Abstract

Pressurized confined water below coal seams are serious threats to mining. The conventional water inrush coefficient method fails to accurately assess the risk of floor water inrush under some specific conditions, such as high water pressure and low water yield in the source aquifers. Large amounts of water inrush data including water inrush flow rate, water inrush coefficient (T s ), floor aquiclude thickness (M), and water abundance, were collected and statistically analyzed. The results indicated that inrushes mostly occurred when M was less than 30 m and that the critical T s increased linearly with M. The occurrence of a water inrush and water inrush yield amount (Q in L/s) were related to both the values of T s and the unit water inflow (q in L/(s m)). In addition, 97.7% of the large- and medium-sized inrush events occurred when q > 2 L/(s m) and only a small proportion (3.2%) of the small-sized inrushes happened when q < 0.1 L (s m). T s , M and q were comprehensively analyzed and used to evaluate vulnerability to floor water inrush. By analyzing the distribution of water inrush points and the scale of water inrush events, the vulnerability was divided into four levels (safe, moderately safe, potentially dangerous, and highly risky) based on T s –M and T s –q models. Successful application of these models in the Huaibei mining area proved that they are feasible in practice. The T s –M and T s –q charts can be used independently or jointly. These new methods should improve the accuracy of predictions and evaluations during deep exploitation where the aquifers are often characterized with high pressure but low water abundance. The results could also help reduce the amount spent on mine water prevention and control.

Zusammenfassung

Gespannte, unter Druck stehende Grundwässer im Liegenden von Kohleflözen stellen für dortigen Bergbau ein erstzunehmendes Risiko dar. Die konventionelle Wassereinbruch-Koeffizienten-Methode versagt unter bestimmten Bedingungen bezüglich einer genauen Vorhersage von Liegendwassereinbrüchen, so bei hohen Wasserdrücken und geringer Ergiebigkeit der betroffenen Grundwasserleiter. Für die vorliegende Arbeit wurden große Datenmengen zu Wassereinbrüchen zusammengetragen und statistisch untersucht, darunter Angaben zur Zuflussmenge, zum Wassereinbruchskoeffizienten (Ts), zur Sohlstauermächtigkeit (M) und zur Wassermenge. Die Ergebnisse zeigen, dass Einbruchsereignisse überwiegend bei M < 30 m auftraten und dass der kritische Ts linear mit M anstieg. Das Auftreten von Wassereinbrüchen sowie die Zuflussmenge (Q in L/s) wurden in Beziehung gesetzt zu TS sowie zur spezifischen Zuflussmenge (q in L/(s∙m)). 97,7% der großen und mittleren Wassereinbrüche traten mit q > 2 L/(s∙m) auf, während nur ein geringer Anteil (3,2%) der kleineren Einbrüche q < 0.1 L/(s∙m) aufwies. Ts, M und q wurden umfassend analysiert und die Ergebnisse genutzt, um die Anfälligkeit gegenüber Liegendwassereinbrüchen zu bewerten. Durch Auswertung der Verteilung von Wasserzutrittspunkten sowie der Schwere der Einbruchsereignisse wurde die Vulnerabilität auf Basis von Ts-M- und Ts-q-Modellen in vier Klassen unterteilt (sicher, mäßig sicher, potentiell gefährlich, hoch gefährlich). Die erfolgreiche Anwendung dieser Modelle in der Bergbauregion von Huaibei ist Beleg für deren Praktikabilität. Die Ts-M- und Ts-q-Diagramme können unabhängig voneinander oder auch kombiniert genutzt werden. Es wird erwartet, dass die neuen Methoden die Genauigkeit von Vorhersagen und Bewertungen in Bezug auf Bergbau in großen Teufen, bei dem häufig Aquifere mit hochgespannten Wässern und geringer Ergiebigkeit auftreten, verbessern. Die Ergebnisse sollten auch dazu beitragen, die Aufwendungen für Prävention und Beherrschung von Wassereinbrüchen zu verringern.

