Abstract

Collapse columns are geological features formed by chimney caving of karst voids. Collapse columns can cut through the rock mass and introduce vast geological complexity in coalfields. When a collapse column becomes accessible to a confined aquifer, water inrush disasters can be triggered. In northern China, inrushes related to collapse columns occur in regions where extensive Ordovician limestone underlies the coal measures. This limestone is strongly karstified and holds large quantities of water. The piezometric surface can be considerably higher than the coal extraction level. Numerical simulation was used to explore how the water inrush pathway forms, based on a demonstration model. First, the evolution of the stress field, damage field, and flow volume within the coal floor was analysed. Then factors such as the column height, mechanical strength of the coal floor, and hydraulic pressure in the aquifer were considered. In the demonstration models, if the height of the collapse column exceeded 35 m and the initial thickness of the aquiclude was less than 15 m, an inrush definitely occurred, even when the strength of the floor strata was relatively high. Finally, a practical case of water inrush in the Fangezhuang coal mine related to a collapse column was numerically investigated. Modelling of the fracturing process provided insight into evolution of the fracture zone and inrush processes that cannot be observed in the field and are difficult to evaluate using static stress analysis.

陷落柱由溶蚀裂隙囱状塌落形成,便煤田地质条件复杂化。当陷落柱与煤田内承压含水层相接,陷落柱可能诱发灾害性煤矿突水。在中国华北,区域性奥陶系灰岩含水层下伏于石炭-二叠系煤层,曾发生多次陷落柱突水。灰岩含水层强烈溶蚀,赋存大量岩溶水。岩溶水承压面远高于煤炭开采标高。基于示范模型,数值模拟了陷落柱突水路径形成过程。首先,分析了煤层底板应力场、损伤场和岩溶水量,考虑了陷落柱高度、煤层底板力学强度和含水层水压等因素。依据示范模型,如果陷落柱高度超过35 m且初始隔水层厚度小于15 m,即使底板力学强度足够大,仍将发生陷落柱突水。最后,利用数值法研究了冯庄矿陷落柱突水案例。模拟研究有助于理解野外现场不能观察和静态应力观测难以评价的裂隙区演化和突水过程。

Zusammenfassung

Erdfallschlote sind kaminförmig angelegte, gefüllte vertikale Karsthohlräume. Erdfallschlote können geologische Gesteinseinheiten vertikal durchörtern und die Abbaubedingungen in Kohlefeldern massiv verkomplizieren. Wenn ein Erdfallschlot in Kontakt mit einem gespannten Grundwasserleiter steht, können sich katastrophale Wassereinbrüche ereignen. In Nordchina treten Wassereinbrüche über Erdfallschlot in den Regionen auf, wo ausgedehnte ordovizische Kalksteine im Liegenden von Kohlelagerstätten lagern. Die Kalksteine sind hochgradig verkarstet und stark wasserführend. Die Grundwasserdruckfläche in den Kalksteinen liegt höher als der Level des Kohleabbaus. Mit Hilfe eines numerischen Demonstrationsmodells wurde untersucht, wie sich Wasserzutrittswege ausbilden. Zunächst wurde die Entwicklung des Spannungs- und Schadensfeldes sowie das Fließvolumen innerhalb der Kohleabbaus untersucht. Im Anschluss wurden Faktoren wie die Höhe der Wassersäule, die mechanische Festigkeit der Abbaubasisfläche und der hydraulische Druck im Grundwasserleiter betrachtet. In den Demonstrationsmodellen wird gezeigt, dass ein Wassereinbruch stattfinden kann, wenn die Erdfallschlote höher als 35 m sind und die Ausgangsmächtigkeit der Grundwassernichtleiter weniger 15 m beträgt, sogar wenn die mechanische Festigkeit der Abbaubasisfläche relativ hoch ist. Schließlich wurde ein Wassereinbruch über einen Erdfallschlot in die Fangezhuang Kohlemine simuliert. Die Modellierung dieser Prozesse unterstützt das Verständnis zur Entwicklung von Wassereinbrüchen über Karstspaltenzonen, welche nicht direkt beobachtet werden können oder nur sehr schwierig durch statische Spannungsanalysen zu bewerten sind.

