Abstract

There is a growing society demand for healthier, safer and environmental-friendly products. For instance, essential oils are emerging as a natural alternatives for replacing synthetic pharmaceuticals. Essential oils have indeed proven in vitro pharmacological activities to treat various diseases. Nonetheless, the application of essential oils is limited by their low solubility, low bioavailability, low permeability, uncontrolled volatility and low long-term stability. These issues can be solved by encapsulation of essential oils in nanoemulsions. Nanoemulsions display unique properties such as nanometric size, increased surface area and stability, which increase the efficiency of pharmaceutical dosage. Here we review nanoemulsion formulations, types of surfactants and oils, and their applications for essential oils encapsulation. We present methods to produce nanoemulsions such as high-pressure homogenization, microfluidizers, ultrasonic homogenization, phase inversion composition and phase inversion temperature. We also discuss nanoemulsion instability.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The clinical application of natural bioactive molecules is an alternative therapeutical approach, because bioactive agents are regarded as safer when compared with the synthetic molecules (Saka and Chella 2020). Such escalade in the application of these natural-based bioactive molecules brings a further need for the research in the development of suitable and stable formulations. Essential oils are bioactive molecules, considered safe and biocompatible with a great range of therapeutic applications due to their heterogeneous composition of fatty acids, terpenes, triterpenes and many other lipophilic components, that offer protection against skin dehydration, solar radiation, inflammation, insect attack, microorganisms, and viruses (Andreu et al. 2015; Donsì and Ferrari 2016; Bonferoni et al. 2017).

Most essential oils can prevent oxidation reactions, reducing the formation of free radicals, which can cause cellular damage and chronicle diseases as cancer. However, the clinical application of essential oils is limited by technological issues, as they are difficult to incorporate into a pharmaceutical product lies due to their low water solubility. Moreover, their bioavailability and stability in hydrophilic formulations tend to be extremely low. In addition, essential oils are often highly volatile and labile under many environmental conditions like light exposure and temperature. These drawbacks must be considered during the development of pharmaceutical formulations (Badgujar et al. 2014; Herman and Herman 2015; Moghimi et al. 2016).

Nanoemulsions are thermodynamically unstable isotropic and kinetically stable colloidal dispersions, in which 2 immiscible liquids are dispersed and stabilized by a surfactant (Solans et al. 2005; Helgeson 2016). They feature droplet size of 20–200 nm of diameter, with great potential for industrial application in pharmaceutical, food, agrochemical, cosmetics and personal care products (McClements and Jafari 2018; Jain and Chella 2020). The large surface area provided by their nanometric size provides higher loading capacity and enhanced solubility, which lead to an increased bioavailability of poorly soluble compounds (Jain and Chella 2020). Nanoemulsions can encapsulate, protect and promote controlled release of lipophilic bioactive molecules (Sutradhar and Amin 2013; Barradas et al. 2017b; McClements and Jafari 2018).

The application of nanoemulsions as vehicles of essential oils for pharmaceutical purposes requires a proper choice of their constituents such as, surfactants, and oils and of their preparation method. A minimum energy input is necessary for producing nanoemulsions by high energy methods of by low energy methods (Helgeson 2016; McClements and Jafari 2018).

In this article, we present a summary on formulation of oil-in-water nanoemulsions, and how they can promote encapsulation of lipophilic components, Additionally, we review their main instability phenomena and the recent applications of nanoemulsions for the encapsulation of natural oils. This article is an abridged version of the chapter published by Barradas and de Holanda e Silva (2020) in the series in the series sustainable agriculture reviews.

General aspects of nanoemulsions

Emulsions are constituted by one immiscible liquid dispersed in another immiscible liquid as droplets, stabilized by a surfactant. Oil-in-water emulsions are formed by a continuous aqueous phase and an oily dispersed phase. When the dispersed phase is an aqueous solution and the continuous phase is constituted by an oil or lipid molecules, the emulsion is called water-in-oil emulsion. In order to reduce interfacial tension between dispersed and continuous phases and provide stable systems, an emulsifier agent or surfactant is needed. The nature of the surfactant and the stabilizing film that it forms can deeply affect general properties of nanoemulsions, such as long-term stability, droplet size and superficial droplet charge. Emulsified systems can be classified according their droplet size and preparation methods as macroemulsions, microemulsions and nanoemulsions.

Nanoemulsions and macroemulsion differ in their droplet size, since both are thermodynamically unstable systems. Although nanoemulsions usually show mean droplet size smaller than 200 nm, their droplet size varies from 20 nm to either 500 or yet 100 nm, being until now controversial (Rao and McClements 2011; Solans and Solé 2012).

Macroemulsions are optically opaque, due to their large droplet size, promoting multiple light scattering, while nanoemulsions are often transparent or translucent, due to the small droplet size, that barely scatter light (McClements 2011; McClements and Jafari 2018). As nanosized droples are much smaller than visible wavelengths, nanoemulsions are often optically transparent systems, useful for pharmaceutical and cosmetic applications (Lohith Kumar and Sarkar 2018).

Nanoemulsions are kinetically stable systems and do not require the addition of a cosurfactant, unlike microemulsions. Kinetic stability is attributed to the Brownian motion of droplets which is more preponderant then sedimentation and coalescence (Tadros et al. 2004; Solans et al. 2005).

There has been much effort to clarify the difference between micro and nanoemulsions (Sonneville-Aubrun et al. 2004; Anton and Vandamme 2011). Both contain droplets of 20–200 nm, differing in certain aspects, especially in their preparation method (Abismail et al. 1999; McClements 2011), stability and in physicochemical concepts (Anton and Vandamme 2011; McClements 2012). Microemulsions are thermodynamically stable isotro oil/surfactant/water systems, while nanoemulsions are kinetically stable systems (McClements 2012). Microemulsions can present several structures with one, two, three ore more phases in equilibrium that can be water-continuous, oil-continuous, bicontinuous. They can feature nanometric sizes, with different geometries such as, worm-like, bicontinuous sponge-like, liquid crystalline, hexagonal, lamellar, and spherical swollen micelles, which is the most often confused with nanoemulsions (Anton and Vandamme 2011; McClements 2012).

Micelles from microemulsion are deeply affected in their morphology and size upon temperature and dilution, while micelles from nanoemulsions remain unchanged under these conditions. Parenteral route can pose those conditions with infinite dilution, temperature, pH and osmolarity variations. In such cases, only nanoemulsions remain stable (Anton and Vandamme 2011; Hörmann and Zimmer 2016; Lefebvre et al. 2017).

Low-energy emulsifying methods can induce the misconfusion between nano and microemulsions. However, in the production of nanoemulsions by low-energy methods, surfactant is added to the oil phase before the addition of water, not being possible to invert the order of components incorporation. Microemulsions can be formed regardless the order in which components are added (Anton and Vandamme 2011).

The large surface area of nano-droplets increases their ability to promote drug solubility and absorption in intestinal epithelium, the cornea and skin for example (Singh et al. 2017). Moreover, they present interesting aesthetic non-greasy characteristics, even with significant quantities of oil in their composition, minimizing organoleptic alteration in the final formulation (Sonneville-Aubrun et al. 2004; Tadros et al. 2004; Lohith Kumar and Sarkar 2018).

Composition of nanoemulsions

In general, nanoemulsion formulations are based on a dispersed phase and a dispersing phase, both stabilized by a surfactant. Typically, relatively high amounts of surfactants, usually from 10–15 wt%, in order to stabilize the high surface area of nanosized droplets are required (Mason et al. 2006; Azeem et al. 2009).

There is a great variety of encapsulated bioactive molecules in the form of nanoemulsions applied to food, packaging, textile and pharmaceutical or cosmetic products. Depending on the requirements of each application, such as food material, food enrichment, enhancing stability, appearance, taste or texture, different components can be weather encapsulated or yet used for the obtention of nanoemulsions (Dasgupta et al. 2019).

The main constituents of nanoemulsions are 3 components: oil or lipid phase, water or an aqueous phase and a surfactant. The formation and stability of the nanoemulsions depend on the physicochemical properties ant the correct mix of its components.

Surfactants

Surfactants are amphoteric molecules with 2 opposing affinities, one with a hydrophilic character and the other with a hydrophobic character. This hydrophilic-lipophilic balance of a surfactant is represented by the HLB (hydrophilic-lipophilic balance) (Abismail et al. 1999; Porras et al. 2004), which offer a good indication for the right the choice of emulsifiers for obtaining stable emulsions. During the production of nanoemulsions, surfactants molecules should be able to quickly adsorb on the droplet surface and maintain droplet integrity once two droplets collide (Tadros 1994).

