Abstract

Myrothecium verrucaria is a nondermatophytic filamentous fungus able to grow and to produce keratinase in submerged (93.0 ± 19 U/ml) and solid state (98.8 ± 7.9 U/ml) cultures in which poultry feather powder (PFP) is the only substrate. The purpose of the present work was to verify how different carbon and nitrogen sources can influence the production of keratinase by this fungus. Addition of carbohydrates, such as glucose and sucrose, caused only slight improvements in keratinase production, but the addition of starch caused a significant improvement (135.0 ± 25 U/ml). The highest levels of keratinase activity, however, were obtained by supplementing the PFP cultures with cassava bagasse, 168.0 ± 28 U/ml and 189.0 ± 26 U/ml in submerged and solid state cultures, respectively. Contrarily, the supplementation of PFP medium with organic or inorganic nitrogen sources, such as casein, soy bean protein, gelatin, ammonium nitrate and alanine, decreased the production of keratinase in both types of cultures (around 20 U/ml), showing that the production of keratinase by M. verrucaria is repressed by nitrogen sources. The results obtained in this work suggest that the association of the two residues PFP plus cassava bagasse could be an excellent option as a cheap culture medium for the production of keratinase in submerged and solid state cultures.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The major component of poultry feathers is keratin, an insoluble structural protein rich in β-helical coils linked through cystine bridges. The structural rigidity of this protein makes feathers to accumulate in large quantities as wastes of commercial poultry processing. Since poultry feathers contain a great deal of potentially useful proteins and amino acids applicable for cheap animal feedstuffs, there have been many efforts to reuse the keratinous biomaterials [24, 27]. Conventionally, feather waste is used on a limited basis as a dietary protein supplement for animal feedstuffs after hydrothermal processing. However, hydrothermal treatment has limitations because of its poor digestive ability, the loss of nutritionally essential amino acids such as methionine, lysine and tryptophan, and the formation of non-nutritive amino acids such as lysinoalanine and lanthionine [6]. Enzymatic degradation of keratin could be an option to obtain amino acids and peptides from poultry feathers, but the structure of keratins makes their hydrolysis by common proteases, such as pepsin and papain, very difficult. However, there is a group of proteolytic enzymes which are able to hydrolyze insoluble keratins more efficiently than other proteases. These proteases are called keratinases (EC 3.4.99.11) and are produced by some insects and especially by microorganisms, bacteria and fungi. Among fungi, keratinolytic activity from dermatophytes has received more attention due to medical and veterinary implications [28, 37]. Although some nondermatophytic fungi have already been described [1, 2, 10, 14, 15, 19, 21, 33], for biotechnological purposes, bacterial keratinases have been received more attention, particularly those produced by Bacillus [5, 13, 20, 36]. Keratinolytic enzymes find use in environment friendly biotechnological processes that use keratin-containing wastes from poultry industry [16, 29]. Moreover, these enzymes could be interesting for pharmaceutical and cosmetic industries [13].

The production of keratinases by microorganisms can be affected by several factors, such as temperature, pH and the nature of carbon and nitrogen sources present in the medium [16]. Most of keratinolytic organisms are able to grow and to produce keratinase using keratin as the sole carbon and nitrogen source. Substrate induction is the major regulatory mechanism, although a few constitutive keratinases have also been reported [12, 20]. Simple sugars, such as glucose, have been reported to suppress the synthesis of keratinase [33], but in some organisms the opposite was found [2, 8, 36]. Concerning the use of nitrogen sources different from keratin, an inductive effect of soybean meal has been reported to occur [14]. However, most reports describe a partial or complete repressive effect of the supplementation of cultures with small nitrogen molecules [8, 19, 36].

Myrothecium verrucaria (Albertini and Schwein) Ditmar:Fr, is a filamentous fungus commonly found in soil and plant substrates worldwide. It has been proposed as a bioherbicide against a wide range of economically important weed species in agronomic, pasture and horticultural systems [4]. Recently, we described for the first time that M. verrucaria possesses the ability of completely disintegrate poultry feather when this material was offered as the only carbon and nitrogen sources to the fungus in submerged cultures [23]. Its culture filtrates presented an elevated efficiency to degrade poultry feather meal liberating amino acids and soluble peptides. It showed a real capability to hydrolyse β-keratin, without necessity of any additional chemical or enzymatic reduction of disulphide bonds. Little information is available about the factors that control the synthesis and release of keratinases by M. verrucaria. These factors vary considerably from organism to organism, so that the study on the nutritional and environmental factors controlling the keratinase production in this potent strain of fungi is of high interest. The objective of this study was, thus, to evaluate the influence of different carbon and nitrogen sources on the production of keratinase by M. verrucaria in both submerged and solid state cultures.

