Abstract

Nanoscale zero-valent iron, named nano-Fe0, is a reagent used to degrade trichloroethylene in groundwater. However, the efficiency of nano-Fe0 is moderate due to issues of dispersion and reactivity. As an alternative we synthesized bentonite-supported nanoscale Fe/Ni bimetals, named bentonite-Fe/Ni, to test the degradation of trichloroethylene in the presence of Suwannee River humic acids, as a representative of natural organic matter. 0.1 mmol/L trichloroethylene was reacted with 0.5 g/L of nano-Fe0, bentonite-Fe, Fe/Ni, and bentonite-Fe/Ni nanoparticles. Results show first that without humic acids the reaction rate constants k obs were 0.0036/h for nano-Fe0, 0.0101/h for bentonite-Fe, 0.0984/h for Fe/Ni, and 0.181/h for bentonite-Fe/Ni. These findings show that bentonite-Fe/Ni is the most efficient reagent. Second, the addition of humic acids increased the rate constant from 0.178/h for 10 mg/L humic acids to 0.652/h for 40 mg/L humic acids, using the bentonite-Fe/Ni catalyst. This finding is explained by accelerated dechlorination by faster electron transfer induced by humic quinone moieties. Indeed, the use of 9, 10-anthraquinone-2, 6-disulfonate as a humic analogue gave similar results.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Organic chlorinated compounds in contaminated groundwater, such as trichloroethylene (TCE), have substantial threats to ecological security and public health (Liu et al. 2007; Stroo et al. 2012). The concentration of trichloroethylene found in groundwater was ranged from 10−3 to 10−6 mol/L (Liu et al. 2007). Among the remediation techniques, zero-valent iron (Fe0) was early introduced for in situ treatment of groundwater polluted by chlorinated contaminants for years (Gillham and Ohannesin 1994). With the development of nanotechnology, nanoscale zero-valent iron (nano-Fe0) has been well explored in recent years (Zhang 2003; Liu et al. 2005, 2007; Johnson et al. 2013; Li et al. 2014; Rajajayavel and Ghoshal 2015). However, nano-Fe0 is easy to be oxidized in water, which could lower its reactivity. So, scientists tried to load a second metal like Pd or Ni onto nano-Fe0 to form the Fe0-based bimetallic nanoparticles for enhanced reductive dechlorination (Wang and Zhang 1997; Schrick et al. 2002; Tee et al. 2005). For instance, the rate constant of degradation of trichloroethylene by nanoscale Fe/Ni particles was nearly two orders faster than that of nano-Fe0 alone (Schrick et al. 2002). On the other hand, nano-Fe0 is easy to be aggregated in water, and the researchers attempted to improve its dispersion stability by using supporting substances, such as carbon nanotubes (Krause et al. 2010) and orange peel pith (Lopez-Tellez et al. 2011)

In our newly study (Zhao et al. 2014), we reported one-step synthesis of bentonite-supported nanoscale Fe/Ni bimetals (B-Fe/Ni) for rapid degradation of methyl orange in water. Furthermore, we are eager to know how about B-Fe/Ni for degradation of trichloroethylene, an important pollutant in groundwater. During the remediation of trichloroethylene in contaminated sites, B-Fe/Ni nanoparticles would unavoidably meet ubiquitous nature organic matter, which is usually formed by alkyl skeletons and aromatics like carboxylic acids, hydroxyls, and quinines. The presence of natural organic matter is an important factor in process of water treatment (Dsikowitzky and Schwarzbauer 2014; Lee et al. 2015). Recently, we studied the sorption/desorption of natural organic matter on zero-valent iron and magnetite nanoparticles, and their interactions are very complex (Fan et al. 2015).

In addition, we early found the rate constant of trichloroethylene degradation by nano-Fe0 alone decreased by 23 % in the presence of humic acid (Chen et al. 2011). Some findings also showed that nature organic matter could be adsorbed and block active surface sites of nano-Fe0, which adversely affects the reactivity (Dong and Lo 2013). However, some other researchers found that nature organic matter serving as an electron transfer mediator could enhance the degradation rate of contaminants (Tratnyek et al. 2001; Xie and Shang 2005; Doong and Lai 2005; Kang and Choi 2009; Wang et al. 2011). For example, Doong and Lai (2005) concluded that humic acid can act as both an inhibitor and an accelerator for perchloroethylene dechlorination by palladized iron. All the results indicated that the effect of nature organic matter on the removal of pollutants by Fe0-based nanoparticles should be further investigated when it is ready to use for in situ remediation.

