Abstract

Although nanoscale zero-valent iron (nano-Fe0) is used to remediate pollutants, this reagent still presents stability and reactivity issues. To solve those issues, we synthesized bentonite-supported nanoscale iron bimetals B-Fe/Ni and B-Fe/Pd. We then used those reagents to degrade the methyl orange dye in water. Results of scanning electron microscopy and X-ray diffraction showed that the presence of bentonite and bimetal decreased nanoscale iron aggregation and increased methyl orange removal efficiency. More than 90 % of methyl orange at 100 mg/L was degraded by B-Fe/Ni (0.15 g/L) in 10 min. By comparison, only 62 % of methyl orange was degraded by B-Fe, and 35 % of methyl orange was degraded by nano-Fe0. The degradation rate decreased with the increase of the initial concentration of methyl orange. Lower pH allowed fast removal of methyl orange. Overall our findings show that a nanoscale Fe/Ni on bentonite-supported material is more efficient than nano-Fe0. One-step synthesis is more convenient than current two-step-synthesized nanoscale bimetals. Bentonite-supported nanoscale bimetals could therefore be an economic competitive candidate for contaminated water remediation.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nanoscale zero-valent iron (nano-Fe0) is a kind of nanoparticles ranging from 1 to 100 nm, which can be obtained through sonochemistry method, electrochemical method, liquid-phase or gas-phase reduction method. Since 1990s, nano-Fe0 has been used to remediate groundwater polluted by toxic contaminants including arsenic (Su and Puls 2001; Klas and Kirk 2013), halogenated organic compounds (Phenrat et al. 2009; Chen et al. 2011a) and heavy metals (Fu et al. 2013). Due to its large specific surface area and high reactivity, nano-Fe0 shows high removal efficiency for pollutants (Trujillo-Reyes et al. 2010; Lee et al. 2011). However, there are still some application challenges associated with a major problem of nano-Fe0 stability and reactivity duration (Phenrat et al. 2007).

Many researchers have tried methods to improve this shortage by modifying nano-Fe0. One way is to make nano-Fe0 dispersed into the solid-phase load materials, such as active carbon (Fu et al. 2013; Tseng et al. 2011), bentonite (Chen et al. 2011b; Shi et al. 2011) and chelating resin (Shi et al. 2013). It showed that bentonite-supported nanoparticles had a very significant degradation efficiencies of 89.73 % for methyl orange (Chen et al. 2011b) and the addition of chelating resin could increase the stability and activity of nanoparticles (Shi et al. 2013). The other way is to coat “green” materials such as polymer carboxymethyl cellulose (He and Zhao 2007; Kim et al. 2012) or polyelectrolyte (Phenrat et al. 2008) on the surface of nano-Fe0 to improve its stability.

In addition to above “load” or “coat” method, nanoscale bimetals have also been introduced to increase the reactivity of nano-Fe0. Liquid-phase reduction method is commonly used for nanoscale Fe/Pd, Fe/Ni and Fe/Cu. Matson and Chun (Chun et al. 2010) compared three kinds of nano-Fe0 bimetals for the removal of carbon tetrachloride, and Fe/Ni bimetallic nanoparticles showed the strongest reducing performance. It was proved that the activity of nano-Fe0 could be greatly enhanced by loading other metal materials (Zhang et al. 1998; Shih et al. 2009; Fang et al. 2011; He and Zhao 2005; Choi et al. 2008; Meyer et al. 2009).

Despite other reports on the degradation of organic contaminant using “load” or “coat” nano-Fe0, or separately using nanoscale bimetals, few studies tried to combine “load” with nanoscale bimetals for the removal of the contaminants in aqueous solution. Bentonite, an environmental friendly material, is a low-cost adsorbent and used here as load material to improve dispersibility and stability of nano-Fe/Ni (B-Fe/Ni) or Fe/Pd (B-Fe/Pd). Methyl orange is difficult to be degraded and regarded as one of the problems of wastewater treatment (Luo et al. 2013; Yun et al. 2013). Herein, we focused on synthesis of bentonite-supported Fe/Ni (B-Fe/Ni) or Fe/Pd (B-Fe/Pd) and explored the reactivity of the nanoscale iron bimetals for removal of methyl orange as the target pollutant, as well as the effects of environmental factors on remediation.

