Abstract

The present research work discusses the systematic Quality by Design (QbD) enabled development of a simple, rapid, economical, and stability-indicating high-performance liquid chromatography (HPLC) method for effective analysis of clofazimine (CFZ). An Ishikawa fish-bone diagram was constructed for initial risk assessment. Analytical target profile (ATP) was defined and critical analytical attributes (CAAs) were assigned to meet these ATP requirements. Taguchi design was applied for screening critical material attributes (CMAs) and critical process parameters (CPPs) making an impact on the assigned CAAs. The major contributing factors were finely tuned using 33 Box-Behnken design with numerical and graphical optimization. Further, the method was validated as per the ICH guidelines and force degradation studies were carried out under different stress conditions. The optimum chromatographic separation was accomplished using 75:25% v/v ratio of methanol and ammonium acetate buffer (0.01 mol/L) as the mobile phase at flow rate 1.0 mL/min, and UV detection at 284 nm. The developed HPLC method was found highly sensitive, specific with linearity ranging between 2 and 10 µg/mL, and correlation coefficient (R2) 0.9995. It showed high accuracy with % recovery between 99.68 and 100.44%. It depicted detection limit and quantitation limit of 0.0066 µg/mL and 0.0199 µg/mL, respectively. In force degradation studies the drug was found to be highly susceptible in alkaline stress conditions. The results reveal successful applicability of the method for the estimation of CFZ from its marketed formulation which can be wisely extrapolated to assess the CFZ from its other formulation systems and different biological samples.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

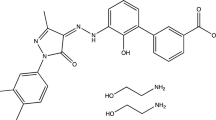

Clofazimine (CFZ) was first discovered as an anti-mycobacterial agent by Barry and colleagues. Chemically it is (3-(4-chloranilino)-10-(4-chlorophenyl)-2,10-dihydro-2-(isopropylamino)phenazine) (Fig. 1), a riminophenazine dye obtained from compounds originated from the lichen Buellia Canescens [1,2,3]. In recent years, the Bangladesh regimen has successfully proven the shortening of the duration of a treatment to 9 months using CFZ in both intensive and continuation phases of the treatment of tuberculosis (TB) [4]. Thus, it has been recommended as a short-term regimen of 9–12 months by WHO [5]. In addition, various observational cohort studies and meta-analyses of these cohort studies carried out on the CFZ-containing regimen proved 62–65% success of the regimen. In one survey carried out by chest physicians in the Maharashtra state in India, it was observed that the CFZ was a desired drug in controlling drug-resistant tuberculosis cases [6]. These ground-breaking findings related to CFZ, its comparatively fewer incidences of resistance, and a weak channel of alternative anti-mycobacterial agents renewed the interest of scientists in CFZ.

In our previous publication, we have critically reviewed different analytical methods available for the estimation of CFZ from different formulations and biological fluids [3]. Till date, various research groups persistently put their efforts in developing and validating HPLC method for the estimation of CFZ. However, complex extraction procedure, processing at high column temperature, use of a high-cost organic solvent (e.g. acetonitrile), incompatibility for mass spectroscopic (MS) analysis, etc., limited their applications. Further, the strong lipophilic, polar, and photosensitive characteristics of CFZ hindered its effective extraction and estimation from various biological and formulation-based samples [3]. The aim of the present research was to develop the highly specific, sensitive, precise, robust, and stability-indicating HPLC method using quality by design (QbD) approach for the effective analysis of CFZ from its bulk and formulation system(s). In the past few years, QbD approach has been effectively implemented for the development and optimization of HPLC method for the evaluation of drug, along with its impurities and degradation products. The most archetypical examples of the implementation of QbD approach in the HPLC method development include works done by Schmidt et al. [7], Kurmi et al. [8], Yadav et al. [9], Sandhu et al. [10], Garg et al. [11], Wingert et al. [12], and Sharma et al. [13]. Though earlier two research groups Khedekar et al. [14] and Patel et al. [15] reported the stability indicating HPLC method for the estimation of CFZ, costly behavior (due to the use of acetonitrile) and absence of QbD-based approach with the predefined objectives crucial for the method development limit their application.