According to the Young–Laplace Theory a minimum energy input capable of promoting the deformation of droplets is needed to produce nanoemulsion (Tadros et al. 2004). Large amounts of surfactants are required to reduce surface tension and stabilize the large interfacial surface. The production of nanoemulsions, therefore, is non-spontaneous process, which requires the input of energy. Since both the high interfacial tension and small droplet size combined provide high Laplace pressures, the minimization of the oil–water interfacial area lead to a spherical shape (McClements 2011).

Selecting a surfactant for pharmaceutical applications is one of the most critical aspects that should consider their toxicity (Wiedmann 2003; Tadros 2009) and can affect the fabrication method, nanoemulsion stability and their performance. Surfactants play a very important role in the stability of nanoemulsions, affecting the electrostatic or steric repulsions at the interface, which are dependent on the surfactant’s structure (such as double electric layer, branching, aromaticity). Other factors like the presence and type of electrolytes, pH, temperature and presence of additives (Myers 2005).

Many molecules can serve as a surfactant agent, depending on their molecular characteristics and their surface-active nature, which can determine their stabilizing mechanism as a stabilizing agent, emulsifying agent, detergent or yet, solubilizing agent (Dasgupta et al. 2019).

Due to their molecular constitution, surfactants are located the interfaces between 2 immiscible fluids, in such a way that polar groups are oriented to the aqueous phase and the non-polar, to the organic phase. The polar group is of great importance because it defines the classification of the surfactants, which can be divided into ionic (anionic and cationic), nonionic and amphoteric (or zwitterionic).

Types of surfactants

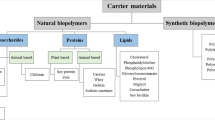

Ionic or non-ionic small-molecules synthetic and natural surfactants such as phospholipids, proteins and polysaccharides can act as surfactants. Non-ionic surfactants include small molecules such as sorbitan esters, like Span and Tween series and polymeric surfactants, such as polyoxyethylene ethers, as Brij® and poly (ethylene oxide)-poly (propylene oxide) copolymers. They can form small-sized droplets due to the rapid adsorption on the surface of droplets (Jafari 2017). Table 1 summarizes the most common types of natural and synthetic surfactants.

Natural surfactants feature excellent surface activity dese their molecular volume. These surfactants feature important properties like biodegradability and biocompatibility (A. Salem and S. Ezzat 2018). They are stable activity under different environmental conditions (high or low temperatures, pH, high pressure and osmolarity) and thus may be more effective in stabilizing nanoemulsions for the most diverse purposes (Dickinson 2003; Qian and McClements 2011). Most of natural surfactants are voluminous molecules, which can delay their ability to adsorb on the droplets surface and provide larger droplets. Still, they can provide stability through steric and electrostatic stabilization (Qian and McClements 2011).

Polysaccharides show a complex structure, being water-soluble, with good emulsifying properties. The most used are xanthan, modified starch, galactomannans and pectin (Dickinson 2003; Prabaharan 2011; Prajapati et al. 2013; Sweedman et al. 2013). Their emulsification properties are due to non-polar and hydrophilic groups that allow the interaction with both oil and water and their stabilization method can occur by both electrostatic repulsion and steric effect, preventing droplet flocculation and coalescence (Jafari et al. 2017).

Some proteins, especially those obtained from bovine milk (casein and whey proteins) can be used as emulsifying and surfactants agents, since they feature both hydrophilic and lipophilic residues and surface activity, providing cohesive and strong films around droplets (Kuhn and Cunha 2012; Mayer et al. 2013; Adjonu et al. 2014; Yerramilli and Ghosh 2017). Proteins can stabilize droplets mainly by steric effect and electrostatic repulsion because of the presence of negatively charged groups (Dickinson et al. 1998; Adjonu et al. 2014). As proteins are very large molecules, their adsorption on droplet surface takes longer. On the other hand, they promote a viscoelastic coating that prevent droplet deformation and aggregation, providing higher stability under several conditions (McClements 2011).

The combination of proteins and polysaccharides-based emulsifiers is interesting due to their ability to form polyelectrolyte complexes the possibility of Maillard reaction, enabling stability of the layer around nanosized micelles end prevent coalescence (Sonu et al. 2018; Farshi et al. 2019).

There is a growing demand on replacing synthetic surfactants for natural molecules. However, their application is still limited. For example, phospholipids and protein-based surfactants are unstable under environmental conditions such as pH, osmotic pressure and heating. Polysaccharides, on the other hand, provide stability under stressful conditions (Zhang et al. 2015). Moreover, they can stabilize nanoemulsions by increasing the viscosity of aqueous phase (Dickinson 2009).

Ionic surfactants enable interactions between the ionic group present in their molecule and water. The ionic surfactants most used in the production of nanoemulsion are summarized in Table 1. In general, they are resistant to changes in temperature and quite soluble in water. Also, pH has great influence on the solubility of the ionic surfactants due to the neutralization reactions that occur with this type of molecules.

The electrical charge on droplet surface plays an important role in stabilizing nanosized droplets as electrostatic repulsion, aggregation stability etc. Moreover, surface charge can be explored to provide nanoemulsions novel application by triggering their interaction with other components in biological media (Tian et al. 2016).

The stability of nanoemulsions with ionic surfactants is mainly promoted by electrostatic interaction between the droplets. Surface charge and zeta potential can be tuned by mixing non-ionic and ionic surfactants and varying their proportion, providing extremely long-term stable nanoemulsion (Babchin and Schramm 2012; Tian et al. 2016). However, they can disorganize cell membrane protein and lipid structures, being highly irritant for skin application and toxic for systemic administration (Elmahjoubi et al. 2009; Bondi et al. 2015).

Non-ionic surfactants are widely used for pharmaceutical purposes because of their low toxicity and their greater stability under different ionic strengths and pH. There are different types of non-ionic surfactants, the most used to provide pharmaceutical nanoemulsions are polyglycerol alkyl ethers, polyoxyethylene alkyl ethers, and ethoxylated hydrogenated castor oil.

Compared with low molecular weight surfactants, non-ionic polymeric surfactants produce more stable micelles, with a slower dissociation rate, which allows controlled payload release. In addition, they provide micelles in a wide variety of solvents (Xing and Mattice 1997; Kataoka et al. 2001).

Mao et al. studied the effect of different surfactants on interfacial tension, droplet size, zeta potential and morphology of β-carotene-loaded nanoemulsions. Tween-20, decaglycerol monolaurate, modified starch, whey protein isolate were evaluated as surfactants. The results showed that Tween 20 and decaglycerol monolaurate provided smaller droplet size, although with poorer stability compared with modified starch and whey protein isolate, which provided larger droplets with higher stability against droplet aggregation due to the formation of stronger interfacial layers. Besides, Tween 20 and whey protein isolate combined promoted higher stability regarding β-carotene content under storage conditions of 55 °C for prolonged time (Mao et al. 2009).

Oil phase

Oil phase constitutes the core of oil-in-water nanoemulsions and it has major impact in both nanoemulsion formation and stability. Several oil-related aspects such as polarity, water miscibility, interfacial tension and viscosity can alter nanoemulsions characteristics such as droplet size and stability (McClements 2011). As a consequence, several functional properties are affected, as bioavailability, miscibility and digestibility (McClements and Jafari 2018). Moreover, molecular weight of oil components, interfacial tension, density and viscosity of the oil phase also can lead the choice of a certain type of surfactant and obtention method (Rao and McClements 2011).

The oil: surfactant and oil: water ratio constitute an essential criteria for droplet formation and stability (Dasgupta et al. 2019). Moreover, as oils can provide a mixture of hydrophilic and lipophilic molecules, droplet stability is dependent on oil solubility, which is influenced by the amount of water soluble and lipophilic oil components. Great amounts of water-soluble components can lead to Ostwald ripening, the major source of instability in nanoemulsions (Chebil et al. 2013).

Oils and lipophilic components can be encapsulated in nano droplets to protect labile and degradable bioactive molecules from environmental conditions, control their release, increase their bioavailability and facilitate their manipulation or incorporation into aqueous formulations. Moreover, nanoencapsulation can mask physicochemical properties of oils, enabling the conversion of solutions into fine powders to mask undesirable tastes when administrated by oral route.

In this work the physicochemical properties of essential oils will be the focus. The most common essential oils often found are clove, peppermint, sweet fennel and bergamot (Strickley 2004; Saberi et al. 2014; Al-Subaie et al. 2015; Barradas et al. 2015; Pengon et al. 2018; Wan et al. 2019). They can act as drug carriers or solvents or be the only component of oil phase due to their pharmacological properties.

Essential oils

Essential oils are volatile substances extracted from aromatic plants. They are of great importance for the cosmetic, pharmaceutical, fragrance and food industries. These extremely potent organic substances are considered the main biochemical components of the therapeutic action of medicinal and aromatic plants (Donsì and Ferrari 2016; Pathania et al. 2018; Pérez-Recalde et al. 2018).

