Abstract

The possibility to utilize fiber sludge, waste fibers from pulp mills and lignocellulose-based biorefineries, for combined production of liquid biofuel and biocatalysts was investigated. Without pretreatment, fiber sludge was hydrolyzed enzymatically to monosaccharides, mainly glucose and xylose. In the first of two sequential fermentation steps, the fiber sludge hydrolysate was fermented to cellulosic ethanol with the yeast Saccharomyces cerevisiae. Although the final ethanol yields were similar, the ethanol productivity after 9.5 h was 3.3 g/l/h for the fiber sludge hydrolysate compared with only 2.2 g/l/h for a reference fermentation with similar sugar content. In the second fermentation step, the spent fiber sludge hydrolysate (the stillage obtained after distillation) was used as growth medium for recombinant Aspergillus niger expressing the xylanase-encoding Trichoderma reesei (Hypocrea jecorina) xyn2 gene. The xylanase activity obtained with the spent fiber sludge hydrolysate (8,500 nkat/ml) was higher than that obtained in a standard medium with similar monosaccharide content (1,400 nkat/ml). Analyses based on deglycosylation with N-glycosidase F suggest that the main part of the recombinant xylanase was unglycosylated and had molecular mass of 20.7 kDa, while a minor part had N-linked glycosylation and molecular mass of 23.6 kDa. Chemical analyses of the growth medium showed that important carbon sources in the spent fiber sludge hydrolysate included xylose, small aliphatic acids, and oligosaccharides. The results show the potential of converting waste fiber sludge to liquid biofuel and enzymes as coproducts in lignocellulose-based biorefineries.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Fiber sludge is a waste material generated by pulp mills and lignocellulose-based biorefineries [17, 23]. The composition of fiber sludges varies from mill to mill, but cellulose and hemicellulose are important constituents. In Sweden, waste fiber sludge was commonly landfilled, but due to prohibition of landfill of organic waste it is nowadays mostly burned. This is, however, not the ideal solution due to the low energy efficiency caused by the high moisture content of fiber sludges. From a biorefinery perspective [14], it would be economically and environmentally beneficial to utilize fiber sludge for production of commodities such as liquid biofuels, chemicals or materials. High carbohydrate and low lignin contents contribute to making fiber sludge a feasible feedstock for liquid biofuel production in lignocellulose-based biorefineries [17]. However, it would be of particular interest to at least partially convert fiber sludge waste into high-value-added products.

In this study, we explore the possibility to utilize fiber sludge for coproduction of biofuels and enzymes, exemplified by cellulosic ethanol and xylanase. This approach offers a possibility to combine production of a low-value-added product (liquid biofuel) with production of a high-value-added product (an enzyme) in a biorefinery, which could also tentatively utilize the produced enzyme, or a part of it, for internal processes.

In recent years, xylanases have attracted attention for several potential industrial applications, such as biobleaching of kraft pulp, production of food and feed, and textile manufacturing [13, 16]. The genus Trichoderma is well known for efficient production of hydrolytic enzymes such as cellulases and hemicellulases [11]. Trichoderma reesei (Hypocrea jecorina) may serve as a production organism for xylan-degrading enzymes, such as the endo-xylanase encoded by the xyn2 gene. However, the enzyme production is dependent on gene induction, and the fungus has a tendency to produce an array of different enzymes when cultivated. Fungi of the Aspergillus genus are known for their high secretion capacity and their ability to produce high concentrations of heterologous proteins, in the range of grams per liter [21]. Furthermore, some Aspergillus species, among them A. niger, displays the ability to grow oligotrophically [12, 22], i.e., in nutrient-poor environments. This ability could potentially make A. niger suitable for production of enzymes from industrial residual streams where the conditions are far from ideal for growth of many other microorganisms. Therefore, we have investigated utilization of spent fiber sludge for production of xylanase by recombinant A. niger harboring the xyn2 gene of T. reesei.

Materials and methods

Raw material

Waste fiber sludge was collected from a Swedish kraft pulp mill. The fiber sludge has previously been characterized in a study by Sjöde et al. [17]. The fiber sludge was dried according to the description in the previously mentioned study. The main components of the fiber sludge were glucan and xylan (66% and 17%, respectively). The lignin content, which varies considerably in different fiber sludges, was low, namely 1.2% [17].