To the best of our knowledge, this is the first-ever study reporting the QbD-based development and optimization of HPLC method of CFZ and its force degradation analysis at various stress conditions. The developed method possesses distinct advantages over some previously reported methods which include implementation of a QbD-based approach with the predefined objectives, its cost-effectiveness pertaining to the use of methanol, MS-compatibility because of ammonium acetate-containing buffer system, time-saving due to short run time, and unresponsiveness to interferences by formulation excipients.

Experimental

Chemicals

A gift sample of CFZ was provided by Sangrose Laboratories Pvt ltd., Kerala, India. HPLC-grade acetonitrile and methanol were purchased from M/s Merck Ltd., India, while ammonium acetate was obtained from RANKEM ltd., India. All other chemicals and reagents used were of analytical grade.

Equipments and Chromatographic Conditions

Two different HPLC systems were used for the method development and force degradation studies. The first system was a Shimadzu prominence (Autosampler). It was a quaternary pump system equipped with SPD-M20A Prominence diode array (PDA) detector, SIL-20 AC HT prominence autosampler, LC-20 AD prominence liquid chromatograph system, DGU-20A5R degassing unit, and CTO-10AS VP column oven. It utilized a Lab Solutions software for monitoring and processing the output signal. The second system used was a Perkin Elmer binary pump system. It was equipped with series 200 UV/Vis detector, series 200 pump and series 200 vacuum degasser. Total chrome navigator software was used to monitor and process the output signal.

Chromatographic grade water was obtained using milli-Q® system (Millipore, Milford, India) and was further filtered via a 0.22-µM membrane filter (Durapore, Millipore) before preparation of all necessary solutions. Standard and sample solutions were prepared in amber colored glassware. Labindia pH meter (Pico+) was used to measure the pH of the buffer. Ultrasonicator [Oscar ultrasonicator (Microclean-103)] was used for the preparation of the drug solutions and mobile phase.

Preparation of Standard Solution

10 ± 1 mg of CFZ drug substance was weighed and transferred quantitatively into a 100-mL volumetric flask. It was dissolved in about 50 mL methanol by vigorous shaking followed by ultrasonication for about 5 min. The volume was made up to the mark with the same solvent to obtain a standard stock solution of concentration 100 µg/mL of the drug. A working standard solution was prepared by diluting 1.0 mL of the standard stock solution upto 10 mL with the mobile phase. Thus, the CFZ working standard contains 10 µg/mL concentration.

Preparation of Sample Solution

Twenty soft gelatin capsules of CFZ (Hansepran capsule 50 mg) were weighed and ground in a clean dry mortar. The amount equivalent to 10 ± 1 mg of drug was weighed and transferred into a 10-mL volumetric flask. To these contents, about 8 mL of benzene was added and the flask was placed on a mechanical shaker for 10 min to disperse the material completely. It was further ultrasonicated for 10 min and the volume was made up to the mark with the same solvent to obtain a stock solution of a concentration of 1000 µg/mL. The resulted stock solution was centrifuged at 5000 rpm for 5 min and working sample solution was prepared by sufficiently diluting the supernatant using mobile phase. Thus, the working sample solution contained CFZ 10 µg/mL. The solution was filtered using a 0.45-µM nylon membrane filter before analysis.

Defining Analytical Target Profile (ATP) and Critical Analytical Attributes (CAAs)

One of the key steps toward the QbD-based development of HPLC method initiates by outlining an analytical target profile (ATP). ATP can be defined as the budding summary of the desired quality characteristics required for the method development. Defining ATP will assure the quality, safety, and applicability of the analytical method [9]. Various components of ATP include principal characteristics like target drug, target samples and method application, analytical method, instrument characteristics, sample preparation, and analytical method quality attributes (see electronic supplementary Table 1).

To meet these ATP requirements, different critical analytical attributes (CAAs) can be selected. CAAs are defined as the measurable attributes of the chromatogram that should be within an appropriate limit or range to warrant the desired quality of the analytical method. These CAAs include number of theoretical plates (NTPs), retention time (Rt), tailing factor (Tf), spectral peak purity, resolution between the impurities, resolution between the main analyte and adjacent impurity, peak area, assay, etc. Out of these, CAAs such as NTPs, Rt, and Tf which really impel the performance of the method were selected.

