Abstract

Sunflower agriculture is an important subsector that plays a key role in the economy of Turkey, contributing 1.38 million tonnes. The aim of this study is to investigate the levels of imidazolinone (IMI) group herbicides in Thrace Region, Turkey. In particular, we aimed to determine the residue levels of imazamox, a herbicide used in sunflower production in Thrace Region, in soil, different parts of plant, and seed. Five herbicides were identified in sunflower samples using solid–liquid extraction with gas chromatography–electrospray ionization mass spectrometry (GC–EI–MS) on single-quadruple instruments in selected ion monitoring (SIM) mode. The optimized conditions were found to be mobile-phase flow rate of 1 mL min−1 and injection volume of 3 μL in programmed temperature vaporization (PTV) solvent vent mode. The recovery of imazamox, imazaquin, imazethapyr, imazapyr, and imazapic from sunflower plant and soil was 89 and 99, 104 and 105, 92 and 93, 96 and 92, and 99 and 96%, respectively.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The number of live macro and micro pests that damage agricultural products is currently estimated to be approximately 65,000–70,000, resulting in product loss of between 15 and 30%. Use of pesticides is considered an essential input in modern agriculture, having both disadvantages and advantages in terms of human health and environmental pollution [1]. Imidazolinone (IMI) herbicides have low toxicity to humans, representing an alternative to phenoxy herbicides (such as atrazine group herbicides, especially triazine herbicide) [2,3,4].

Herbicides of the IMI group are generally amphoteric chemically. Their structure comprises the pyridine group with carboxylic acid and basic functionality. They are weakly acidic compounds that may occur in cationic, neutral, or anionic form [5, 6]. At pH above 6, these compounds are weakly adsorbed in soil [5], whereas at low soil pH, they are strongly adsorbed due to their lack of strong ionic nature [6].

IMIs represent a relatively new class of herbicides that can be used either pre- or postemergence to control a wide range of weeds in broadleaf and cereal crops, as well as in noncrop situations. In addition, IMI herbicides can be used with IMI-tolerant crops (e.g., the Clearfield® system) [7, 8]. The herbicide-tolerant Clearfield® system has been applied for sunflower in the USA, Argentina, and Turkey since 2003 and is drawing increasing attention.

Briefly, as modern crop protection compounds, IMI group herbicides are only used in agriculture. Imazamox, imazaquin, imazethapyr, imazapic, and imazapyr are representative members of the IMI family of herbicides; their structural formulas are shown in Fig. 1. IMI herbicides are used to inhibit weed growth in total vegetation control areas such as legume, cereal, corn, rice, sunflower, and peanut crops [7, 9,10,11,12,13,14,15]. Approximately 1.38 million tonnes of sunflower are produced on more than 600,000 hectares of land in Turkey, including 650,000 tonnes on more than 281,000 hectares in Thrace Region [16]. According to the EU, the European Food Safety Authority (EFSA), Turkish Food codex, and Health Canada, the maximum residue limit (MRL) of imazamox in sunflower seeds is accepted as 0.05, 0.05, 0.05, and 0.3 mg kg−1, respectively [17, 18].

Furthermore, the effect of clay content on herbicide bioavailability is similar to the effect of organic matter, as the high surface area of clay can increase herbicide sorption and may further reduce herbicide bioavailability [15, 19]. Cationic species adsorb on soil by electrostatic attraction, while anionic molecules can adsorb on positively charged soil colloids, even if adsorption of negative species is less strong than on negatively charged clay surfaces [20]. pH and soil type also affect the bioavailability and degradation of imazamox [21, 22]. Therefore, two soils with different pH and clay content were studied.

Widely used and highly sensitive analytical techniques for determination and quantification of these pesticides at low concentrations in food samples are liquid chromatography (LC)–MS [3, 4, 23, 24], high-performance (HP)LC–diode array detection (DAD) [16, 25], capillary electrophoresis (CE)–MS [26, 27], GC–MS, and GC–electron capture detector (ECD) [28,29,30,31,32,33,34]. GC–MS analysis enables identification and quantification of a compound, as well as providing its identity, molecular structure, molecular weight, and fragmentation pattern [28, 35, 36]. The most widely used extraction techniques for pesticides in plants are solid-phase extraction [26], microwave extraction [37], sonication [38], Soxhlet [39], supercritical fluid extraction [40], and the QuEChERS extraction method [41].

