Abstract

Biodiesel is an alternative fuel made from costly vegetable oil feedstocks. Some microorganisms can accumulate lipids when nutrients are limited and carbon is in excess. Rhodococcus rhodochrous is a gram-positive bacterium most often used in bioremediation or acrylamide production. The purpose of this study was to investigate and characterize the lipid accumulation capabilities of R. rhodochrous. Shake flasks and a large-scale fermentation were used to cultivate R. rhodochrous in varying concentrations of glucose. R. rhodochrous achieved almost 50 % of dry cell mass as lipid when grown in 20 g/L of glucose. Wax esters and triglycerides were identified in R. rhodochrous lipid extract. The transesterified extractables of R. rhodochrous consisted of mostly palmitic (35 %) and oleic (42 %) acid methyl esters. This study shows R. rhodochrous to be an oleaginous bacterium with potential for application in alternative fuels.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

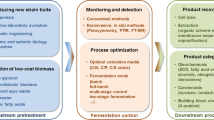

Alternative fuels are necessary to fulfill the increasing demand for sustainable liquid fuel sources. As fossil fuels are expected to remain a dominant source of energy, sustainable fuels are being used to displace the fossil fuels used for transportation [12]. Despite developments in corn ethanol and lignocellulosic ethanol, the issues of land use, chemical input, and food competition persist [10, 31]. Biodiesel is an alternative to diesel fuel that is made from the transesterification of triglycerides, commonly found in animal fat and vegetable oils [19]. Currently, the most common biodiesel feedstock is soybean oil, which accounts for almost 70 % of the total cost of biodiesel and uses acres of arable land that is subject to a volatile climate [11, 29, 31].

An alternative to plant oils is microbial oils, which could use lignocellulosic mono-sugars as substrate to serve as a reliable, climate-independent source of oil [9, 10, 18]. These lignocellulosics, such as energy cane, switchgrass, and giant miscanthus, are advantageous because they require minimal inputs and are more resistant to changes in weather [10]. This lignocellulosic biomass must be pretreated to release sugars for fermentation by microorganisms. While pretreatment releases sugars, it also produces microbial growth inhibitors such as acetic acid, furfural, and phenolic lignin compounds [22]. Not all microbes can tolerate these conditions and lipid yields may be affected. Therefore, identifying novel oleaginous microbes is essential to improving the use of diverse substrates, such as lignocellulosic material, for microbial lipid accumulation.

While the oleaginous capabilities of yeasts are well characterized, the potential of oleaginous bacteria is still being investigated. Microbes accumulating over 20 % of its biomass as lipid are considered to be oleaginous microbes [34]. Generally, this lipid accumulation occurs in stationary phase when a key nutrient (e.g., nitrogen) is limited and a carbon source is in excess [2, 25]. Perhaps the most well-known oleaginous bacterium, Rhodococcus opacus, has been shown to accumulate almost 80 % of its biomass as triglycerides [1]. Other oleaginous bacteria include Mycobacterium, Streptomyces, and Acinetobacter species as well as other species of Rhodococcus [2].

Microbial lipid accumulation has been observed in bacteria belonging to the actinomycetes group, frequently cultivated on gluconate, glucose, and other sugar substrates or hydrocarbons [2]. Rhodococcus rhodochrous is a red-pigmented, gram-positive, soil bacterium also belonging to the Actinomycetes clade. Due to its ability to utilize a range of aromatic compounds and hydrocarbons, including hydrocarbon gasses, R. rhodochrous is also used in bioremediation efforts [20]. A hydrocarbon-degrading strain of R. rhodochrous isolated from Kuwait was grown in 10 g/L of glucose and had a total lipid content of 1.1 %, compared to 4.1 % when grown in 10 g/L of dodecane [30]. Therefore, the limitations of using pure glucose as a carbon source involve not only cost and sustainability, but also that glucose might not be the ideal substrate for the organism to achieve maximum lipid yield (i.e., hydrocarbons could produce higher yields). The purpose of the initial shake flask experiments was to investigate the ability for R. rhodochrous to accumulate lipids and to identify the concentration of glucose for optimum lipid yield.

