Abstract

Clostridium beijerinckii mutant strain IB4, which has a high level of inhibitor tolerance, was screened by low-energy ion implantation and used for butanol fermentation from a non-detoxified hemicellulosic hydrolysate of corn fiber treated with dilute sulfuric acid (SAHHC). Evaluation of toxicity showed C. beijerinckii IB4 had a higher level of tolerance than parent strain C. beijerinckii NCIMB 8052 for five out of six phenolic compounds tested (the exception was vanillin). Using glucose as carbon source, C. beijerinckii IB4 produced 9.1 g l−1 of butanol with an acetone/butanol/ethanol (ABE) yield of 0.41 g g−1. When non-detoxified SAHHC was used as carbon source, C. beijerinckii NCIMB 8052 grew well but ABE production was inhibited. By contrast, C. beijerinckii IB4 produced 9.5 g l−1 of ABE with a yield of 0.34 g g−1, including 2.2 g l−1 acetone, 6.8 g l−1 butanol, and 0.5 g l−1 ethanol. The remarkable fermentation and inhibitor tolerance of C. beijerinckii IB4 appears promising for ABE production from lignocellulosic materials.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Butanol is a four-carbon primary alcohol used as a chemical feedstock and as a renewable fuel. In such applications, butanol is preferable to ethanol, because it is less hygroscopic, less corrosive, less volatile, and has a higher energy density [2, 8]. The biological production of acetone/butanol/ethanol (ABE) has prompted a great deal of interest in the light of diminishing oil resources worldwide and unpredictable fluctuations in petroleum prices [2, 6]. However, ABE fermentation has major disadvantages, including the high cost of the substrates, low productivity, and high recovery costs. Using renewable biomass as substrate is an attractive proposition for introducing an economically competitive biological process [14].

Lignocellulosic materials are the most abundant renewable resource on the planet, and have great potential as substrates for fermentation [9]. Currently, however, no microorganism can produce butanol efficiently from lignocellulosic biomass [16], and a range of toxic compounds, including weak acids, furan derivatives, and phenolic compounds, are generated during the hydrolysis of lignocellulosic materials [4, 10, 15]. Parekh and Wayman [12] produced ABE by SO2-catalyzed prehydrolysis and enzyme-hydrolyzed corn stover using Clostridium acetobutylicum P262. Ezeji et al. [3] found that acetates, furfural, and hydroxymethylfurfural (HMF) are not inhibitory to growth and ABE production of Clostridium beijerinckii BA101; instead, higher solvents are produced when the medium contains a high concentration of acetate, whereas ferulic acid and syringaldehyde are potent inhibitors of ABE production by C. beijerinckii BA101. Qureshi et al. [16] used the C. beijerinckii BA101 strain to produce ABE from sulfuric acid-treated corn fiber hydrolysate (SACFH), which resulted in the production of 9.3 g l−1 ABE after detoxification by passage through a column of XAD-4 resin.

The low-energy ion implantation mutagenesis technique, first used in the breeding of rice seeds by Yu et al. [19], has many advantages, including a low damage rate, a higher mutation rate, and a wider spectrum of mutation compared to traditional mutation methods [5].

The objective of this study was to produce highly inhibitor-tolerant C. beijerinckii mutants that could produce butanol from non-detoxified hemicellulosic hydrolysate of corn fiber treated with dilute sulfuric acid (SAHHC) via low-energy ion implantation.

Materials and methods

Chemicals and gas

The phenolic compounds p-coumaric acid, ferulic acid, 4-hydroxybutyl acrylate (4-HBA), vanillic acid, syringaldehyde, and vanillin were purchased from Sigma Chemicals. Other chemicals were of reagent grade and were obtained from either Sinochem or Fluka Chemical. Corn steep liquor was from Anhui BBCA Biochemical Co. and N2 was from the Nanjing Special Gases Factory (Nanjing, P.R. China).