Risk Assessment and Taguchi Design for Screening of Factors Affecting the Method Development of CFZ

Initially, as an essential element of QbD-based method development, risk assessment study was executed for determining the probability of risk(s) or failure(s). For this purpose, a cause–effect relationship of critical material attributes (CMAs) and critical process parameters (CPPs) with the CAAs was established by constructing an Ishikawa fish-bone diagram with the help of Minitab 17 software (M/s Minitab Inc., Philadelphia, PA). After this, Taguchi orthogonal array design with 7 factors varied at 2 different levels (L8-array; which results into 8 runs) was used for this purpose [9, 10]. The model was applied to identify the CMAs and CPPs making an impact on the method’s CAAs. CMAs include % v/v of solvent (A) and % v/v of buffer (B) in solvent: buffer ratio, pH of the buffer (C), and type of the solvent used (F), while CPPs include flow rate of mobile phase (D), injection volume of solvent (E), and type of column used (G). These CMAs and CPPs were evaluated for 3 CAAs viz., Tf, NTPs, and Rt at a standard concentration of 10 µg/mL for all experimental runs. Analytical runs were performed as per Taguchi design matrix (see electronic supplementary Table 2). Half-normal plots and Pareto charts were employed as a primary model selection tools for quantitatively determining the effect of each factor on the selected CAAs.

Method Development and Optimization using Box–Behnken Design (BBD)

Based on the outcome of the screening studies, two CMAs viz., % v/v of buffer (with respect to % v/v of solvent) in the mobile phase composition (X1), pH of the buffer (X2), and one CPP, i.e. flow rate (X3) were selected for further optimization of the analytical method. The optimization was carried out by implementing a 33 BBD [9, 10]. As per the design matrix (see electronic supplementary Table 3), 17 experimental runs were performed. A standard concentration of 10 µg/mL was used for all experimental runs. Experimental data were analyzed against the stated CAAs (Tf, NTPs, and Rt). Statistical analyses of the experimental data were obtained from factor screening studies, and method optimization was carried out on the Design-Expert® software version 11 (Stat-Ease Inc., Minneapolis, USA). The best fitted second-order quadratic polynomial equation (Eq. 1) was generated and it was selected based on its significance by applying an analysis of variance (ANOVA) F test.

where Y is the response selected; b0 is the intercept; b1–b33 are the regression coefficients; and A, B, and C are the factors investigated.

The model created by design was assessed and compared for different parameters like the correlation coefficient (R2), adjusted correlation coefficient (adjusted R2), predicted correlation coefficient (Predicted R2), and adequate precision. The response surface analysis (RSA) was done by generating 2D-contour plots and 3D-response surface plots [13]. The optimum analytical conditions were predicted by numerical optimization method. These optimized conditions were further located in the “analytical design space region" in the form of “overlay plot" by inserting a flag containing all parameters.

Method Validation

The optimized chromatographic method was validated for specificity, linearity, range, accuracy, precision, lower limit detection, loweer limit of quantitation, robustness, and system suitability testing according to the International Conference on Harmonization (ICH) guideline [16].

Linearity

The linearity is the method’s ability to obtain test results which are directly proportional to the concentration of an analyte in the sample. It was estimated by preparing serial dilutions of the standard stock solution in a concentration range between 2 and 10 µg/mL. The calibration curve was obtained by plotting the peak area vs drug concentration. The analysis was done in triplicate (n = 3) for each concentration.

Lower Limit of Detection (LOD) and Lower Limit of Quantitation (LOQ)

LOD of the developed method is the lowest amount of analyte in a sample that can be detected but not necessarily quantified as an exact value. LOD was calculated using the following equation (Eq. 2):

where σ is the standard deviation of y-intercepts of regression lines, and S is the slope of the calibration curve of CFZ.

LOQ of the developed method is the lowest amount of analyte in a sample which can be quantified with suitable precision and accuracy. LOQ was calculated using the following equation (Eq. 3):

where σ is the standard deviation of y-intercepts of regression lines, and S is the slope of the calibration curve of CFZ.

Specificity

Specificity studies are used to determine the the method’s ability to evaluate unambiguously the analyte in the presence of different components like a matrix, impurities, degradants, etc. The parameter has implications for identification, purity tests, and assay (content or potency).