Enzymatic hydrolysis

The fiber sludge was enzymatically hydrolyzed without any prior thermochemical pretreatment. Air-dried fiber sludge (39.5 g) was mixed with 201.9 ml citrate buffer (0.05 M, pH 5.0) in four separate 750-ml shake flasks. The dry matter content was 15%, and the total content per shake flask was 250 g. The enzyme preparations used for hydrolysis were Celluclast 1.5 and Novozyme 188 (Novozymes, Bagsvaerd, Denmark). Each of the enzyme preparations was added to final concentration of 2% (w/w). The flasks were incubated with orbital shaking (Infors Ecotron, Infors AG, Bottmingen, Switzerland) at 45°C and 200 rpm for 48 h. The glucose level was monitored during hydrolysis using a glucometer (Glucometer Elite XL; Bayer Healthcare, Leverkusen, Germany). After hydrolysis, the slurries were centrifuged (Z 206A; Hermle, Wehingen, Germany) at 5,000 rpm (2,600 g) for 5 min to recover the liquid fraction, hereafter referred to as fiber sludge hydrolysate (FSH). The FSH was stored at −20°C until further use.

Fermentation with Saccharomyces cerevisiae

Prior to fermentation, the pH of the FSH was adjusted to 5.5 using NaOH (5 M) and the solution filtered through a 0.22-μm filter (VWR vacuum filtration system; VWR International, West Chester, PA, USA). Fermentation experiments were carried out with a Sixfors multibioreactor system (Infors AG) equipped with four fermenters. Two vessels were filled with 285 ml FSH and two with 285 ml synthetic sugar solution (84 g/l glucose and 15 g/l xylose). Each vessel was supplemented with 6 ml nutrient solution [150 g/l yeast extract, 75 g/l (NH4)2HPO4, 3.75 g/l MgSO4·7H2O, 23.4 g/l NaH2PO4·2H2O] and three drops of antifoam. Inoculum cultures were grown in 750-ml shake flasks containing YEPD medium (2% yeast extract, 1% peptone, 2% d-glucose). The cells were harvested in the late exponential growth phase by centrifugation (1,500 g, 5 min, 4°C) and resuspended in sterile water. Prior to inoculation the fermentation medium was flushed with nitrogen gas to obtain anaerobic growth conditions. Each fermenter was inoculated with 9 ml suspended yeast cells (Jästbolaget AB, Rotebro, Sweden) to final concentration of 2 g/l (dry weight, DW). The strain of Saccharomyces cerevisiae used in this experiment was common baker’s yeast, which is unable to ferment xylose or arabinose, pentose sugars that are typically present in lignocellulose hydrolysates. The fermentation was conducted at 30°C with stirring (300 rpm). The pH was automatically kept at 5.5 using 1 M NaOH. After suitable dilution of the sample, optical density (OD) was measured spectrophotometrically at 620 nm (Gensis 20; Thermo Scientific, Waltham, MA, USA), and glucose levels during the course of the fermentation were monitored by using the glucometer.

Distillation

After fermentation, the yeast was removed from the fermented hydrolysates by centrifugation (Z 206A, Hermle) at 2,400 rpm (610 g) for 5 min. Prior to distillation, the pH of the fermented hydrolysate was adjusted to 7.0 using 5 M NaOH to reduce the risk of sugar degradation during the distillation. Distillation was performed using standard distillation glassware. A magnetically stirred polyethylene glycol heating bath was used as heating source. The FSH was transferred to 250-ml round-bottom flasks, and three drops of antifoam were added to prevent excessive bubble formation during the distillation. The distillation was performed until all ethanol was recovered. The remaining fractions that were left in the round-bottom flasks after distillation, hereafter called spent fiber sludge hydrolysate (SFSH), were filtered through 0.22-μm filters and stored at −20°C until further use.

Aspergillus niger transformants

A recombinant Aspergillus niger D15 transformant expressing the Hypocrea jecorina xylanase II (xyn2) gene was used for xylanase production (hereafter referred to as A. niger D15[xyn2]). The xyn2 gene was cloned under transcriptional control of the constitutive glyceraldehyde-6-phosphate dehydrogenase (gpd) promoter from A. niger and the glaA terminator from Aspergillus awamori [15]. An A. niger D15 transformant carrying the expression cassette with the above-mentioned promoter and terminator but without the xyn2 gene was used as a reference strain (hereafter referred to as A. niger D15[pGT]). The construction of the two transformants has been described by Rose and van Zyl [15].

