Abstract

In this study, an adaptive neuro fuzzy interface system (ANFIS) based predictor was designed to predict the physical properties of four almond types. Measurements of the dimensions, length, width and thickness were carried out for one hundred randomly selected samples of each type. With using these three major perpendicular dimensions, some physical parameters such as projected area, arithmetic mean diameter, geometric mean diameter, sphericity, surface area, volume, shape index and aspect ratio were estimated. In in a various Artificial Neural Network (ANN) structures, ANFIS structure which has given the best results was selected. The parameters analytically estimated and those predicted were given in the form of figures. The root mean-squared error (RMSE) was found to be 0.0001 which is quite low. ANFIS approach has given a superior outcome in the prediction of the Physical Properties of Almond Nuts.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Almond (Amygdalus communis L.), with a great significance in human nutrition since old times, belongs to Amygdalus sub-genus of Prunus genus Rosaceae family. Almond botanically has a drupe structure, but it is assessed as a nut fruit by the experts since mesocarp dries out and gets a skinny form in ripening period (Soylu 2003). It has about 40 species (Kester and Gradziel 1996) and Prunus amygdalus Batsch. (synonym. Prunus dulcis Miller) is the most common commercial species that is quite valuable with fruits processed into various products.

Beside the U.S.A. which is the world’s largest almond producer, the major producers are Greece, Iran, Italy, Morocco, Portugal, Spain, Pakistan, Syria, Philistine and Turkey (Aktas et al. 2007). Almond has a natural widespread over mountainous sections of Central Asia (Rugini and Monastra 2003) and naturally grows in almost every region of our country with different ecologies. Turkey, with its annual production about 75 thousand tons (FAO 2012), is the ninth major producer (Aktas et al. 2007) and has about 4% share in world almond production of 2 million tons (FAO 2012). Sufficient emphasis has recently been placed on modern almond culture in Turkey.

Hulling, wetting the kernels, shell cracking, drying and peeling are some of the most important processing steps after almond harvesting. The mechanical and physical properties of the product are exceedingly influence these processing methods (Mahmoodi-Eshkaftaki et al. 2013). The mechanical properties of almond are necessary for design of an almond cracker, peeler machines and almond shaker (Mahmood et al. 2008).

In recent years, the neural techniques brought up as a new tool for solving complex problems. Artificial neural networks (ANNs) are one of many computing models used in the sphere of artificial intelligence (Šťastný et al. 2011). ANNs which have the parallel processing capability provide a method to characterize synthetic neurons to solve complex problems (Ayoubi et al. 2011). By the data they gathered in the training phase, ANNs can comply with the new situations in problems such as mapping, modelling, association types (Mancuso et al. 1999), Knowledge-management (Svoboda 2007) and classification (Konečný et al. 2010).

In agriculture, many studies have been conducted with the artificial neural networks (ANNs) (Bala et al. 2005; Diamantopoulou 2005; Movagharnejad and Nikzad 2007; Khalifa et al. 2011; Khalesi et al. 2012; Karimi et al. 2012; Dousti et al. 2013; Goyal 2013; Reshadsedghi and Mahmoudi 2013; Reshadsedghi et al. 2014). However, ANFIS structure hasn’t been used for predicting physical properties of agricultural products in the scientific literature. The aim of this research is to predict the arithmetic mean diameter, geometric mean diameter, sphericity, surface area, volume, projected area, shape index and aspect ratio of the almond nut by ANFIS.

Materials and Methods

‘Ferragnes’, ’Lauranne’, ’Glorieta’ and ’Marta’ varieties of almond nut were used all the measurement in this study. The almond nuts were obtained from the 2015 growing season at the Pistachio Research Institute in the Gaziantep province of Turkey. The nuts were cleaned by in an air from the unwanted describe foreign materials and broken nuts. 100 nut samples were randomly selected from each variety and their three main dimensions were studied. Measurements of these dimensions, length (L, mm), width (W, mm) and thickness (T, mm), were carried out with a digital caliper of precision 0.01 mm. The equations used for calculation of the physical properties are given in Table 1.

