Abstract

Metal–organic frameworks (MOFs) are porous crystalline materials with large surface areas, uniform pore size, and tunable selectivity. In the last few years, the number of analytical applications of MOFs has been growing constantly. However, the direct use of as-synthesized MOFs in packed column format is rather limited for analytical separations because of the small size and non-spherical shape of MOF crystals. In this review, we outline and critically discuss the advantages and limitations of the different methods described to immobilize MOFs into functional supports for analytical separations, including beads, monoliths, and fibers. These methods are based on embedding MOF crystals into functional supports, in situ MOF growth, controlled layer-by-layer MOF growth, or the in situ conversion of immobilized MOF metal oxide precursors. Representative examples of immobilized MOFs for sample preparation and chromatographic separation are overviewed. We also overview recent progress on the use of MOFs as precursors to obtain other functional materials such as layered double hydroxides or porous carbons.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

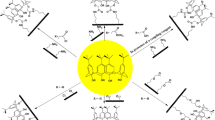

Metal–organic frameworks (MOFs) are a class of porous coordination polymers made by linking metal ions (or clusters) with organic ligands, creating open crystalline structures with permanent porosity and high surface areas (Fig. 1) [1, 2]. Combining different metals and organic linkers, more than 70,000 different MOFs have been described to date [3]. MOFs were initially applied as materials for gas storage and separation [4] or as catalysts [5]. More recently, analytical applications using MOFs have been developed [6]. MOFs can be applied as sorbents for sample preparation [7,8,9,10,11], stationary phases for chromatographic separation [12,13,14,15,16], or in the design of novel sensors [17]. Advantages of MOFs for separation applications are attributed to their pore size selectivity and high surface area, the use of functional organic ligands (including chiral ligands), or their high selectivity for immobilized metal affinity separations.

Different procedures have been reported for the immobilization of MOFs on different types of supports. A simple strategy is the mixing of MOF crystals with the separation support precursors, embedding them in the synthesized support [18, 19]. Alternatively, the synthesis of the separation support can be carried out first, followed by the in situ growth of the desired MOF on the surface of the preformed support [20, 21]. These strategies enabled the incorporation of different MOFs into beads [22], fibers [7], or monoliths [23]. Another interesting strategy for MOF growth on surfaces is the stepwise layer-by-layer procedure based on liquid-phase epitaxy, enabling the growth of MOF thin films on different substrates with a high control over the thickness of the prepared coating [24, 25]. In addition, the immobilization of precursor reactive metal oxides followed by the in situ metal oxide conversion to the desired MOF is an efficient procedure to obtain dense MOF coatings [26, 27].

In the field of chromatography, MOFs were initially explored as stationary phases for gas chromatography (GC) by directly packing MOFs in columns [28] or as capillary coatings [29]. The initial GC applications were followed by liquid-phase applications using MOFs as sorbents for solid-phase extraction [30] or as stationary phases for liquid chromatography [31, 32]. However, in liquid-phase applications, MOF performance is rather limited because of the inherent non-spherical shape and small size of MOF crystals. To solve this limitation, alternatives such as MOF magnetization [33, 34] or MOF immobilization into suitable separation supports have been developed [35, 36].

This review is focused on the different approaches developed for MOF immobilization on supports for analytical separations. The advantages and limitations for each approach are critically discussed, and recent applications for sample preparation prior to chromatographic separation and the design of novel stationary phases for chromatographic separation are overviewed (Table 1).

Direct Embedding of Metal–Organic Frameworks

In the direct embedding method, the selected MOF is dispersed in the precursor mixture containing the reagents required to synthesize the separation support. The dispersed MOF crystals are entrapped into the scaffold of the synthesized separation support. The advantages of the direct embedding procedure are:

-

(i)

It can be applied practically to any MOF dispersible in the precursor reagent mixture.

-

(ii)

Several MOFs have been already commercialized. Therefore, MOF synthesis and characterization skills are not required.

However, the MOF direct embedding method has several limitations:

-

(i)

It requires highly stable MOF dispersions in the precursor reagents to obtain a homogeneous distribution of the MOF in the final support.

-

(ii)

A large amount of the incorporated MOF crystals will be buried in the separation support. Therefore, a considerable amount of the added MOF crystals will not be active in further separation applications.

-

(iii)

It can be a costly preparation procedure depending on the acquisition cost of the selected MOF or MOF precursors.

Polymer Monoliths

MOF direct embedding has been implemented to incorporate MOFs on macroporous organic polymer monoliths. MOF crystals are added into the monolith polymerization mixture containing the monomers, porogens, and the polymerization initiator. A critical step before monolith polymerization is ensuring a stable dispersion of the MOF crystals in the monolith precursor mixture. Crystals of MOF UiO-66 (Universitetet i Oslo, based on [Zr6O4(OH)4] clusters coordinated with terephthalic acid) were incorporated in a methacrylic acid (MAA)–ethylene dimethacrylate (EDMA) monolith and used as stationary phase for liquid chromatography (Fig. 2a) [36]. The incorporation of the UiO-66 crystals increased the surface area of the polymer monolith, thereby improving the separation of small molecules (Fig. 2b). Column efficiencies for the separation of small aromatic molecules using a pure organic polymer monolith were in the range of 2967–8218 plates m−1. Using the same monolith containing UiO-66 crystals achieved up to 28,800 plates m−1. The same procedure was exploited to incorporate the MOF MIL-101(Cr) (Materials Institute Lavoisier, based on Cr(III) coordinated with terephthalic acid) into a butyl methacrylate (BMA)–EDMA monolith [35]. MIL-101(Cr)/polymer monoliths were prepared in capillary format and used as stationary phase for capillary electrochromatography (CEC) and capillary liquid chromatography (CLC). MIL-101(Cr)/polymer monoliths showed an improved separation performance when compared to capillary packings of MOF crystals, demonstrating the need to immobilize MOFs into suitable separation supports.

Reproduced from [36] with permission from The Royal Society of Chemistry

a Scheme for the preparation of a UiO-66/MAA–EDMA monolith. b Separation of ethylbenzene and styrene using a pure organic polymer monolith and a UiO-66/polymer monolith (70.0 mm × 4.6 mm i.d.). Mobile phase, hexane; flow rate, 1.0 mL min−1; UV detection, 254 nm.