There remains much unknown about the performance of newly synthesized B-Fe/Ni for mitigation or enhancement of trichloroethylene degradation in the presence of nature organic matter. Accordingly, the present study elucidates the role of Suwannee River humic acid, a commonly used model for nature organic matter, in trichloroethylene degradation using B-Fe/Ni nanoparticles, which will shed light on in situ groundwater remediation.

Materials and methods

Chemicals

Bentonite was purchased from Alfa Aesar. The montmorillonite content is >90 %, and the cation exchange capacity is 125 meq/100 g. Before using, bentonite was dried at 80 °C for 10 h and then sieved through 200 mesh. FeSO4·7H2O, CH3CH2OH, NaOH, Ni2SO4·6H2O, NaHCO3, and KBH4 were supplied by Sinopharm Chemical Reagent Co., Ltd. Trichloroethylene (TCE) and 9, 10-anthraquinone-2, 6-disulfonate (AQDS) were from Sigma-Aldrich. All the chemicals were at least analytical reagent grade and used as received. The stock solution of Suwannee River humic acid from International Humic Substances Society was prepared as our previous work (Chen et al. 2011). The B-Fe/Ni nanoparticle was synthesized based on our recent study (Zhao et al. 2014). Briefly, 4.7411 g of FeSO4·7H2O, 0.2133 g of NiSO4·6H2O, and 1.0000 g of bentonite were dissolved in a mixed solvent containing 50 mL of deionized water and 20 mL of ethanol. 0.5000 g of polyethylene glycol (PEG-4000) was also added as a dispersant at the same time. 2.8896 g of NaBH4 was dissolved in 30 mL of NaOH solution and added dropwise at 2 drops/s and then stirred for 15 min. The resulting black precipitations (B-Fe/Ni) were washed three times with deionized water and ethanol, respectively. Finally, the particles were dried under vacuum. All the process was performed in nitrogen atmosphere. The synthesis method of nano-Fe0, B-Fe, and Fe/Ni was the same as above description. The desired material weight ratios in B-Fe (1:1), Fe/Ni (20:1), and B-Fe/Ni (20:20:1) were quantitatively prepared.

Trichloroethylene degradation

The anaerobic degradation of trichloroethylene (0.1 mmol/L) in aqueous solution by nano-Fe0, B-Fe, Fe/Ni, or B-Fe/Ni nanoparticles (0.5 g/L) were conducted in the dark in 250-mL serum bottles containing 100 mL bicarbonate buffer (10 mM, pH = 8.2 ± 0.1) in the absence or presence of humic acid (0, 10, 20, 40 mg/L) and shaken at 100 rpm at 25 °C. Buffer solutions were purged with ultra-high purity nitrogen gas for 20 min to remove oxygen before reaction. The bottles were capped with gas-tight Teflon Mininert valves for convenient sampling. Simultaneously, a blank of trichloroethylene alone and a control containing bentonite with trichloroethylene were set up to evaluate the loss of trichloroethylene throughout the experiments. The concentration of trichloroethylene was measured by the gas chromatograph with a flame ionization detector (GC-FID) over time as describe below. All the batch experiments were set in triplicate.

Analytical methods

Morphologies of bentonite, Fe/Ni, and B-Fe/Ni nanoparticles were characterized by the scanning electron microscope (SEM, Zeiss MERLIN VP Compact, Germany) and the energy-dispersive X-ray spectroscopy (EDS). The determination of trichloroethylene was withdrawn the headspace sample (50 µL) from each reactor into GC-FID (GC-2010, Shimadzu, Japan) equipped with a Rtx-5 analytical column (60 m × 0.25 µm × 0.25 mm). Pure nitrogen was served as the carrier gas. Separation program was achieved at 150 °C injection port with split ratio of 1:40, and the FID port temperature was maintained at 300 °C. The temperature of chromatograph column in oven was set from 90 to 150 °C at 10 °C/min, then held at 150 °C for 1 min, and finally increased to 180 °C at 20 °C/min.