Fermentation experiments with A. niger cultivated on spent fiber sludge hydrolysate

Ten 100-ml Erlenmeyer flasks (not baffled), labeled 1–10, were used in the experiments. In these experiments, two nutrient supplements containing different concentrations of nitrogen source were added to the SFSH. This was performed to investigate the effect of the nitrogen source on growth and xylanase production. Flasks 1–6 contained the same amount of SFSH but were supplemented with different nutrients. Flasks 1 and 2 were filled with 48 ml SFSH, 1 ml nutrient supplement A [consisting of 25 g/l (NH4)2HPO4, 1.25 g/l MgSO4·7H2O, 69 g/l NaH2PO4·H2O, and 50 g/l yeast extract], and 0.05 ml of the same trace-element solution as in [1] [0.22 g/l ZnSO4·7H2O, 0.11 g/l H3BO3, 0.05 g/l MnCl2·4H2O, 0.05 g/l FeSO4·7H2O, 0.017 g/l CoCl2·6H2O, 0.016 g/l CuSO4·5H2O, 0.015 g/l Na2MoO4·2H2O, and 0.5 g/l ethylenediamine tetraacetic acid (EDTA)]. Flasks 3–6 were filled with 48 ml SFSH supplemented with nutrient supplement B [giving the following final concentrations in the culture medium: 5 g/l yeast extract, 0.4 g/l MgSO4·7H2O, 2 g/l casamino acids, and 1 × AspA with nitrate (50 × AspA with nitrate: 300 g/l NaNO3, 26 g/l KCl, and 76 g/l KH2PO4)], and 0.05 ml of the trace-element solution. Flasks 7–10 contained 48 ml of a standard growth medium with the same xylose content as that of SFSH (9 g/l), nutrient supplement B, and 0.05 ml of the trace-element solution. The pH of all media used in the experiments was adjusted to 6.5 prior to fermentation by using 1 M HCl. The final volume in flasks 1–10 was adjusted to 50 ml with sterilized deionized water. For preparation of inoculum, spores of A. niger D15[pGT] and A. niger D15[xyn2] were spread on separate spore plates (0.2% neopeptone, 0.1% yeast extract, 0.2% casamino acids, 0.04% MgSO4·7H2O, 10 g/l glucose, and 1.8% agar) and incubated at 30°C for 72 h. The spores were resuspended in NaCl solution (9 g/l) and counted manually using a microscope (Olympus CX31, Olympus, Tokyo, Japan) and a counting chamber (Bürker, Marienfeld, Lauda-Königshofen, Germany). All flasks were inoculated at final concentration of 1 × 106 spores/ml medium. Flasks 1–4 and 7–8 were inoculated with A. niger D15[xyn2], while flasks 5–6 and 9–10 were inoculated with A. niger D15[pGT]. All flasks were sealed with cotton plugs, but no further measures were taken to facilitate aeration. The flasks were incubated for 12 days at 30°C and 120 rpm in an orbital shaker (Infors Ecotron). The xylanase activity was measured every day during the fermentation experiment.

Biomass measurement

Determination of biomass after fermentation with S. cerevisiae was performed using 0.45-μm membrane filters (Millipore, Bedford, MA, USA). The membranes were dried in an oven at 105°C for 24 h and were subsequently placed in a desiccator for 1 h. The samples were filtered with suction through the filters and dried in an oven for 24 h at 70°C before weighing. The DW of the A. niger was measured after filtration through circular pieces of Miracloth (Calbiochem, EMD Biosciences, La Jolla, CA, USA) with approximate diameter 90 mm. The Miracloth was dried in an oven at 80°C for 24 h prior to drying in a desiccator for 1 h. The Miracloth pieces were weighed on an analytical scale prior to use. After 12 days of fermentation, the volumes of all the A. niger cultures from the fermentation experiments were measured, and the cultures were then filtered with suction through the predried Miracloth. The Miracloth pieces with biomass were then washed with 50 ml deionized water and dried at 80°C for 72 h before weighing.

Enzyme activity

Xylanase activity was measured using a reducing sugar assay based on dinitrosalicylic acid (DNS) [2] and 1% birchwood xylan (Sigma-Aldrich, Steinheim, Germany) diluted in 0.05 M citrate buffer (pH 5.5). The assays were carried out in 15-ml glass tubes, which were incubated in a water bath at 55°C. The enzymatic activities are given in nkat/ml.

SDS–PAGE

Determinations of the size and the concentration of the recombinant protein were based on samples from three separate fermentation experiments. Samples from day 11 were chosen for the measurements, since these samples displayed high xylanase activity as well as low standard deviation. The samples were diluted sixfold with deionized water prior to separation by 10% sodium dodecyl sulfate polyacrylamide gel electrophoresis (SDS–PAGE). After electrophoresis, the gels were stained with Sypro Red (Molecular Probes, Eugene, OR, USA) according to the procedure described by Steinberg et al. [19]. The subsequent analyses of the gels were performed by using a laser-excited gel scanner equipped with a 610 nm emission filter (Typhoon 9400; GE Healthcare, Uppsala, Sweden). The concentration of recombinant xylanase was determined by running a concentration gradient of trypsin inhibitor from soybean (Glycine max; Sigma–Aldrich) as standard protein on the same SDS–PAGE gels as were used for analysis of fermentation supernatants. Protein concentrations were determined by intensity comparison of the Sypro Red-stained gels using ImageJ software [5]. The protein concentrations were calculated as the mean value of four replicate measurements (i.e., four separate gels).