Open tubular columns for CEC were also prepared by embedding the MOF CAU-1 (Christian Albrechts University, based on Al(III) coordinated with 2-aminoterephthalic acid) in a methyl methacrylate–EDMA monolith [37]. Less conventional MOFs have been also explored as stationary phases for CEC, such as the lanthanide MOF NKU-1 (Nankai University, Eu(III) coordinated with 3,3′,5,5′-azobenzene-tetracarboxylic acid) embedded in a BMA–EDMA polymer monolith [38].

MOF direct embedding applied to liquid chromatography was extended to the robust MIL-53(Al) (Al(III) coordinated with terephthalic acid), incorporated into a hexyl methacrylate–EDMA monolith for the separation of small aromatic molecules using CLC [39]. This procedure was also explored to incorporate nanoscale MOFs, as exemplified using nanoparticles of HKUST-1 (Hong Kong University of Science and Technology, based on Cu(II) coordinated to trimesic acid) into a glycidyl methacrylate–EDMA monolith [40]. The resulting monolith prepared in capillary format enabled the separation of styrene and ethylbenzene, a separation not feasible using an identical polymer monolith prepared in the absence of HKUST-1 nanoparticles. MOF/polymer monoliths were also explored as chiral CLC stationary phase by embedding the chiral MOF [Zn2(benzene dicarboxylate)(l-lactic acid)(dmf)] in a monolith based on 4-vinylpyridine–EDMA, enabling the separation of (±)-methyl phenyl sulfoxide [41].

Direct MOF embedding in polymer monoliths has been explored to develop novel sample preparation supports, such as capillary microextraction devices [42]. Different MOFs were successfully incorporated into BMA–EDMA monoliths and evaluated for the solid-phase microextraction (SPME) of penicillin. The developed procedure was later extended to Al-based MOFs [43, 44]. The embedding of MOFs in the polymer monolith scaffolds was explored to protect water-sensitive MOFs and subsequently use them for microextraction applications [45].

Epoxy and Sol–Gel Coatings

MOF crystals have been directly immobilized using epoxy resins creating MOF/resin microextraction supports. This procedure was evaluated to fabricate SPME devices on stainless steel wires and afforded MOF crystals permanently immobilized into the SPME support after curing the composite resin. This approach was applied to immobilize different prototypical MOFs, such as MIL-53(Al) [46], or UiO-66 [47], enabling the application of MOFs for SPME prior to GC separation. The gate-opening effect of ZIF-7 (Zn(II) coordinated with benzimidazole) has been also explored for the SPME of aldehydes followed by GC-FID separation [48]. The incorporation of ZIF-7 nanoparticles on a stainless steel wire was carried out by dispersing the nanoparticles in a sol–gel solution applied as SPME coating. Low detection limits, excellent reproducibility, and a long lifetime for the SPME of five aldehydes in exhaled breath samples were obtained.

Mixed-Matrix Membranes

MOF crystals were also dispersed into fluorinated polymer/solvent mixtures, which, after casting and evaporation of the organic solvent, shaped MOF mixed-matrix membranes [49]. In this case, MOFs are incorporated into the membrane by entrapping the MOF crystals between the fibrils of a preformed polymer, usually polyvinylidene fluoride (PVDF), affording MOF/polymer membranes with up to 67 wt% of MOF. The scheme for the preparation of MOF/polymer membranes is shown in Fig. 3. MOF/polymer extraction disks prepared following this procedure enabled the automated flow-through SPE of phenols prior to HPLC separation, with the simultaneous removal of undesired species from the sample matrix (Fig. 3) [50].

Reproduced from [50] with permission from Elsevier

Scheme for the preparation of MOF/polymer disks for SPE applications. HPLC chromatograms of a standard solution containing seven phenols at a concentration of 5 µg L−1 and thionin at 250 µg L−1. Chromatograms correspond to the direct injection of the standard solution, the same standard after SPE using a bare polymer membrane (PVDF disk), and a MOF/polymer mixed-matrix disk (MOF-MMD) based on UiO-66-NH2 nanocrystals (90 nm). Peaks: thionin (*), 4-nitrophenol (1), 2-chlorophenol (2), 2,4-dinitrophenol (3), 2-nitrophenol (4), 2,4-dimethylphenol (5), 4-chloro-3-methylphenol (6), 2,4-dichlorophenol (7).

One should also include here the simultaneous synthesis of MOF crystals and the polymer support shaping metal–organic aerogels, which have been reported as coatings for SPME [51] or as flow-through supports for online analyte enrichment [52] prior to chromatographic separation.

In Situ Growth

The in situ growth approach relies on the synthesis of the desired MOF in a preformed separation support. In this case, the metal and organic precursors are added simultaneously to grow MOF crystals in the presence of the separation support. The advantages of in situ MOF growth are:

-

(i)

MOF growth is performed in a single step.

-

(ii)

MOF is positioned in the active surface of the support.

-

(iii)

MOF is grown from solution precursors, enabling MOF growth on porous supports.

However, the in situ growth procedure also has several limitations:

-

(i)

Growth of MOF crystals not attached to the support, which might require several MOF growth cycles to obtain a dense MOF coating.

-

(ii)

Limited control over the growth of the coating, or growth of non-homogeneous coatings.

Core–Shell Particles

In situ growth has been explored to immobilize MOFs on commercial stationary phase HPLC packings [53]. Silica-C18 particles (3 µm particle size) were impregnated with a dimethyl sulfoxide solution containing Cu(II) and trimesic acid, the precursors of the CuBTC MOF (HKUST-1). After the mixture was spread and heated to remove the solvent, the silica particles were coated with the desired MOF. After the MOF/silica beads were packed in column format, an improved performance for the separation of ethylbenzene and styrene was obtained in comparison with the pure silica beads or the direct packing of the MOF crystals. MOF/silica composites combined the desirable morphology of the silica beads for column packings with the presence of open metal sites from the selected MOF, providing additional selectivity towards the vinyl group of styrene. HKUST-1 was also in situ confined in the fibrous pores of silica particles for improved HPLC separation [54], and following a similar procedure, ZIF-8 was also incorporated into silica particles with dendritic pore channels [55]. HKUST-1 has been also grown in situ on spheres-on-sphere silica particles [56]. Spheres-on-sphere silicas are micrometer-sized particles, which can be packed in column format and contain many smaller silica particles attached on the surface. The addition of MOF crystals to this type of silica contributed to increase their separation selectivity for HPLC applications.