Results and discussion

Surface characterization of B-Fe/Ni

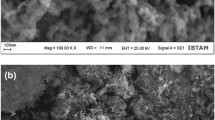

In addition to confirmation of the structure and component of bentonite-supported Fe/Ni nanoparticles by TEM and XRD (Zhao et al. 2014), the surface morphology of B-Fe/Ni was characterized with SEM. Bentonite had an obvious layered structure (Fig. 1a), and Fe/Ni particles with diameter of 30–80 nm were accommodated in crevices between layers (Fig. 1c). Without supported materials, Fe/Ni nanoparticles were aggregated as chain-like clusters (Fig. 1b), while B-Fe/Ni nanoparticles were distributed evenly on the bentonite (Fig. 1c). It indicated that immobilization of metals on bentonite was an effective way to disperse nanoparticles. According to EDS analysis (Fig. 1d), the average weight composition of Fe and Ni on the surface of B-Fe/Ni was 41.55 and 2.23 %, respectively, which is nearly equivalent to prepared ratio of 20:1.

Scanning electron microscope (SEM) images of a bentonite, b Fe/Ni, c B-Fe/Ni, and d energy dispersive X-ray spectroscopy (EDS) analysis of B-Fe/Ni. Note that Fe/Ni nanoparticles without supported materials were aggregated as chain-like clusters, while B-Fe/Ni nanoparticles were distributed evenly. It indicated that immobilization of metals on bentonite was an effective way to disperse nanoparticles

Degradation of trichloroethylene by B-Fe/Ni

The degradation of trichloroethylene by nano-Fe0, B-Fe, Fe/Ni, and B-Fe/Ni was compared in Fig. 2. As expected, the addition of the metal nickel and the bentonite could significantly enhance the degradation of trichloroethylene. Moreover, the degradation rate of trichloroethylene can be obtained according to the pseudo-first-order kinetic model of the reductive dechlorination (Doong and Lai 2005; Chen et al. 2011):

where [TCE] t and [TCE]0 represent the concentration of trichloroethylene at desired time and starting time during reaction, respectively. The values of the rate constant k obs with fitting coefficient R 2 of the reactions were calculated for different systems of nano-Fe0 (k obs = 0.0036/h, R 2 = 0.915), B-Fe (k obs = 0.0101/h, R 2 = 0.918), Fe/Ni (k obs = 0.0984/h, R 2 = 0.974), and B-Fe/Ni (k obs = 0.181/h, R 2 = 0.994).

Degradation of trichloroethylene (0.1 mmol/L) by nano-Fe0, B-Fe, Fe/Ni, and B-Fe/Ni nanoparticles (0.5 g/L) in the absence of humic acid. The excellent performance of trichloroethylene degradation by B-Fe/Ni was owing to evenly distribution of nanoparticles on the bentonite and synergy of catalytic nickel with iron

Trichloroethylene (0.1 mmol/L) was completely removed by Fe/Ni nanoparticles (0.5 g/L) within 31 h in the absence of humic acid, while only 37 % of trichloroethylene was removed by nano-Fe0 in 145 h. The rate constant k obs for Fe/Ni was 27 times higher than that for nano-Fe0. Also, the obvious difference of trichloroethylene reduction using B-Fe/Ni (k obs = 0.181/h) and B-Fe (k obs = 0.0101/h) showed the addition of nickel as the second metal significantly enhanced the degradation of trichloroethylene. It was demonstrated that Fe/Ni bimetals could form galvanic cells in which the iron acted as an electron donor, and catalytic nickel promoted the corrosion of iron for catalytic hydrodechlorination (Xu et al. 2012). Also, some researchers reported that the adsorbed atomic hydrogen instead of the galvanic cells caused the increasing reactivity in the 1,1,1-trichloroethane degradation by bimetals (Cwiertny et al. 2006; Bransfield et al. 2006). The increase in nickel content could enhance the catalytic effect. However, excessive nickel might cover nanoiron, which was unfavorable for dechlorination. We found 5 wt% of nickel was optimal in preparation of B-Fe/Ni (Zhao et al. 2014).