Materials and methods

Microorganism

Myrothecium verrucaria (Albertini and Schwein) Ditmar:Fr CCT 1886 was obtained from the Collection Culture of the Fundação André Tosello, Campinas, SP, Brazil, and was maintained on potato dextrose agar at 4°C. The conidial suspensions were prepared by adding 10 ml of sterilized water to slant cultures and the surface was gently rubbed with a sterilized wire loop.

Pretreatment of the feathers

Poultry feathers were supplied by a local industry. Freshly plucked wet feathers were washed extensively with water and detergent. Wet feathers were dried in a ventilated oven at 40°C for 72 h. The feathers were then milled in a ball mill and passed through a small-mesh grid to remove coarse particles. This material was designated as poultry feather powder (PFP).

Culture conditions

M. verrucaria was cultivated in submerged and solid state conditions. In submerged cultures, 1 × 109 spores were transferred to 250 ml Erlenmeyer flasks containing 50 ml of mineral media plus PFP at 1.0% as substrate. The mineral solution contained per liter: KH2PO4 1.0 g; MgSO4 · 7H2O 2.0 g; CaCl2 1.0 g; yeast extract 1 g. The medium was previously sterilized by autoclaving at 121°C for 15 min. The cultures were incubated at 28°C on a rotary shaker at 120 rpm. At periodic intervals, the cultures were filtered through Whatman No. 1 filter paper to retain insoluble materials, and centrifuged (5,000 g for 10 min at 4°C). The supernatants were used as sources of keratinases.

On solid state conditions, the experiments were carried out in flasks containing 2 g of solid substrate (dry basis) and mineral solution to obtain the same concentration of salts described in “Culture conditions”. The initial moisture contents (IMC) of 65, 70, 75 and 80% (w/w) were obtained by adding corresponding amounts of distilled water. The media were sterilized by autoclaving at 121°C for 15 min and then inoculated with 109 spores from the spore suspensions. Incubation was carried out at 28°C for 4 days. To extract the enzyme a volume of 25 ml of distilled water was added to flasks containing the fermented solids. The mixtures were then mechanically stirred at 130 rpm at 10°C for 1 h. The mixtures were firstly filtered through gaze and the filtrates were centrifuged (5,000g for 10 min). The supernatants were used as sources of keratinases.

Determination of keratinase activity

The protease activity of the culture supernatants was assayed as keratinase activity using PFP as substrate [26]. The reaction mixture containing 10 mg of substrate, 1.0 ml of borate buffer (100 mM, pH 9.0), and 1.0 ml of a suitable diluted culture supernatant (crude keratinase) was incubated under agitation using a stirring bar for 1 h at 40°C. The reaction was stopped by boiling and the mixture was filtered through filter paper. The amount of tyrosine released was estimated by Lowry’s method using a tyrosine standard curve. One unit of enzyme activity was defined as the amount of enzyme producing 1 μg of tyrosine/min.

Degradation of feather powder by the crude enzyme

The cell free crude keratinases were obtained from 4 day-old submerged and solid state cultures developed in PFP medium supplemented or not with different carbon and nitrogen sources. Culture supernatant (1.0 ml) was added to 100 mg of feather meal in 4.0 ml of 0.1 M borate buffer, pH 8.5 and maintained in a shaking water bath (35°C) at 130 rpm for 8 h. Sodium azide (1.0 mM) was added to avoid contamination. Controls of keratinous materials were done under the same conditions using culture filtrate previously boiled for 5 min. The dry weight of the remaining feather meal was determined on membrane filters (pore size, 0.2 μm) after drying at 60°C for 12 h. Feather degradation was determined by subtracting the weight of feather meal before hydrolysis with treatment from the weight of the residue after degradation.

Determination of pH

The pH of cell free samples was determined by using an electronic probe (Tecnal Tec-2 pH Meter).

Statistical analysis

All analyses were performed at least in triplicate. The data were expressed as means plus standard deviations. The statistical analyses were performed using Student’s t-test, ANOVA and Pearson’s correlation (r). Differences between means at the 5% (P < 0.05) level were considered significant.

