Abstract

The recently engineered reversal of the β-oxidation cycle has been proposed as a potential platform for the efficient synthesis of longer chain (C ≥ 4) fuels and chemicals. Here, we demonstrate the utility of this platform for the synthesis of medium-chain length (C6–C10) products through the manipulation of key components of the pathway. Deletion of endogenous thioesterases provided a clean background in which the expression of various thiolase and termination components, along with required core enzymes, resulted in the ability to alter the chain length distribution and functionality of target products. This approach enabled the synthesis of medium-chain length carboxylic acids and primary alcohols from glycerol, a low-value feedstock. The use of BktB as the thiolase component with thioesterase TesA’ as the termination enzyme enabled the synthesis of about 1.3 g/L C6–C10 saturated carboxylic acids. Tailoring of product formation to primary alcohol synthesis was achieved with the use of various acyl-CoA reductases. The combination of AtoB and FadA as the thiolase components with the alcohol-forming acyl-CoA reductase Maqu2507 from M. aquaeolei resulted in the synthesis of nearly 0.3 g/L C6–C10 alcohols. These results further demonstrate the versatile nature of a β-oxidation reversal, and highlight several key aspects and control points that can be further manipulated to fine-tune the synthesis of various fuels and chemicals.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Modern society relies on fossil fuels as the main feedstock for the production of transportation fuels and commodity and fine chemicals. Due to the concerns over sustainability, increasing demand, and localized distribution of fossil feedstocks, price increases and instability are a common concern. These factors, along with environmental concerns, have stimulated the development of alternative methods for fuel and chemical production [32]. Biomass is regarded as an attractive alternative resource due to its sustainability, and, in comparison to fossil fuels, lower environmental impact and more uniform distribution throughout the world. However, the use of biomass as an alternative to fossil fuels requires the development of processes able to efficiently convert biomass feedstocks into a variety of important fuels and chemicals.

While the biological production of short chain products, such as ethanol, from biomass constituents has been demonstrated on the commercial scale, the production of medium to long-chain products (C ≥ 6) is far less established [1, 14]. This is in large part due to the fact that the production of these compounds must take place from 1-, 2- or 3-carbon metabolic intermediates that result from substrate utilization pathways and central carbon metabolism, and as such, require efficient carbon–carbon elongation pathways for their synthesis. These elongation pathways typically require additional energy and cofactors, which in turn result in lower yields and productivity compared to shorter chain molecules. Thus, the exploitation of elongation pathways that are carbon and energy efficient is highly desirable to maximize product yields.

The recently engineered reversal of the β-oxidation cycle provides one such pathway that has been proposed as a potential platform to enable the synthesis of short-, medium-, and long-chain products at high yields [5, 6, 10, 18, 37]. This pathway operates with coenzyme A (CoA) intermediates and directly uses acetyl-CoA for acyl-CoA elongation, characteristics that support product synthesis and maximum carbon and energy efficiency. In addition, the modular and versatile nature of this pathway provides the ability to generate a diverse set of products through the manipulation of any of the modules comprising a β-oxidation reversal [3].

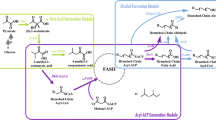

In this study, we sought to exploit a β-oxidation reversal to target the synthesis of medium-chain length (C6–C10) products of varying functionality. Key to this approach is increasing the generation and availability of target chain length acyl-CoA intermediates that can be converted to desired products through appropriate termination pathways (Fig. 1). This was achieved through the use of various thiolase enzyme(s) involved in the condensation reaction of an acyl-CoA intermediate with acetyl-CoA (Fig. 1), as well as the manipulation of the termination enzyme(s) utilized, representing the synthesis of specific products from intermediates generated through a β-oxidation reversal (Fig. 1). The latter included not only the expression of candidate enzymes for carboxylic acid and alcohol production, but also the deletion of native thioesterases that can influence the availability of a given chain length acyl-CoA. This approach provides the opportunity to control both the chain length and functionality of products synthesized through a reversal of the β-oxidation cycle and demonstrate how this pathway can be exploited for the synthesis of a wide array of compounds.

Engineered β-oxidation reversal for the synthesis of saturated carboxylic acids and primary alcohols. Enzymes for each step investigated in this study are as follows (gene names in parentheses): 1 thiolase (atoB, bktB, fadA, yqeF); 2 hydroxyacyl-CoA dehydrogenase (fadB); 3 enoyl-CoA hydratase (fadB); 4 enoyl-CoA reductase (egTER); 5 aldehyde-forming acyl-CoA reductase (ald, acr1, acrM, eutE, mhpF, orf1594); 6 alcohol/aldehyde dehydrogenase (adhP, fucO, yqhD); 7 alcohol-forming acyl-CoA reductase (adhE2, maqu2220, maqu2507); 8 thioesterase (tesA, tesB, fadM, ybcC, yciA, ydiI)

Materials and methods

Strains, plasmids, and genetic methods

Wild-type K12 Escherichia coli strain MG1655 [15] was used as the host for all genetic modifications. Gene knockouts and chromosomal expression constructs were introduced in MG1655 and its derivatives by P1 phage transduction [23]. JST07 (DE3) was constructed from JST07 using a λDE3 Lysogenization Kit (Novagen, Darmstadt, Germany) to allow the expression of genes under the T7 lac promoter. All resulting strains used in this study are listed in Table 1. Creation of constructs for the cumate-controlled chromosomal expression of atoB [34], fadB ∆fadA [34], fadBA [34], bktB ∆atoB [4], and egTER at the fabI chromosomal locus [4] were achieved via standard recombineering protocols as previously described. For the chromosomal expression of yqeF under cumate control, yqeF was PCR amplified from E. coli MG1655 genomic DNA with primers containing homology for recombination in an HME45 strain containing an atoB CT5-cat-sacB insertion cassette [4]. This PCR product was then recombineered into the above HME45 strain, resulting in a kan-cymR-PCT5-yqeF ∆atoB construct at the atoB locus after negative selection on sucrose plates.