Resumen

Las columnas colapsables son fallas geológicas formadas por cavados en forma de chimenea en el karst. Las columnas colapsables pueden cortar a través de la masa de roca e introducir una gran complejidad geológica en las cuencas. Cuando una columna colapsable accede a un acuífero confinado, los desastres de la irrupción de agua pueden ser activados. En el norte de China, las irrupciones de este tipo se producen en regiones donde la caliza ordovícica extensa subyace a las vetas de carbón. Esta caliza es fuertemente karstificada y contiene grandes cantidades de agua. La superficie piezométrica puede ser considerablemente más alta que el nivel de extracción del carbón. La simulación numérica se utilizó para explorar cómo se forma el canal de irrupción del agua, basada en un modelo de demostración. En primer lugar, se analizó la evolución del campo de tensión, el campo del daño y el volumen de flujo dentro del piso de carbón. Luego se consideraron factores como la altura de la columna, la resistencia mecánica del piso de carbón y la presión hidráulica en el acuífero. En los modelos de demostración, si la altura de la columna colapsable superaba los 35 m y el espesor inicial del acuífero era inferior a 15 m, se producía una irrupción en algún momento, incluso cuando la resistencia de los estratos de suelo era relativamente alta. Finalmente, se investigó numéricamente un caso práctico de irrupción de agua, vinculada a columna colapsable, en la mina de carbón de Fangezhuang. El modelado del proceso de fracturación proporcionó una visión de la evolución de la zona de fractura y de los procesos de irrupción que no pueden observarse en el campo y son difíciles de evaluar usando el análisis de tensión estática.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

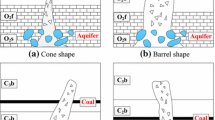

Collapse columns are geological features formed by chimney caving of karst voids and are widely distributed in northern China. A karst cave develops due to the long-term dissolution of limestone until, eventually, collapsed rock and debris fall into the void, where they are often gradually cemented together. Figure 1a is a sketch of a coal seam with a collapse column developing beneath it in a confined aquifer. Geological data from coal mines in northern China show that the height of the columns, which can reach from a few meters to hundreds of meters (Wu and Wang 2006), depends on the size of the early karst caves. A collapse column is generally filled with different sizes of collapsed rock and calcite/muddy fillings (Fig. 1b). Although the heterogeneous mixtures are breccias, in most cases they maintain enough mechanical strength to retain the confined water. Generally, therefore, a collapse column only threatens an underground mine if the coal and the limestone are close together.

However, when a coal seam is mined, the in-situ stress field is redistributed and an abutment pressure will be generated near the working face. When this pressure reaches or exceeds the critical strength of the floor strata, a certain area of the working face floor may be damaged, resulting in a brittle fracture. The re-distribution of the stress field and the damaged floor can further enhance the permeability of the floor (Gross 1993; Li and Peng 2006; Wang and Park 2003; Zuo et al. 2009). When the working face approaches a weakly cemented and/or water-conducting collapse column, the column may become a conduit for the confined water in the aquifer. The resultant water inrush can seriously threaten life and property near the working face.

Most collapse columns are water-resistant because of their cementation and long periods of compaction. Materials like calcite or mudstone fill the voids, and if not destroyed, contribute to their impermeability. For example, 450 columns exposed in the Yangquan coal mine, in Shanxi province, were dry, and not one inrush resulted despite the existence of 400 columns in the Xishan coal mine (Yin et al. 2005). However, some collapse columns, usually those with poor cementation or many caves, have greater permeability, and are generally filled with water. Moreover, some columns are partially permeable. When the mining working face advances close enough to these water-permissible collapse columns, especially those that have a hydraulic connection with a confined aquifer, the collapse column can act as an aqueduct between the aquifer and the goaf, and trigger a water inrush disaster. In 1984, one of the most serious inrush disasters, with an average inflow of 2053 m3/min at peak inflow stage, was caused by a collapse column in the Fangezhuang mine of the Kailuan colliery. The mine and three adjacent mines were completely flooded (Zhong 2001).