Results

M. verrucaria is able to grow using PFP as its sole sources of carbon and nitrogen (PFP medium). Under submerged conditions, the culture supernatants presented a keratinase activity of 93.0 ± 19 U/ml (Fig. 1). Addition of carbohydrates such as glucose, and sucrose improved only slightly the production of enzyme. The addition of starch, however, significantly improved the production of keratinase (135.0 ± 25 U/ml). The highest level of keratinase activity was obtained with the supplementation of cultures with cassava bagasse (168.0 ± 28 U/ml). Contrarily, the supplementation of PFP medium with organic or inorganic nitrogen sources (casein, soy bean protein, gelatin, alanine and ammonium nitrate drastically decreased the production of keratinase to values around 20 U/ml.

Influence of supplementation of PFP medium with carbon and nitrogen sources on the production of keratinase by M. verrucaria in submerged cultures. The cultures were developed at 28°C and 120 rpm for 4 days using poultry feather meal at 1% as substrate. The PFP medium was additionally supplemented with glucose 1% (PFP + G), maltose 1% (PFP + M), sucrose 1% (PFP + S), starch 1% (PFP + Sta), cassava bagasse 1% (PFP + CB), casein 1% (PFP + Cas), soy bean protein 1% (PFP + soy bean), gelatin 0.2% (PFP + gel), alanine 0.1% (PFP + Ala) and ammonium nitrate 5 mM (PFP + NH4NO3)

Figure 2 shows typical time courses for keratinase production in submerged cultures in PFP medium and PMP medium supplemented with carbon and nitrogen sources. The addition of glucose and cassava bagasse improved the production of keratinase, but it did not reduce the time necessary (4 days) for attaining maximal keratinase production. However, in comparison with literature reports, the cultivation time of 4 days is very short.

The supplementation with organic and inorganic nitrogen sources (gelatin, alanine and ammonium nitrate) alone or in association with carbon sources strongly repressed the production of keratinase. Due to the fact that it was impossible to separate the fungal biomass from the residual feather in the media, the fungal biomass production was not determined gravimetrically. However, visual inspection revealed that in PFP medium and in glucose or cassava bagasse supplemented medium, keratin was almost completely degraded, whereas in nitrogen supplemented medium the insoluble substrate was still present after 6 days of cultivation.

Figure 3 shows the pH changes during the fermentation. In all cultures, the increases in keratinolytic activity were associated to pH increases. This was probably due to the accumulation of ammonium ions, the products of deamination. The supplementation of cultures with 5 mM NH4NO3 caused a significant increase of pH (P < 0.05), while supplementation with glucose caused a significant (P < 0.05) decrease of pH solely at the beginning of the fermentation (one day-cultures). The latter is probably due to the fast degradation of glucose to organic acids. For all other conditions similar pH changes were found during the whole cultivation time.

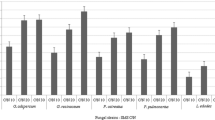

Figure 4 shows the production of keratinase in solid state cultures. The best results were obtained by using an initial moisture content of 70–75%. For the latter it was obtained an activity of 98.8 ± 7.9 U/ml. Here also, supplementation of the medium with glucose slightly improved the production of keratinase while cassava bagasse caused a significant (P < 0.05) improvement in the enzyme production, reaching 189.0 ± 26 U/ml. The supplementation of the medium with a nitrogen source alone or in association with a carbon source (cassava bagasse or glucose) suppressed keratinase production in descending order as follows: alanine > NH4NO3 > soy bean protein.

Production of keratinase by M. verrucaria in solid state cultures. The cultures were developed at 28°C for 4 days with different initial moisture content (IMC). The PFP medium was supplemented with glucose 1% (G), soy bean protein 1% (soy bean), cassava bagasse 1% (CB), alanine 0.1% (Ala) and ammonium nitrate 5 mM (NH4NO3)

Different culture supernatants of both types of cultures (submerged and solid state) were used as sources of crude keratinase to degrade feather powder. A good correlation (r = 0.856) between enzyme activity and keratin degradation was observed (Fig. 5).