Preparation of hemicellulosic hydrolysate of corn fiber

Corn fiber with a moisture content of 5.6% (w/v) was obtained from Shandong Zhengde Foods Ltd., China. The corn fiber was ground with a commercial plant grinder and passed through 20- to 40-mesh screens before mixing with 2% (v/v) sulfuric acid at a ratio of 1:5 (w/v). The suspension was hydrolyzed in an autoclave at 121°C for 2.5 h. The raw hydrolysate was adjusted to pH 6.0 with solid Ca(OH)2 at 50°C and then filtered through filter paper to remove any solid material. After treatment at 121°C for 15 min, SAHHC contained 55.24 g l−1 reducing sugar and 2.77 g l−1 total soluble phenolic compounds (TPC) as shown in Table 1.

Active carbon was used for inhibitor removal, active carbon 2% (w/v) was added to the SAHHC and the mixture was heated at 50°C for 2 h, and then passed through filter paper to remove the active carbon.

Microorganism and culture conditions

C. beijerinckii NCIMB 8052 (purchased from the American Type Culture Collection (ATCC)) was cultivated at 35°C for 14 h in yeast extract/peptone/starch (YPS) medium (3.0 g yeast extract, 5.0 g peptone, 10.0 g soluble starch, 2.0 g ammonium acetate, 2.0 g NaCl, 3.0 g MgSO4·7H2O, 1.0 g KH2PO4, 1.0 g K2HPO4, 0.1 g FeSO4·7H2O, adjusted to pH 6.0 with 1 mol l−1 HCL) [7], purged with nitrogen gas to remove dissolved oxygen. This culture was used for mutation studies and transferred to the butanol production medium (10% (v/v) inoculation). The agar plates used for selection of mutants had YPS medium containing 250 ml l−1 SAHHC, 0.02 g l−1 resazurin, and 0.7 g l−1 TPC.

Low-energy ion beam implantation

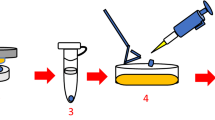

The implantation sources were produced by an ion beam implantation instrument (LZD-900 designed by the Chinese Southwestern Institute of Physics).

C. beijerinckii NCIMB 8052 cells grown in YPS medium were harvested in the exponential phase. The freshly cultured C. beijerinckii NCIMB 8052 cells were diluted in sterile physiologic saline solution to an optical density at 600 nm (OD600) of 0.1, and 100 μl of the suspension was spread on an empty sterile Petri dish (75 mm diameter) and desiccated by a stream of filtrated air to create a dry membrane of cells. The dishes were put into the sample holder and implanted with 10 keV of energy via a beam of N+ ions. The dose for implantation ranged from 0.4 × 1016 to 2.4 × 1016 ions cm−2.

Selection of mutants

After implantation of N+ ions, the C. beijerinckii NCIMB 8052 cells were washed from the plates with sterilized physiologic saline solution. The suspension was spread over six selective agar plates to isolate highly inhibitor-tolerant and high butanol-producing mutants. The highly inhibitor-tolerant and butanol-producing strains were screened for strong deoxidizing activity using resazurin (commonly used as a redox indicator). Colonies showing large haloes on the selective agar medium were selected.

Fermentation

Screw-cap bottles (100 ml) containing 60 ml of medium were used throughout these studies. In all experiments, medium was inoculated with a 10% (v/v) actively growing cell suspension, purged with nitrogen gas to remove dissolved oxygen, maintained at 35°C and incubated with no agitation or pH control for 72 h. Bottles containing 30 g l−1 glucose were sterilized by autoclaving at 121°C for 15 min followed by the addition of filter-sterilized P2 stock solutions: buffer solution, 50 g l−1 KH2PO4, 50 g l−1 K2HPO4, 220 g l−1 ammonium acetate; mineral solution, 20 g l−1 MgSO4·7H2O, 1 g l−1 MnSO4·H2O, 1 g l−1 FeSO4·7H2O, 1 g l−1 NaCl; vitamin solution, 100 g l−1 corn steep liquor [13]. Samples of 10 ml were collected for measurement of OD600 and analysis of ABE after fermentation for 72 h.