Since the Ordovician limestone is extensively distributed in the coal fields of northern China, research on the formation mechanism, distribution characteristics, and material composition of these collapse columns began in the 1970s (Jia and Hu 1989). Particularly due to the Fangezhuang coal mine disaster, numerous studies associated with hydraulic conductivity, detection methodology, and remediation of water-bearing collapse columns have been conducted (Guo et al. 1994; Xu et al. 2006; Du 2012; Yin et al. 2004; Liu and Xiong 2007; Zhu and Wei 2011). The strongly confined aquifer of the Ordovician limestone beneath the collapse columns was believed to be critical in how the columns become permeable (Li and Zhou 1989). Once their permeability increases, the collapse columns greatly decrease the thickness of the water-restraining floor, while the mechanical strength of the floor’s rock mass has been partially weakened by the existence of the collapse columns. Consequently, the configuration of existing collapse columns is a key factor in determining the safety of mining above confined aquifers. Although previous theoretical studies and numerical investigations have contributed significantly to scientific understanding of groundwater outbursts, they did not address failure analysis of the key water-resisting rock layer associated with collapse columns. The crucial questions of when, where, and how these events develop during mining remain unanswered. Fracture initiation, propagation, and coalescence in floor strata, together with the formation of groundwater outburst pathways adjacent to collapse columns, are not completely understood.

In recent years, more and more new techniques and methods have been applied to water inrush evaluations. For example, Dong et al. (2012) described inrushes from a footwall limestone aquifer into a coal mine and demonstrated the predictive use of GIS-based Bayesian network modelling. In this study, a numerical code called Rock Failure Process Analysis (RFPA) was used to simulate the process of mining-induced water inrush from an underlying collapse column. Combined with a fully coupled flow–stress–damage (FSD) model (Tang et al. 2002; Li et al. 2012), it is expected to provide insights into where, when, and how the critical water inrush pathway initiates and propagates. By introducing heterogeneity of rock parameters into the model, the RFPA code can simulate nonlinear behaviour related to damage in rock. Using the above, several models were established to explore the effect of the column height, mechanical strength of the coal floor, and hydraulic pressure in the aquifer on inrush events. Together, they provided supplemental information on the stress distribution and failure-induced stress re-distribution that could not be observed directly. Then, fracture initiation, propagation, and coalescence of the stressed strata, and the transformation of the floor rock mass from aquitard strata to outburst pathway were illustrated. Finally, the case study of the inrush related to the collapse column in the Fangezhuang mine was simulated and analysed.

Numerical Investigation on the Influence Factors of Water Inrush Related to Collapse Column

Numerical Models and Related Parameters

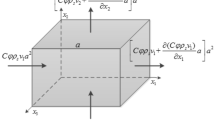

Factors such as the collapse column height, mechanical strength of coal floor, and the magnitude of the hydraulic pressure in the aquifer play an important role in assessing the risk of an inrush related to a collapse column. To investigate the influence of these factors, a numerical model (Fig. 2) was established. The collapse column was composed of rock blocks and unconsolidated fine-grained sediment. The collapse column was water-conductive and the bottom of the collapse column was considered connected with the Ordovician limestone strata, with a hydraulic pressure (confined aquifer) of 3.0 MPa. The model was discretized into a 200 m × 120 m mesh containing 400 × 240 = 96,000 elements. A compressive vertical stress (σ v ) of 6.0 MPa was uniformly imposed on the top boundary to represent the ground stress induced by overburden strata. Normal displacements constrained on right and left side, and the bottom boundaries. Plain strain was assumed for all calculations. The physio-mechanical parameters, based on Liu et al. (2009), are listed in Table 1. To clearly show how mining affected the coal floor and the evolutionary process of the stress field around the mining stope, the model simulated step-by-step (≈ 5 m) excavation. The thickness of the coal stratum in this model was 3 m. At each step, the model was solved in a quasi-static fashion to reach an equilibrium state.

The Evolution of a Water Inrush Pathway and Limited Equilibrium Analysis on the Aquitard

Figure 3 illustrates the development and formation of the water inrush pathway in detail, with the relative magnitude of the shear stress of the mesoscopic elements indicated by a grey scale. The dark elements represent the failed elements induced by the mining. Fractures form by the connection of failed elements. The grey scale indicates the relative magnitude of the stress within the elements. The elements with a lighter shade of grey have relatively higher stresses. Near the working face, the strata are subjected to compression due to the so-called abutment stress. In the floor strata under the stope, the strata are in a state of transition from shear compression to extension. During the transition, the floor strata will inevitably develop shear and tensile fractures due to bending. The unloading effect induces expansion of the floor strata. Fractures then open and develop downward in an asymmetric configuration due to the existence of the collapse column. As the working face advances, damaged zones develop and gradually connect.