In vitro degradation of poultry feather meal by crude M. verrucaria keratinase. One milliliter of culture supernatants (from submerged and solid state cultures) was added to 100 mg of feather meal in 4.0 ml of 0.1 M borate buffer, pH 8.5 and maintained in a shaking water bath (35°C) at 130 rpm for 8 h. Controls of keratinous materials were done in the same conditions using culture filtrate previously boiled for 5 min. The dry weight of the remaining feather meal was determined on membrane filters (pore size, 0.2 μm) after drying at 60°C for 12 h. Feather degradation was determined by subtracting the weight of feather meal before hydrolysis with treatment from the weight of the residue after the degradation

Discussion

It is currently considered that the complete degradation of keratin is a complex event where, in association with extracellular keratinase, several other factors, most of them intracellular, are probably involved [16]. Enzymatic or chemical reducing agents in form of disulfide reductases, sulfite, thiosulfate or cellular membrane potential may play a significant role in the degradation of this insoluble protein [3, 13, 18, 32, 38]. In addition to this, the initial attack by keratinases and disulfide reductases must allow other less specific proteases to act, resulting in an extensive keratin hydrolysis [5]. Although the capability of M. verrucaria to produce chemical and/or enzymatic reducing agents, and the roles of these reducing agents in the fungal capability to degrade poultry feathers have not yet conveniently evaluate, the results of the present work clearly demonstrate that M. verrucaria keratinase is able to hydrolyze feather powder. A good correlation was obtained between keratinase activity and in vitro degradation of feather powder, independent of the type of cultivation used to obtain the enzyme or the additional carbon and nitrogen in the culture medium.

The results presented in this work also show that it is possible to improve the production of keratinase by M. verrucaria by supplementing the PFP medium with an additional source of carbon. The supplementation of medium with a nitrogen sources, on the other hand, had a negative effect on the production of enzyme. Similar results were obtained for other keratinase producing fungi and bacteria, including Chrysosporium georgiae [8], and Bacillus pumillis [36]. However, these effects are not common for all microorganisms. For example, the supplementation of the culture medium with both, carbon and nitrogen sources had a positive effect on the production of keratinase by Scopulariopsis brevicaulis [1], while in cultures of Trichophyton simii, exogenous sugars suppressed keratinase production [34].

Microbial growth and metabolism inevitably lead to changes in the hydrogen ion balance and hence, in the pH of the culture medium. In this study the highest production of keratinase occurred between the fourth and sixth days of cultivation, when the pH of the cultures had attained values between 7.0 and 7.5. Considering that the pH of the cultures supplemented with a nitrogen source was not significantly different from that of the cultures without supplementation or supplemented with carbon sources, it is reasonable to conclude that the drastic reduction in the keratinase production was due, or at least overwhelmingly due, to catabolite repression by the nitrogen sources and not to alterations of medium pH.

Keratinase has been produced under submerged shaking conditions, except for a few thermophilic bacteria [11, 25, 31] and fungi [17, 35] for which static submerged fermentation has been reported. The use of solid state fermentation is much less common [7, 9]. It should be recalled that, with M. verrucaria, elevated levels of keratinase were obtained in both submerged and solid sate cultures. Considering this point, the known advantages of the solid state cultures such as simplicity, lower production costs and low waste water output [22] make it interesting to optimize the production of keratinase in this type of culture. The association of feather and cassava bagasse, two cheap and readily available substrates, could result in a substantial reduction in the costs of enzyme production. Like poultry-processing plants, which create a serious disposal problem leading to environmental pollution due to the large amount of feathers that are produced and accumulated locally, in Brazil, cassava bagasse is a problem for the starch industry, because it has an elevated percentage of water, which makes drying and transportation very expensive. Several processes have been developed that use cassava bagasse for the production of bulk chemicals and value-added fine products such as ethanol, single-cell protein (SCP), mushrooms, enzymes, organic acids, amino acids and biologically active secondary metabolites [30]. Its use as a substrate in association with feather powder for keratinase production would be an additional destination for this troublesome by-product of the cassava-processing industry.

The identification and characterization of new nondermatophytic fungal species able to degrade keratin may help us to understand the role of fungi in the degradation of complex keratinous substrates in nature. In addition to this, the ability of the M. verrucaria to grow and to produce appreciable levels of keratinase using feathers and cassava bagasse as substrates could be potentially useful for the development of biotechnological methods aiming to obtain useful hydrolysis products from feathers.