As interest in renewable fuels increases, oleaginous microbes are at the forefront of multi-disciplined research. Advantages of microbial oil include less land use, controlled cultivation environment, and consistent yields [2, 9, 34]. These advantages make microbial oil a favorable alternative to crop or animal-derived biodiesel feedstocks. The characterization of other oleaginous bacteria creates opportunities for the development of alternative feedstocks and technologies. Despite the widespread use of R. rhodochrous in industry, the understanding of its ability for lipid accumulation is not well known. This research seeks to provide R. rhodochrous with the designation of oleaginous as it investigates its lipid accumulation abilities in an effort to offer a unique approach to addressing the need for alternative fuels.

Materials and methods

Culture conditions

Rhodococcus rhodochrous, obtained from the American Type Culture Collection (#21198), was maintained in nutrient broth or on nutrient agar (Fisher Scientific, Pittsburg, Pennsylvania, USA) and incubated at 30 °C. Inoculums were prepared by transferring lawns of R. rhodochrous grown for 5 days on nutrient agar to phosphate buffer saline or an aliquot of sterile Sorkhoh medium [30]. The medium was supplemented with 10 g/L (C:N of 27:1), 20 g/L (C:N of 54:1) or 40 g/L (C:N of 108:1) of glucose for shake flask experiments and 20 g/L of glucose for the fermenter experiment. The cultures were incubated in baffled flasks at 30 °C in a shaking incubator at 125 rpm (New Brunswick Scientific Model I26, Edison, NJ, USA). The shake flask experiments were conducted in triplicates and the experimental mean and standard deviation were calculated for all gravimetric and sugar analyses. Repeated measures ANOVA was performed using the Statistical Package for the Social Sciences (SPSS) software when necessary and significance was determined when p < 0.05.

Rhodococcus rhodochrous was grown in a 14-L BIOFLO 410 fermenter (New Brunswick Scientific, Edison, NJ, USA) with a working volume of 7 L. The pH of the culture was uncontrolled but monitored using the systems pH probe. Temperature was maintained at 30 °C and agitation was set to 300 rpm [21]. Antifoam 204 concentrate (0.01 % v/v; Sigma-Aldrich, St. Louis, MO, USA) was aseptically added via syringe filter. Air filtered through a 0.45-μm HEPA vent filter (Whatman, Kent, UK) was bubbled through the culture at 1 vvm (volume of air per volume of media per minute [21]). The inoculum was prepared as previously described for the shake flask experiments. Samples were taken as described below every 12 h until 48 h and then daily until 168 h. The average of two samples per time point was reported.

Analysis

Culture samples (50 mL) were collected every 24 h and centrifuged at 4,500 rpm for 10 min. The supernatant was removed and used for shake flask pH (Accumet pH meter) and sugar measurements and the pellet was frozen at −20 °C. Glucose concentrations were measured for all samples in triplicate using an YSI 2900 Biochemistry Analyzer (YSI Incorporated Life Sciences, Yellow Springs, Ohio). The experimental mean and standard deviation are reported for all shake flask experiments. Residual nitrate in the supernatant was determined using the manufacturer’s methods of an ICS 3000 ion chromatography system (Dionex Corp., Sunnyvale, CA, USA) equipped with an IonPac AS16 anion-exchange analytical column (250 × 4 mm), AG16 guard column (50 × 4 mm), and a conductivity detector. Averages and standard deviations of triplicate injections of one sample are reported for nitrate results.