Resumen

El agua presurizada y confinada debajo de las vetas de carbón constituye una seria amenaza para la minería. El método convencional del coeficiente de irrupción de agua falla para predecir con precisión el riesgo de irrupción de agua a través del piso bajo algunas condiciones específicas como son la alta presión del agua y el bajo contenidoo de agua en los acuíferos. Se colectaron y analizaron estadísticamente grandes cantidades de datos incluyendo los flujos de agua, los coeficientes de irrupción de agua (Ts), el espesor del piso (M) y la abundancia de agua. Los resultados indicaron que las irrupciones ocurrieron principalmente cuando M fue menor a 30 m y que el TS crítico se incrementó linealmente con M. La ocurrencia de la irrupción de agua y la cantidad de agua involucrada (Q en L/s) fueron relacionados a los valores de Ts y al flujo de agua (q en L/(s∙m)). Además, 97,7% de los eventos de media y gran escala ocurrieron cuando q > 2 L/(s∙m) y sólo una pequeña porción (3,2%) de los eventos de pequeño tamaño ocurrieron cuando q < 0,1 L/(s∙m). Ts, M y q se analizaron comprensivamente y se usaron para evaluar la vulnerabilidad a la irrupción de agua desde el piso. Analizando la distribución de los puntos de irrupción de agua y la magnitud de los eventos de irrupción de agua, la vulnerabilidad fue dividida en cuatro niveles (seguros, moderamente seguros, potencialmente peligrosos y altamente peligrosos) basado en los modelos Ts-M y Ts-q. La aplicación exitosa de estos modelos en el área minera Huaibei probó que los mismos pueden ser aplicados prácticamente. Las tablas Ts-M y Ts-q pueden ser usadas juntas o independientemente. Estos nuevos métodos deberían mejorar la precisión de las predicciones y las evaluaciones durante la explotación en profundidad donde los acuíferos están frecuentemente caracterizados por alta presión pero baja abundancia de agua. Los resultados podrían también ayudar a reducir el dinero gastado en la prevención y el control de las irrupciones de agua.

摘要

煤层下伏承压含水层威胁煤矿安全开采。传统突水系数法不能精确评价突水含水层高水压却低富水性等特定条件下的突水风险。收集和统计了突水量、突水系数(Ts)、底板隔水层厚度(M)、富水系数等相关突水材料。结果表明,多数突水发生于底板隔水层厚度小于30m,临界突水系数(Ts)随底板隔水层厚度(M)增加而线性增大。突水及突水量(Q,单位L/s)同时与突水系数(Ts)和单位涌水量(q,单位L/( s∙m)有关。97.7%的大型和中型底板突水事故发生于单位涌水量大于2 L/( s∙m)的含水层,仅少量突水(3.2%)发生于单位涌水量小于 0.1 L/(s∙m)的含水层。突水系数、底板隔水层厚度和单位涌水量以用综合评价底板突水脆弱性。通过分析突水点分布和突水规模,基于Ts-M和 Ts-q模型,底板突水脆弱性被分为四个等级(安全、中等安全、潜在危险和高度危险)。该模型在淮北矿区的成功应用证明了方法的可行性。Ts-M和Ts-q图可单独或联合应用。该方法可提高深部高水压、低富水性含水层的突水危险预测精度,有助于减少防治水成本。

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

More than 90% of China’s coal mines are seriously threatened by pressurized confined water below the coal seam (Li et al. 2015; Shi and Singh 2001; Wu et al. 2011). More significantly, the hydrogeological conditions become increasingly complicated as mining is extended to greater depths (Coalfield Geological Central Bureau of China (CGCBC) 2000; State Administration of Coal Mine Safety of China (SACMSC) 2009; Zhou and Li 2001; Hu et al. 2014). Scientific prediction and evaluation of water inrush is urgently needed to reduce the occurrence of accidents and the expense of unnecessary protective measures (Qiao et al. 2014).