Unprocessed and processed agricultural products such as sunflower and sunflower oil play an important role as exports from Turkey. Therefore, the aim of this study is to determine the residue of IMI herbicides in plant products and products obtained from them. The aim of this study is to determine the concentrations of imidazolinone pesticides (imazamox, imazapyr, imazapic, imazethapyr, and imazaquin) in sunflower by GC–MS, focusing on sunflower cultivated in Thrace Region (Turkey) and related products. In the determination step, conditions such as injection volume, flow rate, and injection mode were optimized to determine the concentration of IMI group pesticides by GC–MS. The optimized conditions were then applied to identify their residue in soil.

Materials and Methods

Materials

The IMI pesticides were analyzed by GC–MS using an Agilent 7890A model and Agilent 5975C MSD system at Kırklareli University. HP-5 MS IU column (30 m × 250 μm × 0.25 μm) was used with pure (99.999%) helium as carrier gas.

Samples were prepared by solid–liquid and liquid–liquid extraction under gentle nitrogen stream (TAB-40 WEL). Standards and samples were prepared using a shaking water bath (model JEOTECH-BS-21).

Standards and Reagents

Standards of imazamox, imazaquin, imazapyr, imazethapyr, and imazapic (99% purity) were purchased from Sigma–Aldrich. All solvents were of HPLC grade (Merck and Sigma-Aldrich), while other chemicals were of analytical reagent grade. Double-distilled water (HPLC grade, 18.2 MΩ) obtained using a purification system (ELGA) was used for all preparations.

Procedures modified from those of Lao and Gan [37] and Anisuzzaman et al. [28] were used for preparation of dimethyl derivatives of standard stock solutions. Standards of imazamox, imazaquin, imazapyr, imazethapyr, and imazapic were subjected to derivatization by dissolving approximately 5 mg in 2 mL acetone solution in a vortex in 50-mL screw-capped falcon centrifuge tubes, adding tetrabutylammonium hydroxide (200 µL, 1 M solution in methanol) and iodomethane (400 µL), followed by heating at 40 °C for 90 min in a shaking water bath at stirring speed of 90 rpm. The mixture was evaporated to dryness at 40 °C under a gentle nitrogen stream. The residue was then added to a mixture of 2 mL ultrapure water and 15 mL diethyl ether:n-hexane (1:2 v:v), and stirred by vortex for 2 min. Water in the standards was removed using 12 g anhydrous sodium sulfate. Pesticide standards were concentrated to dryness using a gentle nitrogen stream, then dissolved in 10 mL hexane and filtered through a 0.45-µm polytetrafluoroethylene (PTFE) syringe filter. The derivatization process obtained yield of 80–95%. Stock standards were prepared at 5000 mg L−1. From these derivatized standards, intermediate stocks of 25 mg L−1 were prepared separately. Then, a mixture of 5 mg L−1 of intermediate stocks was prepared (the chromatogram of the mix is shown in Fig. 1). The GC column was connected without splitting to the ion source of an Agilent 5975C mass spectrometer operating in scan mode in the m/z range of 40 to 400. Standard solutions were prepared by dilution of stock standard solutions to concentration of 500, 250, 100, 50, 25, 10, 5, 1, 0.5, 0.1, and 0.05 µg L−1 for soil and plant in hexane. Standard identification, retention time, quantification, and analysis of each compound were carried out by GC–EI–MS using single-quadrupole instruments in SIM mode. Detection of IMI pesticides was based on retention time and fragmentation products (Table 1).

Optimization of GC–MS for IMI Pesticides

The injector temperature, split flow, and injection volume were examined. To study each parameter, the others were chosen at the optimum value using IMI solutions of 0.1 mg L−1. Standard solutions were studied using fragmentor potential of 70 V for optimization. For optimization of injection volume, volumes in the range from 0.5 to 1 μL were studied in splitless mode, but smooth chromatograms were not obtained. Therefore, we applied large volume injection in programmed temperature vaporization (PTV) solvent vent mode to eliminate excess solvent by vaporization without analyte loss [41]. The target ions and retention time of the standards were determined by one-by-one injection. The best result was obtained at 1.0 mL min−1. All injection parameters were investigated in duplicate during 1 week, using different days for validation. Calibration curves were constructed and analyzed at the start and end of the validation process to ensure that no significant changes had occurred.