The methods of extraction vary according to the location of the volatile oil in the plant and the proposed use of it. The most common methods are: enfleurage, steam distillation (azeotropic distillation); extraction with organic solvent in a continuous and discontinuous way; pressing or supercritical CO2 extraction (Asbahani et al. 2015).

Their main characteristic is the volatility, which differs them from the fixed/vegetable oils, which are mixtures of lipid substances normally obtained from seeds. Another major characteristic is given thanks to the pleasant and intense aroma, being therefore also called essences. Essential oils are soluble in organic solvents, such as ether, thus receiving the name of ethereal oils or, in Latin, aetheroleum. Although they have a limited solubility in water, they have been used to increase water solubility of poorly soluble drug by constituting the inner phase of oil-in-water nanoemulsions (Barradas et al. 2017a).

Essential oils constituents range from terpene hydrocarbons and terpene alcohols, aldehydes, ketones, phenols, esters, ethers, oxides, peroxides, furans, organic acids, lactones, coumarins, to sulfur compounds. In the mixture, these compounds are present in different concentrations, and usually one of them is the majority compound, others are in lower levels and some in very low quantities (Donsì and Ferrari 2016).

Essential oils are well known for their flavors, antioxidant and antimicrobial activities and have been widely used as functional ingredients in food, pharmaceutical, and cosmetic products (Jin et al. 2016). In recent years, essential oils-based products have received particular interest because of their recognized safe regulatory status, multiple functionalities, and wide acceptance by consumers. However, their poor water solubility and high volatility during processing are 2 major obstacles of utilizing essential oils in the industrial processes.

A preliminary search in the main patent databases and indexed journal articles reveals the growing interest in the use of nanoemulsions in the last decade as well as the use of these systems in the pharmaceutical industry (Figs. 1 and 2). It is noteworthy the considerable increase in the number of publications describing essential oils-loaded nanoemulsions. Oil-in-water nanoemulsions carefully prepared using appropriate surfactants and emulsification processes are common choices to deliver essential oils in aqueous systems, for several administration routes and distinct applications. Nevertheless, there are still few studies that deal with the particularities in the development, characterization and evaluation of the pharmaceutical properties of these systems, especially with regard to the evaluation of their industrial scale production.

Patents related to nanoemulsions formulations from 2010 to 2019 using Boolean operators (Espacenet search* 6/10/2019). Blue: nanoemulsions; Green: nanoemulsions and drugs; Purple: Nanoemulsions AND essential oil. *https://worldwide.espacenet.com

Publications related to nanoemulsions formulations from 2010 to 2019 using Boolean operators AND (Web of Science search** 6/10/2019). Blue: nanoemulsions; Green: nanoemulsions AND drugs; Purple: nanoemulsions AND essential oil. **https://webofknowlegde.com

Essential oils can be obtained from the peeling of fruits, flowers or leaves. Several essential oils are being used in the development of nanoemulsions, in Table 2 are listed some nanosystems with proven activity. For example, clove oils are the essential oils obtained by distillation of the flower buds, stems, and leaves of the clove tree (Syzygium aromaticum) (Goñi et al. 2016). Among clove oils, clove bud oil is widely used and well-known for its potent antioxidant properties and antibacterial, antifungal, and antiviral activities (Chaieb et al. 2007; Anwer et al. 2014). Eugenol, 4-allyl-2-methoxyphenol, is the primary constituent, with more than 80%, of clove bud oil and is the major contributor of the above biological functions of clove bud oil (Jirovetz et al. 2006; Chaieb et al. 2007).

Another example, Rosmarinus officinalis L. essential oil is usually isolated by hydrodistillation, steam distillation, or extraction with organic solvents. The Rosemary oil is mainly located in leaves and the flowers; it is known for antioxidant, antimicrobial, anti-inflammatory properties and studies suggest that the one chemical compounds more frequently reported molecules was 1,8-cineole, α-pinene, and camphor (Angioni et al. 2004; Hernández et al. 2016).

Beside these, basil and thyme are aromatic herbs that are used extensively to add a distinctive aroma and flavor, and their respective oils extracted from fresh leaves and flowers are very recognized can be used as aroma additives in food, pharmaceuticals, and cosmetics (Li and Chang 2016; Mandal and DebManda 2016). Major compounds found in volatile extracts of basil and thyme exhibited varying amounts of anti-oxidative activity in particular, eugenol, thymol, carvacrol and 4-allylphenol (Marotti et al. 1996; Hudaib et al. 2002; Politeo et al. 2007; Hussain et al. 2008).

Recognized in traditional medicine, lemongrass essential oil is a potent antimicrobial and antioxidant natural bioproduct, its composition consists mainly of 70–85% geranial (citral), neral, geraniol, nerol, citronellol, 1,8-cineole (eucalyptol), α-terpineol, linalool, geranyl acetate. Lemongrass oil is collected by steam distillation of the herbage. It is a viscous liquid, yellow to dark yellow or dark amber in color turning red on prolonged storage (Sharma et al. 2018).

Additionally, essential oils from citrus fruits have countless therapeutic applications. Citrus fruits are well known and appreciated for centuries because of their pleasant aroma and appetizing flavor. The essential oil from these fruits are generally obtained from the juice of the peels of its fruit, but it can also be obtained from flowers or leaves (Asbahani et al. 2015). Among the best-known essential oils are those of orange, lemon, mint, eucalyptus, mint, citronella, clove, among others, as can be seen in Table 2.

Preparation of nanoemulsions

In general, the methods to produce nanoemulsions can be classified as high or low-energy methods. High-energy methods have been widely used to produce nanoemulsions in large industrial scale (McClements and Jafari 2018). They apply mechanical devices to produce nano-sized droplets. Low-energy methods depend on internal energy of the components to produce nanoemulsions upon changes in the compositions or environmental conditions. In both type of methods, surfactants play an important role in reducing the interfacial tension and the shear energy required to reduce the radius of curvature of the formed droplets (Tadros et al. 2004). The choice of the method depends on the properties of the oil phase and the surfactant, physicochemical and functional aspects required for the final application (McClements and Jafari 2018).

The preparation method can impact the properties of the nanoemulsions, such as: droplet size and stability (Gutiérrez et al. 2008). In this section, we provide a brief overview on the most commonly used high-energy and low-energy approaches for nanoemulsion formation.

High-energy methods

High-energy methods depend on high amounts of intense energy supplied by mechanical devices, which generate shear forces able to disrupt oil and water interface, providing nanosized droplets (Solans et al. 2005; Leong et al. 2009).

The obtention of nanoemulsions through high-energy methods can be divided into 2 distinct phases. In a first step the oil and aqueous phases are emulsified with an homogenizer such as Turrax® or Politron® producing a coarse emulsion with droplet size of 500–1000 nm, depending on the equipment and the operating conditions (McClements 2011; Rao and McClements 2011). Then, the droplet diameter is progressively reduced to its minimal value by means of high pressure homogenizers, ultrasonicators or microfluidizers, depending on the energy intensity of the homogenizer used, processing time and sample composition (Tadros et al. 2004; A. Salem and M. Ezzat 2018). It is worth noting that the minimum droplet size achievable may not be stabilized if the surfactant amount is insufficient to cover the newly created interface, as observed by Barradas et al. 2015. Final droplet size results from a balance between 2 phenomena that happen at the same time during homogenization: Breaking of drops into fine droplets and droplet coalescence after processing (Jafari et al. 2008). Higher surfactant concentration, increasing shear intensity or duration can contribute to reducing droplet size (Gupta et al. 2016a).

The obtention of nanoemulsions through high energy methods is considered advantageous for keeping nanoemulsions from instability phenomena without the addition of additives such as stabilizers, thickeners, co-solvents or co-surfactants (Anton et al. 2008).

Ultrasonication techniques for the preparation of nanoemulsions has been described by several authors (Leong et al. 2009; Shahavi et al. 2015; Gupta et al. 2016b). The device produces ultrasonic high-frequency waves, often higher than 20 kHz, which are able to promote a cavitation effect and cause mechanical vibration. Then the formation of micro-sized bubbles takes place, followed by their that collapse, causing the disruption of oil–water interface (McClements 2011). As a result, fine nanosized droplets are obtained after enough time of processing to ensure homogeneous size distribution and polydispersity index (Abismail et al. 1999; Sivakumar et al. 2014; Shahavi et al. 2015).

High pressure homogenization features the advantage of being scalable with greater control in droplet size reduction (Abismail et al. 1999). However, it requires large amounts of energy input, being more expensive to perform. The sample is forced through small channels under a pressure ranging from 500–15,000 psi (Gupta et al. 2016b) and flows under high pressure through microchannels resulting in a very fine emulsion, which causes the disruption of the dispersed droplets. Therefore, the radius of the generated droplets decreases gradually according to the increase of the shear rate. However, due to the lack of homogeneity of the flow, it is often necessary to process this fluid through the device through various cycles, until adequate droplets of size and polydispersity index are obtained. The pressure and number of processing cycles can be adjusted to produce nanoemulsions with tunable droplet size (Ouzineb et al. 2006; Constantinides et al. 2008).

