coating is applied prior to each PCR experiment thereby avoiding CXC. Furthermore, the hydrophobic approach is expected to retard adsorption of PCR reagents increasing the reliability of on-chip PCR.

We have verified the robustness of the SRS method as a simple yet unique method to reuse PCR chips and experimentally demonstrated that the method effectively avoids PCR associated CXC (i.e. false-positive and false-negative data) within the highly sensitive CE detection limits. We also believe that if the SRS method can be reliably applied to the highly sensitive PCR, it could easily be implemented to reuse any glass microfluidic device for most bio-applications including the earlier described continuous flow PCR device (Dorfman et al. 2005).

In the current integrated prototype chip, to enable multiple CE analysis of a PCR amplification, the PCR chambers have much larger fluid capacity than the required PCR sample volume typically utilized for CE analysis (i.e. 0.3 μl); hence wastage of sample occurs in the PCR to CE interconnecting channel when the PCR product is pressure driven from the PCR chamber to the CE section. However, in future prototypes this can be overcome by designing a PCR chamber with only 0.3 μl, as this will completely empty the chamber volume into the CE section by using the same pressure driven flow mechanism thereby avoiding sample wastage.

Here we also implemented a simple valving technique using the PP microvalves incorporated in the PCR–CE chip to provided fluid/vapor retention during the PCR temperature cycling and controlled fluid flow from the PCR chamber to the CE section integrated on-chip. While in the present demonstration the operations of these valves are manual, the inclusion of alternate materials, such as expandable gels, inside the PDMS valves will enable automation by relatively simple on-chip actuation (e.g. heat or light).

References

AppliedBiosystemsUSA (2003–2004) PCR instruments reagents and consumables 2003–04 catalog. Appl Biosyst, Foster city, pp 32–33

Auroux PA, Koc Y, deMello A, Manz A, Day PJR (2004) Miniaturised nucleic acid analysis. Lab Chip 4(6):534–546

Cheng J, Shoffner MA, Hvichia GE, Kricka LJ, Wilding P (1996) Chip PCR.2. Investigation of different PCR amplification systems in microfabricated silicon-glass chips. Nucleic Acids Res 24(2):380–385

Crabtree HJ, Cheong ECS, Tilroe DA, Backhouse CJ (2001) Microchip injection and separation anomalies due to pressure effects. Anal Chem 73(17):4079–4086

Cras JJ, Rowe-Taitt CA, Nivens DA, Ligler FS (1999) Comparison of chemical cleaning methods of glass in preparation for silanization. Biosens Bioelectron 14(8–9):683–688

Curcio M, Roeraade J (2003) Continuous segmented-flow polymerase chain reaction for high-throughput miniaturized DNA amplification. Anal Chem 75(1):1–7

Daniel JH, Iqbal S, Millington RB, Moore DF, Lowe CR, Leslie DL, Lee MA, Pearce MJ (1998) Silicon microchambers for DNA amplification. Sens Actuators A Phys 71(1–2):81–88

Dorfman KD, Chabert M, Codarbox JH, Rousseau G, de Cremoux P, Viovy JL (2005) Contamination free continuous flow microfluidic polymerase chain reaction for quantitative and clinical applications. Anal Chem 77(11):3700–3704

Erill I, Campoy S, Erill N, Barbe J, Aguilo J (2003) Biochemical analysis and optimization of inhibition and adsorption phenomena in glass-silicon PCR-chips. Sens Actuators B Chem 96(3):685–692

Felbel J, Bieber I, Pipper J, Kohler JM (2004) Investigations on the compatibility of chemically oxidized silicon (SiOx)-surfaces for applications towards chip-based polymerase chain reaction. Chem Eng J 101(1–3):333–338

Findlay JB, Atwood SM, Bergmeyer L, Chemelli J, Christy K, Cummins T, Donish W, Ekeze T, Falvo J, Patterson D, Puskas J, Quenin J, Shah J, Sharkey D, Sutherland JWH, Sutton R, Warren H, Wellman J (1993) Automated closed-vessel system for in-vitro diagnostics based on polymerase chain-reaction. Clin Chem 39(9):1927–1933

Giordano BC, Copeland ER, Landers JP (2001a) Towards dynamic coating of glass microchip chambers for amplifying DNA via the polymerase chain reaction. Electrophoresis 22(2):334–340

Giordano BC, Ferrance J, Swedberg S, Huhmer AFR, Landers JP (2001b) Polymerase chain reaction in polymeric microchips: DNA amplification in less than 240 seconds. Anal Biochem 291(1):124–132

Goodenow M, Huet T, Saurin W, Kwok S, Sninsky J, Wainhobson S (1989) Hiv-1 isolates are rapidly evolving quasispecies—evidence for viral mixtures and preferred nucleotide substitutions. J Acquir Immune Defic Syndr Hum Retrovirol 2(4):344–352

Gulliksen A, Solli LA, Drese KS, Sorensen O, Karlsen F, Rogne H, Hovig E, Sirevag R (2005) Parallel nanoliter detection of cancer markers using polymer microchips. Lab Chip 5(4):416–420

Han KH, Frazier AB (2005) Reliability aspects of packaging and integration technology for microfluidic systems. IEEE Trans Device Mater Reliability 5(3):452–457

Hong JW, Fujii T, Seki M, Yamamoto T, Endo I (2001) Integration of gene amplification and capillary gel electrophoresis on a polydimethylsiloxane-glass hybrid microchip. Electrophoresis 22(2):328–333

Khandurina J, McKnight TE, Jacobson SC, Waters LC, Foote RS, Ramsey JM (2000) Integrated system for rapid PCR-based DNA analysis in microfluidic devices. Anal Chem 72(13):2995–3000