The fracturing process of coal floor rocks related to a collapse column. Dark elements represent elements that failed by unloading because of coal excavation. Fractures form by connection of failed elements. The grey scale indicates the relative magnitude of the stress within elements. The elements with a lighter shade of grey have relatively higher stresses

Strata permeability obtained through in-situ drilling tests to quantify the fracture zone depth in floor strata show that the mining-induced fracture zone in the coal floor can lose its water-restraining capability. Previous studies show that damage mechanics can be used to describe the remaining water-restraining capability (Li and Gao 2003; Wang and Park 2003; Wang et al. 2014; Pan et al. 2012). In this study, the damage evolution of the coal floor was calculated by the model to provide detailed observations of the fracture pattern and the evolution of the inrush pathway. Corresponding to Fig. 3, the damage evolution is shown in Fig. 4. In Fig. 4, each circle represents one modelled acoustic emission (AE) event and the diameters of the circles represent the relative magnitude of the AE released energy (Tang and Kaiser 1998). AE events were modelled in steps, and the intensity of the AE events is proportional to the degree of damage (red circles indicate tension failures, circles indicate shear failures, and the black circle represents accumulated failure).

Initially, compressive stress was concentrated on the two abutments around the free faces; the brightest elements have a maximum shear stress of 13.6 MPa, and the floor is stable, with a rather intact rock mass. Only some dispersed damage elements can be seen in the coal floor (Fig. 4a). When the mining face advances by 30 m (in 6 steps), the stress in the area between the working face and the collapse column is obvious and the maximum shear stress increases to 18.6 MPa. Tensional failure elements in the middle of the panel floor exhibit a low grey level because of the released stress. Besides the damage near the stope, a tiny fracture comprising a cluster of damaged elements can be seen above the collapse column. The damaged elements are mainly clustered at the edge of the collapse column, which means that although some unconsolidated fine-grained sediment has been destroyed by the hydraulic pressure, the mining-induced fracture zone is not yet connected to the fractures initiated from the collapse column, so the water-restraining rock layer still remains relatively intact.

As the mining advances a total of 8 steps, the maximum shear stress increases to 20.3 MPa (Fig. 4b). Under the coupled action of mining-induced unloading and the hydraulic pressure from the confined aquifer, more damage elements can be found in the coal floor, which indicates that the damaged zone has grown both in width and depth. Moreover, the right part of the damaged floor extends deeper than the left side due to the existence of the collapse column. A macroscopic fracture forms near the top of the collapse column (Figs. 4b, 5b). At this moment, although the confined water cannot rush into the mining stope, the effective thickness of the water-restraining rock mass has been greatly reduced, from 20 to 12 m (Fig. 4b). With further excavation (step 9; Figs. 4c, 5c), a macroscopic inrush pathway comes into being. This pathway allows confined water from the aquifer to go through the collapse column, and rush into the stope. Due to the abutment pressure and the presence of the collapse column, the inrush pathway is formed almost directly beneath the working face, in this case. Besides this inrush pathway, it can be inferred that a different inrush pathway may develop with different combinations of collapse column height, coal floor mechanical strength, and hydraulic pressure.

One can note that the inrush pathway is not straight but flexural, because the fracture pattern is highly sensitive to the interaction between the isolated failed elements and the local disorder features of the rock matrix in the highly stressed field. In reality, different materials can show different types of failure. In a homogeneous material, failure begins at the high-stress site, whereas in a heterogeneous material (e.g. rock), failure may start at the weaker locations. Because flaws produce greater stress concentrations, the location of fracture initiation also depends on the distribution of the flaws as well as the magnitude of the maximum principal tensile stress. In practice, the strata and the collapse column is heterogeneous because of the presence of pores, micro-fractures, and grain boundaries. As a result, the fracture path is rough, and mixed-mode fracture propagation further affects non-planar fracture growth in a non-preferred direction.

It is evident that the newly generated fractures have created a water flow network. The connected fracture zone, consisting primarily of fractures of various dimensions, is more permeable and acts as an important flow conduit. For more information on how the inrush pathway forms, let’s look at the horizontal fluid flow along the floor at the moments before and after the pathway forms (Fig. 5). Before the pathway develops, the distribution of fluid flow is relatively smooth, with small fluctuations caused mainly by mining-unloading-induced elastic deformation and discrete local damage. Afterwards, the magnitude of flow jumps and the peak flow in the coal floor reaches about 7800 m3/h. Violent fluid flow fluctuations occur, due mainly to fracture propagation and coalescence in the stressed strata where the floor rock mass has translated from water-restraining strata to outburst pathway.