Lipids were extracted from a freeze-dried pellet using a modified Bligh and Dyer [3] method as described by Revellame et al. [27]. The extract was filtered through glass wool into a tared amber vial. The solvent was removed using a TurboVap LV (Caliper Life Sciences, Hopkinton, MA, USA) at 50 °C and a constant flow of nitrogen gas at a rate of 15 psi for 50 min. The recovered extract was weighed to determine the gravimetric lipid yield (mean and standard deviation of triplicate flasks are reported). The extractables were then transesterified into fatty acid methyl esters (FAME) and analyzed by three injections of one sample using an Agilent 6890N gas chromatograph with a flame-ionization detector (GC-FID; Agilent Technologies Inc., Wilmington, Delaware, USA) with a Zebron ZB-FFAP column (30 m × 0.25 mm, film thickness 0.25 μm). Means and standard deviations of triplicate injections of one sample are reported. Oven temperature was 50–250 °C with a rate of 10 °C per minute. Helium was used as the carrier gas with a flow rate of 1.5 mL per minute and the detector temperature was 260 °C. The instrument was calibrated using a standard solution containing known concentration of C9–C24 FAMEs (purchased from Sigma) by taking in account the response factor of internal standard. 1, 3-dichlorobenzene was used as an internal standard.

The composition of the lipid extract from fermenter samples was evaluated using thin-layer chromatography (TLC) as described previously [27]. The dried lipid extracts were reconstituted in 1 mL chloroform and applied to a 20 × 20-cm glass-backed Analtech Uniplate™ pre-coated with 250-mm silica gel-G (Sigma-Aldrich, St. Louis, MO, USA). Drummond microcaps® disposable pipettes (Fisher Scientific, Pittsburg, PA, USA) were used to apply samples (20 μL) and standards (30 μL). Standards of phospholipid mixture, mono-,di-, and triglycerides, and palmityl palmitate (Sigma-Aldrich, St. Louis, MO, USA) were used to represent lipid classes of interest. Plates were developed in either 94/6 (v/v) n-hexane/diethyl ether or 85/15/2 (v/v/v n-hexane/diethyl ether/acetic acid and then sprayed with a 10 % (w/v) cupric sulfate in 8 % (v/v) phosphoric acid to visualize bands. The plates were allowed to dry and then charred in a 150 °C oven.

Transmission electron microscopy (TEM)

Lipid accumulation by R. rhodochrous was visualized using TEM images of samples taken during fermentation. A sample of 2 mL of culture was pelleted to remove the media and fixed in 2.5 % glutaraldehyde in 0.1 M Na-Cacodylate buffer at pH 7.2. Fixed samples were rinsed with 0.1 M Na-Cacodylate buffer and then post fixed in buffered 2 % osmium tetraoxide. Samples were rinsed once more in water, en bloc stained with 2 % aqueous uranyl acetate, dehydrated in a graded ethanol series, and embedded in Spurr’s resin as similarly described by Alvarez et al. [1]. Ultra-thin sections were cut with a Reichert-Jung Ultracut 3 ultra-microtome and stained with uranyl acetate and lead citrate. Stained sections (two sections per sample) were viewed on a JEOL 1230 120 kV TEM.

Results and discussion

Effect of glucose concentration on lipid accumulation

For this study, three different concentrations of glucose were used to investigate the effect of glucose on the lipid accumulation abilities of R. rhodochrous. Glucose was exhausted in the 10-g/L glucose treatment by 48 h whereas in the 20- and 40-g/L treatments, glucose concentrations were reduced to 6.5 and 25.8 g/L, respectively (Fig. 1a). Nitrate was consumed in all treatments after 48 h of incubation (Fig. 1b), which coincides with the start of lipid accumulation (Fig. 1d) that occurs as the cells enter into stationary phase due to depletion of nitrogen (Fig. 1a).

Glucose concentration (gray; g/L ± SD) and R. rhodochrous cell dry weight (black; g/L ± SD; a), nitrate concentration (mg/L ± SD; b), pH (± SD; c), and percent lipid (± SD; d) of cell dry weight accumulated by R. rhodochrous shake flask cultures supplemented with 10 (filled diamond), 20 (filled square), or 40 g/L (filled circle) glucose

Cell growth was observed in all treatments and the 40-g/L glucose treatment achieved the greatest cell dry weight of almost 7 g/L at 96 and 120 h (p < 0.05; Fig. 1a). The 10- and 20-g/L glucose treatment achieved significantly greater lipid accumulation by 72 h than the 40-g/L treatment (p < 0.05; Fig. 1d). There was no significant difference in lipid accumulation between 10- and 20-g/L glucose treatments, but the 20-g/L glucose treatment achieved slightly greater percent lipid to cell dry weight yield of 47 % in 72 h (Fig. 1d) compared to the 10-g/L treatment, suggesting that 20 g/L glucose is better for lipid accumulation as non-lipid biomass did not increase after 48 h (data not shown). These results show that R. rhodochrous was able to grow in various concentrations of glucose as indicated by an increase in cell dry weight (Fig. 1a), but maximum lipid accumulation occurred in shake flasks with 20 g/L glucose (Fig. 1a, d). Controlled pH conditions could help to promote glucose consumption and increase lipid accumulation.

