Abstract

The field of separation science has recently witnessed an explosion of interest and progress in the design and study of porous polymer monolithic materials. Monolithic columns with their unique structure possess some exceptional characteristics, which make them an excellent tool in the hands of analytical chemists, not only for separation but also for sample pretreatment. As a new member of the polymer monolith family, the micro/nanomaterial-functionalized polymer monolith has attracted considerable attention due to its many distinct characteristics, such as high permeability and selectively tailored surface chemistries. It exhibits great potential in separation science and analytical sample preparation. This review summarizes and highlights recent major advances of the micro/nanomaterial-functionalized polymer monolith, focusing on design considerations and the application of separation and enrichment. A brief overview of the properties of polymer monolithic columns is included, and then specific attention is paid to discuss the methods of fabrication and application of the micro/nanomaterial-functionalized polymer monolith in separation, sample pretreatment and enrichment, and highly sensitive detection. Finally, future possible research directions and challenges in the field are discussed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Monolithic columns are a continuous piece of macroporous material usually created by the in situ polymerization of monomers [1, 2]. Monolithic columns can be divided into two categories: silica-based monolithic columns and polymer-based monolithic columns [3].

Porous polymer monolithic columns were successfully developed in the late 1980s and the early 1990s by several pioneers working in this field, including Hjertén et al. [4, 5], and Fréchet and Svec [1, 6, 7]. This alternative format of a stationary phase, which differs from packed bed of non-porous adsorbent particles, has been presented as being best suited for the fast gradient elution of proteins. The best known advantages they present are their large through pores and easy preparation since they can be prepared in a single step from a homogeneous polymerization mixture containing monomers (a particular functional group and a crosslinking monomer), porogenic mixture, and a radical initiator which initiates the polymerization reaction. Monolithic materials are remarkably versatile as they can be readily prepared with different pore sizes, varying porosity, and a wide variety of chemical functionalities through the control of precursors and chemistry during polymerization. This variety is well covered in several comprehensive reviews [8–10]. Polymeric monoliths, which show fast convective mass transfer between the monolith bed and the surrounding solution, have already become important materials in separation science, sample enrichment, and bio-catalysis [11, 12].

Due to the wide variety of potential applications of monoliths, it is desirable to explore new efficient approaches enabling their functionalization. Conventional functionalization can be classified into two strategies: (1) copolymerization of functional monomers [13, 14] and (2) post-polymerization functionalization [15]. In both cases, the resulting functionalities depend on the structure and properties of functional monomers. Micro/nanomaterials have attracted extensive attention in various fields of chemistry, physics, materials, medicine, and optics [16, 17], due to their unique physical and chemical properties relative to the bulk material. Now, the research has been devoted to the application of micro/nanomaterials in separation science [18–21]. Micro/nanomaterials have been used in the preparation of polymer monolithic columns to provide surface functionalization [15, 22–24]. If monoliths are modified with micro/nanomaterials, it is possible to obtain new materials simultaneously possessing the unique properties of micro/nanomaterials (high specific surface area) and monolithic column (high porosity and diverse surface chemistry) through combining their individual characteristics, which will provide good opportunities for applications in the field of chromatography, electrocatalysis, and sample pretreatment. Therefore, micro/nanomaterial-functionalized porous polymer monoliths have recently sparked much research interest. Several studies show that they hold great potential for achieving efficient separations of small molecules [25, 26].

There has been a review focused on the applications of nanomaterial-modified porous polymer monoliths in bioanalysis [27]. The present review article specifically summarizes the design considerations of micro/nanomaterial-functionalized porous polymer monoliths and their applications in separation, sample pretreatment and enrichment, and highly sensitive detection. In addition, representing a number of papers published in journals that are typically below the radar screen of chromatographers, the following text may also inspire them.

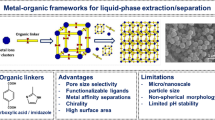

Micro/Nanomaterial-Functionalized Porous Polymer Monoliths

The use of micro/nanomaterials in analytical chemistry with their unique size-related physical and chemical properties was first suggested almost 30 years ago [28]. However, implementation of their use in electrophoretic and chromatographic separation techniques lags behind the rapid development of nanotechnologies, despite the numerous advantages of nanomaterials. The utility and exploitation of nanomaterials are one of the most exciting areas in analytical chemistry or specific areas in analytical science, such as in electrochemical sensors and biosensors [29, 30], photonics and applications in diagnostics [31], and sample pretreatment [21, 32]. As a result of the unique characteristics of nanomaterials, the use of nanomaterials in separation science, especially in polymer monoliths, is growing rapidly [23]. As a new member of the polymer monolith family, Micro/nanomaterial-functionalized porous polymer monoliths with specific chemical properties are one of important contributions to separation science. These novel monolithic materials have fascinated the chromatographers.