Enzymatic deglycosylation

Enzymatic deglycosylation was performed to establish the degree of glycosylation during the heterologous expression of the xylanase protein. N-glycosidase F (Roche, Mannheim, Germany) was used for treatment of the xylanase protein. A supernatant from one of the fermentation experiments with A. niger D15[xyn2] in SFSH was concentrated using a centrifugal filter device (0.5 ml, cutoff 5 kDa) (Millipore). The sample was then split into two samples. Both samples were denaturized using a solution of 20 mM sodium phosphate buffer (pH 8.6), 1% SDS, and 1% β-mercaptoethanol. One of the samples was subsequently deglycosylated in a solution consisting of 25 mM sodium phosphate buffer (pH 7.2), 0.25% SDS, 1% β-mercaptoethanol, 1% Nonidet P-40, 0.5% EDTA, and 5 U N-glycosidase F. For comparison, the other sample was treated in the same manner except that the N-glycosidase F was substituted for deionized water. The samples were incubated at 37°C overnight (approximately 13 h), and the samples were then analyzed by SDS–PAGE.

Protein identification

Identification and verification of the proteins separated by SDS–PAGE were carried out using two-dimensional mass spectrometry [matrix-assisted laser desorption/ionization (MALDI) time-of-flight (TOF)/TOF and MALDI tandem mass spectrometry (MS/MS)]. The analysis was performed using two different samples exhibiting different molecular masses based on the SDS–PAGE analysis. Both these samples originated in supernatants from a single fermentation experiment with the A. niger D15[xyn2] transformant in which the fungus was grown on SFSH. The SDS–PAGE gels were stained with Coomassie Brilliant Blue R-250 prior to excision of the putative xylanase bands from the gels. The samples were submitted to Alphalyse A/S (Odense, Denmark) for protein identification by peptide mass fingerprinting and for sequence analysis. For peptide mass fingerprinting, the protein samples were treated with iodoacetamide, digested with trypsin, and analyzed using MALDI-TOF. Two-dimensional mass spectrometry, MALDI-TOF/TOF, was used to perform peptide sequencing of the samples. The MS and MS/MS spectra were combined and used for database searching using Mascot software (Matrix Science Ltd., London, UK).

Chemical analyses

Analyses of monosaccharides were performed by MoRe Research (Örnsköldsvik, Sweden) using an ion-exchange chromatography system (IC) equipped with a CarboPac PA1 column and an ED40 Electrochemical Detector (Dionex, Sunnyvale, CA, USA).

Analysis of the oligosaccharide content in the SFSH was performed by using dilute sulfuric acid hydrolysis (2.5% sulfuric acid, 60 min at 120°C). Detection of released monosaccharides was performed using IC-PAD (MoRe Research). To confirm the results, an enzymatic hydrolysis of the same sample was performed. The analysis was performed using a mixture of four different enzyme preparations: Celluclast 1.5 and Novozyme 188 from Novozymes together with Ecopulp TX200C and Ecostone HPL1800 from AB Enzymes (Darmstadt, Germany). The sample was incubated at 40°C for 40 h, and the released monosaccharides were detected using IC-PAD.

Samples for analysis of organic acids were performed by MoRe Research using an Ultimate 3000 HPLC system (Dionex) equipped with an Aminex HPX-87H (Bio-Rad Laboratories, Hercules, CA, USA). Total organic carbon (TOC) analysis was also performed by MoRe Research.

Ethanol measurements were performed by using high-performance liquid chromatography (HPLC). A Shodex SH-1011 column (6 μm, 8 × 300 mm) (Showa Denko, Kawasaki, Japan) was used in a YoungLin YL9100 series system (YoungLin, Anyang, Korea) equipped with a YL9170 series refractive index (RI) detector. Elution was performed with isocratic flow of a 0.01 M aqueous solution of H2SO4.

Results

The fiber sludge had an average dry-weight content of approximately 95%. Analysis of the fiber sludge hydrolysate (Table 1) showed that it contained 84 g/l glucose, 15 g/l xylose, and 3 g/l mannose. Glucose consumption in the fermenters containing fiber sludge hydrolysate was significantly faster than in the fermenters containing reference medium (Fig. 1). The growth rate was also higher in the fiber sludge hydrolysate (Fig. 1). The fermentation with S. cerevisiae resulted in a final concentration of 30.9 g/l ethanol for the fiber sludge hydrolysate and 31.6 g/l for the reference medium (Fig. 2). After 9.5 h of fermentation, the ethanol productivity was 3.3 g/l/h for the fiber sludge hydrolysate compared with 2.2 g/l/h for the reference fermentation. After distillation, in which the ethanol was recovered, the monosaccharide content of the spent fiber sludge hydrolysate (SFSH) was 0.2 g/l glucose and 8.8 g/l xylose (Table 1). Analysis of organic acids after distillation showed that the SFSH contained 5 g/l acetic acid, 0.1 g/l formic acid, and <0.1 g/l levulinic acid. Lactic acid (6 g/l) was also detected. 5-Hydroxymethylfurfural (HMF) and furfural were not detected.