UiO-66 has been also grown in situ on silica particles [57, 58] and applied as stationary phases for HPLC (Fig. 4) [59, 60]. In these studies, the unique features of MOFs to introduce flow-dependent separation selectivity in the separation process were explored. The selectivity of the chromatographic separation depended on the flow rate of the mobile phase, tuning the accessibility of the analytes in the porous structure of the UiO-66 crystalline shell (Fig. 4a). This type of core–shell particle enabled the tunable flow-dependent separation of small aromatics like cumene and ethyl benzene (Fig. 4b).

a Flow-dependent separation using porous UiO-66@SiO2 core–shell particles packed in an HPLC column. Insets show the pore size distribution and scanning electron microscopy image of the UiO-66@SiO2 particles. b Effect of the flow rate on the separation of analytes on the UiO-66@SiO2 column. Top: mixture of toluene (first peak) and anthracene; Bottom: mixture of cumene (first peak) and ethyl benzene.

Sample Preparation and Capillary Electrochromatography

Stationary phases for CEC have been prepared by the in situ growth of MOFs by functionalizing the capillary column walls with polydopamine, in order to facilitate the immobilization of ZIF-8 [61]. In addition, several studies exploring MOF in situ growth to fabricate devices for sample preparation have been reported in the recent years. One of the first examples reported was the use of the rough surface of etched stainless steel wires for the in situ hydrothermal growth of HKUST-1 and the application of the resulting SPME device to the extraction of gaseous benzene homologues [62]. The same procedure has been implemented using MIL-88B (Fe(III) coordinated with terephthalic acid) applied to the extraction of polychlorinated biphenyls [63]. MOF attachment on silica fibers was carried out by silica functionalization with amino groups using 3-(aminopropyl)triethoxysilane, and the subsequent reaction of the amino groups from the fiber with the aldehyde groups from the organic linker of ZIF-90 (Zn(II) coordinated with imidazolate-2-carboxyaldehyde) [64]. SPME devices have been also fabricated with less conventional MOFs, such as ytterbium-based MOFs, affording a high sensitivity for the extraction of polycyclic aromatic hydrocarbons [65].

Layer-by-Layer MOF Growth

Implementation of MOFs for sample preparation and chromatographic separation has also been carried out exploiting the stepwise layer-by-layer MOF growth [24, 25]. In contrast to MOF direct embedding or in situ crystal growth, layer-by-layer growth is based on the coordination of the metal and organic MOF precursors in solution in a sequential, stepwise fashion. The main requirement is a functional support with cation exchange properties on which to immobilize the first layer of the MOF metallic solution precursor. The excess of non-immobilized metal precursor is removed by rinsing the support with a pure organic solvent. In the next step, the same procedure is repeated by using the selected organic linker. After the non-retained organic linker is rinsed, the first MOF coating cycle will be completed. The MOF growth cycle can be repeated the desired number of times to precisely control the thickness of the prepared coating.

The advantages of the layer-by-layer MOF growth are:

-

(i)

Precise control over the thickness of the MOF coating.

-

(ii)

Simple solution-based procedure carried out at room temperature.

-

(iii)

Easily implemented to porous, or intricate structures, such a porous silica/organic polymer monoliths, just requires the use of a syringe pump [66, 67].

-

(iv)

MOF grown on flow-through supports can be easily automated [68].

However, the layer-by-layer MOF growth has also several limitations, such as:

-

(i)

It is a time-consuming procedure.

-

(ii)

Larger volumes of organic solvents are required in comparison to other procedures for MOF immobilization.

-

(iii)

Difficult MOF characterization for very thin coatings.

-

(iv)

A limited number of MOFs can be prepared following this method, usually limited to MOFs based on divalent (HKUST-1 or ZIF-8) and trivalent metals (MIL-100).

The layer-by-layer procedure for MOF growth on a macroporous polymer monolith is exemplified in Fig. 5a [67, 69]. In this case, a polymer monolith prepared from styrene–divinylbenzene–MAA was used. The incorporation of MAA provides carboxylic groups to the monolith, enabling the immobilization of the MOF metallic precursor. A MOF based on Fe(III) and benzene-1,3,5-tricarboxylic acid (BTC) was grown layer-by-layer on the polymer monolith, resulting in a material with a high surface area (389 m2 g−1, after 30 MOF growth cycles). In this support, the step-by-step addition of Fe(III) and BTC shaping a porous coordination structure showed an enhanced selectivity for the extraction of phosphopeptides by immobilized metal-ion affinity chromatography (IMAC) (Fig. 5b).

Reprinted from [67] with permission from Wiley

a Illustration of the incorporation of additional metallic sites for IMAC by layer-by-layer growth of the FeBTC MOF on the pore surface of a polymer monolith. b MALDI-TOF-MS spectra of a β-casein digest before and after purification with a polymer monolith with different number of MOF growth cycles. Phosphopeptides are indicated with asterisks and dephosphorylated fragments are indicated with hashes.

The layer-by-layer approach for the growth of Fe(III)BTC was extended to beads and magnetic nanoparticles. The applications developed are focused on coating Fe(III)-BTC on magnetic nanoparticles for the selective capture of peptides prior to MALDI-TOF-MS analysis [70, 71]. This procedure was also implemented on carboxyl-functionalized magnetic silica particles to prepare stationary phases for HPLC separation [72].

The incorporation of HKUST-1 by layer-by-layer growth on polymer monoliths was explored by using an MAA–EDMA capillary monolith (Fig. 6a) [73]. The resulting MOF/polymer monolith was applied as stationary phase for CLC showing a gradual improvement in the analyte separation performance by increasing the number of cycles of the immobilized MOF (Fig. 6b). The same approach was also implemented to prepare a monolith for SPME, followed by direct analysis by real-time mass spectrometry [74]. Other applications of HKUST-1 layer-by-layer coatings rely on hydroxyl-functionalized magnetic silica microparticles and their subsequent application as HPLC stationary phase [72] or HKUST-1 growth on the internal walls of functionalized-silica capillaries for open tubular CEC [75, 76].

Reproduced from [73] with permission from The Royal Society of Chemistry

a Scheme of the synthesis of the HKUST-1 on a methacrylate-based monolith. b Reversed-phase chromatograms of benzenediols using the MOF/polymer monolith prepared layer-by-layer after 0, 2, 4, and 6 cycles of MOF growth. Peaks, 1, p-benzenediol; 2, m-benzenediol; 3, o-benzenediol.