Plasmid-based gene overexpression was achieved by cloning the desired gene(s) into pCDFDuet-1 (Novagen, Darmstadt, Germany) digested with appropriate restriction enzymes utilizing In-Fusion PCR cloning technology (Clontech Laboratories, Inc., Mountain View, CA). Cloning inserts were created via PCR of ORFs of interest from their respective codon-optimized (acr1, acrM, maqu2220, maqu2507, orf1594) or genomic DNA (all others genes) with Phusion polymerase (Thermo Scientific, Waltham, MA, USA). The resulting In-Fusion products were used to transform E. coli Stellar cells (Clontech Laboratories, Inc., Mountain View, CA, USA) and PCR identified clones were confirmed by DNA sequencing.

All molecular biology techniques were performed with standard methods [23, 30] or following manufacturer protocol. Strains were kept in glycerol stocks at −80 °C. Plates were prepared using LB medium containing 1.5 % agar, and appropriate antibiotics were included at the following concentrations: ampicillin (100 µg/mL), kanamycin (50 µg/mL), spectinomycin (50 µg/mL) and chloramphenicol (12.5 µg/mL).

Culture medium and cultivation conditions

The minimal medium designed by Neidhardt et al. [24], with 125 mM MOPS and Na2HPO4 in place of K2HPO4, supplemented with 20 g/L glycerol, 10 g/L tryptone, 5 g/L yeast extract, 5 mM calcium pantothenate, 2.78 mM Na2HPO4, 5 mM (NH4)2SO4, 30 mM NH4Cl, 5 μM sodium selenite, 100 μM biotin, and 1 mg/L thiamine-HCl was used for all fermentations. Antibiotics (100 mg/L of ampicillin for pTH containing strains or 50 μg/mL spectinomycin for pCDF containing strains) and inducers (isopropyl β-d-1-thiogalactopyranoside and cumate) were included when appropriate. All chemicals were obtained from Fisher Scientific Co. (Pittsburg, PA, USA) and Sigma-Aldrich Co. (St. Louis, MO, USA).

Fermentations were conducted under microaerobic conditions in 25-mL Pyrex Erlenmeyer flasks (narrow mouth/heavy duty rim, Corning Inc., Corning, NY, USA) filled with 15 mL of the above culture medium and sealed with foam plugs filling the necks [22]. A single colony of the desired strain was cultivated overnight (14–16 h) in LB medium with appropriate antibiotics and used as the inoculum (1 %) for all fermentations. After inoculation, flasks were incubated at 37 °C and 200 rpm in an NBS C24 Benchtop Incubator Shaker (New Brunswick Scientific Co., Inc., Edison, NJ, USA) until an optical density of ~0.3–0.5 was reached, at which point IPTG (10 µM) and/or cumate (0.1 mM) were added when appropriate. Flasks were then incubated under the same conditions for 48 h post-induction unless otherwise stated.

Analytical methods

Optical density was measured at 550 nm in a Thermo Spectronic Genesys 20 (Thermo Scientific, Waltham, MA, USA) and used as an estimate of cell mass (1 OD 550 nm = 0.34 g dry weight/L). Quantification of glycerol and metabolic products in the culture supernatant was conducted through high-performance liquid chromatography (HPLC) and gas chromatography-flame ionization detection (GC-FID). The concentrations of glycerol, ethanol, and organic acids were determined via ion-exclusion HPLC using a Shimadzu Prominence SIL 20 system (Shimadzu Scientific Instruments, Inc., Columbia, MD, USA) equipped with an HPX-87H organic acid column (Bio-Rad, Hercules, CA, USA) with operating conditions to optimize peak separation (0.3 mL/min flowrate, 30 mM H2SO4 mobile phase, column temperature 42 °C).

Quantification of carboxylic acids (C > 6) was conducted via GC-FID analysis using a Varian CP-3800 (Varian Associates, Inc., Palo Alto, CA, USA) equipped with a flame ionization detector (GC-FID) and an HP-5 capillary column (0.25 mm internal diameter, 0.25 µm film thickness, 30 m length; Agilent Technologies, Santa Clara, CA, USA). Sample preparation was conducted as follows: 2 mL culture supernatant samples were transferred to 5-mL glass vials (Fisher Scientific Co., Fair Lawn, NJ, USA) and 80 μL of 50 % H2SO4 and 340 μL of 30 % NaCl solution were added for pH and ionic strength adjustment, respectively. Tridecanoic acid (final concentration 50 mg/L) was added as internal standard and 2 mL of hexane-MTBE (1:1) added for extraction. The bottles were sealed with Teflon-lined septa (Fisher Scientific Co., Fair Lawn, NJ, USA), secured with caps, and rotated at 60 rpm for 120 min. The samples were then centrifuged for 2 min at 2,375×g to separate the aqueous and organic layers. After centrifugation, 1.5 mL of the top organic layer was separated from the aqueous layer. Each extracted sample was transferred to 5 mL glass vial and dried under a stream of nitrogen. 1 mL of a boron trifluoride-methanol solution was added to the dried extract for derivatization of extracted carboxylic acids to fatty acid methyl esters (FAMEs), and the vials capped tightly and vortexed. These vials were then placed in heater block (AccuBlock digital dry bath; LabNew, Woodbridge, NJ, USA) and heated at 60 °C for 60 min. The transesterification reaction vials were cooled to room temperature, followed by the addition of 1 mL of water and vortexing. FAMEs were extracted with 1.5 mL hexane for 60 min at 60 rpm. The vials were then vortexed for 30 s and centrifuged for 2 min at 2,375×g to separate the aqueous and organic layers. The upper organic phase collected with a glass syringe and transferred to GC vials (Fisher Scientific Co., Fair Lawn, NJ, USA) for GC analysis according to the following method: 1 μL were injected into the GC, which was run in splitless mode using helium gas as a carrier gas with a flow rate of 1 mL/min. The injector temperature was 280 °C and the oven temperature was initially held at 50 °C for 3 min and then raised to 250 °C at 10 °C/min and held for 3 min. Analysis of primary alcohols followed the same procedure except 50 μL of 2 mg/mL tridecanol in ethanol was added to the initial sample as an internal standard (in addition to the carboxylic acid internal standard) and a 1:1 pyridine–acetic anhydride mixture was used in place of the boron trifluoride-methanol solution for the acetylation of extracted primary alcohols followed by heating at 80 °C for 120 min.