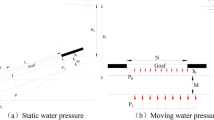

Floor water bursting from underlying confined aquifers has been studied for over 80 years, for in the 1930s, Slesarev studied the failure mechanism of coal seam floor and deduced formulas to calculate the safe water pressure and floor thickness by assuming that the floor behaved like a beam fixed at both ends (Gao 2013; Wang and Liu 2007). The water inrush coefficient (T s ), defined as the water pressure that can be sustained by the unit aquiclude thickness of the coal seam floor, was first put forward at the Jiaozuo Mine Water Control Conference in 1964 (Liu 2009). Since then, the method has experienced two major revisions and developments (Liu 1981; Zhou 1997). In 1979, the effect of mine pressure on the aquiclude was incorporated into T s for the first time, and the thickness of the mining-induced fissure zone (CP), which is typically measured by in-situ water pressure testing, was advised to be subtracted from the total aquiclude thickness (Guan 2012). The second revision introduced the strength ratio coefficient (SRC) for different rock layers by considering the relationship between the water-resisting ability of each rock layer and its strength (Qiao et al. 2009; Yao et al. 2012). The water inrush coefficient method has been widely used to predict and assess floor water inrush risks. However, it is not accurate under some specific conditions, such as when the underlying aquifers have high water pressure and low water yield properties, conditions that are being encountered more frequently as mining depth increases.

Various vulnerability assessment theories and methods for assessing floor water inrush have been developed, including the: “down three perturbed zones theory (water-conducting fractured zone, waterproof zone, confined water up-flowing zone)” (Li 1999); key-strata theory (Qian et al. 1996); nonlinear model (Yang et al. 2005); strong seepage theory (Ye and Liu 2005); seepage-flow conversion theory (Qiao et al. 2013); fractal theory (Wang et al. 2017); numerical and analog simulation methods (Kuznetsov and Trofimov 2002; Yin et al. 2016; Zhang et al. 2014); and various laboratory experiments (Pang et al. 2014; Yu et al. 2016). Together, these laid the foundation for systematic acquisition of hydrogeological parameters and evaluation of water inrush risks.

In addition, many methods have been developed to address the limited accuracy of the water inrush coefficient method, including the: “three-maps-two predictions” method (Wu et al. 2007); vulnerable index method (Wu et al. 2009); artificial neural network (ANN) (Wu et al. 2015); geographic information system (GIS) and grey relational analysis (GRA) (Qiu et al. 2017; Wu et al. 2008); analytic hierarchy process (AHP) method (Li et al. 2015; Wu et al. 2017); fluid–solid coupled numerical model (Chen et al. 2017); and damage-based hydromechanical model (Zhu and Wei 2011). Also, factors that influence inrushes, such as the thickness of the floor aquiclude, rock mass integrity and expansive limits, and anti-permeability strength, have been studied (Duan et al. 2012; Meng et al. 2012; Wang et al. 2012; Wu et al. 2017). However, few have researched the effect of specific capacity on water inrush through the mine floor (Qiao et al. 2009) and the relationship between the thickness of the aquiclude and its water-resisting ability per unit thickness.

The conventional water inrush coefficient method is not very appropriate for deep exploitation. In this study, a large volume of data was collected and analyzed to develop the relationships between floor water inrush vulnerability and water inrush coefficient (T s ), unit water inflow (q), and aquiclude thickness (M) to construct T s –q and T s –M assessment charts to evaluate floor water inrush vulnerability in deep exploitation.

Limitations on Using the Water Inrush Coefficient

The conventional water inrush coefficient method is based on statistical analysis of long-term inrush data and stipulated in Regulation for Coal Mine Water Prevention and Control, China (SACMSC 2009). The water inrush coefficient is expressed as an empirical formula:

where T s is the water inrush coefficient (MPa/m), P is the water pressure sustained by the coal seam floor (MPa), and M is the thickness of the coal floor aquiclude (m). The formula applies to both coal mining and tunneling (Wu et al. 2013).