The use of high-pressure homogenizers and ultrasonicators can lead to nanoemulsions with equivalent physical–chemical properties. However, some authors have reported some disadvantages regarding the use of ultrasonication, such as excessive heating of the sample, larger droplet distribution and low reproducibility in relation to the droplet diameter and polydispersity index, in addition to problems related to the difficulties of scale up (Tadros et al. 2004; Gutiérrez et al. 2008). Moreover, as they require high energy input, they are often considered cost-inefficient (Solans and Solé 2012).

Microfluidizers are composed of an interaction chamber where the fluid is injected and homogenized by cutting, impact and cavitation, in a design that resembles the high pressure homogenizers (Tadros et al. 2004; Lee and Norton 2013; A. Salem and M. Ezzat 2018). In this case, emulsification can occur inside the channels, since both dispersed and continuous phases flow inside fine channels individually. Streams are conducted to an interaction chamber under high pressures, where they are submitted to disruptive conditions, which provide the formation of fine droplets (McClements 2011; Lee and Norton 2013). Droplet is shown to decrease as homogenization pressure, surfactant concentration and number of processing passes increase and viscosity decreases (McClements 2011).

Low-energy methods

All low-energy emulsification methods are based on physicochemical properties and the internal chemical energy of the components. In phase inversion methods nanoemulsification achieve by spontaneous inversion of the surfactant's curvature providing small size globules (Solans and Solé 2012; Jin et al. 2016). Low-energy emulsifying methods are effective in providing small-sized droplets and allow nanoemulsification by simple stirring (Solans and Solé 2012).

Nanoemulsification occur by phase inversion in an coarse emulsion as a result of dramatic changes in the environmental conditions, in which parameters affecting the HLB of the surfactant (Tadros et al. 2004). The formation of nanoemulsions is achievable by various methods based on diffusion of solutes between 2 phases, interfacial turbulence, surface tension gradient and dispersion or condensation mechanisms (A. Salem and M. Ezzat 2018). The self-emulsification method is based on the diffusion of a water-miscible component from the organic phase into aqueous phase when both phases are in contact, and one of the phases contains a component miscible in both phases, such as a surfactant, co-surfactant or a polar organic solvent such as ethanol or acetone (McClements 2011). As a consequence, some of the components partially miscible with both phases diffuse from their original phase towards the other one in a rapid diffusion movement (Solans and Solé 2012). Such phenomenon provides an increased oil–water interfacial area, which trigger other phenomena such as interfacial turbulence, enabling droplets self-assembly (Anton et al. 2008; A. Salem and M. Ezzat 2018).

Moreover, nanoemulsions can also be obtained from dilution of surfactants aggregates such as liquid crystalline particles and bicontinuous microemulsions. Solè et al. produced 20 nm oil-in-water nanoemulsions upon dilution of and water-in-oil microemulsions by self-emulsification method. The effect of dilution procedure, weather stepwise or at once, on nanoemulsion formation was studied. On the other hand, water-in-oil microemulsion resulted in nanoemulsion when water dilution was performed stepwise (Solans and Solé 2012).

Self-emulsification is applied by pharmaceutical industry to obtain nanoemulsions due to this low-cost and to produce self-emulsifying drug delivery systems and self-nanoemulsifying drug delivery systems. Their self-emulsification properties increase in drug bioavailability and stability of the droplets (Anton and Vandamme 2011; Wei et al. 2012; Shahba et al. 2012).

Phase inversion-based methods are low-energy techniques that involve the inversion of the surfactant curvature, after a transition phase in which surfactant achieves zero curvature, such as bicontinuous microemulsions or lamellar liquid crystalline phases (Fernandez et al. 2004; Tadros et al. 2004; Porras et al. 2008; Solans and Solé 2012; Mayer et al. 2013; Sutradhar and Amin 2013). They are based on the chemical energy released from phase transitions phenomena during emulsification process. Phase inversion methods occur when some dramatic change in the environmental conditions take place, i.e., temperature or composition. These methods require selecting the right surfactant and knowledge of its phase behavior. Droplet size provided depends on the selected surfactant, the properties of the intermediary phases formed and the interfacial properties between both fluids (Maestro et al. 2008; Helgeson 2016).

In phase inversion composition method, phase inversion occurs by a major change in composition of the system. There is an increase of the volumetric fraction of the dispersed phase that is added to a microemulsion and then, the curvature of the surfactant is altered. Changing pH is also a useful approach to produce nanoemulsions by phase inversion composition. It can provide changes in electrical charge a stability of surfactants. Solè et al. reported the production of nanoemulsions by phase inversion composition method using ionic surfactant, i.e. potassium oleate. At low pH values, the carboxyl groups from fatty acids are non-ionized and, thus lipid-soluble. Under such condition, these molecules can stabilize emulsion. However, this situation is inverted if pH is raised. At higher pH values, carboxyl groups become ionized which increase their water-solubility and provide the stabilization of oil-in-water emulsions (Solè et al. 2006).

Phase inversion composition method is an interesting approach for large-scale production of nanoemulsions, since it relies only on the addition of one component to a mixture of components avoiding high temperatures and high-energy inputs, being also beneficial when temperature-sensitive components are used. Moreover, phase inversion composition method is not limited a specific type of surfactant (Solans and Solé 2012).

For temperature-sensitive surfactants, a phase inversion can be achieved by changing the temperature of the system, forcing the transition of an emulsion, prepared at low temperatures, for an emulsion, formed at higher temperatures, due to changes in the physicochemical properties of the surfactant. This is a typical example of a transient phase inversion, known as phase inversion temperature, in which nanoemulsions are formed under a fixed composition by changing temperature, by a drastic change in surfactants water solubility, through an intermediate liquid crystalline or bicontinuous microemulsion phase (Fernandez et al. 2004; McClements and Rao 2011).

Modifications in physicochemical properties of surfactant as temperature changes trigger micellization. Polyethoxylated nonionic surfactants are highly temperature-dependent and become lipophilic with increasing temperature due to dehydration of the chain of the polar part of the surfactant, i.e. ethylene oxide groups. During heating, the ethylene oxide hydrophilic groups are "hidden" and, consequently, there is modification of their affinity for the phases. As the system is cooled, the surfactant achieves the point of zero curvature and with minimum surface tension, which provides conditions to the formation of nanoemulsions (Fernandez et al. 2004; Tadros et al. 2004). The inversion point takes place at a specific temperature, called as phase inversion temperature, when the solubility of the surfactant in water and in oil reaches equivalent values. As temperature is continuously raised, the surfactant becomes more soluble in the oil phase than in the aqueous phase. Nanoemulsions are obtained by rapidly breaking up microemulsions formed at phase inversion point by sudden cooling below phase inversion temperature (McClements 2011). Through the phase inversion temperature method very small droplet sizes and stable nanoemulsions are obtained. On the other hand, the systems are highly prone to coalescence, being unstable, which makes cooling step a critical aspect to obtain stable nanoemulsions (Tadros et al. 2004; Solans and Solé 2012).

In emulsion inversion point method, one solvent, weather water or oil, is continuously added under stirring to the dispersed phase until its concentration becomes predominant, at constant temperature. Once a critical amount of solvent is achieved, droplets are so highly packed together that phase inversion occurs and the emulsion reaches a phase inversion point from water-in-oil to oil-in-water or vice-versa. This causes the spontaneous surfactant curvature to change, i.e., micelles are assembled in reverse curvature, which disrupts them into smaller structures thereby obtaining emulsions with nanometric droplets (Anton et al. 2008).

Emulsion inversion point method is considered to cause a catastrophic phase inversion, which occurs through the inversion in oil-to-water ratio. The surfactants used to produce the catastrophic phase inversion comprise small molecule synthetic emulsifiers able to stabilize both oil-in-water and water-in-oil emulsions. In this method, droplet size depends on several parameters such as stirring speed and the solvent addition speed (McClements and Rao 2011).

Although phase inversion temperature method enables the obtention of nanoemulsions with nanometric droplet sizes by the fact that it is possible to achieve very low values of interfacial tension, the dynamics of droplets coalescence can be extremely fast. In order to obtain stable nanoemulsions, the water–oil dispersion formed from phase inversion temperature method is readily cooled at a temperature just below it. Thus, the lamellar or the bicontinuous system collapse forming small droplets kinetically stable, with very small droplet size and narrow size droplet size. If the cooling process is not fast enough, the coalescence predominates and a polydisperse mixture is obtained (Fernandez et al. 2004).

Stability of nanoemulsions

As previously mentioned, nanoemulsions are characterized by their kinetically stability. Nanoemulsions shelf life can be further improved with some stabilization strategies that aim at maintaining bulk and droplet properties stable for longer periods of time. In order to achieve stable nanoemulsions several stabilization methods can be used, such as electrostatic, steric and mechanical stabilization (Cardoso-Ugarte et al. 2016).