The temperature program of the GC oven was as follows: initial temperature of 70 °C with 1-min hold time, then increasing at rate of 10 °C min−1 to 150 °C with 5-min hold time, then increasing at rate of 10 °C min−1 to 280 °C with 2-min hold time. The m/z scan range of 40–400 was used. The maximum oven temperature was set to 300 °C. The front inlet temperature, pressure, and septum purge flow were set to 250 °C, 8.8085 psi, and 3 mL min−1, respectively. Ionization was performed by electron impact at 70 eV, and calibration was performed by autotuning. Solvent delay and all analysis times were set to 20 and 29 min, respectively. The mass selector detector was operated in EI–SIM mode to determine the presence of each analyte (Table 1).

Sample Preparation for Analysis of IMI Herbicides

Sunflowers and corresponding soils from Thrace Region were used as samples in this study. Soils with two different pH/texture features (I and II) were studied, having the following characteristics: pH of 4.74 and 7.28, clay content of 8.33 and 22.92%, silt content of 12.50 and 31.25%, and sand content of 79.17 and 45.83%, respectively. The texture class for soil I and II was Loam and Loam–Sand, respectively [42]. Soil samples were collected at depth of 0–30 and 30–60 cm. For sunflower, we studied leaves, body, and head. Plant samples were transferred to the laboratory in plastic bags, washed with tap water, and rinsed with distilled water. After drying at 35 °C, the samples (plants and soils) were ground using an agate mortar and mixed until homogeneous. Each sample was analyzed at least in quadruplicate, and the mean is reported.

Sample (1.0 g) of soil, leaves, seeds, header, and body of sunflower was mixed by vortex in 2 mL acetone solution. After addition of tetrabutylammonium hydroxide (200 µL, 1 M solution in methanol) and iodomethane (400 µL), heating was applied for 90 min in a 50-mL screw-capped falcon centrifuge tube using a shaking water bath at 40 °C with stirring speed of 90 rpm. The mixture was evaporated to dryness at 40 °C using a gentle nitrogen stream. The residue was then added to a mixture of 2 mL ultrapure water + 15 mL diethyl ether:n-hexane (1:2 v:v) and stirred by vortex for 2 min. Water was removed from the samples using 12 g anhydrous sodium sulfate. Supernatant was concentrated to dryness using a gentle nitrogen stream, then dissolved in 1 mL hexane and filtered using a 0.45-µm PTFE syringe filter. Afterwards, the extractant (3 μL injection volume) was injected for GC–MS.

Quantitation

The method was validated by determining herbicide recoveries from soil and plant samples using the procedure indicated above to determine the precision from a minimum of five replicates and five parallel measurements (i.e., five measurements on each of five extractants prepared from the same sample with the same characteristics) in terms of interday reproducibility. Linearity, precision, accuracy, limit of detection (LOD), limit of quantitation (LOQ), and recovery parameters were determined for each herbicide. The precision of the method is expressed as the standard deviation and % relative standard deviation (RSD) of standard measurements. Precision was measured using a minimum of five determinations (replicates) per concentration. Concentration levels (ranging from low to medium to high) in the expected range were investigated to confirm the accuracy of the measurements. Linearity was evaluated using calibration curves at 0.1, 0.5, 1, 5, 10, 25, 50, 100, 250, and 500 μg L−1 in hexane. The matrix effect was estimated by comparing the slope of curves for matrix blank extract with those obtained from solvent (hexane) curves. An 11-level (1–500 µg L−1 for soil, plant, and parts thereof) calibration series was established, with three analyses at each concentration level to determine linearity. The calibration curve was plotted automatically. The LOD and LOQ were determined as the concentrations resulting in signal-to-noise (S/N) ratio of 3 and 10, respectively, where the signal was taken as the peak weight and the noise corresponds to the baseline near the chromatographic peak of each studied compound [43,44,45]. Recovery rates were determined by adding 50–100–200 µg L−1 concentration standards for soil and plant. The matrices used for recovery studies were locally grown sunflower and soil samples, respectively (Table 2).