Figure 6 illustrates a simplified geological model of an inrush through a collapse column. Given a water-conductive column and a damaged floor zone, the effective thickness of the aquitard rock mass is H. This is a concrete manifestation that the collapse column shortens the distance between the coal seam and the aquifer and provides the shortest and the most critical inrush pathway. If the aquifer water breaks through the damaged zone, water inrush will occur.

As a coal seam is mined, when the floor strength is reached or exceeded, damage may occur in a certain range of the working face floor rock mass. The depth of the damaged floor zone caused by mining is h:

In this formula, \({x_a}\) is the length of the yield zone for the coal seam, which can be measured, and \(\varphi\) is the internal friction angle of the floor rock mass. Calculation of the depth of the floor failure zone assumes that the floor rock mass is uniform, with no cracks (Zhang et al. 1997; Sun 2006). Besides the depth of the damaged zone, the inrush risk is directly determined by H, because the presence of a water-conducting collapse column can cause the aquifer water pressure to increase closer to the damaged zone. The stress distribution and water pressure distribution that governs the model’s behaviour was simulated without considering progressive fracturing (Fig. 7). It was shown that the pressurised water evidently lifts up the coal seam floor, while mining causes stress redistribution around the mine opening and the collapse column. However, as long as the key block (the square region marked with a red dashed line in Fig. 7) is not destroyed, water inrush will not occur.

A brief analysis of an unstable failure of the key region was performed using the limit equilibrium method. The risk of an inrush depends on the failure of the square regional rock mass due to mining and the water pressure. In the zone, a differential unit is chosen with a depth, \(dz\), with the stress state illustrated in Fig. 8. The H in Fig. 8 corresponds to the vertical profile of H in Figs. 6 and 7. In Fig. 8, L is the length of the working face. It is subjected to water pressure at the bottom and horizontal stress from both sides. The upper part is the damaged floor zone where is subjected to less stress, so that here, the stress in the upper part is supposed to be zero. To keep the key region unbroken and unaltered, the condition required to keep balance in the direction z for the unit is:

Then Eq. (3) can be obtained:

According to the Mohr–Coulomb criterion, the broken rock mass should follow the limit equilibrium condition:

If \(\left( {1+\sin \varphi } \right)/\left( {1 - \sin \varphi } \right)=\lambda ,\) then:

This leads to Eq. (6):

And when z = 0, \({\sigma _z}\) = 0, and \(A=C \times ctg\varphi\), Eq. 7 is attained:

When z = H and \({\sigma _z}=p\), the limited water pressure for an effective aquitard can be obtained by:

If water pressure from the collapse column exceeds the limited water pressure, water inrush may occur, so precautionary measures should be taken. Conversely, a stronger limited water pressure promotes safer mining. From Eq. 8, we can derive the limited thickness of the aquitard for a water inrush associated with a water-conductive collapse column under a constant water pressure:

where C is the cohesion of the water-restraining rock layer; L is the length of working face, and h c is the height of the water-conductive collapse column.

Equation 9 shows that the limited thickness of the aquitard is related to natural factors, such as the height of the water-conductive collapse column, the strength of rock floor mass, and the water pressure. Based on the above simulation and limited equilibrium analysis, a water inrush is inevitable if the collapse column is 30 m high and the aquifer has a hydraulic pressure of 3.0 MPa. In the following sections, the influence of natural factors on the formation of a water inrush pathway is numerically investigated.

The Influence of the Height of the Collapse Column and the Mechanical Strength of the Aquitard

Generally, the rock mass between the aquifer and the coal seam is the original aquitard. However, the effective thickness of the aquitard can be reduced by the existence of geological discontinuities (e.g. the water-conductive collapse columns) and the mining-induced fracture zone. Thus, the effective thickness of the aquitard in the coal floor is often considered as the distance from the top of the underlying collapse column to the bottom of the mining-induced fracture zone. When the hydraulic pressure is kept at a constant of 3.0 MPa, a larger collapse column height reduces the effective aquitard thickness. For a constant floor strata strength, the risk of an inrush increases with increasing collapse column height. This is why geologic discontinuities are so important. Considering the depth of the damaged zone in the coal seam floor, the effective thickness of the aquitard is close to or less than the depth of the damaged zone when the height of the collapse column is greater than 35 m. If the height of the collapse column exceeds 35 m, water inrush will definitely occur, even if the strength of the floor strata is high (Table 2).