References

Anbu P, Gobinath SCB, Hilda A, Lakshmipriya T, Annadurai G (2007) Optimization of extracellular keratinase by poultry farm isolate Scopulariopis brevicaulis. Bioresour Technol 98:1298–1303. doi:10.1016/j.biortech.2006.05.047

Anbu P, Hilda A, Sur H-W, Hur B-K, Jayanthi S (2008) Extracellular keratinase from Trichophyton sp HA-2 isolated from feather dumping soil. Int Biodeter Biodegrad 62:287–292. doi:10.1016/j.ibiod.2007.07.017

Bockle B, Müller R (1997) Reduction of disulfide bonds by Streptomyces pactum during growth on chicken feathers. Appl Environ Microbiol 63:790–792

Boyette CD, Hoagland RE, Abbas HK (2007) Evaluation of the bioherbicide Myrothecium verrucaria for weed control in tomato (Lycopersicon esculentum). Biocontrol Sci Technol 17:171–178. doi:10.1080/09583150600937451

Brandelli A (2008) Bacterial keratinases: useful enzymes for bioprocessing agro-industrial wastes and beyond. Food Bioprocess Technol 1:105–116. doi:10.1007/s11947-007-0025-y

Dalev P, Ivanov I, Liubomirova A (1997) Enzymic modification of feather keratin hydrolyzates with lysine aimed at increasing the biological value. J Sci Food Agric 73:242–244. doi:10.1002/(SICI)1097-0010(199702)73:2<242::AID-JSFA712>3.0.CO;2-3

De Azeredo LAI, Lima MB, de-Coleho RRR, Freire DMG (2006) Thermophilic protease production by Streptomyces sp. 594 in submerged and solid state fermentation using feather meal. J Appl Microbiol 100:641–647. doi:10.1111/j.1365-2672.2005.02791.x

El-Naghy MA, El-Ktatny MS, Fadl-Allah EM, Nazeer WW (1998) Degradation of chicken feathers by Chrysosporium georgiae. Mycopathologia 143:77–84. doi:10.1023/A:1006953910743

Esawy MA (2007) Isolation and partial characterization of extracellular keratinase from a novel mesophilic Streptomyces albus AZA. Res J Agric Biol Sci 3:808–817

Farag AM, Hassan MA (2004) Purification, characterization and immobilization of a keratinase from Aspergillus oryzae. Enzyme Microb Technol 34:85–93. doi:10.1016/j.enzmictec.2003.09.002

Frieddrich AB, Antranikian G (1996) Keratin degradation by Fervidobacterium pennavorans, a novel thermophilic anaerobic species of the order thermotogales. Appl Environ Microbiol 62:2875–2882

Gassesse A, Kaul RH, Gashe BA, Mattiasson B (2003) Novel alkaline proteases from alkalophilic bacteria grown on chicken feather. Enzyme Microb Technol 32:519–524. doi:10.1016/S0141-0229(02)00324-1

Ghosh A, Chakrabarti K, Chattopadhyay D (2008) Degradation of raw feather by a novel high molecular weight extracellular protease from newly isolated Bacillus cereus DCUW. J Ind Microbiol Biotechnol 35:825–834. doi:10.1007/s10295-008-0354-5

Gradisar H, Kern S, Frieddrich J (2000) Keratinase of Doratomyces microsporus. Appl Microbiol Biotechnol 53:196–200. doi:10.1007/s002530050008

Gradisar H, Friedrich J, Krizaj I, Jerala R (2005) Similarities and specificities of fungal keratinolytic proteases: comparison of keratinases of Paecilomyces marquandii and Doratomyces microsporus to some known proteases. Appl Environ Microbiol 71:3420–3426. doi:10.1128/AEM.71.7.3420-3426.2005

Gupta R, Ramnani P (2006) Microbial keratinases and their prospective applications: an overview. Appl Microbiol Biotechnol 70:21–33. doi:10.1007/s00253-005-0239-8

Kaul S, Sambali G (1999) Production of extracellular keratinases by keratinophilic fungal species inhabiting feathers of living poultry birds (Gallus domesticus): a comparison. Mycopathologia 146:19–24. doi:10.1023/A:1007086720237

Kunert J, Truper HG (1986) Cystine catabolism in mycelia of Microsporum gypseum, a dermatophytic fungus. Arch Microbiol 150:600–601. doi:10.1007/BF00408257

Malviya HK, Rajak RC, Hasija SK (1992) Synthesis and regulation of extracellular keratinase in three fungi isolated from the grounds of a gelatin factory, Jabalpur, India. Mycopathologia 120:1–4. doi:10.1007/BF00578494

Manczinger L, Rozs M, Vagvolgyi CS, Kevei F (2003) Isolation and characterization of a new keratinolytic Bacillus licheniformis strain. World J Microbiol Biotechnol 19:35–39. doi:10.1023/A:1022576826372

Marcondes NR, Taira CL, Vandresen DC, Svidzinski TIE, Kadowaki MK, Peralta RM (2007) New-feather-degrading filamentous fungi. Microb Ecol 55:1–5