Adaptive Neuro Fuzyy Inference System (ANFIS)

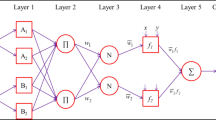

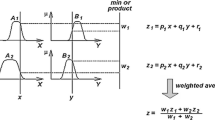

ANFIS integrates neural network with Fuzzy Interface System (FIS). The method of a FIS composes of 3 elements: a rule base, a database and a reasoning mechanism. A schematic representation of an ANFIS is represented in Fig. 1 (Bachir and Zoubir 2012). It is used two inputs as y 1 and y 2 and one output as v to explain the fuzzy inference system. If the rule base contains two fuzzy if-then rules such as:

where θ i and βi are fuzzy membership sets, b i is the number of membership equations, s i is the design parameter that is defined during the train process. The ANFIS consist of six layers:

Layer 1: This is the input layer that determines actual data and desired data.

Layer 2: Each nodal in this layer is an adaptive nodal with a fuzzy membership equation. For two inputs, the nodal outputs are:

where αθ i and αβ i are membership functions.

where {p i , r i ,t i } is the coefficient group.

Layer 3: Each nodal in the third layer is a circle nodal called “Ƞ”, that multiples the all signals and send the product out.

Layer 4: Each nodal in the fourth layer is a circle nodal called “Ɲ”.

Layer 5: In this layer, each nodal i has the following function:

Layer 6: The single nodal in the sixth layer is a circle nodal called “\(\sum\)”.

Result and Discussion

Measurements of the dimensions, length, width and thickness for almond types namely ’Ferragnes’, ’Lauranne’, ’Glorieta’ and ’Marta’ have been carried out in laboratory conditions. These measurements were then used to obtain some physical parameters such as projected area, arithmetic mean diameter, geometric mean diameter, sphericity, surface area, volume, shape index and aspect ratio. Afterwards the data gathered has been used in the training of ANFIS structure. Figs. 2 and 3 depicts the prediction results of the projected area for four almond types using the ANFIS approach. As seen in the figures the prediction results of the projected area parameter are quite good. Prediction results of arithmetic and geometric mean diameter is given in Figs. 4 and 5. The results for these parameters are satisfactory as well. Fig. 6 shows the prediction results of sphericity and Fig. 7 shows the prediction results of aspect ratio, respectively. Simulation results showed that the root mean-squared error (RMSE) for any prediction was found to be 0.0001 which is quite low. Finally, the final parameters predicted for almond types are surface area, shape index and volume. Examining Figs. 8, 9 and 10 together, it is obvious that the ANFIS structure is a suitable tool in prediction of the related physical parameters.

Conclusions

In this study, physical parameters of four almond types were calculated by means of the given equations. As an alternative method to this calculation technique, ANFIS approach has been used. According to the experimental and simulation results, the proposed ANFIS predictor had a superior performance in prediction of some physical parameter such as projected area, arithmetic and geometric mean diameter, sphericity, surface area, volume, shape index and aspect ratio. Therefore, it is obvious that ANFIS predictor can be used as an effective alternative method.

References

Afonso Junior PC, Correa PC, Pinto FAC, Queiroz DM (2007) Aerodynamic properties of coffee cherries and beans. Biosyst Eng 98:39–46

Aktas T, Polat R, Atay U (2007) Comparison of mechanical properties of some selected almond cultivars with hard and soft shell under compression loading. J Food Process Eng 30:773–789

Arslan S, Vursavus KK (2008) Physico-mechanical properties of almond nut and its kernel as a function of variety and moisture content. Philipp Agric Sci 91:171–179

Ayoubi S, Shahri AP, Karchegani PM, Sahrawat KL (2011) Application of Artificial Neural Network (ANN) to predict soil organic matter using remote sensing data in two ecosystems. In: Atazadeh I (ed) Biomass and remote sensing of biomass, pp 181–196

Bachir O, Zoubir AF (2012) Adaptive Neuro-fuzzy inference system based control of Puma 600 robot manipulator. Int J Electr Comput Eng 2:90–97

Bala BK, Ashraf MA, Uddin MA, Janjai S (2005) Experimental and neural network prediction of the performance of a solar tunnel drier for drying jackfruit bulbs and leather. J Food Process Eng 28:552–566

Diamantopoulou MJ (2005) Artificial neural networks as an alternative tool in pine bark volume estimation. Comput Electron Agric 48:235–244

Dousti A, Ghazavi MA, Maleki A (2013) Grading of empty walnut using signal processing and artificial neural network techniques. Int J Agric Crop Sci 6:1072