The strength of the floor strata indirectly determines whether the aquitard survives, since it influences how the floor strata is damaged by mining. Previous research (Zhang et al. 1997) revealed that a mining-induced fracture zone in a coal floor with a medium strength (f c0 = 20 ~ 70 MPa) was 2–3 times deeper than that with a high strength (f c0 > 70 MPa), which indicates that the depth of the mining-induced fracture zone is reduced as the mechanical strength of the coal floor increases. Table 2 shows that the risk of water inrush rises when the floor has less mechanical strength, which simply makes sense, since a rock mass with a greater mechanical strength is more difficult to destroy.

The Influence of Pressure Magnitude in the Aquifer

The aquifer at the bottom of the model is the water source and hydraulic power for inrush events. Based on a geological investigation of an inrush-related collapse column, Gao et al. (1996) divided the effect of confined water into four aspects: (1) mechanically acting to fracture the rock mass; (2) gradually softening the rock mass, especially unconsolidated fine-grained sediment; (3) splitting natural geologic discontinuities, such as fractures and faults; and (4) washing and thereby broadening the pathway. In this study, the combined effects of the redistributed stresses induced by mining and the aquifer’s hydraulic pressure were found to indirectly determine whether the aquitard strata would remain intact.

The stress state in fluid-saturated rock is determined from elasticity equations, and failure is assumed to occur when the conventional effective stress exceeds the strength of the rocks (Jaeger and Cook 1963). This point is assumed to be the location of the initial fracturing or fracture growth. Expanding on Terzaghi’s early experiments (1943) with soils and saturated concrete, the influence of hydraulic pressure on brittle failure indicates that the magnitude of hydraulic pressure at the crack tip contributes directly to the strain energy release rate for tensile fracture extension. Our numerical results (Table 3) shows that the risk of water inrush rises with the magnitude of the hydraulic pressure in the aquifer. No inrush pathway formed when the hydraulic pressure in the aquifer was set at 1.0 MPa, but when the hydraulic pressure was increased to 3.0 and 5.0 MPa, one or more inrush pathways could form.

A Case of Water Inrush Related to a Collapse Column

Geologic Conditions of the Fangezhuang Coal Mine

In June 2, 1984, the most serious water inrush disaster in China occurred during the mining of working face #2171 of coal seam #7, in the Fangezhuang mine in the Kailuan coalfield (north China). The peak inflow was about 2053 m3/min. Based on numerous investigations (drillings, geophysical, and hydrogeological tests), it was concluded that the disaster was caused by an underlying water-conductive collapse column (Fig. 9), which was confirmed to be 50 m in diameter and 280 m in height. The collapse column cut through the coal floor from the Ordovician limestone. Data from borehole logging reveals that the collapse column was fully weathered and filled with very soft interstitial material, with an average porosity of 12.6%. The porosity in the upper half of the column reached about 21%, which is typical for a collapse column with strong water-conductivity. The collapse column was fully saturated, with a hydraulic pressure of about 9.0 MPa (Liu et al. 2009; Zhu and Wei 2011).

Numerical Model

A numerical model based on the geologic conditions was created (Fig. 10). The domain was 600 m × 450 m, with a mesh that contained 600 × 450 = 270,000 elements. A compressive vertical stress (σ v ) of 5.2 MPa was uniformly imposed on the top boundary to represent the stress induced by the overburden strata. Normal displacements were constrained on the right, left, and bottom boundaries. Plain strain was assumed for this calculation and, for the fluid flow analysis, a specific hydraulic pressure of 9.0 MPa was set for the limestone strata. Published physico-mechanical parameters (Liu et al. 2009) used in the model are listed in Table 4. The working face was allowed to advance until the coal pillar was 45 m from the collapse column, at which point, the water inrush occurred. In the mine design, a 45 m long coal pillar was used as a safety pillar to prevent water inrush from the collapse column.