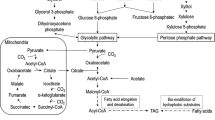

The initial pH for all experiments was 6.8 and increased throughout the duration of the experiment (Fig. 1c), unlike most fermentations of oleaginous yeasts in which the pH decreases with lipid accumulation and glucose consumption [5, 13, 24]. Uncontrolled pH could have caused the observed plateau of glucose consumption and lipid accumulation by R. rhodochrous (Fig. 1a, d). This citrate-producing strain of R. rhodochrous has an optimal pH range of 6–9 [16] and was in this range throughout the experiment (Fig. 1c). If citrate is being produced during fermentation, not only is this citrate potentially driving lipid accumulation [8], but also an abundance could be acting as a buffer to maintain a neutral to alkaline pH. Furthermore, an abundance of citrate could also be used as a substrate, ultimately producing the alkaline by-products of sodium bicarbonate and ammonia.

Characterization of lipid accumulation

A New Brunswick BIOFLO 410 fermenter was used to investigate the effect of larger scale fermentation on growth, glucose consumption and lipid accumulation by R. rhodochrous. The inoculum size and larger volume of the fermenter could have contributed to the longer lag phase, although biomass reached 7 g/L after one week growth (Fig. 2a). Similar total glucose consumption (decreased to <5 g/L) and percent lipid accumulation (over 40 %) were observed in the fermenter trial (Fig. 2a, b) as was observed in the shake flask experiments.

Growth kinetics of R. rhodochrous on glucose fermentation showed that the lipid accumulation increased rapidly after 48 h of fermentation, which is attributed to the nitrogen depletion time. The cell growth also increased rapidly with a rate of biomass production of 0.0503 g/L h. The rate of lipid accumulation (0.0206 g/L h) increased after 48 h of fermentation as interpreted from the slope of the graph for lipid accumulation versus time. However, the lipid is produced during both growth phase (growth and accumulation) and stationary phase (accumulation). This led to a lipid yield YLipid/Glu of 0.3 g lipid/g of sugar consumed. In Table 1, some oleaginous microorganisms and their corresponding kinetic values considering the type of substrate and cultivation mode are presented [7, 23, 28]. This suggests that the cultivation of R. rhodochrous in larger scale fermentations can also achieve oleaginous lipid yields.

Transmission electron microscope images further reveal intracytoplasmic lipid inclusion bodies from fermenter-cultivated cells (Fig. 3), which resemble the electron-transparent inclusions shown in images of other oleaginous microbes [1, 14, 15, 32, 33]. A thin-section sample at 120 h shows intracellular lipid inclusion bodies that correspond to 40 % gravimetric lipid accumulation (Figs. 2b, 3). This lipid accumulation occurred in stationary phase and is consistent with that of other oleaginous microbes [33].

Thin-layer chromatography analysis was used to investigate lipid classes present in R. rhodochrous extractables (Fig. 4). The lipid extract from R. rhodochrous cultivated in the BIOFLO 410 fermenter (Fig. 4 lane RR) showed bands corresponding to triglycerides (Fig. 4 lanes S1 and S3), which are esters of glycerol with three fatty acids and commonly found in animals and plants. However, some bacteria such as Gordonia, Nocardia, Acinetobacter, Mycobacterium, and Rhodococcus have been shown to accumulate lipids in the form of triglycerides [2]. Similarly, microbes can accumulate wax esters for use in times of inorganic nutrient starvation or stress. Wax esters have been identified in Acinetobactor, Pseudomonas, Nocardia, Mycobacterium and Rhodococcus species [33] and in the lipid extract of R. rhodochrous (Fig. 4 lanes S1 and S4). Both wax esters and triglycerides are valuable raw materials that can be used in cosmetics, soaps, plastics, lubricants, and other industrial purposes. Triglycerides and fatty acids could also be a potential feedstock for renewable fuels.