Glucose consumption (filled diamonds; filled squares) and OD at 620 nm (filled triangles; cross symbols) for S. cerevisiae during fermentation of the waste fiber sludge hydrolysate (gray lines) and the reference fermentation (black lines). Every data point is calculated as the mean value of two fermentations. The error bars indicate standard deviations

Fermentation with A. niger transformants in SFSH medium resulted in a high density of fungal pellets, and no signs of inhibition of the growth of the fungus were noticed. The organic acids were consumed within 12 days (Table 1). The TOC analysis indicate that roughly half of the organic carbon in the SFSH medium was consumed by A. niger (Table 1). The fermentation with A. niger D15[xyn2] in SFSH resulted in increasing xylanase activity for 12 days, and the highest activity was measured for the cultures with medium containing nutrient supplement B, which reached volumetric activity of 8,500 nkat/ml (Fig. 3). The fermentation experiment was terminated on day 12 due to indications of decreasing activity in one of the A. niger D15[xyn2] cultures. This also resulted in a larger standard deviation on day 12 (Fig. 3). Consequently, samples from day 11 were used for the activity calculations presented in Table 2. The highest activity achieved on day 11 was 8,300 nkat/ml for the A. niger D15[xyn2] transformant grown on SFSH with nutrient supplement B (Fig. 3) (Table 2). Fermentation with the same transformant in standard medium resulted in a xylanase activity of 1,300 nkat/ml on day 11 (Fig. 3) (Table 2). In the fermentations with standard medium, a maximum activity of 1,400 nkat/ml was reached on day 3, after which the activity did not increase any further throughout the fermentation (Fig. 3). A. niger D15[pGT] did not produce any detectable xylanase activity in either of the fermentations regardless of the growth medium used.

Xylanase activity for A. niger transformants growing on spent fiber sludge hydrolysate (SFSH) or standard medium (SM). Mean values of samples from two separate cultures are shown. The data indicate: filled squares A. niger D15[xyn2] and SFSH with nutrient supplement B; filled diamonds A. niger D15[xyn2] and SFSH with nutrient supplement A; filled triangles A. niger D15[xyn2] and SM with nutrient supplement B; filled circles A. niger D15[pGT] and SFSH with nutrient supplement B; cross symbols A. niger D15[pGT] and SM with nutrient supplement B. Error bars indicate standard deviations

The volumetric activity, xylanase protein concentration, specific xylanase activity, and biomass production in fermentation experiments with A. niger D15[xyn2] and A. niger D15[pGT] are presented in Table 2. With regard to biomass production, A. niger D15[pGT] grown on SFSH reached the highest biomass concentration, 13.7 g/l (DW), whereas A. niger D15[xyn2] grown on SFSH reached a biomass concentration of 10.3–12.9 g/l (DW). When standard medium was used as growth medium, both transformants reached biomass concentration of about 4–5 g/l (DW). The highest Xyn2 protein concentration was noted in the fermentation experiment where A. niger D15[xyn2] was grown on SFSH with nutrient supplement B. This fermentation gave a Xyn2 protein concentration of 0.72 mg/ml after 11 days of fermentation. The fermentation in which A. niger D15[xyn2] was grown on SFSH with nutrient supplement A reached a protein concentration of 0.52 mg/ml. The highest specific activity, 13,100 nkat/mg, was reached in the fermentations with A. niger D15[xyn2] grown on SFSH with nutrient supplement A. A comparable specific activity, 11,500 nkat/mg, was reached in the fermentations with A. niger D15[xyn2] grown on SFSH with nutrient supplement B (Table 2). The specific activity for the xylanase from the reference fermentations were also rather similar and reached a specific activity of 10,000 nkat/mg. However, the xylanase concentrations in samples from cultures where A. niger D15[xyn2] was grown on SFSH were four to five times higher than in samples from cultures where the same transformant was grown on standard medium.