In short, the excellent performance of trichloroethylene degradation by B-Fe/Ni was owing to evenly distribution of nanoparticles on the bentonite and synergy of catalytic nickel with iron. It was noted that the concentrations of trichloroethylene in the blank and control reactors were not changed (data not shown in Fig. 2), which excluded trichloroethylene loss or adsorption effect on bentonite.

Effect of humic acid on dechlorination and mechanism implication

The batch tests were conducted in the present study to further evaluate the effect of humic acid on the degradation of trichloroethylene by B-Fe/Ni. In surprise, the values of k obs in trichloroethylene degradation with B-Fe/Ni were 0.181/h (R 2 = 0.994), 0.178/h (R 2 = 0.966), 0.231/h (R 2 = 0.933), and 0.652/h (R 2 = 0.919) in the presence of 0, 10, 20, and 40 mg/L humic acid, respectively (Fig. 3). Obviously, humic acid accelerated trichloroethylene degradation by B-Fe/Ni, and more than 20 mg/L humic acid in particular enhanced dechlorination significantly. The results were very different from nano-Fe0 system, in which we found that nature organic matter could mitigate reductive dechlorination and the degradation rate constant decreased by 23 % in the presence of 10 mg/L humic acid (Chen et al. 2011).

Degradation of trichloroethylene (0.1 mmol/L) by B-Fe/Ni nanoparticles (0.5 g/L) in the presence of humic acid or quinone compound 9, 10-anthraquinone-2, 6-disulfonate (AQDS). It showed that humic acid accelerated dechlorination by B-Fe/Ni and more than 20 mg/L humic acid enhanced dechlorination significantly. Trichloroethylene was more rapidly removed in the presence of 40 mg/L of AQDS, which was comparable to more than 20 mg/L humic acid and accordance with the role of quinone moieties

The hypothesis was formulated to explain such accelerated effect of humic acid on the dechlorination using B-Fe/Ni (Fig. 4). The interaction between B-Fe/Ni nanoparticles and trichloroethylene was a surface-mediated reaction. The dissolution of iron could excavate the active surface sites and the redox-active moieties in humic acid may serve as electron transfer mediator. Humic acid could be adsorbed on B-Fe/Ni and block the surface reactive sites. Fe/Ni bimetals could form galvanic cells, and catalytic nickel promoted the corrosion of iron (Xu et al. 2012), which leads to fast humic acid adsorption (Giasuddin et al. 2007; Tan et al. 2014; Fan et al. 2015). The adsorbed humic acid could be served as electron shuttle and accelerate the degradation efficiency. To further understand the electron transfer medium effect, a commonly used humic acid analogue quinone compound, 9, 10-anthraquinone-2, 6-disulfonate (AQDS), was applied in comparable experiments as also show in Fig. 3. In contrast to B-Fe/Ni system alone (k obs = 0.181/h) without humic acid, trichloroethylene was more rapidly removed in the presence of 40 mg/L of 9, 10-anthraquinone-2, 6-disulfonate (k obs = 0.331/h, R 2 = 0.932), which was comparable to more than 20 mg/L humic acid and accordance with that the electron shuttle property of nature organic matter are connected with the role of quinone moieties (Xie and Shang 2005; Kang and Choi 2009).

Hypothetical mechanism of the effect of humic acid on dechlorination by B-Fe/Ni nanoparticles. Humic acid could be adsorbed on B-Fe/Ni and block the surface reactive sites. Fe/Ni bimetals could form galvanic cells and catalytic nickel promoted the corrosion of iron, which leads to fast humic acid adsorption. Adsorbed humic acid could be served as electron shuttle with the role of quinone moieties to accelerate the dechlorination

Conclusion

In this study, bentonite-supported nanoscale Fe/Ni bimetals (B-Fe/Ni) showed much better performance on degradation of trichloroethylene than other Fe0-based nanoparticles including nano-Fe0, B-Fe, and Fe/Ni. The dechlorination by B-Fe/Ni could be significantly enhanced in the presence of humic acid, serving as electron shuttles with the role of quinone moieties. This was very different from nano-Fe0 system, in which nature organic matter could mitigate reductive dechlorination. The results indicated that B-Fe/Ni is a preferred candidate for in situ groundwater remediation.