Enzyme assays

Cells were grown overnight in 25 mL LB medium in 125-mL Erlenmeyer flasks at 37 °C and 200 rpm, harvested, washed twice with a 9 g/L NaCl solution, and stored as cell pellets at −80 °C. Cell disruption was carried out by using glass (0.1 mm diameter) beads. The measurement of thioeseterase (TE) activity was carried out by monitoring reduction of 5,5′-dithiobis(2-nitrobenzoic acid) (DTNB) [38]. The reaction mixture contained 0.1 M Tris–HCl (pH 7.5), 0.2 M KCl, 1 mM DTNB, 25 μM acyl-CoA and crude extract in a final volume of 200 μL. Reactions were carried out at 30 °C and DTNB reduction was measured by increase in optical density at 412 nm on a Synergy HT plate reader (BioTek Instruments, Inc., Winooski, VT, USA). For the specific activity assays (reported in nmol substrate/mg protein/min), protein concentration was established using the Bradford Reagent (Thermo Scientific, Waltham, MA, USA) using BSA as the protein standard.

Results and discussion

Reduction of endogenous thioesterase activity provides an efficient background to fine-tune the operation of a β-oxidation reversal

Previously, we have utilized a synthetic approach to construct and functionally characterize a reversal of the β-oxidation cycle [5] establishing the key core/elongation modules (thiolase, 3-hydroxyacyl-CoA dehydrogenase, 3-hydroxyacyl-CoA dehydratase, and trans-enoyl-CoA reductase) required for longer chain (C ≥ 4) product synthesis (Fig. 1). Using this approach, a one-turn reversal was constructed through the use of AtoB (thiolase), FadB (3-hydroxyacyl-CoA dehydrogenase and 3-hydroxyacyl-CoA dehydratase), and the trans-2-enoyl reductase from E. gracilis (egTER) in an E. coli strain devoid of native fermentation pathways (JC01: MG1655 ∆ldhA ∆pta ∆poxB ∆adhE ∆frdA). A multiple turn β-oxidation reversal was facilitated through the use of the longer chain length specific thiolase FadA in addition to AtoB, FadB, and egTER [5]. Product synthesis was demonstrated in the form of carboxylic acids resulting from the expression of these core components without the controlled overexpression of a termination pathway. While this established the key core/elongation components required, the fact that endogenous enzymes resulted in carboxylic acid production represents a significant issue with regard to fine-tuning both the chain length and type(s) of products synthesized.

In order to provide a background more amenable to fine-tuning product synthesis, we sought to eliminate as many endogenous termination pathways as possible. This will not only enable the selection of specific termination pathways for the chain length and type of product desired, but can also facilitate increases in the intracellular pool(s) of required acyl-CoA intermediates by minimizing their conversion to undesired products. Considering the carboxylic acid production observed with only the expression of the core/elongation enzymes, native thioesterases capable of hydrolyzing acyl-CoA intermediates are candidates for the endogenous enzymes leading to product synthesis. E. coli possesses several enzymes that could be functioning in this capacity, including the thioesterases encoded by tesA [2], tesB [25], yciA [38], fadM [7], ydiI [16], and ybgC [11]. Serial deletion of these six genes in JC01 (MG1655 ∆ldhA ∆pta ∆poxB ∆adhE ∆frdA) was undertaken. Using butyrate production as a proxy for product synthesis from a one-turn β-oxidation reversal with AtoB, FadB, and egTER expression, the deletion of these genes had a dramatic impact on product synthesis as the production of acetate and butyrate decreased significantly with a corresponding increase in pyruvate generation (Fig. 2). While the order of deletion could play a role in the influence of a specific thioesterase deletion, it should be noted that yciA and tesB deletions appear to have the most significant impact on the titers of carboxylic acids under these conditions (Fig. 2). The construction of this “thioesterases-deficient” strain should provide a more efficient background for operation of multiple cycle turns, which in turn can facilitate the synthesis of target products upon the controlled expression of termination pathways of interest.