Two general methods have been used to functionalize polymer monolith with micro/nanomaterials [33]. The first approach is entrapment of micro/nanomaterials in the porous polymer matrix. In a typical entrapment method [22], micro/nanomaterials were dispersed and mixed with the porogen. Monomer, cross-linker, porogens containing pretreated single-wall carbon nanotubes (SWCNTs), and the polymerization initiator were mixed ultrasonically into a homogeneous solution. The solution was then filled into a capillary to prepare the monolithic column.

The second approach comprises attachment of micro/nanomaterial to the pore surface of monoliths using specific interactions. In this method, the unmodified monolithic column was commonly firstly prepared with monomer, cross-linker, porogen, and initiator. Micro/nanomaterials were dispersed and pumped through the monolith to prepare with covalent bonds, electrostatic interactions, or hydrogen bonds [24, 34, 35]. For instance, a polymerization mixture consisting of butyl methacrylate, ethylene dimethacrylate, 2-acrylamido-2-methyl-1-propanesulfonic acid, and 2,2′-azobis(2-methylpropionitrile) dissolved in a mixture of 1,4-butanediol with 1-propanol and water was pushed through the capillary to prepare the parent monolith. Latex particles suspended in dimethylformamide were subsequently pumped through the monolith for the goal of functionalization [34].

Entrapment of Micro/nanomaterials in Monolith

Carbon Nanomaterials

Entrapment of nanoparticles into the porous polymer monolith is one of the important approaches to modify monoliths. In 2005, Li et al. [22] first used this approach for the preparation of SWNTs-incorporated poly(vinylbenzyl chloride-co-ethylene glycol dimethacrylate) [poly(VBC-co-EGDMA)] monolithic column for use in micro-high-performance liquid chromatography (μ-HPLC) and capillary electrochromatography (CEC). In order to prepare well-dispersed SWNTs, an acid oxidative method was developed. The result indicated that incorporation of SWNTs enhanced chromatographic retention of small neutral molecules in reversed-phase HPLC presumably because of their strong hydrophobic characteristics. Small increases in mesopore size and electrokinetic porosity were observed (~3 and ~11 %, respectively). However, the surface area was significantly increased (28 %) by incorporation of SWNTs. Comparison of peptide separations on poly(VBC-EDMA-SWNT) and on poly(VBC-EDMA) with annular EOF generation revealed that the incorporation of SWNTs into the monolithic stationary phase improved peak efficiency and influenced chromatographic retention. Similarly, Chambers et al. [25] incorporated multi-walled carbon nanotubes (MWNTs) into a polymethacrylate monolith for achieving separations of small molecules. Although aggregation and sedimentation of pristine MWNTs often occurred because of hydrophobic nature, a homogeneous black mixture was obtained when pristine MWNTs were directly added to polymerization mixture. The authors explained that the surfactant-like properties of the porogens (1-dodecanol and cyclohexanol) enable homogeneous dispersion of the MWNT in the polymerization mixture prior to its polymerization. The results demonstrated that both retention time of the analytes and column efficiency of the prepared column were significantly increased. A maximum column efficiency of 35,000 plates/m was achieved, which was much higher than that of the parent monolithic column, 1,800 plates/m. However, the time required for the separation of the targets was increased to greater than 1 h.

C60-fullerene has a completely sp 2-hybridized zero-dimensional structure, analogous to that of carbon nanotubes. In contrast to CNT, C60-fullerene can be made free of metal impurities and it is a well-defined, discrete, monodispersed molecule. Chambers et al. [14] incorporated C60-fullerenes into a polymethacrylate monolith through the copolymerization of standard monomers with a new synthesized C60 moiety-bearing monomer, i.e., [6,6]-phenyl-C61-butyric acid 2-hydroxyethyl methacrylate ester (PCB-HEM). The resulting butylmethacrylate monolith provided more than 110,000 plates/m for benzene at a linear velocity of 0.32 mm/s and a retention factor of 4.2.