The immobilization of MOF-5 (Zn(II) coordinated with terephthalic acid) [77] has been also explored following the layer-by-layer approach developing capillary coatings for open-tubular CEC. Chiral MOFs have been also grown layer-by-layer as exemplified with Zn(II)/N-(4-pyridylmethyl)-l-alanine·HCl [78], which has been applied as stationary phases for CEC.

Metal Oxide Conversion

The metal oxide conversion approach is based on two steps: (i) introduction of a metal oxide containing the metal precursor of the selected MOF on the separation support and (ii) in situ conversion of the immobilized metal oxide to the desired MOF [27]. This approach has been explored to immobilize ZIFs based on Zn(II) into separation supports. ZnO can be immobilized as a precursor by in situ growth on the surface of the support or by direct embedding. After that, the support containing ZnO is reacted with a solution of the desired imidazole-based ligand. The action of the imidazole is dual: etching the ZnO as a result of its basicity and coordinating the etched ZnO growing a porous crystalline coating.

The advantages of MOF growth by metal oxide conversion are:

-

(i)

Precise growth of MOFs on the effective area of the separation support, in just one MOF growth cycle.

-

(ii)

Less time consuming than the layer-by-layer procedure.

-

(iii)

Requires less solvent than the layer-by-layer procedure.

However, the main limitations are:

-

(i)

The limited number of metal oxides which can be in situ converted to MOFs.

-

(ii)

Some metal oxide precursors are not commercially available.

To date, this approach has been mainly studied using divalent metal oxides (Zn, Cu). In a first application, ZnO was coated on SPE polymer beads affording a reactive metal oxide/polymer core shell precursor. After the resulting beads were immersed in a solution of 2-methylimidazole, the ZnO shell was partially converted into a dense coating of the highly porous ZIF-8 (Fig. 7a) [79]. The hydrophobic nature of the ZIF-8 was evaluated for the SPE in cartridge format of phenolic pollutants. The overall morphology of the prepared ZIF-8@ZnO@polymer beads was not apparently modified (Fig. 7b). However, images of the cross section of the beads showed a ZnO/ZIF-8 double shell coating the polymer bead (Fig. 7c). The prepared material enabled the highly efficient preconcentration of bisphenol A, 4-tert-octylphenol, and 4-n-nonylphenol from water (Fig. 7d).

Adapted from [79] with permission from Wiley

Scheme for the preparation of ZIF-8@ZnO@polymer beads (a). Scanning electron microscopy image of a ZIF-8@ZnO@polymer bead (b) and a bead cross section (c). HPLC chromatogram of a tap water sample containing bisphenol A (1), 4-tert-octylphenol (2), and 4-n-nonylphenol (3) (100 mL, 1 µg L−1) preconcentrated using a ZIF-8@ZnO@polymer-packed column (d).

This procedure was implemented later in monolith format [80]. In this case, the ZnO precursor was incorporated into the polymer monolith by direct embedding of up to 10 wt% of ZnO nanoparticles. ZnO nanoparticles were added to the pre-polymerization mixture containing the monomers (MAA–EDMA), porogens (n-dodecanol/methanol), and the polymerization initiator (Fig. 8a). The ZnO nanoparticle/polymer monoliths have the typical globular structure of methacrylate-based polymer monoliths (Fig. 8b). The reaction of the embedded ZnO nanoparticles with 2-methylimidazole produced a dense coverage of intergrown ZIF-8 in the macropores of the monolith (Fig. 8c). The ZIF-8/polymer monoliths showed an improved performance for the SPE of chlorophenols owing to the possibility to coat the ZIF-8 crystals with n-butylamine, thereby increasing the hydrophobicity of the final SPE monolith (Fig. 8d). The developed procedure is easily adaptable to other interesting formats for sample preparation, such as SPME coatings [81].

Adapted with permission from [80]. Copyright (2017) American Chemical Society

Preparation of a polymer monolith with embedded ZnO nanoparticles (a). Scanning electron microscopy images of a polymer monolith with 10 wt% of embedded ZnO nanoparticles (b) and the same monolith after conversion to ZIF-8/polymer monolith by reaction with 2-methylimidazole (c). SPE of chlorophenols using the prepared ZIF-8/polymer monoliths (d) (PM, polymer monolith; NPM, ZnO nanoparticle/polymer monolith; ZIF-NPM, ZIF/polymer monolith; ZIF-NPM-BUT, ZIF/polymer monolith with n-butylamine).

The in situ conversion approach using ZnO nanoparticles as nucleating agents was applied to the immobilization of a homochiral MOF based on Zn(II) and the ligand (S)-2-(1,8-naphthalimido)-3-(4-imidazole) propanoate, affording a capillary coating for the CEC separation of monoamine neurotransmitters, nitrophenols, and analogues of bisphenols [82].

Strategies for Incorporation of MOF-Derived Materials into Separation Supports

MOFs are also versatile precursors to obtain different materials for sample preparation and chromatographic separation. MOF-derived metal-doped porous carbons are an interesting class of materials obtained from the carbonization of MOFs in an inert atmosphere. The final properties of the MOF-derived porous carbons will be defined by the metal and organic linkers selected to build the precursor MOF. An interesting example is the carbonization of ZIF-67 [83], affording porous carbons with embedded magnetic cobalt nanoparticles, ideal materials for application as sorbents for magnetic SPE [84, 85]. However, ZIF-67-derived carbons have a small surface area compared to ZIF-8 carbons. ZIF-8-derived carbons are highly porous, but their applicability is quite limited, since they have no magnetic properties. To implement ZIF-8-derived carbons for separation applications, these were prepared under different synthetic conditions affording porous carbons with different particle size (< 20 nm, between 100 and 200 nm, and 1 µm particle size). ZIF-8-derived carbons are dispersable in mixtures of methacrylate-based monomers and organic solvents, and they were incorporated by the direct embedding procedure in capillary polymer monoliths. The resulting ZIF-8-derived carbon/polymer monoliths were applied as stationary phases for CEC (Fig. 9) [86], showing different effects for ZIF-8-derived carbons with different properties on the separation of nonsteroidal anti-inflammatory drugs (NSAIDs) (Fig. 9).