Repulsive electrostatic forces between droplets can ensure proper droplet separation and prevent coalescence and/or flocculation. It is related to surfactant superficial charge and is responsible for the high stability of ionically charged nanoemulsions. Such effect is more important with smaller droplets, since they have an increased superficial area (Helgeson 2016).

Superficial charge is often provided by the surfactants, especially natural surfactants, as biopolymers with surface activity like proteins, polysaccharides, which can establish electrostatical intermolecular interactions depending on their concentration, pH and isoelectric point, and ionic strength of the solution (Cardoso-Ugarte et al. 2016). When pH of the surrounding solution is far from protein isoelectrical point, proteins residues are charged and there is an electrostatic repulsion that hinders droplets to aggregate (Dickinson et al. 1991).

Non-ionic surfactants also can provide steric stabilization, particularly amphiphilic non-ionic polymers, which can form voluminous interfacial films around droplets able to prevent coalescence. It is advantageous since fewer amounts of surfactants are required to stabilize droplets. On the other hand, in some cases, macromolecular surfactants can have slow diffusion towards droplets interface due to their size and molecular mobility (Tadros 2009; Qian and McClements 2011; Bouyer et al. 2012).

Steric stabilization comprises three main mechanisms: (1) non-adsorbent macromolecules which provide an elastic film around droplets that avoid droplet collision and deformation, (2) branched macromolecules that form a voluminous surface that prevent droplets from approaching, (3) stabilization due to hydrophobic interactions between adsorbed macromolecular surfactants (Cardoso-Ugarte et al. 2016).

The addition of viscosity agents and gelling polymers in the outer phase of nanoemulsions is often called as mechanical stabilization, since they can reduce droplets mobility by providing a mechanical network that serves as a barrier to aggregation. Such ingredients are often called as stabilizers and produce semi-solid or gel-like systems. However, they should be used with caution, since they can modify important properties as optical appearance, droplet size and encapsulation efficiency (Behrend et al. 2000; Dickinson 2009).

Instability phenomena

As nanoemulsions are formed from non-spontaneous process they have a tendency to undergo instability phenomena such as flocculation, coalescence and Ostwald ripening and gravitational phase separation as conventional emulsions. However, the small size of the droplets in a nanoemulsion confers enhanced kinetic stability, compared to ordinary emulsions (McClements 2011).

Thus, several different phenomena can take place, such as: (1) irreversible phenomena, related to the permanent modification of the droplet size and may lead to complete phase separation; (2) reversible flocculation of droplets, which may be followed by creaming or sedimentation, according to the respective densities of the dispersed and continuous phases (Abismail et al. 1999; Sing et al. 1999; Tadros et al. 2004). In general, nanoemulsions tend to be more stable to gravitational separation, flocculation and coalescence and more susceptible to Ostwald ripening (McClements 2011).

Reversible phenomena involve aggregation and migration of droplets, such as flocculation and creaming. Irreversible phenomena are related to the modification of droplet size such as coalescence. Droplets can co-exist in nanoemulsions as individually separated entities or as flocks, i.e., droplets aggregates formed as consequence of attractive interactions among them, characterizing a flocculated system (McClements 2015; McClements and Jafari 2018).

Flocculation is a reversible phenomenon in which the droplets dispersed in an emulsion aggregate and migrate, aiming to reach the thermodynamic equilibrium by decreasing the chemical potential differences that exist throughout the system. During this process, the droplets collide randomly and can remain in contact after these shocks, producing aggregates or flocks (Katsumoto et al. 2001; Starov and Zhdanov 2003). In flocculation, droplets aggregate without the rupture of the interfacial surfactant film, being a reversible phenomenon.

According to the difference of density between both inner and outer phases, the aggregates formed in the flocculation phenomenon may show gravitational separation such as sedimentation or creaming. When less dense aggregates are formed, they can rise to the surface, characterizing the phenomenon of creaming. Contrariwise, when inner phase shows higher density, denser aggregates are formed and deposited at the bottom of the system, constituting the sedimentation process. Hence, both phenomena are most prone to occur with droplets with increased droplet size, as larger objects are more susceptible to gravitational forces. Thus, gravitational separation can be reduced with smaller droplet sizes, increasing the viscosity of continuous phase or by reducing the density difference between dispersed and continuous phases (McClements 2011; McClements and Jafari 2018).

Some surfactants as proteins and polysaccharides can change droplet density by forming a shell layer on their surface. This can prevent gravitational separation phenomena such creaming, since it reduces density differences between inner and outer phases. Moreover, it can be possible to produce tunable-density droplets by controlling droplet size and thickness of surfactant layer (McClements 2011).

Irreversible phenomena include the Ostwald ripening, phase separation and coalescence, which may lead to the eventual complete phase separation (Sing et al. 1999). Coalescence can occur when droplets collide and merge, producing one larger droplet. Coalescence can lead to complete phase separation but can be avoided when repulsive interactions are provided by either electrostatic or steric effects, which is achievable by the right choice of surfactant (McClements and Jafari 2018).

Ostwald ripening is the process by which the larger particles grow from the smaller droplets due to the greater solubility of the smaller droplets and by the molecular diffusion of the continuous phase. It’s often considered as the main cause of instability of a nanoemulsion (Liu et al. 2006). This process is dependent on the polydispersity of the system, the solubility of dispersed phase in the continuous phase and the difference in solubility between droplets of different sizes.

In polydisperse nanoemulsions, there is a difference between the capillary pressure from different-sized droplets which makes the small droplets of the dispersed phase to diffuse into the large droplets (Taylor 1998; Chebil et al. 2013). As a consequence, the larger droplets grow from the smaller ones that have greater chemical potential. Thus, its content diffuses through the dispersing phase due to the greater solubility of the smaller droplets, which does not require contact between the droplets. This phenomenon aims to decrease the total energy of the system by reducing the total interfacial area, which can be avoided with the use of insoluble oils and with the choice of suitable polymeric surfactants (Tadros et al. 2004; Solans et al. 2005; Constantinides et al. 2008).

The rate of droplet growth depends on the product of the solubility of the dispersed oil in the aqueous continuous phase and its diffusion coefficient and is explained by the Lifshitz-Slezov-Wagner theory (Taylor 1998). Such theory assumes that the droplets of the dispersed phase are spherical and furthermore the distance between them is greater than the diameters of these droplets and the kinetics is controlled by molecular diffusion of the dispersed phase in the continuous phase. Also according to this theory, the Ostwald ripening rate in oil-in-water nanoemulsions, although is predicted to be lower than in conventional emulsions, is directly proportional to the solubility of the oil in the aqueous phase (Helgeson 2016).

However, the decrease in droplet size causes the increase of oil solubility in water, which is the driving force of Ostwald ripening. As the main factor for Ostwald ripening is the solubility of oil phase in water, it does not configure a real issue when it comes to poorly water-soluble oils. On the other hand, for nanoemulsions formulated with oils with some water-solubility, Ostwald ripening might represent the main instability event (McClements 2011).

Several studies were performed to describe and to modulate the Ostwald ripening mechanism. They suggested that the occurrence of Ostwald ripening can also be delayed or disrupted by size, interfacial viscosity or elasticity of the droplets. This occurs when the interfacial tension between the dispersed phase and the continuous phase equals zero. For a number of drops of the emulsion it was also shown that the Ostwald ripening could be disrupted by interfacial elasticity, even at finite interfacial tensions (Meinders and van Vliet 2004; Liu et al. 2006). Irreversible changes caused by Ostwald ripening lead to the formation of larger droplets, i.e., the formation of less stable emulsions, which may be responsible for phase separation. Phase inversion may occur due to temperature variation and/or change in composition of the emulsion.

Coalescence occurs after prolonged contact between the particles, when the adhesion energy between 2 droplets is greater than the turbulent energy that causes the dispersion. The mechanism is based on the rupture of the thin film between adjacent droplets, which leads to the joining of 2 droplets, forming one of larger size. The origin of the rupture of this film can occur due to a mechanical instability in the emulsion. When a large number of particles coalesce, the result is complete separation of the phases. The greater the extent of this phenomenon, the greater the tendency to complete phase separation (Sing et al. 1999).

Nanoemulsions can have their composition tuned towards to produce kinetically stable systems. The adequate selection of oil and aqueous phase and, most importantly, surfactants are essential to an ideal nanoemulsion design.

Pharmaceutical advantages of essential oil-loaded nanoemulsion

Nanoemulsions feature presented throughout that text offer both technological and pharmacological advantages in their use in many pharmaceutical applications, some of them are explored below.