As indicated by SACMSC (2009), inrushes tend not to occur if water inrush coefficients are less than 0.06 MPa/m in areas with geological structures and less than 0.10 MPa/m in areas without geological structures. Otherwise, the areas are considered to be prone to inrushes.

Since T s accounts for some of the characteristics of the underlying aquifer and aquiclude, it has played a key role in floor water inrush vulnerability assessment. Meanwhile, the formula (Eq. 1) is not only simple, but practical as well. Results from the inrush coefficient method are generally consistent with actual conditions when exploitation safety is evaluated at water pressures less than 3 MPa. However, mining is now taking place at depths up to 1200 m (Wu et al. 2017) with water pressures that range from 7.3 to 13.0 MPa. Consequently, the calculated inrush coefficient ranges from 0.144 to 1.256 MPa/m, while the limit for safe exploitation is 0.06–0.1 MPa/m (SACMSC 2009).

However, as shown in supplementary Table 1, at some panels where T s was higher than 0.10 (e.g. panel 91002 of the Chazhuang Coal Mine in Feicheng, T s = 0.16 MPa/m for the Ordovician limestone; panel 10404 of the Baizhuang Coal Mine, T s = 0.17 MPa/m for the Ordovician limestone; panel N7109 in the Guozhang Coal Mine in Zibo, T s = 0.48 MPa/m for the 4th Taiyuan limestone; and panel 142 of the Langquan Coal Mine in Zibo mine zone, T s = 0.18 MPa/m for the Ordovician limestone), the inrush amounts were small during actual exploitation. In addition, no inrushes occurred at panel III616 in the Huaibei Yangzhuang Coal Mine (T s = 0.11 MPa/m for the 1st, 2nd, and 3rd Taiyuan limestone, where M = 50.0 m) and panel 1088 in the Zibo Xiazhuang Mine (T s = 0.14 MPa/m for the Ordovician limestone, where M = 50.9 m), even though T s exceeded the safe range, due to the presence of a thick aquiclude. However, large inrush accidents have occurred at panels where q was large and M was small (see No. 9 and 10 in supplemental Table 1).

The conventional water inrush coefficient method only considers the aquifer’s water pressure, whereas the unit water inflow (q) of the aquifer is neglected. In addition, the effective thickness of the aquiclude is not given enough consideration. When the Ordovician, Taiyuan, and Xu limestone strata are at greater depths, fracture development is often poor, resulting in small unit water inflow, poor aquifer connectivity under confined pressure conditions, and consequently few, if any, inrushes. Even with a high T s value, the probability of an inrush was still very small when the effective thickness of the aquiclude was very large. Thus, the possibility of an inrush cannot just be considered to be a simple reciprocal relationship with the effective aquiclude thickness. The critical water inrush coefficient changes with the aquiclude thickness.

Water Inrush Assessment Based on T s –M and T s –q

T s –M Model

The mining areas in eastern China such as Jiaozuo, Zibo, Feicheng, and Huaibei (Fig. 1), have been exploited for over 40 years. The water inrush sources are the Ordovician, Taiyuan, and Xu limestone aquifers, which underlie the coal seams. In earlier times, the water pressure of the limestone on the mining panels were generally less than 3 MPa because of the shallow mining depths, with most ranging from 1 to 2 MPa. The limestone water pressure increases with depth, and mining under high confining pressures can cause damage to the mine floor. If the intrusion height of the limestone was also counted, the calculated inrush coefficient would far exceed the upper limit stipulated in the Standard for Exploration and Evaluation of Hydrogeology, Engineering Geology and Environment Geology in Coal Beds and Coal Mine Water Prevention and Control Regulations (State Administration of Work Safety of China (SAWSC) 2008; SAWSC and SACMSC 2009).