Thin-layer chromatography of lipid extract from R. rhodochrous fermenter culture (RR). a Lipid extract developed in hexane/diethyl ether (96/4). b Lipid extract developed in hexane/diethyl ether/acetic acid (85/15/2). S1 is a standard mixture of S2, S3, and S4. S2 is a (1) phospholipid standard mixture (S2). S3 is a mixture of (2) monoolein, (3) 1, 2-diolein, and (4) triolein. S4 is (5) palmityl palmitate

Fatty acid methyl ester analysis

Soybean oil is a common feedstock for biodiesel production and has a FAME profile dominant in palmitic, oleic, linoleic, and linolenic fatty acids [6] similar to some oleaginous yeast [17, 18, 26]. Palmitic and oleic methyl esters were the most prevalent of the FAMEs in both the shake flask experiments and the fermenter trial (Figs. 5, 6), which could be advantageous for oxidative stability, cetane number and balancing cold flow of biodiesel [4]. Palmitic and oleic methyl esters were also found to be dominant in the fatty acid composition of R. opacus PD630 after growth on various substrates [1]. The yields of total FAMEs from the lipid extracts of the shake flask experiments range from 19 to 49 % (w/w of total lipid extract; data not shown). The percent yield of FAMEs of the cell dry weight was also highest after 72 h growth in 20 g/L glucose.

Other FAMEs were present in small amounts in 10 and 20 g/L accounting for the large total FAME yield in 20 g/L at 72 h (Fig. 5). FAMEs denoted as other consisted of unknown methyl esters (3–13 % w/w) and small amounts (less than 3 % w/w) of Lauric, Myristic, Arachidic, and/or Erucic methyl esters. This FAME profile is similar to other oleaginous microbes although R. rhodochrous does not produce linoleic or linolenic acids as observed in oleaginous yeasts [17, 18, 26]. Rhodococcus opacus PD630, an oleaginous bacterium, has a FAME profile dominant with palmitic, oleic, and heptadecanoic methyl esters [1]. The percentage of unknown FAMEs of R. rhodochrous with retention times between those of palmitoleic and stearic methyl esters could be representative of heptadecanoic methyl esters that were not included in the standard FAME mix used in this study The effects of fermentation conditions and substrate could influence the fatty acid composition of microbial oils [1, 17, 21]. Further optimization of R. rhodochrous fermentation parameters must be investigated.

Conclusion

Rhodococcus rhodochrous, a gram-positive bacterium belonging to the actinomycete group, was grown in varying concentrations of glucose in an effort to characterize this organism as oleaginous. All glucose concentrations promoted lipid accumulation and R. rhodochrous accumulated over 40 % lipid when grown in 20 g/L. A scaled-up fermentation achieved similar lipid yields and greater biomass (7 g/L). TEM images show intracellular lipid bodies in samples collected during these fermentations. Triglycerides and wax esters were found to be the major components of lipids accumulated by R. rhodochrous. Transesterification of extractable lipids yielded FAMEs with high percentages of palmitic and oleic methyl esters.

Microbial-derived products, such as triglycerides, are potential feedstock alternatives for biofuels. Several bacteria have been identified as oleaginous, accumulating over 20 % of the cell dry weight as lipids, usually in the form of triglycerides. Here, we show lipid accumulation of 40 % in R. rhodochrous when grown in glucose-supplemented medium. However, as a well-known and documented bioremediator, the potential for R. rhodochrous to accumulate lipid when grown on more sustainable and cost-effective substrates is being explored.