Analysis with SDS–PAGE indicated that the Xyn2 protein was present in the supernatants of fermentation experiments performed with A. niger D15[xyn2]. The Xyn2 protein from A. niger D15[xyn2] grown on SFSH and standard medium had molecular mass of about 20.7 kDa (Fig. 4). This compares well with the theoretical molecular mass of the native xylanase from T. reesei, which has molecular mass of 20.8 kDa [9]. However, the SDS–PAGE analysis also revealed the presence of a protein with molecular mass of approximately 23.6 kDa (Fig. 4), which was not present in samples from the reference transformant A. niger D15[pGT]. This suggested that a fraction of the recombinant xylanase was glycosylated during heterologous expression in A. niger. Treatment of the xylanase with N-glycosidase F indeed resulted in almost complete deglycosylation and rendered a protein with molecular mass of 20.7 kDa (Fig. 5).

SDS-PAGE of extracellular protein species in samples from A. niger cultures. The lanes show: (1) molecular size markers; (2) sample from A. niger D15[xyn2] grown in SFSH with nutrient supplement B; (3) sample from A. niger D15[xyn2] grown in SFSH with nutrient supplement A; (4) sample from A. niger D15[pGT] grown in SFSH with nutrient supplement B; (5) sample from A. niger D15[xyn2] grown in SM with nutrient supplement B; (6) sample from A. niger D15[pGT] grown in SM with nutrient supplement B

Protein concentrations and specific activities reported in Table 2 are based on the combined protein concentrations of the 20.7- and 23.6-kDa species, as determined with Sypro Red-based analysis of samples analyzed with SDS–PAGE. The concentration of glycosylated xylanase was estimated to be about 30% of the concentration of the unglycosylated form.

Identification of the two protein species (Fig. 5) with molecular masses of 20.7 and 23.6 kDa was performed using mass spectrometry. Protein samples were taken from the cultivations on SFSH and standard medium. The results of the MALDI-TOF peptide mass fingerprinting and MS/MS sequencing of the two proteins that displayed different molecular mass (i.e., 20.7 and 23.6 kDa) showed that both were identified as endo-1,4-β-beta-xylanase from T. reesei (i.e., the xylanase II protein). The analysis of the protein sample from the cultivation on SFSH resulted in sequence coverage of 47% and a Mascot score of 390. The analysis of the protein sample from the cultivation on standard medium resulted in a sequence coverage of 43% and a Mascot score of 289.

Discussion

Our results indicate that it is feasible to combine production of liquid biofuel from waste fiber sludge with production of enzymes from the stillage left after fermentation. The possibility to utilize fiber sludge as a resource for production of cellulosic ethanol has been explored previously. Lark et al. [10] investigated conversion of recycled paper sludge to ethanol using simultaneous saccharification and fermentation (SSF) with the yeast Kluyveromyces marxianus. Jeffries and Schartman [6] used separate hydrolysis and fermentation (SHF) for studies on enzymatic hydrolysis followed by fermentation with four different species of yeasts. Fan et al. [3] developed a solids-fed bioreactor for conversion of fiber sludge using SSF. Kádár et al. [7] studied conversion of various industrial waste materials, including paper sludge, by SSF. Sjöde et al. [17] analyzed three different fiber sludge samples, including their heat values, before and after enzymatic hydrolysis prior to fermentation with S. cerevisiae.

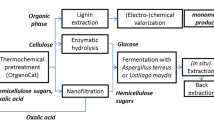

Alriksson et al. [1] recently showed the potential in performing sequential fermentations in which the first step is based on consumption of hexoses by S. cerevisiae and the second step is based on consumption of pentoses, acids, and other organic substances remaining in the stillage after distillation. The second fermentation step was performed with the metabolically diverse fungus A. niger, which is able to utilize many substances that are rejected as carbon sources by S. cerevisiae. Differences between the present study and that of Alriksson et al. [1] include that the latter was focused on fresh lignocellulose rather than fiber sludge and that the hydrolysate was produced by thermochemical pretreatment, which in part generates other degradation products than a process based solely on enzymatic hydrolysis, which serves as the basis of this work. Advantages with the approach of sequential fermentation include optimal utilization of carbon sources by reserving hexoses, such as glucose and mannose, for S. cerevisiae and exploitation of the ability of A. niger to utilize diverse carbon sources for growth and enzyme production. Furthermore, potential problems with glucose catabolite repression in the second fermentation step may be circumvented.

The fermentation with S. cerevisiae in the FSH medium resulted in higher consumption rate of glucose and higher production rate of ethanol than in the reference medium with similar monosaccharide content. The difference may be due to higher content of nutrients in the fiber sludge hydrolysate than in the reference medium. For instance, S. cerevisiae utilizes mannose, which was present in the FSH but not in the synthetic medium. Furthermore, raw material analysis of the fiber sludge [17] showed 1.0% ash, which is generated from minerals that may serve as nutrients. In addition, 13.4% of the content could not be accounted for [17], and that part of the fiber sludge may possibly also have generated nutrients that were not present in the reference medium. The indication that the fiber sludge hydrolysate had high nutrient content is further supported by the higher biomass production with A. niger grown on SFSH compared with when the same transformant was grown on a standard reference medium. The concentrations of monosaccharides prior to fermentation were similar in both SFSH and reference medium, but the organic acids and a large part of the oligosaccharides were also consumed by the fungus and may explain the difference. The presence of oligomeric xylan fragments in fiber sludges subjected to enzymatic hydrolysis was observed by Sjöde et al. [17] through MALDI-TOF analysis. This work shows that the main part of the oligosaccharides that were present in the hydrolysate served as a substrate for A. niger.