Graphene (GN), a two-dimensional atom-thick sheet of sp 2-conjugated carbon network, has gained significant interest in various fields and has generated huge impact in the materials research community since its discovery in 2004 [36]. Due to its ultrahigh specific surface area and π-electron rich structure, GN is emerging as a promising chromatographic material [37]. Tong et al. [38] embedded GN in a poly(butyl methacrylate-co-ethylene glycol dimethacrylate) [poly(BMA-co-EGDMA)] monolith for the enrichment of glucocorticoids. A stable GN dispersion was obtained by surface modification of graphene by polyvinylpyrrolidone (PVP), thereby enabling graphene to be uniformly embedded in the monolithic column. The resultant modified monolithic column exhibited an improvement in enrichment capacity as compared with one without graphene. Graphene oxide (GO) that is a chemically modified GN nanosheet contains a range of reactive oxygen functional groups on the basal planes and edges [39]. Wang and Yan [26] prepared a GO-incorporated poly(methacrylic acid-co-EGDMA) poly(GO-MAA-EGDMA) monolithic column via one-step room temperature polymerization for CEC. The presence of functional groups in GO sheets improved their dispersibility in various solutions, thus providing convenience for the fabrication of monolithic materials. The result revealed that incorporation of GO into monolithic column significantly improved the CEC separation of the neutral analytes.

Metal and Metal Oxide Nanoparticles

A similar approach to that just described above was adopted by Hsieh et al. [40] to encapsulate TiO2 nanoparticles (10–20 nm) within an EGDMA-based monolithic pipette tip for efficient enrichment of phosphopeptides. Similarly, Rainer et al. [41] reported the encapsulation of TiO2, ZrO2, or a mixture of TiO2 and ZrO2 nanoparticles into a poly(divinylbenzene) (DVB)-based monolithic bed as extraction tips in order to increase the enrichment capacity for phosphorylated peptides. For pure poly(DVB) monolith, a total porosity of 46 % and an average pore radius of 12 nm were determined. In case of nanoparticle-embedded monoliths, the average pore radius increased to 52 nm, whereas the total porosity decreased by 5 to 7 %. The specific surface area was highest for pure poly(DVB) (53.6 m2/g) and decreased to almost the half by doping the monolith with nanopowders. Tobal et al. [42] prepared and used Ni-Co nanoparticle-incorporated polymer monolithic columns to enrich β-casein tryptic peptides. These reports demonstrated excellent performance of nanomaterial-functionalized porous polymer monoliths on efficient enrichment of phosphopeptides, indicating that the monoliths are promising for practical applications of proteins and peptides’ purification.

Yao et al. [43] made an acrylamide-based cryogel with incorporated surfactant-stabilized Fe3O4 nanoparticles. Compared with other reported cryogel beds in literature, the protein adsorption capacity of the cryogel bed was improved due to the embedded nano-sized solid adsorbents in the gel matrix.

Surface enhanced Raman scattering (SERS)-active monolithic column with more stable performance was achieved by Dubinsky et al. [44, 45]. They carried out the preparation of macroporous hybrid polymers embedded with gold nanorods. Such materials are very useful for SERS-based sensing or the synthesis catalyzed by gold nanoparticles. Multifunctional polymer-based porous hybrid materials carrying gold nanorods through polymerization-induced phase separation were reviewed by Lee et al. [46]. They reported the potential of nanomaterial-modified porous monoliths in SERS detection.

Li et al. [47] described the preparation of γ-alumina nanoparticle-embedded polyacrylamide monoliths. The authors then applied the monoliths to polymer monolith microextraction (PMME) of synthetic food dyes coupled with HPLC. It is worth noting that Zajickova et al. [48] developed a sol–gel method enabling the in situ preparation of porous alumina monoliths within 100 μm i.d. fused silica capillaries. The effects of varying the preparation conditions on the physical characteristics of monoliths were investigated. These monolithic columns enable separation of phosphorylated adenosines under isocratic conditions. This alumina monolith can be ultimately applied towards assessing ATP activity of proteins and phosphorylation of proteins.

Other Inorganic Nanoparticles

Besides carbon nanomaterials and metallic nanoparticles, other inorganic nanoparticles were also incorporated into the polymer monolithic column to improve the separation efficiency and enrichment capacity of monoliths. Hydroxyapatite, a crystalline form of calcium phosphate with the structural formula of Ca10(PO4)6(OH)2, was successfully applied to the purification and separation of proteins and nucleic acids as a chromatographic medium. Krenkova et al. [33] incorporated these commercially available rodlike nanoparticles into a poly(2-hydroxyethyl methacrylate-co-EGDMA) [poly(HEMA-co-EGDMA)] monolith by encapsulation. The SEM and nitrogen adsorption/desorption analysis confirmed uniformity of the hydroxyapatite rodlike nanoparticles with an average size of 50 × 150 nm and a surface area of 100 m2/g. The authors used this monolith for the separation of a model mixture of proteins and the selective enrichment of phosphopeptides.

Xu et al. [49] prepared SiO2 nanoparticles (7–40 nm) embedded-acrylamide cryogel monoliths by copolymerization. The protein adsorption capacity of the modified cryogel column was measured at different flow velocities.