Experimental

Materials and methods

The clay mineral of bentonite is primarily sodium montmorillonite supplied by Alfa Aesar, Beijing. It has a montmorillonite content (>90 %) and a cation exchange capacity of 125 meq/100 g. After drying at 80 °C for 10 h, the raw bentonite was ground and sieved with a 200 mesh screen prior to use. Methyl orange was supplied by Beijing Chemical Factory. A stock solution containing methyl orange was prepared by dissolving a certain quality of methyl orange with deionized water and then diluted to the desired concentrations for experiments. Polyethylene glycol (PEG-4000), Pd (C2H3O2)2, ferrous sulfate (FeSO4·7H2O), nickel sulfate and KBH4 were purchased from Sinopharm Chemical Reagent Beijing Co. Ltd. All the chemicals were analytical reagent grade and used without further purification.

Synthesis of bentonite-supported nanoscale iron

Nano-B-Fe was synthesized by liquid-phase reduction method. Briefly, to obtain B-Fe with a Fe0/bentonite mass ratio of 1:1, ferrous sulfate (4.9643 g, 17.9 mmol) was dissolved in 50 mL water mixed with 20 mL ethanol, and desired bentonite (1.00 g) was added to this solution. Polyethylene glycol-4000 (PEG-4000) used as the dispersant and the mixture was stirred with an electric rod for 10 min, and then NaBH4 solution (2.8896 g, 76.3 mmol in 30 mL NaOH solution, BH4 −:Fe2+=2:1) was added dropwise (2 d/s) with vigorous stirring. All the experiments were performed under a N2 atmosphere. A synthesis reaction is described below:

After the drops added, the mixture was stirred continuously for another 10 min. The jet-black nanoscale aggregates (B-Fe) were collected by vacuum filtration and quickly rinsed thrice with deionized water and ethanol, respectively.

Preparation of nano-B-Fe/Ni

The preparation method of B-Fe/Ni was similar with above B/Fe procedure. Briefly, bentonite (1.00 g) and nickel sulfate (NiSO4·6H2O) 0.2224 g (0.85 mmol) were added together into the solution of ferrous sulfate (4.9643 g, 17.9 mmol) dissolved in 50 mL water mixed with 20 mL ethanol. Only such one-step synthesis could make nickel loading on the surface of Fe0 (Fig. 1). A synthesis included the following reaction:

Preparation of nano-B-Fe/Pd

The preparation of B-Fe/Ni was one-step method, while B-Fe/Pd was effectively produced by two-step approach (Fig. 1), which was proved by our many preliminary experiments. For B-Fe/Pd preparation, after synthesis of nanoscale B-Fe, a desired prepared Pd solution (10.55 mg, 0.02 mmol palladium acetate dissolved in 30 mL of ethanol) was added into fresh B-Fe and kept for 20 min. B-Fe/Pd (Pd: Fe = 0.5:100) was collected by vacuum filtration and quickly rinsed thrice with ethanol. The reaction occurs as follows:

All the prepared samples (B-Fe, Fe/Ni, B-Fe/Ni, B-Fe/Pd) were dried at 60 °C under vacuum for 10 h, and then kept in a nitrogen atmosphere for next experiments.

Batch experiments for removal of methyl orange

Removal of methyl orange by different materials (bentonite, nano-Fe0, B-Fe, Fe/Ni, B-Fe/Ni and B-Fe/Pd) was performed in a series of 250-mL oxygen-free bottle containing 100 mg/L of methyl orange solution at room temperature (25.0 ± 0.1 °C). The initial solution pH was ~6.07. After adding a desired amount of nanomaterials, the bottles were sealed and stirred at 60 rpm. Samples were withdrawn at a time interval and were centrifuged at 5,000 r/min for 5 min, and the supernatant concentration of methyl orange was measured by using a UV–Vis spectrophotometer (Shimadzu UV-1750) at λ = 464 nm. The removal efficiency (R) of methyl orange was calculated by the following equation:

where ρ 0 is methyl orange initial concentration (mg/L), and ρ 1 is methyl orange residual concentration (mg/L) at a desired time. Various batch experiments for methyl orange removal by bentonite-supported nanoscale iron bimetals were also undertaken for evaluation at conditions including different initial pH, methyl orange concentrations from 50 to 200 mg/L and nickel loading ratios from 2.5 to 10.0 %.

All experiments were conducted in triplicate. The data were calculated as the mean values of the samples and statistically analyzed using software Origin 8.