Results and Discussion

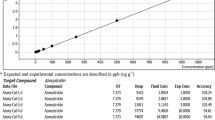

Calibration graphs were established for each herbicide in the range of 1–500 µg L−1, exhibiting correlation coefficient of 0.996 to 0.999 for all analytes. The retention time (RT, min), linear regression (y = ax + b), coefficient of determination (r 2), LOD, LOQ, and % RSD values are presented in Table 1. The linear regression equation obtained from the GC–MS results was applied and used for quantification. The method was validated by determining herbicide recoveries from soil and plant samples using the procedure described above. The LOD for the studied IMI group pesticides ranged from 0.01 to 0.14 µg L−1, while the LOQ ranged from 0.03 to 0.46 µg L−1. The RSD of the migration time of the analytes ranged from 0.5 to 3.5%, indicating good repeatability of the method. The minimum concentration values were determined to be 1 µg L−1 for imazapyr, imazamox, and imazaquin and 5 µg L−1 for imazapic and imazethapyr. The chromatogram, mass spectrum, and calibration graph for each pesticide are shown in Figs. 1, 2, 3, 4 and 5. The minimum concentration for GC–MS analysis of the IMI herbicides in this study reached 40% of that (7 µg L−1) reported by Lao and Gan [37]. The analytes in Table 1 were monitored to determine the most suitable PTV conditions by injecting 1, 2, 3, and 4 μL in PTV solvent vent mode. According to this optimization exercise, the best result was obtained with injection volume of 3 μL. For optimization of the flow rate, the He rate was changed to 0.5, 0.8, 1.0, and 1.5 mL min−1.

The optimized conditions were found to be flow rate of 1 mL min−1, injection volume of 3 μL, and fragmentation potential of 70 V. The initial temperature of the GC oven program was chosen as the boiling temperature (70 °C) of hexane. The method was then applied for determination of IMI pesticides in sunflower and soil samples. For validation purposes, a blank soil sample was selected and various validation parameters evaluated, including linear range (linearity), recovery, precision, and method LOD and LOQ [43,44,45]. The limits of detection (LOQ) and quantitation (LOQ) for imazapyr, imazapic, and imazethapyr are presented in Table 1. The linear dynamic range for imazapyr in the IMI mix standards extended from 1 to 500 µg L−1 using the optimized conditions, with correlation coefficient of 0.996. The linear dynamic range for imazapic in the IMI mix standards extended from 1 to 500 µg L−1 using the optimized conditions, with correlation coefficient of 0.996. The linear dynamic range for imazethapyr in the IMI mix standards extended from 5 to 500 µg L−1 using the optimized conditions, with correlation coefficient of 0.997.

Likewise, the LOD for imazamox and imazaquin was 0.01 and 0.03 µg L−1, with LOQ values of 0.02 and 0.06 µg L−1, respectively. The linear dynamic range for imazamox and imazaquin in the IMI mix standards extended from 1 to 500 µg L−1 using the optimized conditions, with correlation coefficient of 0.999 and 0.996, respectively.

The next experiment used sunflower plant, with the trial being carried out in four replications for the study area. The pH of the studied soils I and II was 4.74 and 7.28, while their clay content was 8.33 and 22.92%, respectively. The recovery rates were determined and employed to characterize the accuracy by adding 50–100–200 µg L−1 concentration standards to soil and plant samples. The recovery and precision were studied for five replicates of each spiked concentration. In total, 25 individual recoveries were measured; the results are summarized in Table 2. The obtained recoveries of the IMI herbicides ranged from 76 to 105% of the theoretical concentration for the evaluated compounds. RSD % values of less than 3.5% for replicates were obtained for intraday (repeatability) and interday (intermediate) precision. Imazethapyr and imazaquin were not detected in seeds, soil, or sunflower parts, whereas imazapyr, imazapic, and imazamox were detected. The concentrations of imazapyr, imazapic, and imazamox found in sunflower seed were 2.76, 5.42, and 15.2 µg kg−1, respectively. The maximum concentration of imazapyr and imazapic in leaf of sunflower grown in soil I was found to be 25.5 and 29.3 µg kg−1, respectively, versus 21.2 and 38.2 µg kg−1 for soil II. The maximum concentrations of imazamox in body, leaf, and header of sunflower grown in soil I were found to be 74.2, 105, and 151 µg kg−1, respectively, versus 70.4, 51.9, and 169 µg kg−1 for soil II (Table 3).

The concentration of imazamox in acidic soil was found to range from 29.8 to 58.0 µg kg−1. In general, the imazamox residue was about 1.5 times lower in neutral compared with acidic soil. The concentration of imazamox decreased about 0.7-fold with increasing soil depth (Table 3). The imazamox concentration accumulated in header of sunflower grown in acidic soil was higher than when grown in neutral soil. It is believed that the cause is related to the clay content of the soil [16, 41].