Impact of endogenous thioesterase deletion on (a) cell growth, pH, and glycerol consumption, (b) acetic, butyric, and pyruvic acids, (c) total C4–C10 saturated carboxylic acid titer, and (d) C4–C10 saturated carboxylic acid distribution. Components for a functional β-oxidation reversal (AtoB, FadB, and egTER) were expressed from pTrcHis2A in all strains. Serial deletion of thioesterases in JC01 (MG1655 ∆ldhA ∆pta ∆poxB ∆adhE ∆frdA) in the following order with JST06 representing JC01 will all 6 deletions: yciA, ybgC, ydiI, tesA, fadM, tesB (see text for details)

While the above results demonstrated the reduction in shorter chain carboxylic acid synthesis, in the context fine-tuning medium-chain length product synthesis from a β-oxidation reversal, it is also important to determine the impact these thioesterase deletions have on the cleavage of longer chain length acyl-CoA intermediates. This was evaluated through the measurement of acyl-CoA hydrolysis activities from crude cell extracts of strains JC01 (DE3) ∆fadE and JST07 (DE3) with the serial deletion of the six thioesterases described above being the difference between the two strains (Table 2). It should be noted that each of these strains contains a deletion of fadE, encoding the acyl-CoA dehydrogenase responsible for the degradation of acyl-CoA intermediates in the catabolic operation of the β-oxidation cycle, as well as a λDE3 Lysogen to allow the expression of genes under the T7 lac promoter. As seen in Table 2, JST07 (DE3) exhibits significantly lower activities for the hydrolysis of all C2–C10 saturated acyl-CoAs tested, when compared to JC01 (DE3) ∆fadE. Based on these findings, JST07 (DE3) provides the ideal background for a multiple cycle turn reversal, as the minimization of acyl-CoA cleavage should enable the generation of significant levels of medium-chain acyl-CoA intermediates, which can be converted to products of interest through the expression of termination pathways exhibiting appropriate chain length specificity.

Controlling product chain length through the selection of appropriate thiolase and termination enzymes

While the deletion of endogenous thioesterases lowered acyl-CoA hydrolysis activities and minimized saturated carboxylic acid production with the expression of enzymes required for a one-turn β-oxidation reversal, the synthesis of medium-chain length products requires both the operation of multiple cycle turns as well as the expression of termination pathways with target chain length specificity. Given the broad chain length specificity of FadB and egTER, the ability to operate multiple cycles depends on the selection of thiolase(s) with the ability to efficiently condense acetyl-CoA with the growing chain length acyl-CoA intermediates (Fig. 1). For the synthesis of medium-chain length (C6–C10) products, thiolases that facilitate the generation of C6–C10 acyl-CoAs are required to provide an adequate intracellular pool of these key intermediates. Potential thiolases for use in this context include the aforementioned AtoB and FadA, along with the predicted E. coli acetyl-CoA acetyltransferease YqeF [28] and the β-ketothiolase BktB from Ralstonia eutropha, which has been shown to condense acetyl-CoA with C4 and C6 acyl-CoA intermediates [20, 21].

We chose to employ expression mechanisms allowing for the independent control of core/elongation and termination enzymes. For this, chromosomal expression of core/elongation enzymes under a cumate-inducible promoter was selected based on our previous results with the expression of AtoB, BktB, FadB(A), and/or egTER [4, 34]. For YqeF expression, a cumate-controlled expression construct was created in which yqeF seamlessly replaced atoB for expression at the atoB locus. Individual constructs for each of these various thiolases were then combined with FadB and egTER constructs in JST07 (DE3) to enable full core/elongation module expression in this background strain with minimized endogenous thioesterase expression. While these strains have all required core/elongation enzymes for a functional β-oxidation reversal, the lack of acyl-CoA hydrolysis activity in this background (Table 2) requires the controlled expression of a thioesterase to enable product synthesis at high levels. For this purpose, tesA’ (leaderless version of tesA [2]) was selected. TesA’ was selected due in part to our preliminary characterization in which crude extracts of cells expressing tesA showed ~tenfold higher specific activities on decanoyl-CoA compared to butyryl-CoA and other short chain CoA intermediates [5]. Considering the competition between the condensation and termination enzymes for the growing chain length acyl-CoA intermediates, these properties should minimize the cleavage of shorter-chain acyl-CoAs, while functioning for the hydrolysis reaction after medium-chain length acyl-CoAs are generated through a multiple turn β-oxidation reversal.

tesA’ was cloned into a pCDF vector to enable expression independently from the core/elongation enzymes. As seen in Fig. 3, with tesA’ expression, the production of various amounts of C4–C10 saturated carboxylic acids were observed dependent on the choice of thiolase in combination with FadB and egTER. The use of AtoB as the only thiolase component results in butyric acid as the only C4 or longer saturated carboxylic acid product (Fig. 3). However, the use of a longer chain length specific thiolase, such as FadA or BktB, enables the synthesis of longer chain length carboxylic acids. Given the longer chain length specificity of FadA, however, its expression needs to be combined with that of AtoB in order to increase the synthesis of C4–C10 carboxylic acids, as more than a twofold increase in total titer was observed with AtoB and FadA expression compared to FadA as the sole thiolase (Fig. 3). The use of BktB as the sole thiolase component yielded an improved performance on both titer and selectivity towards medium-chain length carboxylic acids, as the synthesis of greater than 1 g/L total C4–C10 saturated carboxylic acids were observed with about 90 % of the products being C6–C10 (Fig. 3). These characteristics make this strain ideally suited to targeting medium-chain length (C6–C10) products.