Micromaterials

Jandera et al. [50] prepared the hybrid particle-monolithic capillary by in situ polymerization in capillary packed with porous spherical beds (bare silica or bonded C18 ligands), 37–50 μm. Fabrication of hybrid interparticle monolithic capillary columns aimed at fast gradient separation of proteins. The retention behavior of proteins on all prepared columns is consistent with the reversed-phase gradient elution theory. Hybrid interparticle capillary monolithic columns show improved hydrodynamic flow properties with respect to whole-volume monolithic capillary columns prepared using the same polymerization mixture. This is due to a higher “equivalent permeability particle diameter” and enables shorter separation times of proteins. In 2010, the author used a similar method to prepare the hybrid particle-monolithic polymethacrylate columns in fused silica capillaries pre-packed with 3–5 μm C18 and aminopropyl silica bonded particles for μ-HPLC of the reversed-phase mode and hydrophilic interaction mode [51]. The result showed that the separation efficiency of the hybrid capillary columns was generally in between the packed and monolithic columns. The properties of the hybrid columns were still not at optimum, however, the work seemed encouraging and showed that the efficiency and permeability were good enough to allow separation times and resolution comparable or even better than with packed capillary columns.

Fan et al. [52] reported new application of polymer monolithic columns, which act as collection devices for sampling neuropeptide release. They prepared micro-particle-embedded polymer monolithic capillaries as sample pretreatment tools for analyzing single-neuron release by MALDI-TOF MS. Pyrrolidone (PY) or ethylenediamine (EDA) particles with an average size of 30 μm were chosen as extraction particles to enable the collection of a wide range of neuropeptides. The successful collection of releasates from single neurons isolated from A. californica with cell sizes demonstrated the effectiveness of this approach.

From the examples given in Table 1, it is clear that micro/nanomaterial-incorporated organic monolithic columns have been widely used for μ-HPLC, CEC, SERS, sample pretreatment and enrichment.

Attachment of Micro/Nanomaterials to Monolith Surface

Latex Nanoparticles

Another option for the functionalization of monoliths is the attachment of nanoparticles to the monolith surface [8]. Hilder et al. [34] firstly described the preparation of a polystyrene latex nanoparticle-modified monolith and used the column for the separation of saccharides. In their work, latex particles were functionalized with tertiary amine groups via reaction with iodomethane. The surface area increased from 35.2 to 47.3 m2/g after coating the monolith with the latex beads. The back pressure in the column grew from 2.6 to 5.7 MPa at a flow rate of 5 μL/min, indicating that the layer of latex particles decreased the pore size. Haddad and co-workers significantly extended the application of the latex-coated polymer monolith with the preparation of columns for ion chromatography (IC) and CEC [53–56]. Latex particles with quaternary ammonium functionalities were also employed to coat the monolith [53]. Table 2 listed examples of attachment of nanoparticles to the pore surface of polymer monolithic column, which are available at the time of this writing.

Gold Nanoparticles

Gold nanoparticles hold promise for uses as advanced materials in several fields of catalysis, biological labeling, and sensing, and thus gold nanoparticles have attracted considerable attention from a fundamental and practical point of view [57–59]. However, they have not been used extensively in separation science, apart from the few known reports [60–63]. Recently, gold nanoparticle-modified porous polymer monolithic capillaries have been used as separation media [15, 23, 24, 35, 64, 65] and for enrichment [66]. The high surface coverage of AuNPs confirmed a significant increase in surface area was achieved through the nanoparticle modification.

Gold nanoparticles have been applied for the attachment of a wide range of functional groups. As well known, the surface of gold nanoparticles (GNPs) can readily be modified by taking advantage of the high affinity between gold and thiol ligands [67]. Hence, GNPs-modified polymer monolithic columns are one of the most extensively studied materials in the monolithic arena.

Connolly et al. [24] firstly reported the attachment of 20 nm GNPs upon polymer monolithic capillary using photografting methods, which was based on either the nitrogen lone pair of electrons or the strong covalent bonds between gold and thiol-containing compounds. The resultant column contained 21.3 wt% Au on three separate 10 μm2 areas of a monolith cross-section. The authors clearly demonstrated that the amine-functionalized monolith allowed a full, homogenous, and dense covalent attachment of GNPs as compared to the monolith modified with thiol groups for which the coverage of GNPs is quite sparse. In addition, the significant increase in surface area for the monolith was determined when compared with the bare unfunctionalized monolith.

At nearly the same time, Xu et al. [23] described the preparation of a novel monolithic stationary phase coated with GNPs, which conferred selectivity to the monolithic column for use in reducing the complexity of analytes in proteomic studies. The GNPs-coated monoliths can selectively capture cysteine-containing peptides from their mixtures with other peptides and subsequently release them for μ-HPLC–MS analysis. The best performing gold modified column in this study was one containing 15.4 atom % Au with a nanoparticle size of 40–50 nm.