References

Bransfield SJ, Cwiertny DM, Roberts AL, Fairbrother DH (2006) Influence of copper loading and surface coverage on the reactivity of granular iron toward 1,1,1-trichloroethane. Environ Sci Technol 40(5):1485–1490. doi:10.1021/es051300p

Chen J, Xiu Z, Lowry GV, Alvarez PJJ (2011) Effect of natural organic matter on toxicity and reactivity of nano-scale zero-valent iron. Water Res 45(5):1995–2001. doi:10.1016/j.watres.2010.11.036

Cwiertny DM, Bransfield SJ, Livi KJT, Fairbrother DH, Roberts AL (2006) Exploring the influence of granular iron additives on 1,1,1-trichloroethane reduction. Environ Sci Technol 40(21):6837–6843. doi:10.1021/es060921v

Dong H, Lo I (2013) Influence of calcium ions on the colloidal stability of surface-modified nano zero-valent iron in the absence or presence of humic acid. Water Res 47(7):2489–2496. doi:10.1016/j.watres.2013.02.022

Doong RA, Lai YJ (2005) Dechlorination of tetrachloroethylene by palladized iron in the presence of humic acid. Water Res 39(11):2309–2318. doi:10.1016/j.watres.2005.04.036

Dsikowitzky L, Schwarzbauer J (2014) Industrial organic contaminants: identification, toxicity and fate in the environment. Environ Chem Lett 12(3):371–386. doi:10.1007/s10311-014-0467-1

Fan J, Liu F, Hu Y, Chen J (2015) Effects of pH and ionic composition on sorption/desorption of natural organic matter on zero-valent iron and magnetite nanoparticles. Water Sci Technol 72(2):303–310. doi:10.2166/wst.2015.219

Giasuddin ABM, Kanel SR, Choi H (2007) Adsorption of humic acid onto nanoscale zerovalent iron and its effect on arsenic removal. Environ Sci Technol 41(6):2022–2027. doi:10.1021/es0616534

Gillham RW, Ohannesin SF (1994) Enhanced degradation of halogenated aliphatics by zero-valent iron. Ground Water 32(6):958–967. doi:10.1111/j.1745-6584.1994.tb00935.x

Johnson RL, Nurmi JT, O’Brien Johnson GS, Fan D, O’Brien Johnson RL, Shi Z, Salter-Blanc AJ, Tratnyek PG, Lowry GV (2013) Field-scale transport and transformation of carboxymethylcellulose-stabilized nano zero-valent iron. Environ Sci Technol 47(3):1573–1580. doi:10.1021/es304564q

Kang SH, Choi W (2009) Oxidative degradation of organic compounds using zero-valent iron in the presence of natural organic matter serving as an electron shuttle. Environ Sci Technol 43(3):878–883. doi:10.1021/es801705f

Krause RWM, Mamba BB, Dlamini LN, Durbach SH (2010) Fe–Ni nanoparticles supported on carbon nanotube-co-cyclodextrin polyurethanes for the removal of trichloroethylene in water. J Nanopart Res 12(2):449–456. doi:10.1007/s11051-009-9659-1

Lee HJ, Kim HH, Lee H, Lee C (2015) Reaction of aqueous iodide at high concentration with O3 and O3/H2O2 in the presence of natural organic matter: implications for drinking water treatment. Environ Chem Lett 13(4):453–458. doi:10.1007/s10311-015-0519-1

Li S, Wang W, Liu Y, Zhang W (2014) Zero-valent iron nanoparticles (nZVI) for the treatment of smelting wastewater: a pilot-scale demonstration. Chem Eng J 254:115–123. doi:10.1016/j.cej.2014.05.111

Liu YQ, Majetich SA, Tilton RD, Sholl DS, Lowry GV (2005) TCE dechlorination rates, pathways, and efficiency of nanoscale iron particles with different properties. Environ Sci Technol 39(5):1338–1345. doi:10.1021/es049195r

Liu Y, Phenrat T, Lowry GV (2007) Effect of TCE concentration and dissolved groundwater solutes on NZVI-promoted TCE dechlorination and H-2 evolution. Environ Sci Technol 41(22):7881–7887. doi:10.1021/es0711967