The ability to encapsulate lipophilic bioactive molecules and improve their solubility and stability makes oil-in-water nanoemulsions a useful tool to enhance the delivery of lipophilic components. Qian et al. produced β-lactoglobulin-stabilized nanoemulsions for encapsulation of carotenoids, natural antioxidant easily chemically degradable. The influence of ionic strength, temperature and pH on chemical stability of β-carotene and physical stability of nanoemulsions was studied. Color fading due to chemical degradation of β-carotene was significantly smaller to β-lactoglobulin-stabilized nanoemulsions, which showed to be an effective approach to increase chemical stability of bioactive molecules, such as β-carotene (Qian et al. 2012).

The encapsulation of lipophilic components such as vegetable oils provides easier handling or administration and incorporation into a pharmaceutical secondary formulation such as gels, lotions or creams. Besides, nanoencapsulation of essential oils can also increase their bioavailability by increasing water solubility and due to small droplet size, promote rate and site-controlled delivery and protect from environmental degradation and prevent early evaporation (Sutradhar and Amin 2013; Dias et al. 2014).

Such approach can be useful in developing novel pharmaceutical formulations for masking unpleasant taste or smell of some drugs, which is especially useful for pediatrics formulations (Amin et al. 2018). Moreover, nanoemulsions are useful tools to improve bioavailability of both synthetic drugs and biologically active lipids, as polyphenols and oil-soluble vitamins, for example, which can improve their pharmacological effect (Chen et al. 2011; A. Salem and M. Ezzat 2018; Lohith Kumar and Sarkar 2018; Walia et al. 2019). The use of liquid-based encapsulation systems, as nanoemulsions, not only enhances drug penetration through biological membranes, as skin, intestinal tract or mucosae by altering their permeability, as also increase residence time in the target-tissue due to the enhanced bioadhesivity enabled by the nanoscale surface.

Yen et al. developed nanoemulsions for improving bioavailability of andrographolide, a poorly water-soluble anti-inflammatory diterpenoid obtained from Andrographis paniculata, with many pharmacological activities including antioxidant, anticancer and anti-inflammatory. Andrigrapholide is also suggested to have a therapeutical effect against various chronic infectious diseases. Their results indicated a significantly enhanced bioavailability of sixfold from nanoemulsions in comparison with conventional drug suspension. The ability of preventing gastrointestinal inflammatory disorders was much higher for nanoemulsions then for drug suspension (Yen et al. 2018). Besides, there is a general understanding that both solubility and bioavailability of poorly soluble drugs increase with reduced droplet size. The most plausible explanation is the enhancement of surface contact area, which can increase contact with solvents or cells.

Lane et al. studied the bioavailability of omega-3-rich algal oil encapsulated by nanoemulsions as a prophylactic strategy to prevent coronary heart disease and cerebrovascular disease in 11 subjects, which were fed with the formulations. Their study investigated whether the ingestion of omega-3-loaded nanoemulsions increased bioavailability in comparison with free oil. The results showed that bioavailability of omega-3 and polyunsaturated oils was drastically enhanced in patients fed with nanoemulsions (Lane et al. 2014).

The solubility of oil encapsulated in nanoemulsions increases with the reduction of droplet size. According to McClements studies (2011), the solubility of a typical oil was increased by 2.24, 1.08, 1.01 and 1.00 when droplet sizes of 10, 100, 1000 and 10 000 nm, respectively, were obtained. It is due to modification in oil–water partition coefficient of the encapsulated substance (McClements 2011).

A great number of studies have reported that oil-in-water nanoemulsions can increase antimicrobial activity of essential oils against several microorganisms as bacteria and fungus (Salvia-Trujillo et al. 2015; Sonu et al. 2018; Chuesiang et al. 2019; Saini et al. 2020). The encapsulation of essential oils into nanosized droplets can lead to a great disruptive activity of essential oils on cell membranes of such microorganisms (McClements and Jafari 2018). Chuesiang et al. produced cinnamon oil-loaded oil-in-water nanoemulsions by phase inversion temperature method and investigated their water-miscibility and antimicrobial activity against Escherichia coli, Salmonella enterica serova Triphimurim, Staphylococcus aureus and Vibrio parahaemolyticus. Cinnamon oil is known for its biological activities, which is related to cinnamaldehyde, its main constituent, that is able to interact with bacterial cell membranes (Chuesiang et al. 2019). Nanoemulsions increased antimicrobial activity probably due to the encapsulation of cinnamaldehyde, which is prone to chemical degradation in its free form. Besides, water dispersibility of cinnamon oil was enhanced by nanoencapsulation, which can allow its use as a natural preservative to be incorporated in food or beverages. Moreover, smaller droplets seemed to be more efficiently transported through bacterial membranes, and thus provided high antimicrobial activity in comparison with larger droplets, even though the latter contained higher amounts of cinnamon oil (Chuesiang et al. 2019).

A wide range of bioactive natural oils feature important antioxidant properties, however, as they are highly lipophilic molecules, their incorporation into many aqueous pharmaceutical formulations can be limited. In this context nanoemulsions rise as an encapsulation approach to provide protection to the droplet content, while preserving their functional properties. Rinaldi et al. (2017) produced neem oil-loaded nanoemulsions by ultrasound sonication Tween 20 as surfactant. The antioxidant activity of neem oil alone and encapsulated into nanoemulsions were quite similar, which suggest that nanoemulsions are efficient in encapsulating bioactive molecules, while maintaining their functional activity. Moreover, cytotoxicity was significantly reduced when neem oil was incorporated in droplets in comparison with free neem oil.

Nanoemulsions can be applied in the controlled release of bioactive molecules in the pharmaceutical and cosmetic area. This is due to their large surface area and low interfacial tension of droplets, which allows the effective penetration of active pharmaceutical ingredient (API). Because of their small size, nanosized oil-loaded droplets can penetrate the stratum corneum and can they also be applied in alcohol-free perfume formulations (Rai et al. 2018). The encapsulation of vegetable oils can be particularly beneficial for volatile components, such as essential oils and aromas, as it can control their release and evaporation rate, which can bring important for aroma perception and duration (McClements 2015). Time-controlled oil release can be tuned by modulating the lipophilicity of the inner phase. High lipophilicity can lead to a more sustained oil release. Droplet size in the case of nanoemulsions is not a limiting parameter for release profile (McClements 2011).

Our group developed and characterized oil-in-water hydrogel-thickened nanoemulsions based on sweet fennel and clove essential oil to transdermal delivery of 8-methoxsalen. In this study we demonstrate that the changes in the formulations can to modulate transdermal drug delivery and skin retention (Barradas et al. 2017a). In addition, it was clear from this work that any change in the internal phase composition implies the adjustment of the surfactant system necessary to produce emulsions with acceptable characteristics, as was well discussed throughout this work.

Because nanoemulsions are often transparent, they are related to freshness, purity and simplicity even when carrying great amounts of oil. This characteristic has been very much valued in both pharmaceutical and cosmetic industries. It is only achieved when droplet size is too small, smaller than 70 nm, to avoid strong light scattering and ensure optical transparency, which is also dependent on polydispersity. In that context, optically transparent products can be produced when small droplet size and narrow size distribution are obtained and maintained for a considerable period of time (Wooster et al. 2008). Transparent nanoemulsions can be prepared by both high-energy and low-energy methods by adjusting and optimizing their composition and processing parameters to achieve small droplet sizes and prevent Ostwald ripening and aggregation phenomena (McClements 2011).

Nanoemulsions with small droplet size can be sterilized through filtration and lead to a wide variety of water-based pharmaceutical products. A wide variety of products are obtained with the use of nanoemulsions, such as: lotions, moisturizers and transparent gels, with different rheological behavior (Helgeson 2016). Parenteral or injectable administration of nanoemulsions is employed for a variety of purposes, i.e., nutrition, for example, in the administration of vegetable oils, vitamins, among others and topical or systemic drug release. Nanoemulsions are advantageous for intravenous administration because of the rigid requirements of this route of administration, particularly the need for a droplet size in the formulation below 1 μm (Hörmann and Zimmer 2016). The benefit of nanoemulsions in oral drug administration has also been reported in the absorption of the emulsion in the gastrointestinal tract which has been correlated with droplet size (Bali et al. 2011).

Conclusion

Nanoemulsions are unique nanocarriers for the delivery lipophilic components as they provide a more stable, bioavailable, readily manufacturable, and acceptable formulation. They also impart good protection to the entrapped bioactive molecules against the effects of external conditions, as they encapsulate bioactive molecules in the core of nanosized micelles. In addition, nanoemulsions exhibit properties such as high surface area, stability and tunable rheology, which can improve drug bioavailability, making many treatments less toxic and invasive. Recently, a growing interest in the use of natural oils has been taking place, since they are proving to feature interesting characteristics, such as antimicrobial, antioxidants and anti-inflammatory properties. In this chapter the main aspects on nanoemulsion formulation, obtention methods, characterization techniques and applications were presented.