Cao et al. [64] reported the preparation of capillary columns containing a high percentage of GNPs bound to a porous polymer monolith. Applications of the columns were demonstrated with the capillary electrochromatographic separation of peptides and the μ-HPLC separation of proteins in both reversed phase and ion exchange modes. The energy dispersive X-ray spectrum indicated that the monolithic column modified with 15 nm GNPs contains 33.5 atom % Au. This content is significantly higher than the 21.3 atom % observed by Connolly et al. [24].

In another study, Lv et al. [15] described the combination of hypercrosslinked large surface area polymer-based monoliths with GNPs attached through layered architecture and functionalized with hydrophilic functionalities. First, a monolith with a very large surface area (430 m2/g) was prepared from a generic poly(4-methylstyrene-co-VBC-co-DVB) [poly(4-MS-co-VBC-co-DVB)] monolith by a Friedel–Crafts reaction catalyzed with iron chloride. And then, free radical bromination provided this hypercrosslinked monolith with Br that further reacted with cystamine, resulting in a product containing sulfur. Thiol groups that bind the first layer of gold nanoparticles were liberated by clipping the disulfide bonds with tris(2-carboxylethyl) phosphine. These immobilized nanoparticles were an intermediate ligand enabling the attachment of polyethyleneimine as a spacer followed by immobilization of the second layer of gold nanoparticles which were eventually functionalized with zwitterionic cysteine. Chromatographic performance of these hydrophilic monolithic columns was demonstrated through the separation of nucleosides and peptides. Despite the technique being more complex an involving numerous steps, this work further demonstrated the versatility of functionalization approaches for monoliths relying on gold nanoparticles.

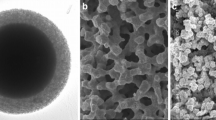

To further enhance the coverage density of GNPs, Lv et al. [35] reported that a new approach that enabled the preparation of monoliths with significantly enhanced pore surface coverage with GNPs exceed 60 wt%, which is the highest value published until now. A detailed preparation process was shown in Fig. 1. Since the size of the GNPs may affect the surface coverage, they tested attachment of GNP with sizes varying from 5 to 40 nm onto pore surfaces of monoliths containing free thiol groups. Figure 2 showed the resultant dense coverage and homogenously dispersed monolayer of gold nanoparticles achieved at the polymer surface. As expected, gold content increased with the increase in GNP size since the layer at the same extent of surface coverage is thicker and contains more gold. Use of the smallest 5 nm particles resulted in monolith that only contained 2.7 wt% gold while 40 nm GNPs-coated monolith held the highest quantity of gold 60.6 wt%. The modified monolithic columns were successfully used for the separations of proteins in reversed phase mode.

Scheme of the attachment of gold nanoparticles on a poly (GMA-co-EGDMA) monolith. Reprinted from Ref. [35] with permission from Elsevier

Scanning electron microscopy images of the internal structures of the poly(GMA-co-EGDMA) monoliths with attached (a) 15 nm, (b) 20 nm, (c) 30 nm, and (d) 40 nm gold nanoparticles. Reprinted from Ref. [35] with permission from Elsevier

Guerrouache et al. [65] developed a new photochemical method for the surface functionalization of the porous monoliths allowing the site-specific immobilization of gold nanoparticles at the pore interface. In order to realize their desired goal, chelating primary amino groups were photochemically attached to the alkyne-functionalized monolith surface through thiol-yne radical addition reaction. Though thiol-yne reaction is mechanistically comparable to the thiol-ene one, it may allow higher grafting density because the surface-grafted alkyne can react with two thiols.

A novel affinity monolithic extraction phase was described by Alwael et al. [66], onto which GNPs were covalently attached. The surface area was significantly increased, resulting in increased loading capacity when a selective lectin was immobilized onto the gold surface. The successful modification of polymer monolithic phases, housed within pipette-tips, for the highly selective affinity extraction of target glycoproteins from samples of varying complexity was presented.