Results and discussion

Characterization of nano-iron particles

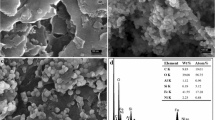

The techniques of X-ray diffraction (XRD, Rigaku D/Max B), transmission electron microscopy (TEM, Hitachi H8100), scanning electron microscopy with energy dispersive spectrometer (SEM–EDS, JSM-6460) and specific surface area (BET, Autosorb-iQ2-MP) were applied to character structure and properties of the nanoparticles. The XRD and TEM images of nano-Fe0, B-Fe and B-Fe/Ni were illustrated in Fig. 2, which could confirm the existence of Fe0 in bentonite-supported nanoscale bimetals. TEM images showed that the size of most nano-Fe0 was below 70 nm and almost B-Fe nanoparticles about 40–50 nm. The particles size of B-Fe/Ni was smaller than B-Fe, with average size of 30 nm.

Compared with aggregated fresh nano-Fe0 (Fig. 3a), bentonite-supported nano-iron (B-Fe) showed a better dispersion and nano-iron embedded in layered bentonite (Fig. 3b). B-Fe/Ni nanoparticles were connected and occupied in the layers of bentonite (Fig. 3c). The localized elemental information B-Fe/Ni was also provided from SEM–EDS as Fig. 3c. The mass of Ni on the surface site of B-Fe/Ni was 3.16 %, which was lower than the theoretical initial preparation of 5.0 % Ni loading. It indicated that Ni was unevenly coated on the iron and nano-iron also aggregated and distributed on bentonite.

Specific surface areas were measured that BET of B-Fe was 11.387 m2/g and B-Fe/Ni 15.811 m2/g, which were larger than nano-Fe0 (6.289 m2/g) and common Fe power (0.135 m2/g). It proved that bentonite could obviously increase surface area for more reaction sites.

Removal of methyl orange by bentonite-supported nanoscale bimetals

The decolorization rate of methyl orange (100 mg/L) using various nanoparticles (0.1 g/L) was investigated under 60 rpm at 298.15 K as showed in Fig. 4a. The bentonite was also performed as control. Bentonite-supported nano-iron bimetals showed higher reactivity for methyl orange removal compared to nano-Fe0 and B-Fe. After 20-min reaction, methyl orange was degraded nearly all by B-Fe/Pd (97.3 %) and B-Fe/Ni (94.5 %). Degradation of methyl orange by nano-iron followed pseudo first-order kinetics, and the rate constant (k obs) was calculated for nano-Fe0 (k = 0.005/min, R 2 = 0.853), B-Fe (k = 0.046/min, R 2 = 0.944), B-Fe/Ni (k = 0.121/min, R 2 = 0.896) and B-Fe/Pd (k = 0.258/min, R 2 = 0.999), respectively. The results indicated the addition of bentonite and other metal onto iron significantly enhanced the degradation of methyl orange. In consideration of future economic application with Pd or Ni, bentonite-supported nanoscale Fe/Ni was preferred to choose for further discussion. After B-Fe/Ni reacted with methyl orange, the chain-like structure was broken and Fe/Ni particles decreased on bentonite (Fig. 3d). This was possibly due to the corrosion of Fe0 and formation of iron oxide or hydroxide onto the surface of the B-Fe/Ni.

Removal of methyl orange in aqueous by iron nanoparticles at different conditions. a Bentonite-supported nano-iron bimetals (B-Fe/Pd and B-Fe/Ni, 0.1 g/L) showed higher reactivity for removal of methyl orange (100 mg/L) compared to nano-Fe0 and bentonite-supported nano-iron of B-Fe; b more nickel loading (2.5, 5.0, 10.0 %) in B-Fe/Ni nanoparticles (0.15 g/L) enhanced methyl orange (100 mg/L) removal efficiency; c methyl orange removal by B-Fe/Ni (0.20 g/L) indicated the degradation rate decreased with the increase of the initial concentration of methyl orange (50, 100, 200 mg/L); d effect of initial pH (3, 7, 10) on methyl orange (100 mg/L) removal by B-Fe/Ni (0.25 g/L) demonstrated the reactivity of B-Fe/Ni was highly pH dependent and lower pH was helpful for the degradation of methyl orange

Effects of Ni loading, methyl orange initial concentration and pH on methyl orange removal by nano-B-Fe/Ni

The effect of different prepared Ni loading (2.5, 5.0, 10.0 %) in B-Fe/Ni (0.15 g/L) on methyl orange (100 mg/L) removal was determined under 60 rpm at 298.15 K (Fig. 4b). The pseudo first-order kinetics was studied for 2.5 % Ni loading system (k = 0.099/min, R 2 = 0.903), 5.0 % Ni loading (k = 0.091/min, R 2 = 0.971) and 10.0 % Ni loading (k = 0.104/min, R 2 = 0.901), respectively. B-Fe/Ni with <5.0 % Ni loading could degrade more than 90 % methyl orange in 10 min. Nickel was catalyst, and nickel loading in B-Fe/Ni system could enhance the methyl orange removal efficiency (Bokare et al. 2007).