As for any organic molecule released into the environment, transport of herbicides is determined by their chemical–physical characteristics. Adsorption on clays or organic matter may occur via the following interactions: hydrogen bonding, van der Waals forces, dipole–dipole interactions, ionic exchange, covalent bonding, protonation, ligand exchange, H2O effect, and hydrophobic interactions [20]. However, Laganá et al. indicated that the organic matter content does not have a major influence on the determination of IMIs [46].

In Australian barley trials, residues of imazamox in grain were <0.01 mg kg−1 (n = 4) after application at 25–50 g ai ha−1 (1–2-fold the proposed maximum rate). Residues in wheat grain in Australia after imazamox applications of 25–50 g ai ha−1 (1–2×) were <0.01 mg kg−1 (n = 6). Residues in wheat grain in Canada after imazamox applications of 20–41 g ai ha−1 (0.8–1.7×) were <0.05 mg kg−1 (n = 10). An MRL of 0.05 mg kg−1 is recommended for imazamox in barley, in line with that previously recommended for wheat [18, 47].

Moreover, the Codex Alimentarius and legislation of different countries (e.g., USA, China, and India) have commonly set maximum residue limits (MRLs) for cereal products, while European Union (EU) countries have recently harmonized their MRLs on food and feed, including cereals [30]. Turkey has also begun to implement new policies. Pesticide-residue monitoring programs, which often emphasize raw agricultural products, are the only tool to control the type and quantity of herbicides in food and apply limits.

Conclusions

We describe the development and validation of a more sensitive and reliable method for identification and quantitation of IMI herbicides in sunflower plant and seeds and corresponding soil using GC–MS. The linearity, precision, accuracy, and repeatability of the method were validated by studying recoveries. The LOD and LOQ were found to be 0.01–0.14 and 0.03–0.46 µg L−1. The optimized conditions were found to be He flow rate of 1 mL min−1 and injection volume of 3 μL in PTV splitless mode. Field samples of soil, plants, and sunflower seeds were analyzed for imazamox and its derivatives. In a second field experiment, the residues of imazamox and its derivatives in soil, plants, and seeds were investigated. The results showed that residual herbicides were present in cultivated seeds. Furthermore, the soil with almost neutral pH and high clay content showed higher imazamox residue than the soil with acidic pH. Consequently, we conclude that the residual imazamox concentration in sunflower depends on soil properties. The results obtained are lower than those in literature. Moreover, this is the first detailed study of imazamox accumulation in sunflower samples from Thrace Region. These results will contribute to food safety regarding herbicide application and may demonstrate the need to establish pesticide-residue monitoring programs for analysis of sunflowers for human consumption to improve food safety and decrease exposure risks to consumers.

References

Galon L, Lima AM, Guimarães S, Belarmino JG, Burg GM, Concenço G, Bastiani MO, Beutler AN, Zandona RR, Radünz AL (2014) Potential of plant species for bioremediation of soils applied with imidazolinone herbicides. Planta Daninha 32:719

Pintado S, Montoya MR, Rodrıguez Mellado JM (2011) Imidazolinone herbicides in strongly acidic media: speciation and electroreduction. CR Chim 14:957

Oliver DP, Kookana RS, Miller RB, Correll RL (2016) Comparative environmental impact assessment of herbicides used on genetically modified and non-genetically modified herbicide-tolerant canola crops using two risk indicators. Sci Total Environ 557–558:754

Denga H, Fenga D, Hec J, Li F, Yub H, Ge C (2017) Influence of biochar amendments to soil on the mobility of atrazine using sorption–desorption and soil thin-layer chromatography. Ecol Eng 99:381

Martins GL, Friggi CA, Prestes OD, Vicari MC, Friggi DA, Adaime MB, Zanella R (2014) Simultaneous LC–MS/MS determination of imidazolinone herbicides together with other multiclass pesticide residues in soil. Clean Soil Air Water 10:1441

Kemmerich M, Bernardi G, Adaime MB, Zanella R, Prestes OD (2015) A simple and efficient method for imidazolinone herbicides determination in soil by ultra-high performance liquid chromatography–tandem mass spectrometry. J Chromatogr A 1412:82

Tan S, Evans RR, Dahmer ML, Singh BK, Shaner DL (2005) Imidazolinone-tolerant crops: history, current status and future. Pest Manag Sci 61:246