There might be severe floor water inrushes in other mining areas with thin aquicludes, even if the water inrush coefficient is less than the critical values of 0.06 and 0.10 MPa/m. The statistics of 328 inrush cases in eastern China (Jiaozuo, Zibo, Feicheng, and Huaibei mining areas) are presented in Supplemental Table 2. A scatter plot was made to analyze the relationship between the inrush vulnerability and water inrush coefficient, with effective aquiclude thickness (M) as the abscissa and water inrush coefficient (T s ) as the ordinate (Fig. 2). The points of panels with inrushes are mainly distributed in areas where the thickness of the coal floor aquiclude was less than 30 m. The proportion of water inrush points with M < 30 m and T s < 0.06 MPa/m is 48.3%, nearly half of the total cases. Further, water inrush still occurred when the inrush coefficient was as low as 0.012 MPa/m, much less than the suggested critical value. The floor aquiclude thickness of panels without an inrush mainly ranged from 30 to 80 m, and accounted for 98.9% of all non-water inrush panels. Even though there were faults in panels where the aquiclude thickness was over 80 m and the water inrush coefficient exceeded the critical value of 0.06 MPa/m, no inrush events occurred. These indicate that the water inrush vulnerability is closely related to the aquiclude thickness. Mines with thinner aquicludes are more vulnerable to water inrushes.

Mining-induced pressure damage to the floor and original fractures in the aquiclude can cause floor water inrushes when the aquiclude is thin. As the aquiclude thickness increases, the existence of a sufficient protective layer is critical in resisting floor water invasion. For a specific panel, at a constant coal seam thickness, mining depth, and crustal stress, the floor damage zone and original progressive intrusion height are determined by the “down three perturbed zones theory”. A thicker floor aquiclude provides better protection, and vice versa. The critical inrush coefficient would exceed the suggested 0.06 MPa/m with greater floor aquiclude thickness and can be expressed with the linear relationship: T s,c = αM + β. The relationship between critical inrush coefficient T s,c and M can be expressed by the following:

Hence, the water inrush assessment method can be represented by Fig. 3, of which the abscissa is the floor aquiclude thickness and the ordinate is the floor water inrush coefficient. The straight lines represent the critical water inrush coefficients and divide the graph into a safe zone and a water inrush zone. Thus, the assessment of floor water inrush at any panel can be predicted by projecting the M and T s values onto Fig. 3.

Ts–q Model

For an inrush to occur in a coal panel, a water source and flow path(s) are required. To take the extreme case, an aquifer can be considered to be an aquiclude when it contains no water, making an inrush unlikely, even when the inrush coefficient exceeds the critical value. In deep mines, crustal stress increases with depth, resulting in fracture closure, a decrease in the specific capacity of the karst aquifer, and poor karst water dynamics and karst development. So, the amount of water in fractured karst aquifers decreases with depth (Qiao et al. 2009). As a result, inrushes were not observed in some places where the critical water inrush coefficient was clearly exceeded. Data describing 216 water inrush cases in the Feicheng, Jiaozuo, and Zibo mining areas were collected (Fig. 4), and statistically analyzed. The relationship between inrush vulnerability, water inrush coefficient, and aquifer water abundance was systematically analyzed to construct the T s –q water inrush assessment chart.

Table 1 presents an analysis of the 216 inrush cases (Fig. 4), consisting of 87 minor inrushes (inflow rates ≤60 m3/h), 114 medium inrushes (inflow rates between 60 and 600 m3/h), and 15 major events (inflow rates >600 m3/h). There were few inrush events when T s < 0.04 MPa/m. There was no water inrush at T s < 0.01 MPa/m. Major and medium inrushes mainly occurred when q > 2 L/(s m), accounting for 97.7% of the total major and medium inrush cases. Minor inrushes occurred when 0.1 < q < 2 L/(s m). Few minor inrush events, accounting for 3.2% of the total, were observed when q < 0.1 L (s m).