In order to investigate the effect of initial methyl orange concentration on the experiment, we chose three different concentrations (50, 100, 200 mg/L) for kinetics. The result was displayed in Fig. 4c. The degradation rate of methyl orange was fast by B-Fe/Ni (0.20 g/L), and it reached above 90 % within 15 min. With the increase of the initial concentration of methyl orange, the degradation rate decreased. Some scientists found that sulfanilic acid was possibly the degradation products of methyl orange by bentonite-supported nano-Fe0 (Chen et al. 2011b), and the degradation rate constant was k = 0.1083/min for 100 mg/L methyl orange. In contrast to their B-Fe system, B-Fe/Ni in this study showed more reactivity for 100 mg/L methyl orange (k = 0.136/min, R 2 = 0.958). The results indicated that the B-Fe/Ni exhibited excellent removal capacity for methyl orange.

The effect of initial pH (3, 7, 10) on methyl orange (100 mg/L) degradation by B-Fe/Ni (0.25 g/L) was performed under 60 rpm at 298.15 K as showed in Fig. 4d. It demonstrated the reactivity of B-Fe/Ni was highly pH dependent at start-up process, while methyl orange removal could be nearly completed at the end of reaction. The rate constant (k obs) was 0.141/min (R 2 = 0.863), 0.056/min (R 2 = 0.980), 0.051/min (R 2 = 0.963) for initial pH values of 3, 7, 10, respectively. According to the research (Zhang and Elliott 2006), zeta potential of zero in nano-Fe0 suspension occured at pH ~ 8.1. The surface of particles was negatively charged at pH < 8.1, while positively charged at pH > 8.1. For methyl orange removal system, the azo dyes carried negative charge, so lower pH could help nano-iron degrade methyl orange faster.

Conclusion

A series of nanoscale particles of bentonite-supported iron (B-Fe), Fe/Ni, B-Fe/Ni and B-Fe/Pd were synthesized and characterized. Bentonite-supported bimetals showed an excellent degradation for methyl orange in water. It implied that bentonite is an effective dispersant and stabilizer and the nickel or palladium loading could enhance the reactivity of nanoscale zero-valent iron for contaminated water remediation.

References

Bokare AD, Chikate RC, Rode CV, Paknikar KM (2007) Effect of surface chemistry of Fe–Ni nanoparticles on mechanistic pathways of azo dye degradation. Environ Sci Technol 41(21):7437–7443

Chen J, Xiu Z, Lowry GV, Alvarez PJJ (2011a) Effect of natural organic matter on toxicity and reactivity of nano-scale zero-valent iron. Water Res 45(5):1995–2001

Chen ZX, Jin XY, Chen Z, Megharaj M, Naidu R (2011b) Removal of methyl orange from aqueous solution using bentonite-supported nanoscale zero-valent iron. J Colloid Interface Sci 363(2):601–607

Choi H, Al-Abed SR, Agarwal S, Dionysiou DD (2008) Synthesis of reactive nano-Fe/Pd bimetallic system-impregnated activated carbon for the simultaneous adsorption and dechlorination of PCBs. Chem Mater 20(11):3649–3655

Chun CL, Baer DR, Matson DW, Amonette JE, Penn RL (2010) Characterization and reactivity of iron nanoparticles prepared with added Cu, Pd, and Ni. Environ Sci Technol 44(13):5079–5085

Fang Z, Qiu X, Chen J, Qiu X (2011) Debromination of polybrominated diphenyl ethers by Ni/Fe bimetallic nanoparticles: influencing factors, kinetics, and mechanism. J Hazard Mater 185(2–3):958–969

Fu F, Han W, Huang C, Tang B, Hu M (2013) Removal of Cr (VI) from wastewater by supported nanoscale zero-valent iron on granular activated carbon. Desalin Water Treat 51(13–15):2680–2686

He F, Zhao DY (2005) Preparation and characterization of a new class of starch-stabilized bimetallic nanoparticles for degradation of chlorinated hydrocarbons in water. Environ Sci Technol 39(9):3314–3320

He F, Zhao D (2007) Manipulating the size and dispersibility of zerovalent iron nanoparticles by use of carboxymethyl cellulose stabilizers. Environ Sci Technol 41(17):6216–6221