Silver Nanoparticles

Inspired by this approach, work continues to develop new functionalized monolithic materials. Silver nanoparticles (AgNP) immobilized-polymer monoliths based on physical interactions were described and used for high-sensitivity SERS detection [68]. In contrast to conventional SERS sensors based on noble metal colloid solutions, the monoliths exhibited low background noise for SERS measurements and provided significantly higher signal stabilities. The authors tried to adopt the method of attachment, namely AgNP aggregates were dispersed in a monolith monomer solution before UV polymerization. The resulting monolith exhibited homogeneously distributed AgNP; however, poor sensitivity was obtained during the detection of Rhodamine 6G that suggested a scarcity of SERS-active hot-spots within the monolith. Increasing the concentration of AgNP in the monomer solution did not yield improved sensitivity. To avoid this difficulty, the attachment of AgNP aggregates to the pore surface of pre-polymerized (glycidyl methacrylate-co-ethoxylated trimethylolpropane triacrylate) (GMA-co-SR454) monoliths was investigated. The results demonstrated that strong SERS signals were readily detected along the full length of an AgNP-trapped GMA-SR454 monolith. This work favorably proved that attachment of nanoparticles to the pore surface is a momentous approach for monoliths with specific chemical properties. Furthermore, this report expands application of the porous polymer monolith.

Platinum/Palladium Bimetallic Nanoparticles

Floris et al. [69] made platinum/palladium bimetallic nano-flowers-immobilized methacrylate monoliths availing of nano-flowers affinity for amine functionalities. First, vinyl azlactone (VAL) was grafted onto a poly(BMA-co-EGDMA) monolith by photografting methods followed by amination with ethylenediamine. Second, nano-flowers were pumped across the monoliths. Finally, the high coverage density and uniform coverage of nano-flowers were observed by field emission scanning electron microscopy. Subsequent application of bimetallic Pd/Pt nano-flowers-immobilized monoliths as flow-through catalytic reactors was evaluated in flow-through mode. The result demonstrated that Pd/Pt nano-flowers immobilized upon a polymer monolith still retain their catalytic activity, and complete reduction occurred despite the extremely short contact time through the micro-reactor.

Fe3O4 Nanoparticles

Krenkova and Foret [70] reported an iron oxide nanoparticle-coated organic polymer monolith. On the basis of the electrostatic interactions, Fe3O4 nanoparticles, stabilized with citrate ions, were attached to the quaternary amine functionalized pore surface of the organic polymer-based monolithic column. The developed column was successfully applied for selective and efficient enrichment of phosphorylated peptides, and demonstrated its potential as a new tool for phosphoproteomic analysis.

Graphene Oxide/Graphene Nanosheets

Tong et al. [71] reported the preparation of the new type of GO/GN naonosheet-decorated poly(GMA-co-EGDMA) monolithic column via a chemical bonding method. GN employed in polymer monolith not only improved the mechanical stability of the native polymer monolith, but, more importantly, enhanced their enrichment capacities. GN @ poly(GMA-co-EGDMA) monolithic column exhibited high enrichment efficiency and good recovery for sarcosine, potential prostate cancer biomarker.

Conclusions and Outlook

Micro/nanomaterial-functionalized porous polymer monolithic columns have developed quickly in recent years due to their potential as separation and detection platforms. A variety of nanoparticles have been successfully used to modify porous polymer monoliths, such as GNPs, AgNPs, TiO2, and ZrO2. Specifically, numerous strategies have been proposed to enhance immobilization of GNPs. We anticipate that studies will be initiated, which will extend the range of nanoparticles and lead to the design of columns with high performance.

However, it should be noted that the field of micro/nanomaterial-functionalized polymer monolithic columns is still in its infancy and needs more attention from analysts. The main challenges are as follows: The column efficiency and analytical performances should be increased. For instance, the selectivity greatly depends on the structure and the properties of the target analytes, which leads to various enrichment efficiencies. For this goal, further research in theoretical studies such as mechanism is respected, many of which are currently not fully understood. In addition, the micro/nanomaterial-functionalized monoliths are mostly produced in laboratories. There is still much work to be done for their robust and reproducible production in industries.

As to future development trends, several aspects are expected. First, due to their biocompatibility, tunable surface chemistry, and morphology of porous polymer monoliths, the fields of separation science and proteomics have recently witnessed an explosion of interest in the use of a variety of accurately engineered polymer monoliths for various applications. Work in this area is driven more strongly by specific applications such as proteomics, protein, and DNA purification and it can reasonably be expected that this will continue to be the case.

Second, polymer monoliths have offered advantages for the separation or purification of cells [72], however, we have reasons to believe that they may be replaced by micro/nanoparticle-functionalized monoliths because of a variety of fascinating properties. It is likely that micro/nanoparticle-functionalized monoliths will be significant future developments in the area of separation and purification of cells. Furthermore, if this technology is to realize its full potential, then it is critical that the benefits continue to be demonstrated for a range of real applications, rather than for standard separations.

Third, a suite of techniques available for characterization of polymer monoliths has been developed such as transmission electron microscopy, scanning electron microscopy, and Fourier transform infrared spectroscopy. However, it is clear that this is still an area where much further development is needed, especially for the analysis of these materials under typical operating conditions rather than in the dry state. The introduction of techniques such as small angle neutron scattering [73], capillary flow porometry [74], and magnetic resonance imaging [75] offers exciting new possibilities in this regard.