Batch fermentation was done in a 3-l fermentor (Bioflo 110, USA) with an initial broth volume of 2 l containing the hemicellulosic hydrolysate of corn fiber, sterilized in an autoclave (121°C for 15 min), then filter-sterilized P2 stock solutions were added, and nitrogen gas was bubbled through the medium to remove oxygen before and after inoculation; the temperature was maintained at 35°C and there was no agitation or pH control for 90 h. During the course of fermentation, 10-ml samples were collected regularly for measurement of OD600 and sugars and for analysis of ABE.

Analytical methods

Dry cell weight (DCW) was computed from a curve of OD600 versus dry weight; an OD600 of 1.0 represented 260 mg dry weight. TPC was estimated by a modification of Folin–Ciocalteu’s method using vanillic aldehyde and tannin as standards [17].

Glucose, xylose, and arabinose were analyzed by high-performance liquid chromatography (HPLC, Chromeleon server monitor, P680 pump, Dionex, USA). Glucose, xylose, and arabinose were measured with an RI101 refractive index detector (Shodex, USA) and an Aminex HPX-87H ion-exchange column (7.8 mm × 300 mm, BioRad, USA) with a mobile phase of 0.005 mol/l of H2SO4 at a flow rate of 0.6 ml/min at 55°C. The total reducing sugar concentration was measured by the 3,5-dinitrosalicyclic acid method.

Fermentation products (ABE, acetic acid, and butyric acid) were analyzed by gas chromatography (GC-2010, Shimadzu Scientific Instruments, Japan, equipped with a flame ionization detector and an InterCap WAX column (0.25 mm × 30 m, GL Sciences Inc., Japan)). Total ABE was the sum of acetone, butanol, and ethanol. The ABE yield is defined as the amount (expressed in grams per gram) of solvent produced from 1 g of total sugar.

Results and discussion

Mutant dose for C. beijerinckii NCIMB 8052

The ion source, e.g., N+, C2+, and Ti2+, can be varied depending on the specific purpose. In this study, N+ ions were chosen as the ion source and the energy was set to 10 keV. Figure 1 shows the effect of the dose of N+ ions beam irradiation on the survival rate of C. beijerinckii NCIMB 8052 cells. According to earlier reports [7, 18], the “saddle” region of the survival curve was the appropriate dose for further mutation and a dosage of 1.6 × 1016 ions cm−2 was chosen for this study.

Mutant screening

Strains producing high yields of butanol and ABE can be screened with resazurin for strong deoxidization activity [7]. The mutants were isolated after implantation of N+ ions (1.6 × 1016 ions cm−2) into C. beijerinckii NCIMB 8052 cells. Thirty colonies showing large transparent zones were selected for screw-cap bottle batch fermentation as described above. The butanol and ABE concentrations of all mutants were higher than those of the wild type (produced 7.1 g l−1 of butanol and 10.6 g l−1 of ABE). Figure 2 shows the butanol and ABE concentrations of the wild type and six mutants. C. beijerinckii IB4 and C. beijerinckii IB11 produced more than 9.0 g l−1 of butanol. C. beijerinckii IB4 was generated and inoculated into the fermentation medium to test its butanol-producing stability. During five generations of C. beijerinckii IB4, the average concentration of butanol was 9.1 g l−1 and that of total ABE was 12.4 g l−1, indicating that the butanol-producing ability was fairly stable following mutation. In addition, the final concentration of butanol and the yield of ABE produced by C. beijerinckii IB4 were increased by 27 and 17% compared to the wild type.

Toxicity evaluation of model compounds

A range of toxic compounds, mainly weak acids, furan derivatives, and phenolic compounds, are generated by hydrolysis of lignocellulosic material. Ezeji et al. [3] found that acetates, furfural, and HMF were not inhibitory to ABE production in C. beijerinckii BA101. By contrast, phenolic compounds were potent inhibitors of ABE production in C. beijerinckii BA101 and were chosen as inhibitors to investigate in this study. The effects of six model phenolic compounds on cell growth and butanol production with C. beijerinckii NCIMB 8052 and C. beijerinckii IB4 were tested by adding each of the compounds at 0.5 g l−1 into the fermentation medium.