Kim HJ, Phenrat T, Tilton RD, Lowry GV (2012) Effect of kaolinite, silica fines and pH on transport of polymer-modified zero valent iron nano-particles in heterogeneous porous media. J Colloid Interface Sci 370:1–10

Klas S, Kirk DW (2013) Advantages of low pH and limited oxygenation in arsenite removal from water by zero-valent iron. J Hazard Mater 252:77–82

Lee CL, Lee HY, Tseng KH, Andy Hong PK, Jou C-JG (2011) Enhanced dechlorination of chlorobenzene by microwave-induced zero-valent iron: particle effects and activation energy. Environ Chem Lett 9(3):355–359

Luo S, Qin P, Shao J, Peng L, Zeng Q, Gu J-D (2013) Synthesis of reactive nanoscale zero valent iron using rectorite supports and its application for orange II removal. Chem Eng J 223:1–7

Meyer DE, Hampson S, Ormsbee L, Bhattacharyya D (2009) A study of groundwater matrix effects for the destruction of trichloroethylene using Fe/Pd nanoaggregates. Environ Prog Sustain Energy 28(4):507–518

Phenrat T, Saleh N, Sirk K, Tilton RD, Lowry GV (2007) Aggregation and sedimentation of aqueous nanoscale zerovalent iron dispersions. Environ Sci Technol 41(1):284–290

Phenrat T, Saleh N, Sirk K, Kim H-J, Tilton RD, Lowry GV (2008) Stabilization of aqueous nanoscale zerovalent iron dispersions by anionic polyelectrolytes: adsorbed anionic polyelectrolyte layer properties and their effect on aggregation and sedimentation. J Nanopart Res 10(5):795–814

Phenrat T, Liu Y, Tilton RD, Lowry GV (2009) Adsorbed polyelectrolyte coatings decrease Fe-0 nanoparticle reactivity with TCE in water: conceptual model and mechanisms. Environ Sci Technol 43(5):1507–1514

Shi LN, Lin YM, Zhang X, Chen ZL (2011) Synthesis, characterization and kinetics of bentonite supported nZVI for the removal of Cr (VI) from aqueous solution. Chem Eng J 171(2):612–617

Shi J, Yi S, He H, Long C, Li A (2013) Preparation of nanoscale zero-valent iron supported on chelating resin with nitrogen donor atoms for simultaneous reduction of Pb2+ and NO3. Chem Eng J 230:166–171

Shih YH, Chen YC, Chen MY, Tai YT, Tso CP (2009) Dechlorination of hexachlorobenzene by using nanoscale Fe and nanoscale Pd/Fe bimetallic particles. Colloids Surf A Physicochem Eng Asp 332(2–3):84–89

Su CM, Puls RW (2001) Arsenate and arsenite removal by zerovalent iron: kinetics, redox transformation, and implications for in situ groundwater remediation. Environ Sci Technol 35(7):1487–1492

Trujillo-Reyes J, Sánchez-Mendieta V, Colín-Cruz A, Morales-Luckie RA (2010) Removal of indigo blue in aqueous solution using Fe/Cu nanoparticles and C/Fe–Cu nanoalloy composites. Water Air Soil Pollut 207(1–4):307–317

Tseng HH, Su JG, Liang C (2011) Synthesis of granular activated carbon/zero valent iron composites for simultaneous adsorption/dechlorination of trichloroethylene. J Hazard Mater 192(2):500–506

Yun DM, Cho HH, Jang JW, Park JW (2013) Nano zero-valent iron impregnated on titanium dioxide nanotube array film for both oxidation and reduction of methyl orange. Water Res 47(5):1858–1866

Zhang WX, Elliott DW (2006) Applications of iron nanoparticles for groundwater remediation. Remediat J 16(2):7–21

Zhang WX, Wang CB, Lien HL (1998) Treatment of chlorinated organic contaminants with nanoscale bimetallic particles. Catal Today 40(4):387–395

Acknowledgments

This study was sponsored by National Natural Science Foundation of China (41272061, 41030423), Fundamental Research Funds for the Central Universities (2652012128). We appreciate Dr. Prof. Gregory V. Lowry (Carnegie Mellon University) for his valuable suggestions. We also thank the editors and two anonymous reviewers for their instructive comments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, D., Cheng, J. & Chen, J. One-step synthesis of bentonite-supported nanoscale Fe/Ni bimetals for rapid degradation of methyl orange in water. Environ Chem Lett 12, 461–466 (2014). https://doi.org/10.1007/s10311-014-0473-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10311-014-0473-3