References

Alvarez HM, Mayer F, Fabritius D, Steinbuchel A (1996) Formation of intracytoplasmic lipid inclusions by Rhodococcus opacus strain PD630. Arch Microbiol 165:377–386

Alvarez HM, Steinbuchel A (2002) Triacylglycerols in prokaryotic microorganisms. Appl Microbiol Biotechnol 60(4):367–376. doi:10.1007/s00253-002-1135-0

Bligh EG, Dyer WJ (1959) A rapid method of total lipid extraction and purification. Can J Biochem Physiol 37:911–917

Bringe NA (2005) Soybean oil composition for biodiesel. In: Knothe G, Krahl J, Van Gerpen J (eds) The biodiesel handbook. AOCS Press, Champaign, pp 161–164

Brown DE, Hasan M, Lepe-Casillas M, Thornton AJ (1990) Effect of temperature and pH on lipid accumulation by Trichoderma reesei. Appl Microbiol Biotechnol 34:335–339

Canakci M, Sanli H (2008) Biodiesel production from various feedstocks and their effects on the fuel properties. J Ind Microbiol Biotechnol 35(5):431–441. doi:10.1007/s10295-008-0337-6

Economou CN, Aggelis G, Pavlou S, Vayenas DV (2011) Modeling of single-cell oil production under nitrogen-limited and substrate inhibition conditions. Biotechnol Bioeng 108(5):1049–1055. doi:10.1002/bit.23026

Evans CT, Ratledge C (1984) Effect of nitrogen source on lipid accumulation in oleaginous yeasts. J Gen Microbiol 130:1693–1704

Fortman JL, Chhabra S, Mukhopadhyay A, Chou H, Lee TS, Steen E, Keasling JD (2008) Biofuel alternatives to ethanol: pumping the microbial well. Trends Biotechnol 26(7):375–381. doi:10.1016/j.tibtech.2008.03.008

Graham-Rowe D (2011) Beyond food versus fuel. Nature 474:56–58

Hill J, Nelson E, Tilman D, Polasky S, Tiffany D (2006) Environmental, economic, and energetic costs and benefits of biodiesel and ethanol biofuels. Proc Natl Acad Sci USA 103(30):11206–11210. doi:10.1073/pnas.0604600103

IEA (2012) Energy Technology Perspectives (2012 ed). International Energy Agency

Johnson V, Singh M, Saini VS, Sista VR, Yadav NK (1992) Effect of pH on lipid accumulation by an oleaginous yeast: Rhodotorula glutinis IIP-30. World J Microbiol Biotechnol 8:382–384

Kalscheuer R, Stoveken T, Luftmann H, Malkus U, Reichelt R, Steinbuchel A (2006) Neutral lipid biosynthesis in engineered Escherichia coli: jojoba oil-like wax esters and fatty acid butyl esters. Appl Environ Microbiol 72(2):1373–1379. doi:10.1128/AEM.72.2.1373-1379.2006

Kalscheuer R, Stoveken T, Malkus U, Reichelt R, Golyshin PN, Sabirova JS, Ferrer M, Timmis KN, Steinbuchel A (2007) Analysis of storage lipid accumulation in Alcanivorax borkumensis: evidence for alternative triacylglycerol biosynthesis routes in bacteria. J Bacteriol 189(3):918–928. doi:10.1128/JB.01292-06

Kimura K, Nakanishi T (1975) Production of citric acid. Isocitric acid and microbial cells by fermentation, United States Patent

Leiva-Candia DE, Pinzi S, Redel-Macías MD, Koutinas A, Webb C, Dorado MP (2014) The potential for agro-industrial waste utilization using oleaginous yeast for the production of biodiesel. Fuel 123:33–42. doi:10.1016/j.fuel.2014.01.054

Li Q, Du W, Liu D (2008) Perspectives of microbial oils for biodiesel production. Appl Microbiol Biotechnol 80(5):749–756. doi:10.1007/s00253-008-1625-9

Ma F, Hanna MA (1999) Biodiesel production: a review. Bioresour Technol 70:1–15

Martinkova L, Uhnakova B, Patek M, Nesvera J, Kren V (2009) Biodegradation potential of the genus Rhodococcus. Environ Int 35(1):162–177. doi:10.1016/j.envint.2008.07.018