As shown in Fig. 4, most of the minor inrush points were on the left side of the straight line q = 2 L/(s m) and the water inrush points corresponded mainly to T s values ranging from 0.00 to 0.25 MPa/m. Inrush inflow was less when the abscissa values were closer to zero. Only a few minor inrush events occurred when T s < 0.04 MPa/m. Similarly, when q < 0.1 L (s m), there were few inrush cases, and there were none when q < 0.06 L (s m). When T s < 0.04 MPa/m and q > 2 L/(s m), more medium water inrushes occurred, whereas there were few inrush events when T s < 0.01 MPa/m. This is because high crustal stress results in fracture closure and therefore low water abundance. Crustal stress increases as depth increases and is in a linear relation with the water pressure of the fractured karst aquifer. Under the same aquiclude conditions, deep coal seam exploitation demonstrated a significantly greater inrush coefficient than shallow exploitation, but less water in the aquifer.

Based on the distribution of water inrush points, the scale of water inrushes, and the above analysis, a risk assessment model of floor water inrush was established (Fig. 5). The risk was graded into four classes: safe, moderately safe, potentially dangerous, and highly risky. In the T s –q chart, the ordinate is the water inrush coefficient and the abscissas is the unit water inflow of the aquifer. By combining the abundance index (q) of the aquifer with the calculated inrush coefficient of the mine area, one can project site-specific data onto Fig. 5 and thus approximate the inrush vulnerability of the area based on the positions of the points in the figure.

Application of T s –M and T s –q in Huaibei Mining Area

In the Huaibei mining area, which is located north of Huaihe, Anhui Province, China (Fig. 1), the No. 10 coal seam was exploited with floor altitudes from −637.4 to −455.0 m in the Taoyuan, Yangliu, Yuandian, Zhuxianzhuang, and Liudian mines. The aquifer consists of the Taiyuan Formation limestone, while the aquiclude directly under the coal seam comprises a massive mudstone interbedded with fine siltstone, with strong water resistance. The floor water pressures were between 3.0 and 6.89 MPa.

Eight panels were selected (Table 2). According to the T s –M assessment chart, the polygonal line of Equations (2) and (3) was drawn onto Fig. 3. Then, the T s and M values of the panels were projected to the graph. Points above the line represent panels have a risk of water inrush, and those further from the line are more at risk. Figure 3 shows the T s –M assessment results of the panels in the Huaibei mining area.

The current standard critical water inrush coefficient in the Huaibei Mining Group is 0.07 MPa/m. From Table 2 and Fig. 3 it can be seen that, of the above eight panels, only panel 10414 of the Yangliu mine had a water inrush coefficient less than the critical value. The other seven panels had excessive inrush coefficients. Despite this, according to the T s –M method, safe exploitation was determined for panels: ①1023 and ②1024 of the Taoyuan II Mine, and ⑤1034 and ⑥ 1036 1 of the Zhuxianzhuang II Mine. There was a risk of water inrush found for panels: ④1021 of the Yuandian No. 1 Mine, and the ⑦1044 and ⑧1037 of the Liudian Mine. In other words, these three panels have a risk of water inrush according to both the current water inrush coefficient method and the T s –M method. However, since the Archaean Eon limestone aquifer q index or the maximal water discharge in boreholes were very small for these three panels, the T s –q method was used for further assessment.

The modified parameters for panel 1021 of the Yuandian No. 1 Mine were T s = 0.075 MPa/m and q = 0.0098–0.045 L (s m). The modified parameters for panel 1044 of the Liudian Mine were T s = 0.033 MPa/m, and q = 0.00014–0.024 L (s m); the borehole maximal water discharge was 60 m3/h. For panel 1037 of the Liudian Mine, the modified parameters were T s = 0.023 MPa/m and q = 0.0054–0.024 L (s m). These points were plotted in the T s –q chart (Fig. 5). It can be concluded that although both the water inrush coefficient method and the T s –M method indicated a risk of water inrush, they were still safe due to the small aquifer q value, according to the results of T s –q method.