As shown in Fig. 3, cell growth and butanol production were inhibited slightly by syringaldehyde, with values being similar to those of the control (free from toxic compounds). Except for syringaldehyde, the model compounds reduced cell growth by more than 76%, and a little butanol (less than 1.1 g l−1) was produced by C. beijerinckii NCIMB 8052.

Cell growth (a) and butanol concentration (b) of C. beijerinckii NCIMB 8052 and C. beijerinckii IB4. Cells were grown in screw-capped bottles in fermentation medium containing 30 g l−1 glucose and each of the phenolic compounds (0.5 g l−1). 8052, C. beijerinckii NCIMB 8052; IB4, C. beijerinckii IB4; 4-HBA, 4-hydroxybutyl acrylate; control, free from toxic compounds

C. beijerinckii IB4 was inhibited significantly by vanillin; DCW and butanol production were decreased by 70 and 75%, respectively. Syringaldehyde slightly inhibited growth and production of butanol by C. beijerinckii IB4. Ferulic acid, 4-HBA, vanillic acid, and p-coumaric acid reduced cell growth of C. beijerinckii IB4 by 10, 20, 30, and 35%, respectively, and reduced its butanol production by 14, 18, 25, and 17%, respectively. Although p-coumaric acid was very toxic to cell growth, the level of inhibition of butanol production was quite different. In summary, the test compounds (except vanillin) did not inhibit growth or production of ABE by C. beijerinckii IB4 significantly.

Ezeji et al. [3] reported that syringaldehyde (1.0 g l−1) had very little effect on C. beijerinckii BA101 growth, especially before solventogenic growth. However, syringaldehyde was a potent inhibitor of ABE production even at concentrations as low as 0.3 g l−1. Conversely, Cho et al. [1] found that the level of toxicity of syringaldehyde (1.0 g l−1) was very low, inhibiting cell growth and butanol production by 3 and 20%, respectively. In this study, 0.5 g l−1 syringaldehyde in the fermentation medium inhibited cell growth and butanol production by 0.5 and 2%, respectively. The results suggested that C. beijerinckii BA101, a mutant form of C. beijerinckii NCIMB 8052, had altered tolerance to syringaldehyde. The mode of inhibition of ABE production was explained by the fact that there was a twofold decrease in the expression of butanol dehydrogenase BDHII and a 7- to 11-fold increase in the stage V sporulation genes in C. beijerinckii during fermentation in the presence of syringaldehyde [3].

Little or no ABE was produced by C. beijerinckii BA101 or C. beijerinckii NCIMB 8052 during batch fermentation in the presence of ferulic acid [1, 3]. In this study, 2.14 g l−1 DCW and 7.8 g l−1 butanol were produced by C. beijerinckii IB4 in the presence of ferulic acid (0.5 g l−1), similar to values obtained in the control. On the basis of the literature and the results of this study, C. beijerinckii IB4 is a mutant strain with high tolerance to phenolic compounds.

ABE fermentation in SAHHC-based medium

During batch fermentation, only 28–33 g l−1 sugars (glucose, xylose, or glucose/xylose/arabinose) was utilized by C. beijerinckii NCIMB 8052 (data not shown). When the non-detoxified SAHHC was used as carbon source, the fermentation medium contained 30.3 g l−1 reducing sugar with a total concentration of xylose, glucose, and arabinose of 28.8 g l−1. Control batch fermentation was done with detoxified SAHHC (detoxified by active carbon, containing 0.3 g l−1 TPC) as carbon source. ABE productivity and yield of 0.14 g l−1 h−1 and 0.36 g g−1, respectively, were obtained with C. beijerinckii IB4 at 72 h (Table 2). The concentration of total ABE was 10.1 g l−1 (2.3 g l−1 acetone, 7.2 g l−1 butanol, and 0.6 g l−1 ethanol).

As shown in Fig. 4, the concentrations of residual sugars were changed slightly after 54-h fermentation with SAHHC as carbon source; 24.1 g l−1 xylose, 2.6 g l−1 glucose, and 0.9 g l−1 arabinose were consumed in 72 h (Fig. 4a). At the end of the fermentation, total ABE in the broth was 9.5 g l−1, including 2.2 g l−1 acetone, 6.8 g l−1 butanol, and 0.5 g l−1 ethanol (Fig. 4b).