FAO (2012) FAO web page. www.fao.org. Accessed 10.11.2016

Goyal S (2013) Artificial neural networks in vegetables: a comprehensive review. Sci J Crop Sci 2:75–94

Karimi H, Navid H, Mahmoudi A (2012) Detection of damaged seeds in laboratory evaluation of precision planter using impact acoustics and artificial neural networks. J Artif Intell Res 1:67

Kester DE, Gradziel TM (1996) Almonds. Fruit breeding. In: Janick J, Moore JN (eds) vol III. Wiley & Sons, Hoboken, pp 1–240. ISBN 978-0471126690

Khalesi S, Mahmoudi A, Hosainpour A, Alipour A (2012) Detection of walnut varieties using impact acoustics and artificial neural networks (ANNs). Mod Appl Sci 6:43

Khalifa S, Komarizadeh MH, Tousi B, Nikbakht AM (2011) An intelligent system for grading walnuts based on acoustic emission and neural networks. J Food Agric Environ 9:109–112

Konečný V, Trenz O, Svobodová E (2010) Classification of companies with the assistance of self-learning neural networks. Agric Econ 56:51–58

Mahmood M, Mojtaba T, Javad K, Narjes M (2008) Modeling some mechanical properties distributions of almond using weibull function. 18th National Congress on Food Technology, Iran, pp 1–6

Mahmoodi-Eshkaftaki M, Ebrahimi R, Torki-Harchegani M (2013) Determination of critical conditions for puncturing almonds using coupled response surface methodology and genetic algorithm. Food Technol Biotechnol 51:500–508

Mancuso S, Ferrini F, Nicese FP (1999) Chestnut (Castanea sativa mill.) genotype identification: an artificial neural network approach. J Hortic Sci Biotechnol 74:777–784

McCabe WL, Smith JC, Harriot P (1986) Unit operations of chemical engineering. McGraw-Hill, New York

Mirzabe AH, Khazaei J, Chegini GR, Gholami O (2013) Some physical properties of almond nut and kernel and modeling dimensional properties. Agric Eng Int 15:256–265

Mohsenin NN (1986) Physical properties of plant and animal materials. Gordon & Breach Science, New York

Movagharnejad K, Nikzad M (2007) Modeling of tomato drying using artificial neural network. Comput Electron Agric 59:78–85

Mpotokwane SM, Gaditlhatlhelwe E, Sebaka A, Jideani VA (2008) Physical properties of bambara groundnuts from Botswana. J Food Eng 89:93–98

Reshadsedghi A, Mahmoudi A (2013) Detection of almond varieties using impact acoustics and artificial neural networks. Int J Agric Crop Sci 6:1008

Reshadsedghi A, Mahmoudi A, Azimirad V, Hajilou J, Ghaffari H (2014) Non-destructive detection of unshelled almonds quality based on their kernel percentage using impact-acoustics and ANN’s techniques. Agric Sci Dev 3:360–365

Rugini E, Monastra F (2003) Temperate fruits. In: Mitra SK, Rathora DS, Bose TK (eds) vol II. Display Printers, India, pp 344–414. ISBN 978-8190017114

Sayinci B, Ercişli S, Akbulut M, Şavşatli Y, Baykal H (2015) Determination of shape in fruits of cherry laurel (Prunus laurocerasus) accessions by usıng elliptic fourier analysis. Acta Sci Pol Hortorum Cultus 14:63–82

Soylu A (2003) Ilıman iklim Meyveleri II. Ders Notları No: 72. Uludağ Üniversitesi Zir. Fak., Bursa, pp 204–220

Svoboda E (2007) Knowledge-management in managerial work of business management. Agric Econ 53:298–303

Šťastný J, Konečný V, Trenz O (2011) Agricultural data prediction by means of neural network. Agric Econ 57:356–361

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

B. Demir, İ. Eski, F. Gürbüz, Z. Abidin Kuş, K. Uğurtan Yilmaz, M. Uzun and S. Ercişli declare that they have no competing interests.

Rights and permissions

About this article

Cite this article

Eski, İ., Demir, B., Gürbüz, F. et al. Design of Neural Network Predictor for the Physical Properties of Almond Nuts. Erwerbs-Obstbau 60, 153–160 (2018). https://doi.org/10.1007/s10341-017-0349-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10341-017-0349-3