Influence of thiolase components on carboxylic acid production from a β-oxidation reversal. C4–C10 saturated carboxylic acid (a) titer and (b) distribution from JST07 (DE3) containing chromosomal constructs for the expression of fadB, egTER, and the indicated thiolase(s). TesA’ (expressed from pCDF-P1-tesA’) was used for thioesterase termination

While the above results demonstrate the influence of the thiolase component on product chain length from a β-oxidation reversal, further refinement to this distribution can potentially be achieved through the use of thiosterases with varying chain length specificity. Given the lower titers of decanoic acid in comparison to hexanoic and octanoic acids observed with tesA’ expression with BktB as the thiolase (Fig. 3), we looked to employ a longer chain length specific thioesterase in an attempt to increase C10 production. For this purpose, the long-chain acyl-CoA thioesterase encoded by fadM from E. coli was cloned into pCDF for expression. Upon overexpression of fadM in JST07 (DE3) with the BktB, FadB, and egTER chromosomal expression constructs, a significant increases in decanoic acid production was observed compared to that with tesA’ expression (Fig. 4A). This also corresponded to lower levels of C6 and C8 saturated carboxylic acid production, demonstrating the ability of the termination pathway to influence the chain length distribution (Fig. 4a). This type of fine-tuning of product synthesis was only achieved with fadM overexpression in JST07 (DE3), as significantly lower levels of decanoic acid were produced in JC01 (DE3) with the same core/elongation components and fadM expression (Fig. 4a).

Controlling carboxylic acid chain length through the manipulation of termination pathways (a) and improving titer of carboxylic acid (b). a C4–C10 saturated carboxylic acid titer and yield in various backgrounds with thioesterases TesA’ or FadM as termination enzymes. Both JC01 (DE3) and JST07 (DE3) contain constructs for bktB, fadB, and egTER chromosomal expression with tesA’ or fadM expressed from plasmid pCDF. 10 μM IPTG and 100 μM cumate were used for expression; b Carboxylic acid production in JST07(DE3) with bktB, fadB, and egTER chromosomal expression and tesA’ overexpression from plasmid pCDF at extended fermentation time. 10 μM IPTG and 200 μM of cumate were used for expression

The same trend described above for fadM overexpression was also observed with tesA’ expression in the two backgrounds, as the use of tesA’ in JST07 (DE3) resulted in higher C6, C8, and C10 titers with decreased butyrate titer in comparison to JC01 (DE3) (Fig. 4a). Further increase in medium-chain (C6–C10) carboxylic acid production was observed when strain JST07 (DE3) with tesA’ overexpression was cultivated for an extended fermentation time and using higher concentration of inducer (200 μM cumate) (Fig. 4b).

Overall, these results demonstrate the importance of manipulating both the thiolase component and termination pathways to ensure the generation of medium-chain length acyl-CoA intermediates available for product synthesis. The deletion of endogenous thioesterases with the use of appropriate thiolase(s) provides a background in which sufficient supply of medium-chain length acyl-CoAs are generated. The overexpression of a thioesterase with desirable properties (i.e., sufficient activity on medium-chain acyl-CoAs with low activity for short chain acyl-CoA intermediates) can then be utilized to promote the synthesis of desired chain length carboxylic acids while minimizing the loss of carbon from the cleavage of shorter chain length CoA intermediates. While a more rigorous screening of potential acyl-CoA thioesterases is envisioned as a means to increase the total titer and chain length specificity of carboxylic acid synthesis, the ~1.3 g/L of medium-chain (C6–C10) carboxylic acids represent the largest concentration of these products reported in the literature. Moreover, the improved strain background in regard to the generation of medium-chain length acyl-CoAs enables the use of additional termination pathways for varying product functionality.

Synthesis of medium-chain length primary alcohols through a β-oxidation reversal

With the efficiency of the β-oxidation reversal for medium-chain acyl-CoA generation improved through the deletion of native thioesterases and use of proper thiolases, the next area of investigation involved the overexpression of termination enzymes for the production of medium-chain length primary alcohols. This requires the use of various alcohol/aldehyde-forming acyl-CoA reductases or CoA-dependent dehydrogenases that can reduce target acyl-CoA intermediates (Fig. 1). With the individual core/elongation components expressed from the chromosome under cumate-inducible control, candidate enzymes for alcohol production were cloned into pCDF to provide independent control of expression in JST07 (DE3). Alcohol-forming termination pathways explored for this purpose included bi-functional alcohol-forming acyl-CoA reductases, in which a single enzyme converts the acyl-CoA to an alcohol, as well as a pathway in which multiple enzymes, an aldehyde-forming acyl-CoA reductase and alcohol dehydrogenase/aldehyde reductase, convert the acyl-CoA intermediate into the desired primary alcohol. The alcohol-forming acyl-CoA reductases AdhE2 from Clostridium acetobutylicum [9] and Maqu2507 [17, 35] and Maqu2220 [12, 17] from Marinobacter aquaeolei were selected for the single enzyme approach. For the first step of the multi-enzyme termination pathway, we chose the aldehyde-forming acyl-CoA/ACP reductases Acr1 from Acinetobacter calcoaceticus [27], AcrM from Acinetobacter sp. strain M-1 [13], Ald from Clostridium beijerinckii [33], and Orf1594 from Synechococcus elongatus PCC 7942 [31], as well as predicted acyl-CoA reductases EutE from Salmonella typhimurium [36] and MhpF from E. coli [8].

As seen in Table 3, when genes encoding these enzymes were expressed in JST07 (DE3) along with bktB, fadB, and egTER, varying amounts of C4–C10 primary alcohols were produced dependent on the enzymes utilized. Acyl-CoA reductases Acr1, AcrM, and Orf1594 did not produce alcohols shorter than 10 carbons in length, consistent with previous studies demonstrating preference for longer chain length substrates [13, 27, 31]. While the Clostridal enzymes AdhE2 and Ald are involved in butanol production in their native species, when these enzymes were expressed in a background enabling the generation of C6–C10 acyl-CoA intermediates, hexanol, octanol, and decanol were produced in addition to butanol (Table 3). While Ald expression resulted in significant amounts of butanol production, greater than 150 mg/L of C6–C10 alcohols were produced demonstrating the potential of this enzyme for medium-chain length primary alcohol production. Furthermore, of all candidate enzymes tested, the alcohol-forming acyl-CoA reductase Maqu2507 from M. aquaeolei produced the highest titer (~200 mg/L) of C6–C10 primary alcohols, while also limiting the amount of butanol produced in relation to these target chain lengths (Table 3).