Reprinted from [86] with permission from Elsevier

Scheme for the preparation of ZIF-8-derived carbon (cZIF)/polymer monoliths (Top). CEC separations of an NSAID standard mixture using a pure polymer monolith (a), and polymer monoliths containing 0.5 wt% cZIF with < 20 nm particle size (b), 100–200 nm particle size (c), and 1 µm particle size. Conditions: mobile phase, 50:50 (v/v) ACN/5 mM phosphate buffer (pH 2.5); applied voltage, 10 kV. Peaks: thiourea (1), tolmetin (2), ketoprofen (3), and indomethacin (4).

Layered double hydroxides (LDHs) also were prepared from MOF precursors via conversion of precursor ZIF-67 crystals immobilized using a surfactant-assisted dip coating method on melamine–formaldehyde polymer sponges. The immobilized ZIF-67 reacted in situ with a Ni(II) solution to obtain a Ni-Co LDH coating [87]. LDH/sponges fabricated via MOFs were packed in a syringe and used for the in-syringe SPE of phenolic acids prior to HPLC separation. Elution was carried out under acidic conditions dissolving the LDH coating. However, since large LDH/sponges can be prepared, these are cut into multiple smaller disposable sponges for extraction.

Conclusions

Different strategies to immobilize MOFs on fibers, beads, and monoliths have led to novel sample preparation supports, and stationary phases for analytical separations. The advantages and limitations of the described methods for MOF immobilization have been critically discussed with representative examples including MOF embedding into functional supports, in situ MOF growth, layer-by-layer MOF growth, and the immobilization of precursor metal oxides followed by their in situ conversion to MOFs.

Approximately half of the recent applications based on MOFs immobilized into analytical separation supports are based on the development of stationary phases for liquid chromatography, or capillary electrochromatography, while the other half are applications related to sample preparation. MOF-based applications as stationary phases are mainly developed for exploratory purposes, while sample preparation applications involve the analysis of real samples and are typically based on highly stable and hydrophobic MOFs in aqueous medium (ZIFs, MILs, and UiOs). The most employed immobilization methods to date are the direct embedding and the in situ growth. However, the layer-by-layer growth and the in situ conversion of metal oxides are promising alternatives. The most applied MOFs are the UiO-66, HKUST-1, MIL-100, MIL-53, and ZIF-8. This is attributed to the versatile and simple synthesis procedure of these MOFs, based on commercial and cheap metal and organic ligand precursors.

Future developments in the field can be directed towards the design of novel separation applications with chiral MOFs, multivariated MOFs simultaneously containing different metals (or organic linkers), the immobilization of MOF hybrids containing encapsulated metallic nanoparticles (or biomolecules), or the use of MOFs as precursors towards other functional materials (LDHs, porous carbons).

References

Li H, Eddaoudi M, O’Keeffe M, Yaghi OM (1999) Design and synthesis of an exceptionally stable and highly porous metal–organic framework. Nature 402:276–279

Park KS, Ni Z, Côté AP et al (2006) Exceptional chemical and thermal stability of zeolitic imidazolate frameworks. Proc Natl Acad Sci 103:10186–10191. https://doi.org/10.1073/pnas.0602439103

Moghadam PZ, Li A, Wiggin SB et al (2017) Development of a Cambridge Structural Database subset: a collection of metal–organic frameworks for past, present, and future. Chem Mater 29:2618–2625. https://doi.org/10.1021/acs.chemmater.7b00441

Li J-R, Kuppler RJ, Zhou H-C (2009) Selective gas adsorption and separation in metal-organic frameworks. Chem Soc Rev 38:1477–1504. https://doi.org/10.1039/B802426J

Lee J, Farha OK, Roberts J et al (2009) Metal-organic framework materials as catalysts. Chem Soc Rev 38:1450–1459. https://doi.org/10.1039/B807080F

Gu Z-Y, Yang C-X, Chang N, Yan X-P (2012) Metal–organic frameworks for analytical chemistry: from sample collection to chromatographic separation. Acc Chem Res 45:734–745. https://doi.org/10.1021/ar2002599

Rocío-Bautista P, Pacheco-Fernández I, Pasán J, Pino V (2016) Are metal-organic frameworks able to provide a new generation of solid-phase microextraction coatings?—a review. Anal Chim Acta 939:26–41. https://doi.org/10.1016/j.aca.2016.07.047

Rocío-Bautista P, González-Hernández P, Pino V et al (2017) Metal-organic frameworks as novel sorbents in dispersive-based microextraction approaches. TrAC Trends Anal Chem 90:114–134. https://doi.org/10.1016/j.trac.2017.03.002

Hashemi B, Zohrabi P, Raza N, Kim K-H (2017) Metal–organic frameworks as advanced sorbents for the extraction and determination of pollutants from environmental, biological, and food media. TrAC Trends Anal Chem 97:65–82. https://doi.org/10.1016/j.trac.2017.08.015

Wang Y, Rui M, Lu G (2018) Recent applications of metal–organic frameworks in sample pretreatment. J Sep Sci 41:180–194. https://doi.org/10.1002/jssc.201700401

Liu C, Yu L-Q, Zhao Y-T, Lv Y-K (2018) Recent advances in metal-organic frameworks for adsorption of common aromatic pollutants. Microchim Acta 185:342. https://doi.org/10.1007/s00604-018-2879-2

Yusuf K, Aqel A, AL Othman Z (2014) Metal-organic frameworks in chromatography. J Chromatogr A 1348:1–16. https://doi.org/10.1016/j.chroma.2014.04.095

Duerinck T, Denayer JFM (2015) Metal–organic frameworks as stationary phases for chiral chromatographic and membrane separations. Chem Eng Sci 124:179–187. https://doi.org/10.1016/j.ces.2014.10.012

Zhang J, Chen Z (2017) Metal–organic frameworks as stationary phase for application in chromatographic separation. J Chromatogr A 1530:1–18. https://doi.org/10.1016/j.chroma.2017.10.065

Wang X, Ye N (2017) Recent advances in metal-organic frameworks and covalent organic frameworks for sample preparation and chromatographic analysis. Electrophoresis 38:3059–3078. https://doi.org/10.1002/elps.201700248

Li XC, Sha SL (2016) Application of metal-organic frameworks in chromatographic separation. Acta Chim Sin 74:969–979

Kreno LE, Leong K, Farha OK et al (2012) Metal–organic framework materials as chemical sensors. Chem Rev 112:1105–1125. https://doi.org/10.1021/cr200324t

Bae T-H, Lee JS, Qiu W et al (2010) A high-performance gas-separation membrane containing submicrometer-sized metal–organic framework crystals. Angew Chem Int Ed 49:9863–9866. https://doi.org/10.1002/anie.201006141