Sala CA, Bulos M, Altieri E, Weston B (2012) Response to imazapyr and dominance relationships of two imidazolinone-tolerant alleles at the Ahasl1 locus of sunflower. Theor Appl Genet 124:385

Hekmat S, Soltani N, Shropshire C, Sikkema PH (2008) Effect of imazamox plus bentazon on dry bean (Phaseolus vulgaris L.). Crop Protect 27:1491

Kaloumenos NS, Capote N, Aguado A, Eleftherohorinos IG (2013) Red rice (Oryza sativa) cross-resistance to imidazolinone herbicides used in resistant rice cultivars grown in northern Greece. Pestic Biochem Physiol 105:177

Beckie HJ, Tardif FJ (2012) Herbicide cross resistance in weeds. Crop Protect 35:15

Vigueira CC, Olsen KM, Caicedo AL (2013) The red queen in the corn: agricultural weeds as models of rapid adaptive evolution. Heredity 110:303

Délye C, Jasieniuk M, Le Corre V (2013) Deciphering the evolution of herbicide resistance in weeds. Trends Genet 29:649

Pfenning M, Palfay G, Guillet T (2008) The Clearfield® technology—a new broad-spectrum post-emergence weed control system for European sunflower growers. J Plant Dis Protect 21:649

Guan AY, Liu CL, Sun XF, Xie Y, Wang MA (2016) Discovery of pyridine-based agrochemicals by using intermediate derivatization methods. Bioorg Med Chem 24:342

Anonymous (2015) Oilseeds and products Annual_Ankara_Turkey_3-13-2015. In: Gain report number TR5013

EFSA (2013) European Food Safety Authority, Reasoned opinion on the review of the existing maximum residue levels (MRLs) for imazamox according to article 12 of regulation (EC) No. 396/2005. Eur Food Saf Auth J 11(6):3282. doi:10.2903/j.efsa.2013.3282

Anonymous (2011). Health Canada, Consumer Product Safety, EMRL2011-70 (30 Nov 2011)

Bresnahan GA, Koskinen WC, Dexter AG, Lueschen WE (2000) Influence of soil pH—sorption interactions on imazethapyr carry-over. J Agric Food Chem 48:1929

Braschi I, Gessa CE, Blasioli S (2011) The fate of herbicides in soil, chap 8. ISBN 978-953-307-476-4. Published 8 Jan 2011

Ball DA, Yenish JP, Alby T (2003) Effect of imazamox soil persistence on dryland rotational crops. Weed Technol 17:161

Pintado S, Montoya MR, Mellado JMR (2009) Protonation-dissociation reactions of imazamethabenz-methyl and imazamethabenz-acid in relation to their soil sorption and abiotic degradation. J Agric Food Chem 57:11292

Anastassiades M, Lehotay SJ, Stajnbaher D, Schenck FJ (2003) Fast and easy multiresidue method employing acetonitrile extraction/partitioning and “dispersive solid-phase extraction” for the determination of pesticide residues in produce. J AOAC Int 86:412

Krynitsky AJ, Stout SJ, Nejad H, Cavalier TC (1999) Multiresidue determination and confirmation of imidazolinone herbicides in soil by high-performance liquid chromatography/electrospray ionization mass spectrometry. J AOAC Int 82:956

Ramezani M, Simpson N, Oliver D, Kookana R, Gill G, Preston C (2009) Improved extraction and clean-up of IMI herbicides from soil solutions using different solid-phase sorbents. J Chromatogr A 1216:5092

Safarpour H, Asiaie R, Katz S (2004) Quantitative analysis of imazamox herbicide in environmental water samples by capillary electrophoresis electrospray ionization mass spectrometry. J Chromatogr A 1036:217

Hernández-Borges J, Borges-Miquel TM, Rodríguez-Delgado MA, Cifuentes A (2007) Sample treatments prior to capillary electrophoresis–mass spectrometry. J Chromatogr A 1153:214

Anisuzzaman AKM, Amin M, Ogg N, Hoq F, Kanithi MR, Jenkins RE (2000) Synthesis of dimethyl derivatives of imidazolinone herbicides: their use in efficient gas chromatographic methods for the determination of these herbicides. J Agric Food Chem 48:5893

Ozcan C (2015) Pollution evaluation of organochlorine pesticides and heavy metals from cheese samples in Kirklareli, Turkey. J Food Agric Environ 13:70