Production of ABE from non-detoxified SAHHC in a batch reactor by C. beijerinckii IB4. Cells of C. beijerinckii IB4 were grown in non-detoxified SAHHC containing 30.3 g l−1 residual sugars for 90 h. Residual sugars in fermentation broth versus fermentation time (a). ABE production versus fermentation time (b)

ABE productivity of 0.13 g l−1 h−1 and ABE yield of 0.34 g g−1 were obtained in 72 h with C. beijerinckii IB4; these values are similar to those of the control and the values in the literature obtained using corn fiber residues (Table 2). Qureshi [16] used the BA101 strain to produce butanol from SACFH; however, cell growth and butanol production were inhibited, and 9.3 g l−1 ABE and an ABE yield of 0.39 g g−1 were achieved only after detoxification with XAD-4 resin.

Besides corn fiber, wheat straw and wheat bran have been used for ABE production. When sulfuric acid-treated wheat bran hydrolysate (SAWBH) was used as substrate, ABE fermentation resulted in the production of 11.8 g l−1 ABE and a yield of 0.32 g g−1 in 72 h using C. beijerinckii ATCC 55025; however, the concentrations of the inhibitors generated from SAWBH were not reported [11].

Generally, the inhibitors and their concentrations generated during pretreatment and hydrolysis differed between lignocellulosic materials. In this study, the fermentation medium contained 1.4 g l−1 TPC from SAHHC. As shown in Table 3, C. beijerinckii NCIMB 8052 could utilize the non-detoxified SAHHC to grow well, achieving a DCW of 2.01 g l−1, similar to that of C. beijerinckii IB4 (2.14 g l−1). However, solvent production was inhibited, producing only 1.63 g l−1 of butanol. Acetic acid and butyric acid accumulated to concentrations of 5.3 and 2.8 g l−1, respectively. In contrast, 9.5 g l−1 of total ABE and 6.8 g l−1 of butanol were produced by C. beijerinckii IB4, and the concentrations of acetic and butyric acids were both less than 0.7 g l−1. Butanol production by C. beijerinckii IB4 was decreased by 9% compared to the control.

ABE-producing Clostridia possess an acidogenic phase and a solventogenic phase in the metabolic pathways: acetic acid and butyric acid are produced in the acidogenic phase and re-assimilated in the solventogenic phase [6]. The results showed that the inhibitors from SAHHC acted selectively on ABE production by C. beijerinckii NCIMB 8052. Inhibitors from SAHHC are a mixture of chemicals, some of which are toxic to cell growth, whereas others are toxic to both growth and ABE production. The underlying mechanisms of inhibition are unclear. Studies of the mechanism of high inhibitor tolerance are underway in our laboratory.

The inhibitors affect cell growth and ABE production, which makes the detoxification of inhibitors difficult and increases production costs. Improving the inhibitor tolerance of microorganisms is a promising method for facilitating industrial-scale fermentation. The results presented here demonstrate that C. beijerinckii IB4 is a highly inhibitor-tolerant, butanol-producing strain, which can utilize non-detoxified SAHHC to produce butanol.

Conclusions

A highly inhibitor-tolerant, butanol-producing mutant strain C. beijerinckii IB4 has been obtained. When non-detoxified corn fiber hemicellulosic hydrolysate was used as substrate for butanol production, 9.5 g l−1 ABE and 6.8 g l−1 butanol were produced, with an ABE yield of 0.34 g g−1 in 72 h. C. beijerinckii IB4 offers the prospect of ABE production from lignocellulosic materials.