Rodenas T, Luz I, Prieto G et al (2014) Metal–organic framework nanosheets in polymer composite materials for gas separation. Nat Mater 14:48

Sachse A, Ameloot R, Coq B et al (2012) In situ synthesis of Cu-BTC (HKUST-1) in macro-/mesoporous silica monoliths for continuous flow catalysis. Chem Commun 48:4749–4751. https://doi.org/10.1039/C2CC17190B

Sorribas S, Zornoza B, Tellez C, Coronas J (2012) Ordered mesoporous silica-(ZIF-8) core-shell spheres. Chem Commun 48:9388–9390. https://doi.org/10.1039/C2CC34893D

Hayes R, Ahmed A, Edge T, Zhang H (2014) Core–shell particles: preparation, fundamentals and applications in high performance liquid chromatography. J Chromatogr A 1357:36–52. https://doi.org/10.1016/j.chroma.2014.05.010

Lv Y, Tan X, Svec F (2017) Preparation and applications of monolithic structures containing metal-organic frameworks. J Sep Sci 40:272–287. https://doi.org/10.1002/jssc.201600423

Shekhah O, Wang H, Kowarik S et al (2007) Step-by-step route for the synthesis of metal–organic frameworks. J Am Chem Soc 129:15118–15119. https://doi.org/10.1021/ja076210u

Shekhah O, Liu J, Fischer RA, Woll C (2011) MOF thin films: existing and future applications. Chem Soc Rev 40:1081–1106. https://doi.org/10.1039/C0CS00147C

Yue Y, Qiao Z-A, Li X et al (2013) Nanostructured zeolitic imidazolate frameworks derived from nanosized zinc oxide precursors. Cryst Growth Des 13:1002–1005. https://doi.org/10.1021/cg4002362

Zhan W, Kuang Q, Zhou J et al (2013) Semiconductor@metal–organic framework core–shell heterostructures: a case of ZnO@ZIF-8 nanorods with selective photoelectrochemical response. J Am Chem Soc 135:1926–1933. https://doi.org/10.1021/ja311085e

Chen B, Liang C, Yang J et al (2006) A microporous metal–organic framework for gas-chromatographic separation of alkanes. Angew Chem Int Ed 118:1418–1421. https://doi.org/10.1002/ange.200502844

Gu Z-Y, Yan X-P (2010) Metal–organic framework MIL-101 for high-resolution gas-chromatographic separation of xylene isomers and ethylbenzene. Angew Chem Int Ed 49:1477–1480. https://doi.org/10.1002/anie.200906560

Zhou Y-Y, Yan X-P, Kim K-N et al (2006) Exploration of coordination polymer as sorbent for flow injection solid-phase extraction on-line coupled with high-performance liquid chromatography for determination of polycyclic aromatic hydrocarbons in environmental materials. J Chromatogr A 1116:172–178. https://doi.org/10.1016/j.chroma.2006.03.061

Alaerts L, Kirschhock CEA, Maes M et al (2007) Selective adsorption and separation of xylene isomers and ethylbenzene with the microporous vanadium(IV) terephthalate MIL-47. Angew Chem Int Ed 46:4293–4297. https://doi.org/10.1002/anie.200700056

Yang C-X, Yan X-P (2011) Metal–organic framework MIL-101(Cr) for high-performance liquid chromatographic separation of substituted aromatics. Anal Chem 83:7144–7150. https://doi.org/10.1021/ac201517c

Maya F, Cabello CP, Estela JM et al (2015) Automatic in-syringe dispersive microsolid phase extraction using magnetic metal-organic frameworks. Anal Chem 87:7545–7549. https://doi.org/10.1021/acs.analchem.5b01993

Maya F, Palomino Cabello C, Frizzarin RM et al (2017) Magnetic solid-phase extraction using metal-organic frameworks (MOFs) and their derived carbons. TrAC Trends Anal Chem 90:142–152. https://doi.org/10.1016/j.trac.2017.03.004

Huang H-Y, Lin C-L, Wu C-Y et al (2013) Metal organic framework–organic polymer monolith stationary phases for capillary electrochromatography and nano-liquid chromatography. Anal Chim Acta 779:96–103. https://doi.org/10.1016/j.aca.2013.03.071

Fu Y-Y, Yang C-X, Yan X-P (2013) Incorporation of metal-organic framework UiO-66 into porous polymer monoliths to enhance the liquid chromatographic separation of small molecules. Chem Commun 49:7162–7164. https://doi.org/10.1039/C3CC43017K

Li L-M, Yang F, Wang H-F, Yan X-P (2013) Metal-organic framework polymethyl methacrylate composites for open-tubular capillary electrochromatography. J Chromatogr A 1316:97–103. https://doi.org/10.1016/j.chroma.2013.09.081

Zhang L-S, Du P-Y, Gu W et al (2016) Monolithic column incorporated with lanthanide metal-organic framework for capillary electrochromatography. J Chromatogr A 1461:171–178. https://doi.org/10.1016/j.chroma.2016.07.015

Yusuf K, Badjah-Hadj-Ahmed AY, Aqel A, ALOthman ZA (2016) Monolithic metal–organic framework MIL-53(Al)-polymethacrylate composite column for the reversed-phase capillary liquid chromatography separation of small aromatics. J Sep Sci 39:880–888. https://doi.org/10.1002/jssc.201501289

Yang S, Ye F, Lv Q et al (2014) Incorporation of metal-organic framework HKUST-1 into porous polymer monolithic capillary columns to enhance the chromatographic separation of small molecules. J Chromatogr A 1360:143–149. https://doi.org/10.1016/j.chroma.2014.07.067

Wang X, Lamprou A, Svec F et al (2016) Polymer-based monolithic column with incorporated chiral metal-organic framework for enantioseparation of methyl phenyl sulfoxide using nano-liquid chromatography. J Sep Sci 39:4544–4548. https://doi.org/10.1002/jssc.201600810

Lin C-L, Lirio S, Chen Y-T et al (2014) A novel hybrid metal-organic framework-polymeric monolith for solid-phase microextraction. Chem Eur J 20:3317–3321. https://doi.org/10.1002/chem.201304458