Clement RE, Yang PW, Koester CJ (2001) Environmental analysis. Anal Chem 73:2761

Ozcan C, Dilgin Y, Yaman M (2012) Determination of quercetin in medicinal plants such as rose hip (Rosa canina), bettle (Urtica dioica), terebinth (Terebinthina chica) and purslane (Portulace oleracea) using HPLC–MS method. Asian J Chem 24:3396

Ozcan C, Yaman M (2013) Determination of kaempferol in Rosa canina, Urtica dioica, Terebinthina chica and Portulace oleracea by HPLC–MS. Asian J Chem 25:9758

Ozcan C, Yaman M (2015) Determination of myricetin in medicinal plants by high-performance liquid chromatography. Instrum Sci Technol 43:44

Taskın ÖS, Aksu A, Balkıs N (2011) Metal (Al, Fe, Mn and Cu) distributions and origins of polycyclic aromatic hydrocarbons (PAHs) in the surface sediments of the Marmara Sea and the coast of Istanbul, Turkey. Mar Pollut Bull 62:2568

González-Curbelo MA, Herrera-Herrera AV, Ravelo-Pérez LM, Hernández-Borges J (2012) Sample-preparation methods for pesticide-residue analysis in cereals and derivatives. TrAC Trends Anal Chem 38:32

Lao W, Gan J (2006) High-performance liquid chromatographic separation of imidazolinone herbicide enantiomers and their methyl derivatives on polysaccharide-coated chiral stationary phases. J Chromatogr A 1117:184

Mao X, Wan Y, Yan A, Shen M, Wei Y (2012) Simultaneous determination of organophosphorus, organochlorine, pyrethriod and carbamate pesticides in Radix astragali by microwave-assisted extraction/dispersive-solid phase extraction coupled with GC–MS. Talanta 97:131

Luzardo OP, Almeida-González M, Ruiz-Suárez N, Zumbado M, Henríquez-Hernández LA, Meilán MJ, Camacho M, Boad LD (2015) Validated analytical methodology for the simultaneous determination of a wide range of pesticides in human blood using GC–MS/MS and LC–ESI/MS/MS and its application in two poisoning cases. Sci Justice 55:307

Dong R, Lee C (1999) Determination of organochlorine pesticide residues in foods using solid-phase extraction clean-up cartridges. Analyst 124:1284

Lehotay SJ, Eller KI (1995) Development of a method of analysis for 46 pesticides in fruits and vegetables by supercritical fluid extraction and gas chromatography/ion trap mass spectrometry. J AOAC Int 78:821

Gómez-Ruiz JÁ, Cordeiro F, López P, Wenzl T (2009) Optimisation and validation of programmed temperature vaporization (PTV) injection in solvent vent mode for the analysis of the 15 + 1 EU-priority PAHs by GC–MS. Talanta 80:643

Bahtiyar M (1996) Toprak Fiziği. Trakya Üniversitesi, Tekirdağ Ziraat Fakültesi, Tekirdağ

Olivieri AC, Faber NM, Ferré J, Boqué R, Kalivas JH, Mark HD (2006) Uncertainty estimation and figures of merit for multivariate calibration (IUPAC technical report). Int Union Pure Appl Chem 73(3):633

Rambla-Alegre M, Esteve-Romero J, Carda-Broch S (2012) Is it really necessary to validate an analytical method or not? That is the question. J Chromatogr A 1232:101

Harris CD (2015) Quantitative chemical analysis, 8th edn. Turker AR (ISBN 978-1-4292-1815-3) (Turkish language edition published by Palme Yayincilik 2015)

Laganá A, Fago G, Marino A, Penazzi VM (2000) Liquid chromatography mass spectrometry tandem for multiresidue determination of selected post-emergence herbicides after soil column extraction. Anal Chim Acta 415:41

NRA (2000) Evaluation of the new active Imazamox in the products. National Registration Authority for Agricultural and Veterinary Chemicals, Canberra (ISSN 1443-1335)

Acknowledgements

This study was financially supported by the TUBITAK-CAYDAG Research Foundation (Project No. PGR_113Y529).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Human rights and participants

This article does not contain any studies with human participants or animals performed by any of the authors.

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Ozcan, C., Cebi, U.K., Gurbuz, M.A. et al. Residue Analysis and Determination of IMI Herbicides in Sunflower and Soil by GC–MS. Chromatographia 80, 941–950 (2017). https://doi.org/10.1007/s10337-017-3307-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10337-017-3307-1