Numerical Results

The distribution of shear stress and strata damage is shown in Fig. 11. Initially, the pillar is safe and the coal seam floor is intact although there is evident stress concentration. As mining advanced in coal seam #7 about 40 m, the water-restraining pillar was partially damaged, but it still effectively resisted the confined water pressure. When mining had advanced 60 m, the disordered failure elements together destroyed the pillar and the floor strata. Based on the failure mode, the following triggers contributed to the formation of the water inrush pathway: (1) due to the weakness of the interstitial material in the collapse column and the high hydraulic pressure, the unconsolidated fine-grained sediment in the column was eroded, which both reduced the water-restraining capacity and enabled water to rise up to the coal seam; (2) the safety pillar was weakened and partially damaged due to the mining-induced unloading effect; and (3) the integrity of the water-restraining floor was relatively poor, which caused an abnormally large damage zone to form. Under coal seam #7, there are two thin coal seams, #9 and #12. Since the mechanical strength of coal is much less than that of sandstone and shale, these coal seams further reduced the macroscopic strength of the floor strata. Consequently, incorporating the mining-induced stress redistribution, serious floor damage occurred, particularly near coal seam #12 at a level of − 390 m.

To get additional information about the formation of the inrush pathway in the model, the fluid flow values at a series of elements horizontally along the floor from the open-off cut to the edge of the collapse column, just before and after the formation of the inrush pathway, were incorporated (Fig. 12). Before the pathway formed, the magnitude of the fluid flow fluctuated within a narrow range, with slight variations as mining-induced fractures developed in the floor. However, after the pathway formed, the fluid flow rose dramatically, especially the fluid flow elements located between the working face and the collapse column.

Conclusions

The influence of collapse column height, mechanical strength of rock in coal floor, and hydraulic pressure in the aquifer on the risk of water inrush related to a collapse column was numerically investigated. The height of a water-conductive collapse column can directly reduce the effective thickness of aquitard strata, thereby increasing the risk of water inrush. The strength of the floor strata helps indirectly determine the amount of floor strata damage that occurs and thus, whether the aquitard can be destroyed. The aquifer is the source of both the water and hydraulic power. Therefore, the hydraulic pressure is considered to be the other mechanical source that indirectly determines whether the aquitard strata can be destroyed. Our investigation showed that the formation of the inrush pathway evolves as the floor strata is damaged. Although some of the conclusions that result may be common sense, the numerical results provide a better understanding of the effect of the mining-induced stress redistribution as well as fracture initiation, propagation, and coalescence as the water inrush pathway forms, as natural cases are often situated in complex geologic conditions.

The results of the simulations support multiple factors contributed to the serious Fangezhuang mine water inrush disaster. Based on the failure mode of the numerical results, three processes contributed to the formation of the inrush pathway: (1) the unconsolidated fine-grained sediment in the collapse column eroded; (2) the safety pillar was weakened due to the unloading effect; and (3) the coal seam and the floor rock mass were penetrated by the collapse column, destroying the integrity of the coal seam floor, which disturbed the stress field that should have been regularly distributed.

Finally, we know there is still considerable room for future improvement in understanding the water inrush mechanisms related to karst collapse column. For example, artificial grouting reinforcement of the coal floor may affect water inrush. As another area of future study, 3D simulations should be considered to more accurately capture the fracturing pattern of the water inrush pathway, because of the three-dimensional geometry of the karst collapse column.

References

Dong D, Sun W, Xi S (2012) Water inrush assessment using a GIS-based Bayesian network for the 12-2 coal seam of the Kailuan Donghuantuo coal mine in China. Mine Water Environ 31:138–146

Du B (2012) Fathering practice of hidden water inrush subsided column in Jiulong coalmine, Fengfeng mining area. Coal Geol China 24:31–35 (Chinese)

Gao Y, Yu Y, Niu X (1996) The mechanical actions of water pressure on water inrush from coal floor. Coal Geol Expl 24:37–39

Gross MR (1993) The origin and spacing of cross-joints: examples from the Monterey Formation, Santa Barbara, California. J Struct Geol 15:737–751

Guo D, Sheng Y, Jin X (1994) Basic principles and methods for survey of karst pillars. J Chin Coal Soc 19:626–634 (Chinese)

Jaeger JC, Cook NG (1963) Pinching-off and disking of rocks. J Geophys Res 68:1759–1765