SFSH resulted in higher xylanase activity than when recombinant A. niger was grown in standard medium, a difference which could be attributed to better growth in SFSH. The presence in SFSH of substances that might induce native xylanase genes of A. niger is not a plausible explanation for the high xylanase activity due to the lack of xylanase activity displayed by the reference transformant A. niger D15[pGT] cultivated in the same medium. It is, however, possible that the expression of native A. niger enzymes is important for allowing the fungus to utilize nutrients such as oligosaccharides, which were not utilized by S. cerevisiae.

The protein concentrations and specific activities reported in our study are based on the concentrations determined by Sypro Red-based analysis of specific protein species on gels rather than on commonly used methods for determination of total protein content, such as assays based on bicinchoninic acid or dyes such as Coomassie Brilliant Blue G-250. There are several advantages with the gel-based assay: (1) peptides and proteins derived from medium components or from the first fermentation step (with S. cerevisiae) would contribute to protein concentrations determined with standard methods, but do not contribute to the concentrations determined with the gel-based assay, and (2) by restricting the assay to specific protein species, other proteins secreted by A. niger are not included in the determination.

It is known that heterologous expression of T. reesei proteins in Aspergillus may result in proteins with lower activity than those of the native host, possibly due to different glycosylation patterns of the two organisms [20]. SDS–PAGE analysis of the fermentation samples indicated that the major portion of the recombinant enzyme was similar to the native T. reesei xylanase II and represented the unglycosylated form, which is expected to be 20.8 kDa as judged from the amino acid sequence of the protein. Deglycosylation with N-glycosidase F resulted in a protein with the same size as the unglycosylated form, which suggests that the larger size (~14%) displayed by the 23.6 kDa form was due to N-linked glycosylation. The reason why only a fraction of the recombinant xylanase was glycosylated during heterologous expression in A. niger may possibly be that the level of expression of the recombinant xylanase exceeds the glycosylation capacity of the host organism. Furthermore, Stals et al. [18] reported that variable glycosylation can also be due to medium composition.

Organisms that previously have been used as hosts for production of recombinant xylanase include S. cerevisiae [8], Pichia pastoris [4], and A. niger [15]. The highest activity reached in our study, 8,500 nkat/ml, is about 6 times higher than obtained with S. cerevisiae and about 2 times higher than obtained with P. pastoris. Rose and van Zyl [15] used the same A. niger transformant as in the present study to produce xylanase and obtained similar results (8,000 nkat/ml) when it was cultivated in a nutrient-rich glucose-based medium and a lower value (5,000 nkat/ml) with a growth medium based on molasses. Thus, our results show that similar levels can be achieved with medium based mainly on hemicellulose degradation products that were discarded by S. cerevisiae. The xylanase level reported in this study (8,500 nkat/ml) is about 1.5 times higher than what was achieved with native T. reesei (5,400 nkat/ml) [2]. When taking all the data into account, the comparisons indicate that spent fiber sludge hydrolysate serves as an excellent growth medium for enzyme production with recombinant A. niger.

In conclusion, the results of this study show that fiber sludge is well suited for combined production of liquid biofuel and enzyme production. The ability of A. niger to grow in inexpensive and nutrient-poor industrial residual streams and still produce impressive amounts of enzyme makes it a very promising microorganism for future research on on-site enzyme production in biorefineries.

References

Alriksson B, Rose SH, van Zyl WH, Sjöde A, Nilvebrant N-O, Jönsson LJ (2009) Cellulase production from spent lignocellulose hydrolysates by recombinant Aspergillus niger. Appl Environ Microbiol 75:2366–2374

Bailey M, Buchert JJ, Viikari L (1993) Effect of pH on production of xylanase by Trichoderma reesei on xylan-based and cellulose-based media. Appl Microbiol Biotechnol 40:224–229

Fan Z, South C, Lyford K, Munsie J, van Walsum P, Lynd LR (2003) Conversion of paper sludge to ethanol in a semicontinuous solids-fed reactor. Bioprocess Biosyst Eng 26:93–101

He J, Yu B, Zhang K, Ding K, Chen D (2009) Expression of endo-1, 4-beta-xylanase from Trichoderma reesei in Pichia pastoris and functional characterization of the produced enzyme. BMC Biotechnol 9:56