Kuypers A, Linssen PCM, Lauer HH, Mensink E (1998) Contamination-free and automated composition of a reaction mixture for nucleic acid amplification using a capillary electrophoresis apparatus. J Chromatogr A 806(1):141–147

Lagally ET, Scherer JR, Blazej RG, Toriello NM, Diep BA, Ramchandani M, Sensabaugh GF, Riley LW, Mathies RA (2004) Integrated portable genetic analysis microsystem for pathogen/infectious disease detection. Anal Chem 76(11):3162–3170

Li SF, Fozdar DY, Ali MF, Li H, Shao DB, Vykoukal DM, Vykoukal J, Floriano PN, Olsen M, McDevitt JT, Gascoyne PRC, Chen SC (2006) A continuous-flow polymerase chain reaction microchip with regional velocity control. J Microelectromechan Syst 15(1):223–236

Ma RB, Crabtree HJ, Backhouse CJ (2005) A rejuvenation method for poly (N,N-dimethylacrylamide)-coated glass microfluidic chips. Electrophoresis 26(14):2692–2700

Matsubara V, Kerman H, Kobayashi M, Yamamura S, Morita V, Takamura Y, Tamiya E (2004) On-chip nanoliter-volume multiplex TaqMan polymerase chain reaction from a single copy based on counting fluorescence released microchambers. Anal Chem 76(21):6434–6439

Nagai H, Murakami Y, Morita Y, Yokoyama K, Tamiya E (2001) Development of a microchamber array for picoliter PCR. Anal Chem 73(5):1043–1047

Obeid PJ, Christopoulos TK, Crabtree HJ, Backhouse CJ (2003) Microfabricated device for DNA and RNA amplification by continuous-flow polymerase chain reaction and reverse transcription-polymerase chain reaction with cycle number selection. Anal Chem 75(2):288–295

Ou CY, Kwok S, Mitchell SW, Mack DH, Sninsky JJ, Krebs JW, Feorino P, Warfield D, Schochetman G (1988) DNA amplification for direct detection of Hiv-1 in DNA of peripheral-blood mononuclear-cells. Science 239(4837):295–297

Prakash AR, Pilarski LM, Backhouse CJ, Kaler KVIS (2005) An integrated and reusable array PCR genetic amplification and CE detection microfluidic chip with incorporated valves. In: Paper presented at the 9th international conference on miniaturized systems for chemistry and life sciences, vol 1. MicroTAS (μTAS), Boston, pp 145–147

Prakash AR, Adamia S, Sieben V, Pilarski P, Pilarski LM, Backhouse CJ (2006) Small volume PCR in PDMS biochips with integrated fluid control and vapour barrier. Sens Actuators B Chem 113(1):398–409

Rodriguez SA, Colon LA (1999) Investigations of a sol-gel derived stationary phase for open tubular capillary electrochromatography. Anal Chim Acta 397(1–3):207–215

Rodriguez I, Lesaicherre M, Tie Y, Zou QB, Yu C, Singh J, Meng LT, Uppili S, Li SFY, Gopalakrishnakone P, Selvanayagam ZE (2003) Practical integration of polymerase chain reaction amplification and electrophoretic analysis in microfluidic devices for genetic analysis. Electrophoresis 24(1–2):172–178

Shin YS, Cho K, Lim SH, Chung S, Park SJ, Chung C, Han DC, Chang JK (2003) PDMS-based micro PCR chip with parylene coating. J Micromech Microeng 13(5):768–774

Shoffner MA, Cheng J, Hvichia GE, Kricka LJ, Wilding P (1996) Chip PCR.1. Surface passivation of microfabricated silicon-glass chips for PCR. Nucleic Acids Res 24(2):375–379

Sundberg M, Rosengren JP, Bunk R, Lindahl J, Nicholls IA, Tagerud S, Omling P, Montelius L, Mansson A (2003) Silanized surfaces for in vitro studies of actomyosin function and nanotechnology applications. Anal Biochem 323(1):127–138

Taylor TB, Harvey SE, Albin M, Lebak L, Ning Y, Mowat I, Schuerlein T, Principe E (1998) Process control for optimal PCR performance in glass microstructures. Biomed Microdevices 1(1):65–70

Walsh EJ, King C, Grimes R, Gonzalez A (2005) Segmenting fluid effect on PCR reactions in microfluidic platforms. Biomed Microdevices 7(4):269–272

Waters LC, Jacobson SC, Kroutchinina N, Khandurina J, Foote RS, Ramsey JM (1998) \ple sample PCR amplification and electrophoretic analysis on a microchip. Anal Chem 70(24):5172–5176

Yoon DS, Lee YS, Lee Y, Cho HJ, Sung SW, Oh KW, Cha J, Lim G (2002) Precise temperature control and rapid thermal cycling in a micromachined DNA polymerase chain reaction chip. J Micromech Microeng 12(6):813–823

Zhao XS, Lu GQ (1998) Modification of MCM-41 by surface silylation with trimethylchlorosilane and adsorption study. J Phys Chem B 102(9):1556–1561

Acknowledgment

This research is funded by the Alberta Cancer Diagnostic Consortium (ACDC), Canada. Microfabrication of the integrated device was carried out at a nanofabrication facility—Nanofab, University of Alberta, Edmonton, Canada. The authors thank Dr. Linda Pilarski and Erin Beuk for providing the plasmid DNA sample.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Prakash, R., Kaler, K.V.I.S. An integrated genetic analysis microfluidic platform with valves and a PCR chip reusability method to avoid contamination. Microfluid Nanofluid 3, 177–187 (2007). https://doi.org/10.1007/s10404-006-0114-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10404-006-0114-7