Given the higher titers of C6–C10 primary alcohols with the use of Ald and Maqu2507, and the potential for acyl-CoA reductases to act on acyl-ACP intermediates from the fatty acid biosynthesis pathway, experiments were run to confirm the production of these alcohols were a result of a functional β-oxidation reversal. Alcohol production with Ald and Maqu2507 was only observed when combined with a full β-oxidation reversal (BktB, FadB, and egTER), with no alcohol production detected with the expression of either enzyme in JST07 (DE3) without all core/elongation enzymes (data not shown). Based on these results, Ald and Maqu2507 were selected as the termination pathways for further investigation into alcohol production from a β-oxidation reversal.

One interesting facet of the use of Ald for acyl-CoA reduction is that despite Ald representing an aldehyde-forming acyl-CoA reductase, as opposed to a bi-functional alcohol-forming enzyme, alcohol production was observed without the overexpression of an alcohol dehydrogenase/aldehyde reductase. This is likely because E. coli possesses numerous aldehyde reductases that can reduce varying chain length aldehydes to the corresponding alcohols [26, 29]. While this can explain alcohol production in the case of the aldehyde-forming acyl-CoA reductase expression, it also represents a potential control point for increasing the titer and chain length specificity of the primary alcohols formed. This was further explored by the combined overexpression of ald with several native aldehyde reductases/alcohol dehydrogenases. These included FucO and YqhD, previously demonstrated to function for butanol production from a β-oxidation reversal [6], as well as AdhP, an enzyme recently shown to be involved in the reduction of aldehydes to primary alcohols in an engineered E. coli strain [19].

The genes encoding these enzymes were cloned into pCDF-P1-ald behind the second T7 promoter for expression in JST07 (DE3) with chromosomal expression of bktB, fadB, and egTER. Interestingly, while the co-expression of adhP or fucO with ald had neutral to negative impact on alcohol production, yqhD overexpression with ald resulted in an overall increase to C4–C10 alcohol production (Fig. 5). This increase in total titer was associated with higher levels of butanol and hexanol production, indicating that YqhD could contribute to the conversion of C4–C6 aldehydes to the respective alcohol.

Primary alcohol production from a β-oxidation reversal with the expression of the aldehyde-forming acyl-CoA reductase Ald from C. beijerinckii individually or in combination with the E. coli alcohol dehydrogenases AdhP, FucO, or YqhD. Termination pathway enzyme(s) expressed from pDCF in JST07 (DE3) containing constructs for bktB, fadB, and egTER chromosomal expression

In contrast to Ald, the bi-functional alcohol-forming acyl-CoA reductase Maqu2507 from M. aquaeolei is capable of fully reducing an acyl-CoA intermediate to the primary alcohol, likely negating any potential influence of endogenous alcohol dehydrogenases on target product synthesis. However, the broad chain length specificity of this enzyme displayed within the context of a β-oxidation reversal (Table 3) provides the opportunity to dictate product chain length through control of the chain length of acyl-CoA intermediates generated. As previously demonstrated with carboxylic acid synthesis (Fig. 3), the combination of various thiolases with different termination pathways can greatly influence the product chain length distribution depending on the key characteristics of the enzymes utilized. Using a similar approach with Maqu2507, we sought to determine the influence the use of various thiolases had on alcohol production. For this purpose, the pCDF vector expressing the gene encoding Maqu2507 was transformed into the JST07 (DE3) containing chromosomal expression constructs for FadB and egTER in combination with the construct(s) for AtoB, BktB, or AtoB and FadA. As seen in Fig. 6, when these various thiolase(s) are utilized as the condensation enzyme, the chain length of alcohols varies according to the chain length specificity of the thiolase.

Controlling primary alcohol chain length from a β-oxidation reversal through the use of various thiolase modules. Maqu2507 from M. aquaeolei (expressed from pCDF-P1-maqu2507) was used for termination in JST07 (DE3) containing chromosomal constructs for the expression of fadB, egTER, and the indicated thiolase(s)

As expected based on the kinetic properties of AtoB, when this enzyme is used as the exclusive thiolytic component, butanol is the predominant alcohol produced. However, when AtoB is used in conjunction with FadA, the distribution of chain length produced shifts to longer chain length alcohols with C6–C10 alcohols accounting for the highest product fraction (Fig. 6). Interestingly, unlike the case of carboxylic acid production with tesA’ expression, in which BktB is enabled in the highest titers (Fig. 3), with Maqu2507 as the termination pathway the combination of AtoB and FadA enables the higher total titers of targeted C6–C10 products (296 mg/L) (Fig. 6). This could be reflective of the relative kinetic properties of the thiolase(s) and termination enzymes in regard to the acyl-CoA intermediates. Considering the acyl-CoA intermediate(s) represent the substrate for both the condensation enzyme(s) as well as the termination pathways to saturated carboxylic acids and primary alcohols in this case, the competition between these enzymes for varying chain length acyl-CoA intermediates represents a key element in determining the distribution of products. While the kinetic properties of these enzymes for the acyl-CoA chain lengths in question have not been determined, one can envision a scenario in which the relative substrate affinities and catalytic properties of the thiolase(s) and termination enzymes dictate the distribution of products based on the overall competition for the acyl-CoA intermediates. As such, the continued refinement and identification and characterization of core/elongation and termination pathways with favorable kinetic properties can be utilized to improve both the overall titer and product selectivity from a β-oxidation reversal.