Both high-energy and low-energy emulsification methods provide nanoemulsions with small droplet size and stability. However, much research is still needed to the achieving scaling up of these processes and their impact on size and stability aspects for nanoemulsions. Such fact is responsible for so few nanoemulsion-based products are commercially available in contrast with so much research being published in this field.

Before nanoemulsions become widespread in pharmaceutical field, other challenges must be overcome. First, pharmaceutical-grade excipients should be ideally chosen, such as synthetic polymers and surfactants. Next, there are some safety concerns involving nanotechnological products, as their toxicological profile is different from conventional emulsion. In this context further research is needed to promote wide nanoemulsions production and utilization.

References

Abismail B, Canselier JP, Wilhelm AM et al (1999) Emulsification by ultrasound-drop size distribution and stability. Ultrason Sonochem 6:75–83

Adjonu R, Doran G, Torley P, Agboola S (2014) Formation of whey protein isolate hydrolysate stabilised nanoemulsion. Food Hydrocoll 41:169–177. https://doi.org/10.1016/j.foodhyd.2014.04.007

Al-Subaie MM, Hosny KM, El-Say KM et al (2015) Utilization of nanotechnology to enhance percutaneous absorption of acyclovir in the treatment of herpes simplex viral infections. Int J Nanomed. https://doi.org/10.2147/IJN.S83962

Alam P, Shakeel F, Anwer MK et al (2018) Wound healing study of eucalyptus essential oil containing nanoemulsion in rat model. J Oleo Sci 67:957–968. https://doi.org/10.5650/jos.ess18005

Amin F, Khan S, Shah SMH et al (2018) A new strategy for taste masking of azithromycin antibiotic: development, characterization, and evaluation of azithromycin titanium nanohybrid for masking of bitter taste using physisorption and panel testing studies. Drug Des Dev Ther 12:3855–3866. https://doi.org/10.2147/DDDT.S183534

Andreu V, Mendoza G, Arruebo M, Irusta S (2015) Smart dressings based on nanostructured fibers containing natural origin antimicrobial, anti-inflammatory, and regenerative compounds. Mater (Basel) 8:5154–5193. https://doi.org/10.3390/ma8085154

Angioni A, Barra A, Cereti E et al (2004) Chemical composition, plant genetic differences, antimicrobial and antifungal activity investigation of the essential oil of rosmarinus officinalis L. J Agric Food Chem 52:3530–3535. https://doi.org/10.1021/jf049913t

Anton N, Benoit J-P, Saulnier P (2008) Design and production of nanoparticles formulated from nano-emulsion templates—a review. J Control Release 128:185–199. https://doi.org/10.1016/j.jconrel.2008.02.007

Anton N, Vandamme TF (2011) Nano-emulsions and micro-emulsions: clarifications of the critical differences. Pharm Res 28:978–985. https://doi.org/10.1007/s11095-010-0309-1

Anwer MK, Jamil S, Ibnouf EO, Shakeel F (2014) Enhanced antibacterial effects of clove essential oil by nanoemulsion. J Oleo Sci. https://doi.org/10.5650/jos.ess13213

El AA, Miladi K, Badri W et al (2015) Essential oils: from extraction to encapsulation. Int J Pharm 483:220–243. https://doi.org/10.1016/j.ijpharm.2014.12.069

Azeem A, Rizwan M, Ahmad FJ et al (2009) Nanoemulsion components screening and selection: a technical note. AAPS PharmSciTech 10:69–75. https://doi.org/10.1208/s12249-008-9178-x

Babchin AJ, Schramm LL (2012) Osmotic repulsion force due to adsorbed surfactants. Coll Surf B Biointerfaces. https://doi.org/10.1016/j.colsurfb.2011.10.050

Badgujar SB, Patel VV, Bandivdekar AH (2014) Foeniculum vulgare mill: a review of its botany, phytochemistry, pharmacology, contemporary application, and toxicology. Biomed Res, Int

Bai L, Huan S, Gu J, McClements DJ (2016) Fabrication of oil-in-water nanoemulsions by dual-channel microfluidization using natural emulsifiers: saponins, phospholipids, proteins, and polysaccharides. Food Hydrocoll 61:703–711. https://doi.org/10.1016/j.foodhyd.2016.06.035

Bali V, Ali M, Ali J (2011) Nanocarrier for the enhanced bioavailability of a cardiovascular agent: in vitro, pharmacodynamic, pharmacokinetic and stability assessment. Int J Pharm. https://doi.org/10.1016/j.ijpharm.2010.10.018

Barradas TN, de Campos VEB, Senna JP et al (2015) Development and characterization of promising o/w nanoemulsions containing sweet fennel essential oil and non-ionic sufactants. Coll Surf A Physicochem Eng Asp. https://doi.org/10.1016/j.colsurfa.2014.12.001

Barradas TN, Senna JP, Cardoso SA et al (2017a) Hydrogel-thickened nanoemulsions based on essential oils for topical delivery of psoralen: permeation and stability studies. Eur J Pharm Biopharm. https://doi.org/10.1016/j.ejpb.2016.11.018

Barradas TNTNTN, Senna JPJP, Cardoso SASA et al (2017b) Hydrogel-thickened nanoemulsions based on essential oils for topical delivery of psoralen: permeation and stability studies. Eur J Pharm Biopharm 116:38–50. https://doi.org/10.1016/j.ejpb.2016.11.018

Barradas TN, de Holanda e Silva KG (2020) Nanoemulsions as optimized vehicles for essential oils. In: Saneja A, Panda A, Lichtfouse E (eds) Sustainable agriculture reviews 44. Sustainable agriculture reviews, vol 44. Springer, Cham. https://doi.org/10.1007/978-3-030-41842-7_4

Behrend O, Ax K, Schubert H (2000) Influence of continuous phase viscosity on emulsification by ultrasound. Ultrason Sonochem. https://doi.org/10.1016/S1350-4177(99)00029-2

Bondi CA, Marks JL, Wroblewski LB et al (2015) Human and environmental toxicity of sodium lauryl sulfate (sls): evidence for safe use in household cleaning products. Environ Health Insights 9:27–32. https://doi.org/10.4137/EHI.S31765

Bonferoni MC, Rossi S, Cornaglia AI et al (2017) Essential oil-loaded lipid nanoparticles for wound healing. Int J Nanomed 13:175–186. https://doi.org/10.2147/IJN.S152529

Borges RS, Lima ES, Keita H et al (2018) Anti-inflammatory and antialgic actions of a nanoemulsion of Rosmarinus officinalis L. essential oil and a molecular docking study of its major chemical constituents. Inflammopharmacol 26:183–195. https://doi.org/10.1007/s10787-017-0374-8

Botas G, Cruz R, de Almeida F et al (2017) Baccharis reticularia DC and limonene nanoemulsions: promising larvicidal agents for aedes aegypti (diptera: culicidae) control. Mol. https://doi.org/10.3390/molecules22111990

Bouyer E, Mekhloufi G, Rosilio V et al (2012) Proteins, polysaccharides, and their complexes used as stabilizers for emulsions: alternatives to synthetic surfactants in the pharmaceutical field? Int J Pharm 436(1–2):359–378

Cardoso-Ugarte GA, López-Malo A, Jiménez-Munguía MT (2016) Application of nanoemulsion technology for encapsulation and release of lipophilic bioactive compounds in food. Emuls. https://doi.org/10.1016/B978-0-12-804306-6.00007-6

Cerqueira-Coutinho C, Santos-Oliveira R, dos Santos E, Mansur CR (2015) Development of a photoprotective and antioxidant nanoemulsion containing chitosan as an agent for improving skin retention. Eng Life Sci. https://doi.org/10.1002/elsc.201400154

Chaieb K, Hajlaoui H, Zmantar T et al (2007) The chemical composition and biological activity of clove essential oil, Eugenia caryophyllata (Syzigium aromaticum L. Myrtaceae): a short review. Phyther Res 21:501–506. https://doi.org/10.1002/ptr.2124

Chebil A, Desbrières J, Nouvel C et al (2013) Ostwald ripening of nanoemulsions stopped by combined interfacial adsorptions of molecular and macromolecular nonionic stabilizers. Coll Surf A Physicochem Eng Asp 425:24–30. https://doi.org/10.1016/j.colsurfa.2013.02.028

Chen H, Khemtong C, Yang X et al (2011) Nanonization strategies for poorly water-soluble drugs. Drug Discov, Today

Chuesiang P, Siripatrawan U, Sanguandeekul R et al (2019) Antimicrobial activity and chemical stability of cinnamon oil in oil-in-water nanoemulsions fabricated using the phase inversion temperature method. LWT 110:190–196. https://doi.org/10.1016/j.lwt.2019.03.012

Constantinides PP, Chaubal MV, Shorr R (2008) Advances in lipid nanodispersions for parenteral drug delivery and targeting. Adv Drug Deliv Rev 60:757–767. https://doi.org/10.1016/j.addr.2007.10.013