Chromatographic runs of CFZ standard solution and sample solution of CFZ marketed formulation at 10 µg/mL concentrations (prepared as described in Sects. 3.5.3 and 3.5.4) were carried out in order to determine the specificity of the method.

Accuracy

The accuracy of an analytical procedure expresses the closeness of agreement between the value which is accepted as a conventional true value or an accepted reference value and the value found. The accuracy of the analytical procedure was determined by spiking a known concentration of CFZ at three different levels. Standard solution of a drug at concentration 4 µg/mL was accurately prepared from stock solution and further spiked at 80%, 100%, and 120% of the theoretical CFZ concentration level in the sample. Sample solutions were prepared in triplicate for each spike level. The percentage of recovery was calculated.

Precision

The precision of an analytical method measures the close agreement between a series of measurements achieved from multiple sampling of the same homogeneous sample under the suggested conditions. A precision of the developed method is expressed in terms of percentage relative standard deviation (% RSD) for peak area. Precision studies were carried out at three levels as follows:

Repeatability

Repeatability was assessed using six determinations at a concentration of 4 µg/mL.

Intermediate Precision

Intermediate precision was assessed at three different concentrations: 4, 6, and 8 µg/mL in triplicates on different days by a different analyst.

Robustness

The robustness of an analytical method is a measure of its ability to remain unaffected by small, but deliberate changes in method parameters. This parameter gives an indication of the consistency of the developed method during normal usage. Typical variations made were pH of the buffer (± 0.5), a composition of the mobile phase (± 5%), and flow rates (± 0.2 mL/min).

System Suitability Testing

System suitability test of the chromatographic system was carried out by injecting six replicate injections of a standard solution of 10 µg/mL. Earlier to sample analysis, % RSD of peak area and Rt were determined for suitability samples and were found acceptable below 2%. The results were expressed in terms of Rt, Tf, NTPs, and capacity factor (k′). The acceptance criteria for Tf less than 2.0 and theoretical plates greater than 2000 should be maintained.

Solution Stability

Stability of CFZ standard sample solution was evaluated over the 15-day period at 35 ± 2 °C. The results were matched by % assay value for studied standard samples with those of freshly prepared samples.

Force Degradation Studies

Force degradation studies were carried out as per ICH-recommended conditions to demonstrate the stability indicating ability and specificity of the developed method [17, 18]. Standard samples were prepared at a concentration of 200 µg/mL and exposed to different stress conditions. All samples were then diluted accordingly to give a final concentration of 20 µg/mL. The samples were neutralized if required and filtered prior to injection. Control samples of 20 µg/mL were also prepared during analysis.

Acid Degradation Studies

Solutions for acid degradation were prepared using 0.1 and 1 N HCl, protected from light, and stored at room temperature. Samples were withdrawn at 0, 1, 2, 3 h time points and diluted as described above.

Base Degradation Studies

Solutions were prepared using 0.1 N NaOH, protected from light, and stored at room temperature. Samples were withdrawn at 0, 1, 2, and 3 h time points and diluted as described above.

Oxidation Studies

Solutions for oxidation studies were prepared using 10% H2O2, protected from light, and stored at room temperature. Samples were withdrawn at 0, 1, 2, and 3 h time points and diluted as described above.

Photodegradation Studies

Samples were exposed to UV light with an illumination of 7500 lx m with UV radiation at 320–400 nm in UV light chamber. Samples were withdrawn over 6 h time period and diluted as previously described.

Results and Discussion

Preliminary Method Development and Factor Selection Studies

In order to develop a simple, cost-effective, and stability-indicating HPLC method for effective assessment of the CFZ from its bulk or formulation samples, preliminary experiments were carried out. The pKa of CFZ is 8.51 and basic nature. Initially, the mobile phase was varied by utilizing different combinations of solvents (e.g. acetonitrile, methanol) and ammonium acetate buffer at various strength (0.01 mol/L and 0.02 mol/L). The buffer system is tried at different pH (between 4.0 and 6.0) by adjusting it with acetic acid. The pH is included as factor in initial screening studies as well as subsequent method optimization to confirm the effect of pH of the buffer on the separation of the analyte and to assure the better sensitivity of the buffer. In preliminary findings, it was observed that the selection of ammonium acetate buffer at 10 mM concentration and at pH between 4.4 and 5.4 leads to effective and faster chromatographic separation with lower Rt value together with the satisfactory peak symmetry and low peak tailing.