Conclusions

Expanding upon the synthetic approach to reconstructing a functional β-oxidation reversal, we have expanded the utility of this pathway for the synthesis of medium-chain length (C6–C10) products. This was accomplished through manipulation of the thiolase and termination components of the pathway to increase the generation of medium-chain length acyl-CoA intermediates and enable their conversion to products of interest. Key to this approach was the deletion of endogenous thioesterases, which imparted broad chain length specificity for acyl-CoA hydrolysis and resulted in the depletion of generated acyl-CoA intermediates to carboxylic acids. In this efficient background, the expression of thiolases of varying chain length specificity, along with all core β-oxidation modules and controlled thioesterase termination pathways altered the chain length distribution of carboxylic acid production. Titers of about 1.3 g/L C6–C10 saturated carboxylic acids (hexanoic, octanoic, and decanoic acids) were observed with the use of BktB as the thiolase component and TesA’ as the thioesterase termination pathway, representing the highest titers of this chain length distribution reported to date. Product functionality was tuned through the expression of various aldehyde/alcohol-forming acyl-CoA reductases in this background, resulting in the synthesis of C6–C10 primary alcohols from a β-oxidation reversal. The highest total titers of medium-chain primary alcohols hexanol, octanol, and decanol (~0.3 g/L) were achieved with the combination of AtoB and FadA as the thiolase components with the alcohol-forming acyl-CoA reductase Maqu2507 from M. aquaeolei. These results demonstrate both the ability to fine-tune product synthesis as well as the importance of selecting appropriate core/elongation and termination enzymes based on the targeted products. Furthermore, the feedstock-independent nature of the pathway (i.e., only requires the generation of acetyl-CoA from a given carbon source) was demonstrated through the use of the low-value feedstock glycerol as the carbon source. Overall, the results reported here further establish the β-oxidation pathway as a modular and versatile pathway that can be utilized for the synthesis of a wide array of fuels and chemicals.

References

Buchholz K, Collins J (2013) The roots-a short history of industrial microbiology and biotechnology. Appl Microbiol Biotechnol 97:3747–3762

Cho HS, Cronan JE (1993) Escherichia coli thioesterase I, molecular cloning and sequencing of the structural gene and identification as a periplasmic enzyme. J Biol Chem 268:9238–9245

Cintolesi A, Clomburg JM, Gonzalez R (2014) In silico assessment of the metabolic capabilities of an engineered functional reversal of the β-oxidation cycle for the synthesis of longer-chain (C ≥ 4) products. Metab Eng 23:100–115

Clomburg JM, Blankschien MD, Vick JE, Chou A, Kim S, Gonzalez R (2014) Integrated engineering of β-oxidation reversal and ω-oxidation pathways for the synthesis of medium chain ω-functionalized carboxylic acids. Metab Eng. doi:10.1016/j.ymben.2015.01.007

Clomburg JM, Vick JE, Blankschien MD, Rodriguez-Moya M, Gonzalez R (2012) A synthetic biology approach to engineer a functional reversal of the β-oxidation cycle. ACS Synth Biol 1:541–554

Dellomonaco C, Clomburg JM, Miller EN, Gonzalez R (2011) Engineered reversal of the β-oxidation cycle for the synthesis of fuels and chemicals. Nature 476:355–359

Feng Y, Cronan JE (2009) A new member of the Escherichia coli fad regulon: transcriptional regulation of fadM (ybaW). J Bacteriol 191:6320–6328

Fischer B, Boutserin S, Mazon H, Collin S, Branlant G, Gruez A et al (2013) Catalytic properties of a bacterial acylating acetaldehyde dehydrogenase: evidence for several active oligomeric states and coenzyme a activation upon binding. Chem-Biol Interact 202:70–77

Fontaine L, Meynial-Salles I, Girbal L, Yang XH, Croux C, Soucaille P (2002) Molecular characterization and transcriptional analysis of adhE2, the gene encoding the NADH-dependent aldehyde/alcohol dehydrogenase responsible for butanol production in alcohologenic cultures of Clostridium acetobutylicum ATCC 824. J Bacteriol 184:821–830

Gulevich AY, Skorokhodova AY, Sukhozhenko AV, Shakulov RS, Debabov VG (2012) Metabolic engineering of Escherichia coli for 1-butanol biosynthesis through the inverted aerobic fatty acid beta-oxidation pathway. Biotechnol Lett 34:463–469

Gully D, Bouveret E (2006) A protein network for phospholipid synthesis uncovered by a variant of the tandem affinity purification method in Escherichia coli. Proteomics 6:282–293

Hofvander P, Doan TTP, Hamberg M (2011) A prokaryotic acyl-CoA reductase performing reduction of fatty acyl-CoA to fatty alcohol. FEBS Lett 585:3538–3543

Ishige T, Tani A, Takabe K, Kawasaki K, Sakai Y, Kato N (2002) Wax ester production from n-alkanes by Acinetobacter sp strain M-1: Ultrastructure of cellular inclusions and role of acyl coenzyme A reductase. Appl Environ Microbiol 68:1192–1195

Jang YS, Kim B, Shin JH, Choi YJ, Choi S, Song CW et al (2012) Bio-based production of C2–C6 platform chemicals. Biotechnol Bioeng 109:2437–2459

Kang YS, Durfee T, Glasner JD, Qiu Y, Frisch D, Winterberg KM et al (2004) Systematic mutagenesis of the Escherichia coli genome. J Bacteriol 186:4921–4930