Mondala AH, Hernandez R, French T, McFarland L, Santo Domingo JW, Meckes M, Ryu H, Iker B (2012) Enhanced lipid and biodiesel production from glucose-fed activated sludge: kinetics and microbial community analysis. AIChE J 58(4):1279–1290

Palmqvist E, Hahn-Hagerdal B (2000) Fermentation of lignocellulosic hydrolysates. II: inhibitors and mechanisms of inhibition. Bioresour Technol 74:25–33

Papanikolaou S, Fakas S, Fick M, Chevalot I, Galiotou-Panayotou M, Komaitis M, Marc I, Aggelis G (2008) Biotechnological valorisation of raw glycerol discharged after bio-diesel (fatty acid methyl esters) manufacturing process: production of 1,3-propanediol, citric acid and single cell oil. Biomass Bioenergy 32(1):60–71. doi:10.1016/j.biombioe.2007.06.007

Ratledge C (1982) Microbial oils and fats: an assessment of their commercial potential. Prog Ind Microbiol 16

Ratledge C (2002) Regulation of lipid accumulation in oleaginous microorganisms. Biochem Soc Trans 30(6):1047–1050

Ratledge C, Cohen Z (2008) Microbial and algal oils: do they have a future for biodiesel or as commodity oils? Lipid Technol 20(7):155–160. doi:10.1002/lite.200800044

Revellame ED, Hernandez R, French W, Holmes WE, Benson TJ, Pham PJ, Forks A, Callahan Ii R (2012) Lipid storage compounds in raw activated sludge microorganisms for biofuels and oleochemicals production. RSC Adv 2(5):2015. doi:10.1039/c2ra01078j

Saenge C, Cheirsilp B, Suksaroge TT, Bourtoom T (2011) Potential use of oleaginous red yeast Rhodotorula glutinis for the bioconversion of crude glycerol from biodiesel plant to lipids and carotenoids. Process Biochem 46(1):210–218. doi:10.1016/j.procbio.2010.08.009

Shi S, Valle-Rodriguez JO, Siewers V, Nielsen J (2011) Prospects for microbial biodiesel production. Biotechnol J 6(3):277–285. doi:10.1002/biot.201000117

Sorkhoh NA, Ghannoum MA, Ibrahim AS, Stretton RJ, Radwan SS (1990) Sterols and diacylglycerosphocholines in the lipids of the hydrocarbon-utilizing prokaryote Rhodococcus rhodochrous. J Appl Bacteriol 69:856–863

Tao L, Aden A (2009) The economics of current and future biofuels. Vitr Cell Dev Biol Plant 45(3):199–217. doi:10.1007/s11627-009-9216-8

Waltermann M, Hinz A, Robenek H, Troyer D, Reichelt R, Malkus U, Galla HJ, Kalscheuer R, Stoveken T, von Landenberg P, Steinbuchel A (2005) Mechanism of lipid-body formation in prokaryotes: how bacteria fatten up. Mol Microbiol 55(3):750–763. doi:10.1111/j.1365-2958.2004.04441.x

Waltermann M, Steinbuchel A (2005) Neutral lipid bodies in prokaryotes: recent insights into structure, formation, and relationship to eukaryotic lipid depots. J Bacteriol 187(11):3607–3619. doi:10.1128/JB.187.11.3607-3619.2005

Wynn JP, Ratledge C (2005) Oils from Microorganisms. In: Shahidi F (ed) Bailey’s industrial oil and fat products, vol 6. Wiley, NewYork, pp 121–153

Acknowledgments

The authors thank Amanda Lawrence, Magan Green, Kamal Lamichhane Upadhyaya and Jacqueline Blake for their technical assistance. This research was funded by the United States Department of Energy, Office of Energy Efficiency and Renewable Energy (Grant No.: DE-FG36-06GO86025).

Conflict of interest

The authors declare that all experiments documented in this manuscript comply with the current laws of the USA. The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shields-Menard, S.A., Amirsadeghi, M., Sukhbaatar, B. et al. Lipid accumulation by Rhodococcus rhodochrous grown on glucose. J Ind Microbiol Biotechnol 42, 693–699 (2015). https://doi.org/10.1007/s10295-014-1564-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-014-1564-7