Risk Assessment and Screening Studies

To understand the univariate and/or multivariate relationship between CMAs and CPPs, and how they affect the CAAs, risk assessment is of utmost importance. The possible risk factors are summarized in the Ishikawa fish-bone diagram (see electronic supplementary Fig. 1). Taguchi design was applied for factor screening studies using seven different factors short-listed from the risk assessment studies. The major objective of this screening study was to detect the main factors contributing significantly to the method development with the minimum possible experimentation. The impact of these studied factors on the effects/responses/CAAs was represented in the form of half-normal plots and Pareto charts (Fig. 2a–c). Two factors viz., % v/v of solvent in the mobile phase (proportionally % v/v of a buffer) and type of solvent used were contributed mainly on all three responses, i.e. Tf, NTPs, and Rt. pH of the buffer system has slightly influenced the Tf as acidic pH does not ionize the surface silanols of the stationary phase and diminishes the tailing of basic analyte [19]. Also, the flow rate affected the NTPs and Rt. On the basis of factor screening studies, % v/v of a buffer in the mobile phase, pH, and flow rate were chosen for further optimization. Methanol was selected as a solvent in further optimization process as it is cost-effective as compared to acetonitrile. It also showed the comparative results with respect to NTPs and Rt, and depicted less Tf as compared to acetonitrile (see electronic supplementary Fig. 2a–b and supplementary Table 4). Other parameters like type of column (C18) and injection volume (20 µL) were kept constant throughout the optimization.

Method Optimization using Response Surface Methodology

In the present study, BBD was implemented for optimization of the selected independent variables. Design expert software recommended quadratic model as a best fitting model for all the three responses viz., NTPs, Rt, and Tf. ANOVA F test also confirmed the high degree of significance for a chosen quadratic model with p < 0.05. Table 1summarizes the analysis report of all the three responses using BBD. All the three responses showed high R2 values ranging from 0.9831 to 0.9968 depicting the best fit of created polynomials to the response data (p < 0.0001 in all cases). All the three responses depicted insignificant values of “lack of fit" (p > 0.05 in all cases) indicating that the selected model is appropriate. The difference between predicted R2 value and the adjusted R2 value was found less than 0.2, and the closeness of these values with the actual model R2 further confirmed the excellent fit of the data.

Ten coefficients from b0 to b33 (as mentioned in Eq. 1), indicating various quadratic and interaction terms were generated using b0 as an intercept. Table 2 provides the coefficients of polynomial equations according to the second-order quadratic polynomial model for the three CAAs viz. Number of Theoretical Plates (Y1), retention time (Y2), and tailing factor (Y3).

The response surface diagrams (3D graphs and contour plots) were drawn over the whole experimental design to recognize the interactions between the variables. Figures 3a–c, 4a–c, and 5a–c portray 2-D contour plots and 3-D response surface plots for NTPs, Rt, and Tf, respectively. The desired maximum NTPs, less Rt of the analyte, and Tf closer to one were obtained at intermediate levels of the selected independent variables. The extreme values of the pH of the buffer were responsible for an increase in the Tf and decrease in the NTPs. The higher level of % v/v of a buffer in the mobile phase was responsible for a decrease in the NTPs, while decrease in the flow rate has resulted in the increase in the Tf. It is usually accepted that an increase in the flow rate reduces the retention time. In Fig. 4b, c, the factor flow rate is compared with the % v/v of a buffer in the mobile phase and its pH, respectively. Figure 4b depicts an increase in the retention time upon increasing the % v/v of buffer in mobile, though at higher values of flow rate. This portrays the dominance of the percentage of buffer in mobile phase over flow rate. Similarly, in Fig. 4c, extreme values of pH show slight increase in the Rt. However, the minimum retention time is observed at optimized concentration 25% v/v and pH 4.92 of the buffer, and flow rate (1 mL/min). These observations clearly indicate that the selected independent variables for optimization have shown the strong influence on dependent variables.