Mitchell DA, Berovic N, Krieger K (2002) Overview of solid state bioprocessing. Biotechnol Annu Rev 8:183–225. doi:10.1016/S1387-2656(02)08009-2

Moreira FG, Souza CGM, Costa MAF, Reis S, Peralta RM (2007) Degradation of keratinous materials by the plant pathogenic fungus Myrothecium verrucaria. Mycopathologia 163:153–160. doi:10.1007/s11046-007-0096-3

Moritz JS, Latshaw JD (2001) Indicators of nutritional value of hydrolyzed feather meal. Poult Sci 80:79–86

Nam GW, Lee DW, Lee NJ, Kim BC, Choe EA, Hwang JK, Suhartono MT, Pyun YR (2002) Native feather degradation by Fervidobacterium islandicum AW–1, a newly isolated keratinase-producing thermophilic anaerobe. Arch Microbiol 178:538–547. doi:10.1007/s00203-002-0489-0

Nickerson WJ, Noval JJ, Robinson RS (1963) Keratinase I. Properties of the enzyme conjugate elaborated by Streptomyces fradie. Biochim Biophys Acta 77:73–86. doi:10.1016/0006-3002(63)90470-0

Odetallah NH, Wang JJ, Garlich JD, Shih JCH (2003) Keratinase in starter diets improves growth of broiler chicks. Poult Sci 82:664–670

Okafor JI, Ada N (2000) Keratinolytic activity of five human isolates of the dermatophytes. J Commun Dis 32:300–305

Onifade AA, Al-Sane NA, Al-Musallam AA, Al-Zarban S (1998) A Review: potentials for biotechnological applications of keratin-degrading microorganisms and their enzymes for nutritional improvement of feathers and others keratins as livestock feed resources. Bioresour Technol 66:1–11. doi:10.1016/S0960-8524(98)00033-9

Pandey A, Soccoll CR, Nigam P, Soccoll VT, Vandenberghe LPS, Mohan R (2000) Biotechnological potential of agroindustrial residues. II. Cassava bagasse. Bioresour Technol 74:81–87. doi:10.1016/S0960-8524(99)00143-1

Rissen S, Antranikian G (2001) Isolation of Thermoanaerobacter keratinophilus sp nov., a novel thermophilic, anaerobic bacterium with keratinolytic activity. Extremophiles 5:399–408. doi:10.1007/s007920100209

Sangali S, Brandelli A (2000) Feather keratin hydrolysis by a Vibrio sp strain kr2. J Appl Microbiol 89:735–743. doi:10.1046/j.1365-2672.2000.01173.x

Santos RMDB, Firmino ALP, de Sá CM, Felix CR (1996) Keratinolytic activity of Aspergillus fumigatus Fresenius. Curr Microbiol 33:364–370. doi:10.1007/s002849900129

Singh CJ (1997) Characterization of an extracellular keratinase of Trichophyton simii and its role in keratin degradation. Mycopathologia 137:13–16. doi:10.1023/A:1006844201399

Singh CJ (1999) Exocellular proteases of Malbranchea gypsea and their role in keratin deterioration. Mycopathologia 143:147–150. doi:10.1023/A:1006968600404

Son H-J, Park H-C, Kim H-S, Lee C-Y (2008) Nutritional regulation of keratinolytic activity in Bacillus pumilis. Biotechnol Lett 30:461–465. doi:10.1007/s10529-007-9567-3

Vianni FC, dos Santos JI, Paula CR, Larson CE, Gambale W (2001) Production of extracellular enzymes by Microsporum canis and their role in its virulence. Med Mycol 39:463–468. doi:10.1080/714031047

Yamamura S, Morita Y, Hasan Q, Yokoyama K, Tamiya E (2002) Keratin degradation: a cooperative action of two enzymes from Stenotrophomonas sp. Biochem Biophys Res Commun 294:1138–1143. doi:10.1016/S0006-291X(02)00580-6

Acknowledgments

This study was supported by grants from Conselho Nacional de Pesquisa e Desenvolvimento (CNPq) and Fundação Araucária. RM Peralta is research fellow of CNPq. FG Moreira-Guillen is a recipient of CAPES Fellowships. We thank A Chaves and MAF Costa for their technical assistances.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

da Gioppo, N.M.R., Moreira-Gasparin, F.G., Costa, A.M. et al. Influence of the carbon and nitrogen sources on keratinase production by Myrothecium verrucaria in submerged and solid state cultures. J Ind Microbiol Biotechnol 36, 705–711 (2009). https://doi.org/10.1007/s10295-009-0540-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-009-0540-0