Latham JA, Chen DQ, Allen KN, Dunaway-Mariano D (2014) Divergence of substrate specificity and function in the Escherichia coli hotdog-fold thioesterase paralogs YdiI and YbdB. Biochemistry 53:4775–4787

Lenneman EM, Ohlert JM, Palani NP, Barney BM (2013) Fatty alcohols for wax esters in Marinobacter aquaeolei VT8: two optional routes in the wax biosynthesis pathway. Appl Environ Microbiol 79:7055–7062

Lian J, Zhao H (2014) Reversal of the β-oxidation cycle in Saccharomyces cerevisiae for production of fuels and chemicals. ACS Synth Biol. doi:10.1021/sb500243c

Liu R, Zhu FY, Lu L, Fu AS, Lu JK, Deng ZX et al (2014) Metabolic engineering of fatty acyl-ACP reductase-dependent pathway to improve fatty alcohol production in Escherichia coil. Metab Eng 22:10–21

Machado HB, Dekishima Y, Luo H, Lan EI, Liao JC (2012) A selection platform for carbon chain elongation using the CoA-dependent pathway to produce linear higher alcohols. Metab Eng 14:504–511

Martin CH, Dhamankar H, Tseng HC, Sheppard MJ, Reisch CR, Prather KLJ (2013) A platform pathway for production of 3-hydroxyacids provides a biosynthetic route to 3-hydroxy-gamma-butyrolactone. Nat Commun 4:9

Mazumdar S, Blankschien MD, Clomburg JM, Gonzalez R (2013) Efficient synthesis of L-lactic acid from glycerol by metabolically engineered Escherichia coli. Microb Cell Fact 12:7–11

Miller JH (1972) Experiments in molecular genetics. Cold Spring Harbor Laboratory Press, New York

Neidhardt FC, Bloch PL, Smith DF (1974) Culture Medium for Enterobacteria. J Bacteriol 119:736–747

Nie L, Ren Y, Janakiraman A, Smith S, Schulz H (2008) A novel paradigm of fatty acid β-oxidation exemplified by the thioesterase-dependent partial degradation of conjugated linoleic acid that fully supports growth of Escherichia coli. Biochemistry 47:9618–9626

Pick A, Ruhmann B, Schmid J, Sieber V (2013) Novel CAD-like enzymes from Escherichia coli K-12 as additional tools in chemical production. Appl Microbiol Biotechnol 97:5815–5824

Reiser S, Somerville C (1997) Isolation of mutants of Acinetobacter calcoaceticus deficient in wax ester synthesis and complementation of one mutation with a gene encoding a fatty acyl coenzyme a reductase. J Bacteriol 179:2969–2975

Riley M, Abe T, Arnaud MB, Berlyn MKB, Blattner FR, Chaudhuri RR et al (2006) Escherichia coli K-12: a cooperatively developed annotation snapshot-2005. Nucleic Acids Res 34:1–9

Rodriguez GM, Atsumi S (2014) Toward aldehyde and alkane production by removing aldehyde reductase activity in Escherichia coli. Metab Eng 25:227–237

Sambrook J, Fritsch EF, Maniatis T, Russell DW (2001) Molecular cloning: a laboratory manual. Cold Spring Harbor Laboratory Press, Cold Spring Harbor, NY

Schirmer A, Rude MA, Li XZ, Popova E, del Cardayre SB (2010) Microbial Biosynthesis of Alkanes. Science 329:559–562

Straathof AJJ (2014) Transformation of biomass into commodity chemicals using enzymes or cells. Chem Rev 114:1871–1908

Toth J, Ismaiel AA, Chen JS (1999) The ald gene, encoding a coenzyme A-acylating aldehyde dehydrogenase, distinguishes Clostridium beijerinckii and two other solvent-producing clostridia from Clostridium acetobutylicum. Appl Environ Microbiol 65:4973–4980

Vick JE, Clomburg JM, Blankschien MD, Chou A, Kim S, Gonzalez R (2015) FabI and other bacterial enoyl-acyl carrier protein reductases (ENR) support efficient operation of a functional reversal of the β-oxidation cycle. Appl Environ Microbiol 81 doi:10.1128/AEM.03521-14

Willis RM, Wahlen BD, Seefeldt LC, Barney BM (2011) Characterization of a fatty acyl-CoA reductase from Marinobacter aquaeolei VT8: a bacterial enzyme catalyzing the reduction of fatty acyl-CoA to fatty alcohol. Biochemistry 50:10550–10558

Zhu HL, Gonzalez R, Bobik TA (2011) Coproduction of acetaldehyde and hydrogen during glucose fermentation by Escherichia coli. Appl Environ Microbiol 77:6441–6450

Zhuang Q, Wang Q, Liang Q, Qi Q (2014) Synthesis of polyhydroxyalkanoates from glucose that contain medium-chain-length monomers via the reversed fatty acid β-oxidation cycle in Escherichia coli. Metab Eng 24:78–86

Zhuang ZH, Song F, Zhao H, Li L, Cao J, Eisenstein E et al (2008) Divergence of function in the hot dog fold enzyme superfamily: the bacterial thioesterase YciA. Biochemistry 47:2789–2796

Acknowledgments

This work was supported by grants from the U.S. National Science Foundation (CBET-1134541, CBET-1067565).

Author information

Authors and Affiliations

Corresponding author

Additional information

Special Issue: Metabolic Engineering.

Rights and permissions

About this article

Cite this article

Kim, S., Clomburg, J.M. & Gonzalez, R. Synthesis of medium-chain length (C6–C10) fuels and chemicals via β-oxidation reversal in Escherichia coli . J Ind Microbiol Biotechnol 42, 465–475 (2015). https://doi.org/10.1007/s10295-015-1589-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-015-1589-6