Jia G, Hu K (1989) The formation and distribution of collapse columns in north-China-type coalfields. Carsologica Sinaca 8:261–267

Li X, Gao Y (2003) Damager analysis of floor strata. Chin J Rock Mech Eng 22:35–39 (Chinese)

Li Y, Peng S (2006) Classifications and characteristics of karst collapse columns in north China coal fields. Coal Geol Explor 34:53–56

Li J, Zhou W (1989) Geohydrological environment and prediction of water outburst through collapse columns in coalfield of North China. Carsologica Sinaca 8:192–199

Li L, Tang C, Li G (2012) Numerical simulation of 3D hydraulic fracturing based on an improved flow–stress–damage model and a parallel FEM technique. Rock Mech Rock Eng 45:801–818

Liu Z, Xiong C (2007) Numerical simulation study on water inrush mechanism from collapse column. Chin J Rock Mech Eng 26:4013–4018 (Chinese)

Liu H, Yang T, Zhu W, Yu Q (2009) Investigation on failure and water inrush from roof of 5th coal seam in Fangezhuang coal mine. J Min Safety Eng 26:332–335 (Chinese)

Pan P, Feng X, Hudson J (2012) The influence of the intermediate principal stress on rock failure behaviour: a numerical study. Eng Geol 124:109–118

Sun W (2006) Study on the influence of fault to floor water-inrush. Shandong Univ of Science and Technology, Qingdao (Chinese)

Tang CA, Kaiser PK (1998) Numerical simulation of cumulative damage and seismic energy release during brittle rock failure—part 1: fundamentals. Int J Rock Mech Min Sci 35:113–121

Tang CA, Tham LG, Lee PKK (2002) Coupled analysis of flow, stress and damage (FSD) in rock failure. Int J Rock Mech Min Sci 39:477–489

Terzaghi K (1943) Closure of “earth pressure and shearing resistance of plastic clay: a symposium: liner-plate tunnels on the Chicago (IL) subway”. Nucl Phys 4:91–111

Viero DP, Valipour M (2017) Modeling anisotropy in free-surface overland and shallow inundation flows. Adv Water Resour 104:1–14

Wang J, Park H (2003) Coal mining above a confined aquifer. Int J Rock Mech Min 40:537–555

Wang T, Zhou W, Chen J (2014) Simulation of hydraulic fracturing using particle flow method and application in a coal mine. Int J Coal Geol 121:1–13

Wu Q, Wang M (2006) Characterization of water bursting and discharge into underground mines with multilayered groundwater flow systems in the north China coal basin. Hydrogeol J 14:882–893

Xu J, Kong Y, Tong H (2006) The mechanism and criterion of karst collapse column activating to conduct water under weak runoff state. Carsologica Sinaca 25(1):35–39

Yin S, Wang S, Wu Q (2004) Water inrush patterns and theoretic criteria of karstic collapse columns at mine area of north China. Chin J Rock Mech Eng 23:120–123 (Chinese)

Yin S, Wu Q, Wang S (2005) Water-bearing characteristics and hydro-geological models of karst collapse columns in north China. Chin J Rock Mech Eng 24:77–82 (Chinese)

Zhang J, Zhang Y, Liu T (1997) Flow in coal seams and water inrush from seam floor. The Geological Publ House, Beijing (Chinese)

Zhong Y (2001) Studies on integrate technology of water prevention in Kailuan mines. China Coal Industry Publ House, Beijing (Chinese)

Zhu W, Wei C (2011) Numerical simulation on mining-induced water inrushes related to geologic structures using a damage-based hydromechanical model. Environ Earth Sci 62:43–54

Zuo J, Peng S, Li Y (2009) Investigation of karst collapse based on 3-D seismic technique and DDA method at Xieqiao coal mine, China. Int J Coal Geol 78:276–287

Acknowledgements

The study was jointly supported by the National Natural Science Foundation of China (Grants 51479024 and 51404067), the Fundamental Research Funds for the Central Universities (Grant 160104005), and the Anhui Province Science and Technology Project of China (Grant 1604a0802109). The authors are grateful for this financial assistance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, H., Li, L., Li, Z. et al. Numerical Modelling of Mining-induced Inrushes from Subjacent Water Conducting Karst Collapse Columns in Northern China. Mine Water Environ 37, 652–662 (2018). https://doi.org/10.1007/s10230-017-0503-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10230-017-0503-z