Analytical Design Space

The optimum chromatographic separation was achieved using methanol and ammonium acetate buffer (0.01 mol/L, pH 4.92 adjusted by acetic acid) in 75: 25 ratio (% v/v) as the mobile phase with a flow rate 1.0 mL/min, column temperature at 25 ± 2 °C, and UV detection at 284 nm. To locate the optimum analytical conditions in the design space, numerical optimization was carried out by applying constraints on the variables (see electronic supplementary Table 5). The anticipated optimum analytical method conditions were flagged in the overlay plot (see electronic supplementary Fig. 3). The values displayed in the overlay plot for CAAs were in close proximity with those used for optimum chromatographic separation [X1(% v/v of buffer in mobile phase): 24.0492–25, and X2 (pH of the buffer): 4.877–4.92]. This clearly demonstrated the definite accuracy of the anticipated QbD model in the estimation of CAAs. This optimized method was validated as per ICH guidelines.

Method Validation

Linearity

The linearity of the developed analytical method was confirmed by plotting the calibration curve between peak area (mAU) vs the concentration of the analyte (µg/mL) (Fig. 6). The correlation coefficient (R2) was found to be 0.9995, which depicted the excellent closeness between the observed data and the predicted data.

LOD and LOQ

LOD and LOQ values were found to be 0.0066 µg/mL and 0.0199 µg/mL, respectively, for the developed analytical method. These values indicate the higher sensitivity of the developed analytical method for its effective detection and quantification.

Specificity

The chromatograms of the CFZ standard solution and sample solution extracted from marketed soft gelatin capsule of CFZ (see electronic supplementary Fig. 4a–b) showed that there was no significant change in the Rt of the analyte from its sample solution to that with its standard solution. Also, there were no additional peaks observed for the formulation matrix from which the analyte sample was extracted. This indicated the significant specificity and selectivity of the developed analytical method for the estimation of CFZ.

Accuracy

Developed analytical method for standard CFZ solution spiked at 80%, 100%, and 120% concentration showed % recovery between 99.68-100.44%. Thus, the developed method showed a significantly high level of accuracy with % RSD between 0.043 and 0.059. These results of accuracy data are depicted in Table 3.

Precision

Table 4 depicts the results for precision studies in terms of % RSD of the peak areas of CFZ. In both repeatability and intermediate studies/inter-day precision studies, % RSD of the peak areas of CFZ were well within 1%. These results demonstrated the significant level of precision of the developed analytical method.

Robustness

Changes in different chromatographic conditions such as pH, composition, and flow rate of the mobile phase caused insignificant changes in the CAAs such as NTP, Rt, and Tf. This insensitivity of responses towards the deliberate slight variations in the method conditions demonstrated the robustness of the developed HPLC method.

System Suitability Testing

Results from the system suitability testing showed no remarkable difference in the peak area, NTP, Rt, and Tf of CFZ between six replicates. %RSD for studied parameters was found to be < 1%, which proved the high level of accuracy of the developed analytical method.

Solution Stability

Stability of CLF solution was established experimentally over 15 days in the volumetric flask stored at 35 ± 2 °C. The % assay was found to be 100.50% which is within the limit of acceptance. This study validated the friendly characteristics of the developed method for use in the manufacturing environment.

Force Degradation Studies

Force degradation studies were performed under various stress conditions and obtained chromatograms are depicted in Fig. 7a–e. Details of the degradation products (DPs) and % total degradation are presented in Table 5. The drug was found to be highly susceptible to basic stress conditions followed by acidic and oxidative stress conditions, while it was found to be comparatively less susceptible to the photolytic stress condition.

a–e Typical HPLC chromatograms of CFZ (20 µg/mL) and its degradation products (DPs) from a untreated CFZ standard solution, b CFZ solution treated with 1 N HCl for 3 h, c CFZ solution treated with 0.1 N NaOH for 3 h, d CFZ solution treated with 10% H2O2 for 3 h, and e CFZ solution treated under UV for 6 h