In conclusion, micro/nanomaterial-functionalized porous polymer monoliths are still young and explorations will certainly lead to discoveries of novel shapes and materials with unexpected properties and applications in their field. It is also predicted that nanomaterial-functionalized polymer monoliths will continue to find new applications in both separation science and analytical detection science, as it is clear that their unique properties have much more to offer, many of which are currently not fully understood.

References

Peters EC, Svec F, Fréchet JMJ (1999) Adv Mater 11:1169–1181

Svec F, Fréchet JMJ (1992) Anal Chem 64:820–822

Legido-Quigley C, Marlin ND, Melin V, Manz A, Smith NW (2003) Electrophoresis 24:917–944

Hjertén S, Li YM, Liao JL, Mohammad J, Nakazato K, Pettersson G (1992) Nature 356:810–811

Svec F (2008) Electrophoresis 29:1593–1603

Svec F, Fréchet JMJ (1996) Science 273:205–211

Viklund C, Svec F, Fréchet JMJ, Irgum K (1996) Chem Mater 8:744–750

Svec F (2010) J Chromatogr A 1217:902–924

Svec F (2012) J Chromatogr A 1228:250–262

Arrua RD, Causon TJ, Hilder EF (2012) Analyst 137:5179–5189

Ikegami T, Tanaka N (2004) Curr Opin Chem Biol 8:527–533

Xie CH, Ye ML, Jiang XG, Jin WH, Zou HF (2006) Mol Cell Proteomics 5:454–461

Yu C, Davey MH, Svec F, Fréchet JMJ (2001) Anal Chem 73:5088–5096

Chambers SD, Holcombe TW, Svec F, Fréchet JMJ (2011) Anal Chem 83:9478–9484

Lv Y, Lin Z, Svec F (2012) Anal Chem 84:8457–8460

Henglein A (1993) J Phys Chem 97:5457–5471

Martin CR, Mitchell DT (1998) Anal Chem 70:322A–327A

Chester TL (2013) Anal Chem 85:579–589

Nilsson C, Birnbaum S, Nilsson S (2007) J Chromatogr A 1168:212–224

Nesterenko EP, Nesterenko PN, Connolly D, He X, Floris P, Duffy E, Paull B (2013) Analyst 138:4229–4254

Lucena R, Simonet BM, Cardenas S, Valcarcel M (2011) J Chromatogr A 1218:620–637

Li Y, Chen Y, Xiang R, Ciuparu D, Pfefferle LD, Horwath C, Wilkins JA (2005) Anal Chem 77:1398–1406

Xu Y, Cao Q, Svec F, Fréchet JMJ (2010) Anal Chem 82:3352–3358

Connolly D, Twamley B, Paull B (2010) Chem Commun 46:2109–2111

Chambers SD, Svec F, Fréchet JMJ (2011) J Chromatogr A 1218:2546–2552

Wang MM, Yan XP (2012) Anal Chem 84:39–44

Connolly D, Currivan S, Paull B (2012) Proteomics 12:2904–2917

Stevens TS, Langhorst MA (1982) Anal Chem 54:950–953

Rurack K (2012) Nat Mater 11:913–914

Guo SJ, Wen D, Zhai YM, Dong SJ, Wang EK (2010) ACS Nano 4:3959–3968

Yezhelyev MV, Gao X, Xing Y, Al-Hajj A, Nie S, O’Regan RM (2006) Lancet Oncol 7:657–667

Liu Q, Shi J, Jiang G (2012) TrAC Trend Anal Chem 37:1–11

Krenkova J, Lacher NA, Svec F (2010) Anal Chem 82:8335–8341

Hilder EF, Svec F, Fréchet JMJ (2004) J Chromatogr A 1053:101–106

Lv Y, Alejandro FM, Fréchet JMJ, Svec F (2012) J Chromatogr A 1261:121–128

Novoselov KS, Geim AK, Morozov SV, Jiang D, Zhang Y, Dubonos SV, Grigorieva IV, Firsov AA (2004) Science 306:666

Qu Q, Gu C, Hu X (2012) Anal Chem 84:8880–8890

Tong SS, Liu QW, Li YC, Zhou WH, Jia Q, Duan TC (2012) J Chromatogr A 1253:22–31

Dreyer DR, Park S, Bielawski CW, Ruoff RS (2010) Chem Soc Rev 39:228–240

Hsieh HC, Sheu C, Shi FK, Li DT (2007) J Chromatogr A 1165:128–135

Rainer M, Sonderegger H, Bakry R, Huck CW, Morandell S, Huber LA, Gjerde DT, Bonn GK (2008) Proteomics 8:4593–4602