Lyu D-Y, Yang C-X, Yan X-P (2015) Fabrication of aluminum terephthalate metal-organic framework incorporated polymer monolith for the microextraction of non-steroidal anti-inflammatory drugs in water and urine samples. J Chromatogr A 1393:1–7. https://doi.org/10.1016/j.chroma.2015.03.020

Lirio S, Liu W-L, Lin C-L et al (2016) Aluminum based metal–organic framework-polymer monolith in solid-phase microextraction of penicillins in river water and milk samples. J Chromatogr A 1428:236–245. https://doi.org/10.1016/j.chroma.2015.05.043

Shih Y-H, Kuo Y-C, Lirio S et al (2017) A simple approach to enhance the water stability of a metal–organic framework. Chem Eur J 23:42–46. https://doi.org/10.1002/chem.201603647

Chen X-F, Zang H, Wang X et al (2012) Metal–organic framework MIL-53(Al) as a solid-phase microextraction adsorbent for the determination of 16 polycyclic aromatic hydrocarbons in water samples by gas chromatography-tandem mass spectrometry. Analyst 137:5411–5419. https://doi.org/10.1039/C2AN35806A

Shang H-B, Yang C-X, Yan X-P (2014) Metal–organic framework UiO-66 coated stainless steel fiber for solid-phase microextraction of phenols in water samples. J Chromatogr A 1357:165–171. https://doi.org/10.1016/j.chroma.2014.05.027

Yu L-Q, Wang L-Y, Su F-H et al (2018) A gate-opening controlled metal–organic framework for selective solid-phase microextraction of aldehydes from exhaled breath of lung cancer patients. Microchim Acta 185:307. https://doi.org/10.1007/s00604-018-2843-1

Denny MS, Cohen SM (2015) In situ modification of metal–organic frameworks in mixed-matrix membranes. Angew Chem Int Ed 54:9029–9032. https://doi.org/10.1002/anie.201504077

Ghani M, Font Picó MF, Salehinia S et al (2017) Metal–organic framework mixed-matrix disks: versatile supports for automated solid-phase extraction prior to chromatographic separation. J Chromatogr A 1488:1–9. https://doi.org/10.1016/j.chroma.2017.01.069

Li L, Xiang S, Cao S et al (2013) A synthetic route to ultralight hierarchically micro/mesoporous Al(III)-carboxylate metal–organic aerogels. Nat Commun 4:1774

Hu Y, Fan Y, Huang Z et al (2012) In situ fabrication of metal–organic hybrid gels in a capillary for online enrichment of trace analytes in aqueous samples. Chem Commun 48:3966–3968. https://doi.org/10.1039/C2CC17048E

Ameloot R, Liekens A, Alaerts L et al (2010) Silica–MOF composites as a stationary phase in liquid chromatography. Eur J Inorg Chem 2010:3735–3738. https://doi.org/10.1002/ejic.201000494

Qu Q, Si Y, Xuan H et al (2017) A nanocrystalline metal organic framework confined in the fibrous pores of core-shell silica particles for improved HPLC separation. Microchim Acta 184:4099–4106. https://doi.org/10.1007/s00604-017-2439-1

Qu Q, Xuan H, Zhang K et al (2017) Core-shell silica particles with dendritic pore channels impregnated with zeolite imidazolate framework-8 for high performance liquid chromatography separation. J Chromatogr A 1505:63–68. https://doi.org/10.1016/j.chroma.2017.05.031

Ahmed A, Forster M, Clowes R et al (2013) Silica SOS@HKUST-1 composite microspheres as easily packed stationary phases for fast separation. J Mater Chem A 1:3276–3286. https://doi.org/10.1039/C2TA01125E

Yan Z, Zheng J, Chen J et al (2014) Preparation and evaluation of silica-UIO-66 composite as liquid chromatographic stationary phase for fast and efficient separation. J Chromatogr A 1366:45–53. https://doi.org/10.1016/j.chroma.2014.08.077

Ehrling S, Kutzscher C, Freund P et al (2018) MOF@SiO2 core-shell composites as stationary phase in high performance liquid chromatography. Microporous Mesoporous Mater 263:268–274. https://doi.org/10.1016/j.micromeso.2018.01.003

Peristyy A, Nesterenko PN, Das A et al (2016) Flow-dependent separation selectivity for organic molecules on metal–organic frameworks containing adsorbents. Chem Commun 52:5301–5304. https://doi.org/10.1039/C6CC00111D

Arrua RD, Peristyy A, Nesterenko PN et al (2017) UiO-66@SiO2 core-shell microparticles as stationary phases for the separation of small organic molecules. Analyst 142:517–524. https://doi.org/10.1039/C6AN02344D

Li Y, Bao T, Chen Z (2017) Polydopamine-assisted immobilization of zeolitic imidazolate framework-8 for open-tubular capillary electrochromatography. J Sep Sci 40:954–961. https://doi.org/10.1002/jssc.201601152

Cui X-Y, Gu Z-Y, Jiang D-Q et al (2009) In situ hydrothermal growth of metal–organic framework 199 films on stainless steel fibers for solid-phase microextraction of gaseous benzene homologues. Anal Chem 81:9771–9777. https://doi.org/10.1021/ac901663x

Wu Y-Y, Yang C-X, Yan X-P (2014) Fabrication of metal–organic framework MIL-88B films on stainless steel fibers for solid-phase microextraction of polychlorinated biphenyls. J Chromatogr A 1334:1–8. https://doi.org/10.1016/j.chroma.2014.01.079

Yu L-Q, Yan X-P (2013) Covalent bonding of zeolitic imidazolate framework-90 to functionalized silica fibers for solid-phase microextraction. Chem Commun 49:2142–2144. https://doi.org/10.1039/C3CC00123G

Li Q-L, Wang X, Chen X-F et al (2015) In situ hydrothermal growth of ytterbium-based metal–organic framework on stainless steel wire for solid-phase microextraction of polycyclic aromatic hydrocarbons from environmental samples. J Chromatogr A 1415:11–19. https://doi.org/10.1016/j.chroma.2015.08.036

Shekhah O, Fu L, Sougrat R et al (2012) Successful implementation of the stepwise layer-by-layer growth of MOF thin films on confined surfaces: mesoporous silica foam as a first case study. Chem Commun 48:11434–11436. https://doi.org/10.1039/C2CC36233C

Saeed A, Maya F, Xiao DJ et al (2014) Growth of a highly porous coordination polymer on a macroporous polymer monolith support for enhanced immobilized metal ion affinity chromatographic enrichment of phosphopeptides. Adv Funct Mater 24:5790–5797. https://doi.org/10.1002/adfm.201400116