Image J (2010) Available from: rsb.info.nih.gov/ij. Accessed 17 Apr 2010

Jeffries TW, Schartman R (1999) Bioconversion of secondary fiber fines to ethanol using counter-current enzymatic saccharification and co-fermentation. Appl Biochem Biotechnol 77–79:435–444

Kádár Z, Szengyel Z, Réczey K (2004) Simultaneous saccharification and fermentation (SSF) of industrial wastes for the production of ethanol. Ind Crop Prod 20:103–110

La Grange DC, Pretorius IS, van Zyl WH (1996) Expression of a Trichoderma reesei β-xylanase gene (XYN2) in Saccharomyces cerevisiae. Appl Environ Microbiol 62:1036–1044

Lappalainen A, Siika-Aho M, Kalkkinen N, Fagerström R, Tenkanen M (2000) Endoxylanase II from Trichoderma reesei has several isoforms with different isoelectric points. Biotechnol Appl Biochem 31:61–68

Lark N, Xia Y, Qin C-G, Gong CS, Tsao GT (1997) Production of ethanol from recycled paper sludge using cellulase and yeast Kluveromyces marxianus. Biomass Bioenerg 12:135–143

Meyer V (2008) Genetic engineering of filamentous fungi—progress, obstacles and future trends. Biotechnol Adv 26:177–185

Parkinson M, Wainwright M, Killham K (1989) Observations on oligotrophic growth of fungi on silica gel. Mycol Res 93:529–534

Polizeli ML, Rizzatti AC, Monti R, Terenzi HF, Jorge JA, Amorim DS (2005) Xylanases from fungi: properties and industrial applications. Appl Microbiol Biotechnol 67:577–591

Ragauskas AJ, Nagy M, Kim DH, Eckert CA, Hallett JP, Liotta CL (2006) From wood to fuels: integrating biofuels and pulp production. Ind Biotechnol 2:55–65

Rose SH, van Zyl WH (2002) Constitutive expression of the Trichoderma reesei beta-1, 4-xylanase gene (xyn2) and the beta-1, 4-endoglucanase gene (egI) in Aspergillus niger in molasses and defined glucose media. Appl Microbiol Biotechnol 58:461–468

Sixta H, Süss H-U, Potthast A, Schwanninger M, Krotscheck AW (2006) Pulp bleaching. In: Sixta H (ed) Handbook of pulp, vol 2. Wiley, Weinheim, pp 818–822

Sjöde A, Alriksson B, Jönsson LJ, Nilvebrant N-O (2007) The potential in bioethanol production from waste fiber sludges in pulp mill-based biorefineries. Appl Biochem Biotechnol 136–140:327–338

Stals I, Sandra K, Geysens S, Contreras R, Van Beeumen J, Claeyssens M (2004) Factors influencing glycosylation of Trichoderma reesei cellulases. I: postsecretorial changes of the O- and N-glycosylation pattern of Cel7A. Glycobiology 14:713–724

Steinberg TH, Haugland RP, Singer VL (1996) Applications of SYPRO orange and SYPRO red protein gel stains. Anal Biochem 239:238–245

Takashima S, Nakamura A, Hidaka M, Masaki H, Uozumi T (1999) Isolation and characterization of the actin gene from the cellulolytic fungus Humicola grisea and analysis of transcription levels of actin and cellulase genes. J Biochem 125:728–736

Verdoes JC, Punt PJ, van den Hondel CAMJJ (1995) The complete karyotype of Aspergillus niger: the use of introduced electrophoretic mobility variation of chromosomes for gene assignment studies. Appl Microbiol Biotechnol 43:195–205

Wainwright M, Al-Wajee K, Grayston SJ (1997) Effect of silicic acid and other silicon compounds on fungal growth in oligotrophic and nutrient-rich media. Mycol Res 101:933–938

Webb L (1994) Sludge disposal: the unregulated loophole. Pulp Paper 36:18–23

Acknowledgments

The assistance of Marcus Jonsson in performing preliminary experiments is gratefully acknowledged. One of the authors (A.C.) was supported by SEKAB E-Technology (Örnsköldsvik, Sweden) through the Umeå University Industrial Post Graduate School. The research received financial support from the Kempe Foundations, the Knut and Alice Wallenberg Foundation, the Biorefinery of the Future (www.bioraffinaderi.se), and the Bio4Energy research initiative (www.bio4energy.se).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cavka, A., Alriksson, B., Rose, S.H. et al. Biorefining of wood: combined production of ethanol and xylanase from waste fiber sludge. J Ind Microbiol Biotechnol 38, 891–899 (2011). https://doi.org/10.1007/s10295-010-0856-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-010-0856-9