Lopez-Tellez G, Barrera-Diaz CE, Balderas-Hernandez P, Roa-Morales G, Bilyeu B (2011) Removal of hexavalent chromium in aquatic solutions by iron nanoparticles embedded in orange peel pith. Chem Eng J 173(2):480–485. doi:10.1016/j.cej.2011.08.018

Rajajayavel SRC, Ghoshal S (2015) Enhanced reductive dechlorination of trichloroethylene by sulfidated nanoscale zerovalent iron. Water Res 78:144–153. doi:10.1016/j.watres.2015.04.009

Schrick B, Blough JL, Jones AD, Mallouk TE (2002) Hydrodechlorination of trichloroethylene to hydrocarbons using bimetallic nickel–iron nanoparticles. Chem Mater 14(12):5140–5147. doi:10.1021/cm020737i

Stroo HF, Leeson A, Marqusee JA, Johnson PC, Ward CH, Kavanaugh MC, Sale TC, Newell CJ, Pennell KD, Lebrón CA, Unger M (2012) Chlorinated ethene source remediation: lessons learned. Environ Sci Technol 46(12):6438–6447. doi:10.1021/es204714w

Tan L, Liang B, Fang Z, Xie Y, Tsang EP (2014) Effect of humic acid and transition metal ions on the debromination of decabromodiphenyl by nano zero-valent iron: kinetics and mechanisms. J Nanopart Res 16(12):2786. doi:10.1007/s11051-014-2786-3

Tee YH, Grulke E, Bhattacharyya D (2005) Role of Ni/Fe nanoparticle composition on the degradation of trichloroethylene from water. Ind Eng Chem Res 44(18):7062–7070. doi:10.1021/ie050086a

Tratnyek PG, Scherer MM, Deng BL, Hu SD (2001) Effects of natural organic matter, anthropogenic surfactants, and model quinones on the reduction of contaminants by zero-valent iron. Water Res 35(18):4435–4443. doi:10.1016/S0043-1354(01)00165-8

Wang CB, Zhang WX (1997) Synthesizing nanoscale iron particles for rapid and complete dechlorination of TCE and PCBs. Environ Sci Technol 31(7):2154–2156. doi:10.1021/es970039c

Wang Y, Zhou D, Wang Y, Zhu X, Jin S (2011) Humic acid and metal ions accelerating the dechlorination of 4-chlorobiphenyl by nanoscale zero-valent iron. J Environ Sci 23(8):1286–1292. doi:10.1016/S1001-0742(10)60543-8

Xie L, Shang C (2005) Role of humic acid and quinone model compounds in bromate reduction by zerovalent iron. Environ Sci Technol 39(4):1092–1100. doi:10.1021/es049027z

Xu F, Deng S, Xu J, Zhang W, Wu M, Wang B, Huang J, Yu G (2012) Highly active and stable Ni–Fe bimetal prepared by ball milling for catalytic hydrodechlorination of 4-chlorophenol. Environ Sci Technol 46(8):4576–4582. doi:10.1021/es203876e

Zhang WX (2003) Nanoscale iron particles for environmental remediation: an overview. J Nanopart Res 5(3–4):323–332. doi:10.1023/A:1025520116015

Zhao D, Cheng J, Chen J (2014) One-step synthesis of bentonite-supported nanoscale Fe/Ni bimetals for rapid degradation of methyl orange in water. Environ Chem Lett 12(3):461–466. doi:10.1007/s10311-014-0473-3

Acknowledgments

This study was supported by National Natural Science Foundation of China (41472232, 41272061), Fundamental Research Funds for the Central Universities and National Innovation Experiment Program for University Students (201411415051). We appreciate Dr. Prof. Gregory V. Lowry (Carnegie Mellon University) for valuable discussion. We also thank the editors and two anonymous reviewers for their instructive comments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, S., Han, Y., Cao, X. et al. Enhanced degradation of trichloroethylene using bentonite-supported nanoscale Fe/Ni and humic acids. Environ Chem Lett 14, 237–242 (2016). https://doi.org/10.1007/s10311-015-0548-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10311-015-0548-9