Maya F, Palomino Cabello C, Clavijo S et al (2015) Automated growth of metal–organic framework coatings on flow-through functional supports. Chem Commun 51:8169–8172. https://doi.org/10.1039/C5CC01186H

Lamprou A, Wang H, Saeed A, Svec F, Britt D, Maya F (2015) Preparation of highly porous coordination polymer coatings on macroporous polymer monoliths for enhanced enrichment of phosphopeptides. J Vis Exp e52926–e52926. https://doi.org/10.3791/52926

Zhichao X, Yongsheng J, Fang C et al (2014) Facile preparation of core–shell magnetic metal–organic framework nanospheres for the selective enrichment of endogenous peptides. Chem Eur J 20:7389–7395. https://doi.org/10.1002/chem.201400389

Chen Y, Xiong Z, Peng L et al (2015) Facile preparation of core–shell magnetic metal–organic framework nanoparticles for the selective capture of phosphopeptides. ACS Appl Mater Interfaces 7:16338–16347. https://doi.org/10.1021/acsami.5b03335

Qin W, Silvestre ME, Li Y, Franzreb M (2016) High performance liquid chromatography of substituted aromatics with the metal-organic framework MIL-100(Fe): mechanism analysis and model-based prediction. J Chromatogr A 1432:84–91. https://doi.org/10.1016/j.chroma.2016.01.006

Yang S, Ye F, Zhang C et al (2015) In situ synthesis of metal–organic frameworks in a porous polymer monolith as the stationary phase for capillary liquid chromatography. Analyst 140:2755–2761. https://doi.org/10.1039/C5AN00079C

Li X, Wang X, Ma W et al (2017) Fast analysis of glycosides based on HKUST-1-coated monolith solid-phase microextraction and direct analysis in real time mass spectrometry. J Sep Sci 40:1589–1596. https://doi.org/10.1002/jssc.201601115

Bao T, Zhang J, Zhang W, Chen Z (2015) Growth of metal–organic framework HKUST-1 in capillary using liquid-phase epitaxy for open-tubular capillary electrochromatography and capillary liquid chromatography. J Chromatogr A 1381:239–246. https://doi.org/10.1016/j.chroma.2015.01.005

Xu Y, Lv W, Ren C et al (2018) In situ preparation of multilayer coated capillary column with HKUST-1 for separation of neutral small organic molecules by open tubular capillary electrochromatography. J Chromatogr A 1532:223–231. https://doi.org/10.1016/j.chroma.2017.11.064

Bao T, Tang P, Mao Z, Chen Z (2016) An immobilized carboxyl containing metal-organic framework-5 stationary phase for open-tubular capillary electrochromatography. Talanta 154:360–366. https://doi.org/10.1016/j.talanta.2016.03.089

Pan C, Wang W, Zhang H et al (2015) In situ synthesis of homochiral metal–organic framework in capillary column for capillary electrochromatography enantioseparation. J Chromatogr A 1388:207–216. https://doi.org/10.1016/j.chroma.2015.02.034

del Rio M, Palomino Cabello C, Gonzalez V et al (2016) Metal oxide assisted preparation of core–shell beads with dense metal–organic framework coatings for the enhanced extraction of organic pollutants. Chem A Eur J 22:11770–11777. https://doi.org/10.1002/chem.201601329

Darder M, del M, Salehinia, Parra S JB, et al (2017) Nanoparticle-directed metal–organic framework/porous organic polymer monolithic supports for flow-based applications. ACS Appl Mater Interfaces 9:1728–1736. https://doi.org/10.1021/acsami.6b10999

Ghani M, Masoum S, Ghoreishi SM et al (2018) Nanoparticle-templated hierarchically porous polymer/zeolitic imidazolate framework as a solid-phase microextraction coatings. J Chromatogr A 1567:55–63. https://doi.org/10.1016/j.chroma.2018.06.059

Pan C, Wang W, Chen X (2016) In situ rapid preparation of homochiral metal-organic framework coated column for open tubular capillary electrochromatography. J Chromatogr A 1427:125–133. https://doi.org/10.1016/j.chroma.2015.12.020

Torad NL, Hu M, Ishihara S et al (2014) Direct synthesis of MOF-derived nanoporous carbon with magnetic Co nanoparticles toward efficient water treatment. Small 10:2096–2107. https://doi.org/10.1002/smll.201302910

Hao L, Wang C, Wu Q et al (2014) Metal–organic framework derived magnetic nanoporous carbon: novel adsorbent for magnetic solid-phase extraction. Anal Chem 86:12199–12205. https://doi.org/10.1021/ac5031896

González A, Avivar J, Maya F et al (2017) In-syringe dispersive µ-SPE of estrogens using magnetic carbon microparticles obtained from zeolitic imidazolate frameworks. Anal Bioanal Chem 409:225–234. https://doi.org/10.1007/s00216-016-9988-8

Carrasco-Correa EJ, Martínez-Vilata A, Herrero-Martínez JM et al (2017) Incorporation of zeolitic imidazolate framework (ZIF-8)-derived nanoporous carbons in methacrylate polymeric monoliths for capillary electrochromatography. Talanta 164:348–354. https://doi.org/10.1016/j.talanta.2016.11.027

Ghani M, Frizzarin RM, Maya F, Cerdà V (2016) In-syringe extraction using dissolvable layered double hydroxide-polymer sponges templated from hierarchically porous coordination polymers. J Chromatogr A 1453:1–9. https://doi.org/10.1016/j.chroma.2016.05.023

Acknowledgements

The Spanish Ministerio de Economía y Competitividad (MINECO) and the European Funds for Regional Development (FEDER) are gratefully acknowledged for financial support through Project CTQ2016–77155-R. A.F. thanks the Spanish Servicio Público de Empleo Estatal and European Social Funds for financial support through Program SOIB Jove-Qualificats Sector Públic.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Published in the topical collection Rising Stars in Separation Science, as part of Chromatographia’s 50th Anniversary Commemorative Issue.

Rights and permissions

About this article

Cite this article

Maya, F., Palomino Cabello, C., Figuerola, A. et al. Immobilization of Metal–Organic Frameworks on Supports for Sample Preparation and Chromatographic Separation. Chromatographia 82, 361–375 (2019). https://doi.org/10.1007/s10337-018-3616-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10337-018-3616-z