Tobal K, Guerre O, Rolando C, Le Gac S (2006) Mol Cell Proteomics 5:S278

Yao K, Yun J, Shen S, Wang L, He X, Yu X (2006) J Chromatogr A 1109:103–110

Dubinsky S, Petukhova A, Gourevich I, Kumacheva E (2010) Chem Commun 46:2578–2580

Dubinsky S, Petukhova A, Gourevich I, Kumacheva E (2010) Macromol Rapid Commun 31:1635–1640

Lee A, Dubinsky S, Tumarkin E, Moulin M, Beharry AA, Kumacheva E (2011) Adv Funct Mater 21:1959–1969

Li W, Zhou X, Tong S, Jia Q (2013) Talanta 105:386–392

Zajickova Z, Rubi E, Svec F (2011) J Chromatogr A 1218:3555–3558

Xu PP, Yao YC, Shen SC, Yun JX (2010) Chin J Chem Eng 18:667–671

Jandera P, Urban J, Moravcová D (2006) J Chromatogr A 1109:60–73

Jandera P, Urban J, Skerikova V, Langmaier P, Kubickova R, Planeta J (2010) J Chromatogr A 1217:22–33

Fan Y, Rubakhin SS, Sweedler JV (2011) Anal Chem 83:9557–9563

Zakaria P, Hutchinson JP, Avdalovic N, Liu Y, Haddad PR (2005) Anal Chem 77:417–423

Hutchinson JP, Hilder EF, Shellie RA, Smith JA, Haddad PR (2006) Analyst 131:215–221

Hutchinson JP, Macka M, Avdalovic N, Haddad PR (2006) J Chromatogr A 1106:43–51

Hutchinson JP, Zakaria P, Bowie AR, Macka M, Avdalovic N, Haddad PR (2005) Anal Chem 77:407–416

Cao YC, Jin R, Mirkin CA (2002) Science 297:1536–1540

Lee JS, Han MS, Mirkin CA (2007) Angew Chem 119:4171–4174

Daniel MC, Astruc D (2003) Chem Rev 104:293–346

Yu CJ, Su CL, Tseng WL (2006) Anal Chem 78:8004–8010

Qu Q, Zhang X, Shen M, Liu Y, Hu X, Yang G, Wang C, Zhang Y, Yan C (2008) Electrophoresis 29:901–909

Yang L, Guihen E, Holmes JD, Loughran M, O’Sullivan GP, Glennon JD (2005) Anal Chem 77:1840–1846

Kobayashi K, Kitagawa S, Ohtani H (2006) J Chromatogr A 1110:95–101

Cao Q, Xu Y, Liu F, Svec F, Frechet JMJ (2010) Anal Chem 82:7416–7421

Guerrouache M, Mahouche-Chergui S, Chehimi MM, Carbonnier B (2012) Chem Commun 48:7486–7488

Alwael H, Connolly D, Clarke P, Thompson R, Twamley B, O’Connor B, Paull B (2011) Analyst 136:2619–2628

Guihen E, Glennon JD (2003) Anal Lett 36:3309–3336

Liu JK, White I, DeVoe DL (2011) Anal Chem 83:2119–2124

Floris P, Twamley B, Nesterenko P, Paull B, Connolly D (2012) Microchim Acta 179:149–156

Krenkova J, Foret F (2011) J Sep Sci 34:2106–2112

Tong SS, Zhou X, Zhou CH, Li YY, Li WJ, Zhou WH, Jia Q (2013) Analyst 138:1549–1557

Kumar A, Srivastava A (2010) Nat Protoc 5:1737–1747

Ford KM, Konzman BG, Rubinson JF (2011) Anal Chem 83:9201–9205

Aggarwal P, Tolley HD, Lee ML (2011) Anal Chem 84:247–254

Teisseyre TZ, Urban J, Halpern-Manners NW, Chambers SD, Bajaj VS, Svec F, Pines A (2011) Anal Chem 83:6004–6010

Acknowledgments

The authors gratefully acknowledge support from the National Natural Science Foundation of China (21145004 and 21205047), Jilin Provincial Science and Technology Department (201105102), and Open Project of State Key Laboratory of Supramolecular Structure and Materials, Jilin University (sklssm201218).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tong, S., Liu, S., Wang, H. et al. Recent Advances of Polymer Monolithic Columns Functionalized with Micro/Nanomaterials: Synthesis and Application. Chromatographia 77, 5–14 (2014). https://doi.org/10.1007/s10337-013-2564-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10337-013-2564-x