In basic stress conditions, treatment with 0.1 N NaOH for 3 h showed nearly 99% degradation of CFZ. This leads to the conclusion that the drug is highly susceptible to a basic environment. Two degradation products were observed viz. DP 3 and DP 7 at Rt 1.094 and 1.337 min, respectively. In acidic stress conditions, no remarkable degradation was noticed in 0.1 N HCl for 3 h, whereas treatment with 1 N HCl for 3 h resulted into 78.23% degradation. Four degradation products were observed in acidic stress conditions viz. DP 2, DP 6, DP 9, and DP 10 at Rt 1.071, 1.334, 1.656, and 2.020 min, respectively. In oxidative stress conditions, treatment with 10% H2O2 for 3 h resulted in 35.56% drug degradation. The single degradation product was observed (DP 4) at Rt 1.134 min. Under photolytic stress conditions, a maximum number of degradation products were observed and demarcated as DP 1, DP 5, DP 8, DP 11, DP 12 at Rt 1.042, 1.168, 1.600, 2.378, and 3.381 min, respectively. The drug showed 22.70% degradation at the end of 6 h indicating its photosensitive nature. From these results, it is clear that the degradants formed in the solutions with different stress conditions were detected and well separated from the analyte. Thus, the developed analytical method is stability indicating and highly applicable for routine as well as analysis of stability samples.

Conclusion

A QbD based, simple, rapid, economical, and stability-indicating HPLC method has been successfully developed for CFZ. The developed method is able to detect and quantify CFZ in its bulk form and formulation system(S). Initially, to summarize the quality features required for the HPLC method development, ATP is defined. Based on this ATP, different CAAs such as NTPs, Rt, and Tf that majorly depict the method performance were selected. Further, a cause–effect relationship of CMAs and CPPs with the CAAs was established by building an Ishikawa fish-bone diagram. Based on this risk assessment, seven different chromatographic factors were assessed for their impact on the selected CAAs using Taguchi screening design. Three factors that majorly impacted CAAs were further optimized using 33 Box-Behnken design. To study the main effects and interactions among different CMAs and CPPs with the CAAs, 2D-contour plots, and 3D-response surface plots were drawn. The optimum analytical conditions were projected by a numerical optimization method. These conditions were further located in the analytical design space region by flagging all parameters in the form of an overlay plot. The optimized method was further validated for linearity, LOD, LOQ, specificity, accuracy, precision, robustness, and system suitability testing parameters. Further, the force degradation studies of CFZ were carried out under different stress conditions. Totally 12 degradation products (DPs) were detected and % total degradation of the drug was determined under various stress conditions. Unambiguously, the developed method reveals its successful applicability that can be wisely extrapolated to other formulation systems of CFZ and the utility of a QbD approach in the development and validation of HPLC method for CFZ. Also, this validated method can be transferred to a bioanalytical assessment of the CFZ.

References

Barry VC, Belton JG, Conalty ML, Denneny JM, Edward DW, O’sullivan JF, Twomey D, Winder F (1957) A new series of phenazines (Rimino-Compounds) with high antituberculosis activity. Nature 179:1013–1015

O’Donnell MR, Padayatchi N, Metcalfe JZ (2016) Elucidating the role of clofazimine for the treatment of tuberculosis. Int J Tuberc Lung Dis 20:S52–S57. https://doi.org/10.5588/ijtld.16.0073

Patil TS, Deshpande AS, Deshpande S (2018) Critical review on the analytical methods for the estimation of clofazimine in bulk, biological fluids and pharmaceutical formulations. Crit Rev Anal Chem 48:492–502

Van Deun A, Maug AKJ, Salim MAH, Das PK, Sarker MR, Daru P, Rieder HL (2010) Short, highly effective, and inexpensive standardized treatment of multidrug-resistant tuberculosis. Am J Respir Crit Care Med 182:684–692. https://doi.org/10.1164/rccm.201001-0077OC

Global tuberculosis report 2016 World Health Organization (2016) Geneva. (WHO/HTM/TB/2016.13) http://apps.who.int/medicinedocs/en/d/Js23098en/.Accessed 10 Aug 2018

Hwang TJ, Dotsenko S, Jafarov A, Weyer K, Falzon D, Lunte K, Nunn P, Jaramillo E, Keshavjee S, Wares DF (2014) Safety and availability of clofazimine in the treatment of multidrug and extensively drug-resistant tuberculosis: analysis of published guidance and meta-analysis of cohort studies. BMJ Open 4:e004143. https://doi.org/10.1136/bmjopen-2013-004143

Schmidt AH, Molnár I (2013) Using an innovative Quality-by-Design approach for development of a stability indicating UHPLC method for ebastine in the API and pharmaceutical formulations. J Pharm Biomed Anal 78:65–74. https://doi.org/10.1016/j.jpba.2013.01.032