References

Cho DH, Lee YJ, Um Y, Sang BI, Kim YH (2009) Detoxification of model phenolic compounds in lignocellulosic hydrolysates with peroxidase for butanol production from Clostridium beijerinckii. Appl Microbiol Biotechnol 83:1035–1043

Dürre P (2007) Biobutanol: an attractive biofuel. Biotechnol J 2:1525–1534

Ezeji TC, Qureshi N, Blaschek HP (2007) Butanol production from agricultural residues: impact of degradation products on Clostridrium beijerinckii growth and butanol fermentation. Biotechnol Bioeng 97:1460–1469

Eva P, Bärbel HH (2000) Fermentation of lignocellulosic hydrolysates. I: inhibition and detoxification. Bioresour Technol 74:17–24

Feng HY, Yu ZL, Chu PK (2006) Ion implantation of organisms. Mater Sci Eng R 54:49–120

Jones DT, Woods DR (1986) Acetone-butanol fermentation revisited. Microbiol Rev 50:484–524

Jin XQ, Zhou H, Wu X, Zhang G, He BF (2008) A rapid screening method of producing strain in acetone-butanol fermentation. Chin J Process Eng 8:1185–1189

Kirschner M (2006) n-Butanol, Chemical Market Reporter, 30 Jan–5 Feb, ABI/INFORM Global, p 42

Koukiekolo R, Cho HY, Kosugi A, Inui M, Yukawa H, Doi RY (2005) Degradation of corn fiber by Clostridium cellulovorans cellulases and hemicellulases and contribution of scaffolding protein CbpA. Appl Environ Microbiol 71:3504–3511

Larsson S, Palmqvist E, Bärbel HH, Tengborg C, Stenberg K, Zacchi G, Nilvebrant NO (1999) The generation of fermentation inhibitors during dilute acid hydrolysis of softwood. Enzyme Microbiol Technol 24:151–159

Liu ZY, Ying Y, Li FL, Ma CQ, Xu P (2010) Butanol production by Clostridium beijerinckii ATCC 55025 from wheat bran. J Ind Microbiol Biotechnol 37:495–501

Parekh SR, Wayman M (1988) Ethanol and butanol production by fermentation of enzymatically saccharified SO2-prehydrolysed lignocellulosics. Enzyme Microbiol Technol 10:660–668

Qureshi N, Blaschek HP (1999) Butanol recovery from model solution/fermentation broth by pervaporation: evaluation of membrane performance. Biomass Bioenergy 17:175–184

Qureshi N, Blaschek HP (2000) Economics of butanol fermentation using hyper-butanol producing Clostridium beijerinckii BA101. Food Bioprod Process 78:139–144

Qureshi N, Saha BC, Cotta MA (2007) Butanol production from wheat straw hydrolysate using Clostridium beijerinckii. Bioprocess Biosyst Eng 30:419–427

Qureshi N, Ezeji TC, Ebener J, Dien BS, Cotta MA, Blaschek HP (2008) Butanol production by Clostridium beijerinckii part I: use of acid and enzyme hydrolyzed corn fiber. Bioresour Technol 99:5915–5922

Singleton VL, Orthofer R, Lamuela-Ravento′s RM (1999) Analysis of total phenols and other oxidation substrates and antioxidants by means of Folin-Ciocalteu reagent. Methods Enzymol 299:152–178

Xu TT, Bai ZZ, Wang L, He BF (2010) Breeding of d(−)-lactic acid high producing strain by low-energy ion implantation and preliminary analysis of related metabolism. Appl Biochem Biotechnol 160:314–321

Yu ZL, Deng JG, He JJ, Huo YP, Wu YJ, Wang XD, Lui GF (1991) Mutation breeding by ion implantation. Nucl Instrum Methods Phys Res Sect B 59:705–708

Acknowledgments

This work was supported by the “973” program of China (grant no. 2011CB707405), the public benefit research foundation of CAF (201004001), the State Key Laboratory of Materials-Oriented Chemical Engineering Foundation of Nanjing University of Technology (ZK201001), a project funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions, the “Qinglan project” of Jiangsu Province, and “The six talent summit” of Jiangsu Province (grant no. 06-A-047).

Author information

Authors and Affiliations

Corresponding author

Additional information

Ting Guo and Yan Tang contributed equally to this work.

Rights and permissions

About this article

Cite this article

Guo, T., Tang, Y., Zhang, Qy. et al. Clostridium beijerinckii mutant with high inhibitor tolerance obtained by low-energy ion implantation. J Ind Microbiol Biotechnol 39, 401–407 (2012). https://doi.org/10.1007/s10295-011-1017-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-011-1017-5