Dasgupta N, Ranjan S, Gandhi M (2019) Nanoemulsion ingredients and components. Environ Chem Lett 17:917–928. https://doi.org/10.1007/s10311-018-00849-7

de Dias D, O, Colombo M, Kelmann RG, et al (2014) Optimization of copaiba oil-based nanoemulsions obtained by different preparation methods. Ind Crops Prod 59:154–162. https://doi.org/10.1016/j.indcrop.2014.05.007

Dickinson E (2003) Hydrocolloids at interfaces and the influence on the properties of dispersed systems. Food Hydrocoll 17(1):25–29

Dickinson E (2009) Hydrocolloids as emulsifiers and emulsion stabilizers. Food Hydrocoll 23:1473–1482. https://doi.org/10.1016/j.foodhyd.2008.08.005

Dickinson E, Galazka VB, Anderson DMW (1991) Emulsifying behaviour of gum arabic. part 1: effect of the nature of the oil phase on the emulsion droplet-size distribution. Carbohydr Polym 14:373–383. https://doi.org/10.1016/0144-8617(91)90003-U

Dickinson E, Semenova MG, Antipova AS (1998) Salt stability of casein emulsions. Food Hydrocoll 12:227–235. https://doi.org/10.1016/S0268-005X(98)00035-6

Donsì F, Ferrari G (2016) Essential oil nanoemulsions as antimicrobial agents in food. J Biotechnol 233:106–120

Duarte JL, Amado JRR, Oliveira AEMFM et al (2015) Evaluation of larvicidal activity of a nanoemulsion of rosmarinus officinalis essential oil. Rev Bras Farmacogn 25:189–192. https://doi.org/10.1016/j.bjp.2015.02.010

Elmahjoubi E, Frum Y, Eccleston GM et al (2009) Transepidermal water loss for probing full-thickness skin barrier function: correlation with tritiated water flux, sensitivity to punctures and diverse surfactant exposures. Toxicol Vitr. https://doi.org/10.1016/j.tiv.2009.06.030

Farshi P, Tabibiazar M, Ghorbani M et al (2019) Whey protein isolate-guar gum stabilized cumin seed oil nanoemulsion. Food Biosci 28:49–56. https://doi.org/10.1016/j.fbio.2019.01.011

Fernandez P, André V, Rieger J, Kühnle A (2004) Nano-emulsion formation by emulsion phase inversion. Coll Surf A Physicochem Eng Asp. https://doi.org/10.1016/j.colsurfa.2004.09.029

Goñi MG, Roura SI, Ponce AG, Moreira MR (2016) Clove (Syzygium aromaticum) oils. In: Preedy VR (ed) Essential oils in food preservation, flavor and safety. Academic Press

Gupta A, Eral HB, Hatton TA, Doyle PS (2016a) Nanoemulsions: formation, properties and applications. Soft Matter. https://doi.org/10.1039/C5SM02958A

Gupta A, Eral HB, Hatton TA, Doyle PS (2016b) Controlling and predicting droplet size of nanoemulsions: scaling relations with experimental validation. Soft Matter. https://doi.org/10.1039/C5SM02051D

Gutiérrez JM, González C, Maestro A et al (2008) Nano-emulsions: new applications and optimization of their preparation. Curr. Opin, Colloid Interface Sci

Hashem AS, Awadalla SS, Zayed GM et al (2018) Pimpinella anisum essential oil nanoemulsions against tribolium castaneum—insecticidal activity and mode of action. Environ Sci Pollut Res 25:18802–18812. https://doi.org/10.1007/s11356-018-2068-1

Hashemi Gahruie H, Ziaee E, Eskandari MH, Hosseini SMH (2017) Characterization of basil seed gum-based edible films incorporated with zataria multiflora essential oil nanoemulsion. Carbohydr Polym 166:93–103. https://doi.org/10.1016/j.carbpol.2017.02.103

Hasssanzadeh H, Alizadeh M, Rezazad Bari M (2018) Formulation of garlic oil-in-water nanoemulsion: antimicrobial and physicochemical aspects. IET Nanobiotechnol 12:647–652. https://doi.org/10.1049/iet-nbt.2017.0104

Helgeson ME (2016) Colloidal behavior of nanoemulsions: interactions, structure, and rheology. Curr. Opin, Colloid Interface Sci, p 25

Herman AAP, Herman AAP (2015) Essential oils and their constituents as skin penetration enhancer for transdermal drug delivery: A review. J. Pharm, Pharmacol

Hernández MD, Sotomayor JA, Hernández Á, Jordán MJ (2016) Rosemary (Rosmarinus officinalis L.) oils. In: Preedy VR (ed) Essential oils in food preservation. San Diego, Flavor and safety, pp 677–688

Hoeller S, Sperger A, Valenta C (2009) Lecithin based nanoemulsions: a comparative study of the influence of non-ionic surfactants and the cationic phytosphingosine on physicochemical behaviour and skin permeation. Int J Pharm 370:181–186. https://doi.org/10.1016/j.ijpharm.2008.11.014

Hörmann K, Zimmer A (2016) Drug delivery and drug targeting with parenteral lipid nanoemulsions—a review. J Control Release 223:85–98. https://doi.org/10.1016/j.jconrel.2015.12.016

Hudaib M, Speroni E, Di Pietra AM, Cavrini V (2002) GC/MS evaluation of thyme (Thymus vulgaris L.) oil composition and variations during the vegetative cycle. J Pharm Biomed Anal 29:691–700

Hussain AI, Anwar F, Hussain Sherazi ST, Przybylski R (2008) Chemical composition, antioxidant and antimicrobial activities of basil (Ocimum basilicum) essential oils depends on seasonal variations. Food Chem 108:986–995. https://doi.org/10.1016/j.foodchem.2007.12.010

Jafari SM (2017) Nanoencapsulation technologies for the food and nutraceutical industries. Academic Print

Jafari SM, Assadpoor E, He Y, Bhandari B (2008) Re-coalescence of emulsion droplets during high-energy emulsification. Food Hydrocoll 22(7):1191–1202

Jafari SM, Paximada P, Mandala I, et al (2017) Encapsulation by nanoemulsions. In: Nanoencapsulation technologies for the food and nutraceutical industries. Elsevier, pp36–73

Jain H, Chella N (2020) Methods to improve the solubility of therapeutical natural products: a review. Environ Chem Lett. https://doi.org/10.1007/s10311-020-01082-x

Jin W, Xu W, Lian H et al (2016) Nanoemulsions for food: properties, production, characterization and applications. In: Grumezescu A (ed) Emulsions. Elsevier Inc., London, pp 1–36

Jirovetz L, Buchbauer G, Stoilova I et al (2006) Chemical composition and antioxidant properties of clove leaf essential oil. J Agric Food Chem 54:6303–6307. https://doi.org/10.1021/jf060608c

Kataoka K, Harada A, Nagasaki Y (2001) Block copolymer micelles for drug delivery: design, characterization and biological significance. Adv Drug Deliv Rev 47:113–131. https://doi.org/10.1016/S0169-409X(00)00124-1

Katsumoto Y, Ushiki H, Lachaise J, Graciaa A (2001) Time evolution of the size distribution of nano-sphere droplets in the hexadecane-in-water miniemulsion stabilized by nonionic surfactants. Coll Polym Sci 279:122–130. https://doi.org/10.1007/s003960000395

Khan MS, Krishnaraj K (2014) Phospholipids: a novel adjuvant in herbal drug delivery systems. Crit Rev Ther Drug Carrier Syst 31:407–428. https://doi.org/10.1615/CritRevTherDrugCarrierSyst.2014010634

Kiaei N, Hajimohammadi R, Hosseini M (2018) Investigation of the anti-inflammatory properties of calendula nanoemulsion on skin cells. Bioinspired, Biomim Nanobiomater 7:228–237. https://doi.org/10.1680/jbibn.17.00033

Klang V, Valenta C (2011) Lecithin-based nanoemulsions. J Drug Deliv Sci Technol 21:55–76. https://doi.org/10.1016/S1773-2247(11)50006-1

Kuhn KR, Cunha RL (2012) Flaxseed oil – Whey protein isolate emulsions: effect of high pressure homogenization. J Food Eng 111:449–457. https://doi.org/10.1016/j.jfoodeng.2012.01.016

Lane KE, Li W, Smith C, Derbyshire E (2014) The bioavailability of an omega-3-rich algal oil is improved by nanoemulsion technology using yogurt as a food vehicle. Int J Food Sci Technol 49:1264–1271. https://doi.org/10.1111/ijfs.12455

Lee L, Norton IT (2013) Comparing droplet breakup for a high-pressure valve homogeniser and a microfluidizer for the potential production of food-grade nanoemulsions. J Food Eng 114:158–163. https://doi.org/10.1016/j.jfoodeng.2012.08.009