Kurmi M, Kumar S, Singh B, Singh S (2014) Implementation of design of experiments for optimization of forced degradation conditions and development of a stability-indicating method for furosemide. J Pharm Biomed Anal 96:135–143. https://doi.org/10.1016/j.jpba.2014.03.035

Yadav NK, Raghuvanshi A, Sharma G, Beg S, Katare OP, Nanda S (2015) QbD-based development and validation of a stability-indicating HPLC method for estimating ketoprofen in bulk drug and proniosomal vesicular system. J Chromatogr Sci 54:377–389. https://doi.org/10.1093/chromsci/bmv151

Sandhu PS, Beg S, Katare OP, Singh B (2016) QbD-driven development and validation of a HPLC method for estimation of tamoxifen citrate with improved performance. J Chromatogr Sci 54:1373–1384. https://doi.org/10.1093/chromsci/bmw090

Garg LK, Reddy VS, Sait SS, Krishnamurthy T, Vali ST, Reddy AM (2013) Quality by design: design of experiments approach prior to the validation of a stability-indicating HPLC method for montelukast. Chromatographia 76:1697–1706

Wingert NR, Ellwanger JB, Bueno LM, Gobetti C, Garcia CV, Steppe M, Schapoval EE (2018) Application of Quality by Design to optimize a stability-indicating LC method for the determination of ticagrelor and its impurities. Eur J Pharm Sci 118:208–215. https://doi.org/10.1016/j.ejps.2018.03.029

Sharma T, Khurana RK, Jain A, Katare OP, Singh B (2018) Development of a validated liquid chromatographic method for quantification of sorafenib tosylate in the presence of stress-induced degradation products and in biological matrix employing analytical quality by design approach. Biomed Chromatogr 32:e4169. https://doi.org/10.1002/bmc.4169

Khedekar G, Mirgane S (2017) Development and validation of stability indicating HPLC assay method for Clofazimine capsules. IPP 5:112–120

Patel HA, Patel KG, Pathak DS, Patel DJ, Meshram DB (2017) Development and validation of stability indicating RP-HPLC method for estimation of clofazimine in soft gelatine capsule. Int J Pharm Qual Assur 8:32–38

International Conference on Harmonization (ICH) (2005) ICH Harmonised tripartite guideline: Validation of analytical procedures: text and methodology Q2 (R1)

International conference on harmonization (ICH) (1996) Guidance for industry: Q1B photostability testing of new drug substances and products

Singh S, Junwal M, Modhe G, Tiwari H, Kurmi M, Parashar N, Sidduri P (2013) Forced degradation studies to assess the stability of drugs and products. Trends Analyt Chem 49:71–88. https://doi.org/10.1016/j.trac.2013.05.006

Dong MW (2006) Modern HPLC for practicing scientists. Wiley, New Jersey

Acknowledgements

Authors are grateful to Chancellor, NMIMS (Deemed-to-be University) and management of SVKM’s NMIMS, School of Pharmacy and Technology Management, Shirpur for providing various reprographic sources for implementing this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Authors declare no conflict of interest.

Ethical standards

The present work is in compliance with ethical standards.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Suppl. Figure 1

Ishikawa fish-bone diagram depicting the possible risk factors for the development of HPLC method (PPTX 71 KB)

Suppl. Figure 2 (a-b)

Chromatograms of CFZ standard solution with different solvents (Organic modifiers) (a) acetonitrile and (b) Methanol (PPTX 225 KB)

Suppl. Figure 3

Overlay plot depicting the optimized conditions of the analytical method (PPTX 143 KB)

Suppl. Figure 4 (a-b)

Chromatograms of CFZ from (a) standard solution and (b) sample extracted from marketed soft gelatin capsule (PPTX 141 KB)

Rights and permissions

About this article

Cite this article

Patil, T.S., Deshpande, A.S. Development of an Innovative Quality by Design (QbD) Based Stability-Indicating HPLC Method and its Validation for Clofazimine from its Bulk and Pharmaceutical Dosage Forms. Chromatographia 82, 579–590 (2019). https://doi.org/10.1007/s10337-018-3660-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10337-018-3660-8