According to the current standard of the Huaibei Mining Group, seven of the eight selected panels were vulnerable to floor water inrush. However, the T s –M and T s –q methods indicated that all seven panels could be safely mined. In fact, all eight panels were safely mined and a cumulative total of 3.44 million tons of raw coal were produced. Thus, the feasibility of the T s –M and T s –q methods were demonstrated in the Huaibei mining area for the Archaean Eon limestone aquifer floor with its high confined pressure and weak water abundance.

Results and Discussion

T s –q Model

The new model inherits the easy usability of the conventional T s method, and, more significantly, provides a more accurate prediction of the risk of water inrush. The T s –q model takes the inherent property (q) of the aquifer into account, while the conventional T s method does not consider this property. The method can explain, from the perspective of the water inrush source, the phenomena of large inrushes with low T s and high q, and no inrushes with high T s and low q. The vulnerability for floor water bursting was assessed correctly by the new method. Furthermore, water control measures can be recommended in response to each risk level. For example, no pre-treatment is necessary in safe areas but in high risk areas, many essential techniques or means need to be implemented or mining needs to cease. By projecting site-specific data on the Ts–q chart, coal mine technicians can predict the risk of water inrush easily and quickly and take relevant water inrush control measures to reduce unnecessary project costs.

Given the fact that most of the water inrush data collected from practice were medium or small sized, the distribution of large water inrush points is not clear enough. However, based on the available statistical data, the scale on which the medium water inrush points were gathered can be approximated with a polyline, which could be extrapolated when a security coefficient is considered. Areas out of the polyline were known as high risk areas where large or extremely large water inrush occurred. The issue can be better resolved by adding more large inrush data. In addition, the borders of these four risk zones were based on the inrush data collected from the Feicheng, Jiaozuo, and Zibo mining areas. Though the model was applied successfully in the Huaibei mining area, more practical water inrush data is needed to verify and modify the accuracy of the zones.

T s –M Model

The T s –M method incorporates the linear relationship between T s and M. The method explains why there is still water inrush in panels with small M when T s is much less than the critical value of T s = 0.1 Mpa/m. It also provides a more accurate evaluation method of water inrush prediction for t mines similar to the Huaibei mines where panels are characterized by a thick aquiclude under the floor.

In mines or panels whose M < 30 m, the T s –M method is more accurate. For mines with an aquiclude thickness that exceeds 50 m, the T s –M method has greatly enhanced the critical T s value. This new method provides greater critical T s and allows some mines to produce safely. The correlation results of T s – M method have been applied and promoted in the Huaibei mining area and the method is now included in the ‘Water Control and Prevention Standard of Huaibei Coal Mining Group’ as an internal specification for the company. The Ts–M method provides both a theoretical foundation for floor water control and prevention and practical guidance for coal mines in China and other regions that are affected by water inrushes.

The effective thickness of the aquiclude (M) has been considered in the T s method, but it’s not sufficient, as concluded in this paper: the critical condition of water inrush does not remain constant but varies with the value of M. The probable cause of this phenomenon might be the incremental improvement of unit thickness water-resistance caused by the increase of M. However, experiments are still necessary to verify this corollary. Similar to the T s – q method proposed in this paper, it could be applied successfully in the Huaibei mining area because of all of the available data. The T s –M method may require more practical cases to test and correct the zone values.

As demonstrated above, more reasonable predictions can be accomplished by combining unit water inflow (q) and the effective thickness of the aquiclude (M) into the conventional T s method. By observing how the critical T s value changes at different M values from the view of floor water inrush pathways, one can conclude that thicker aquicludes indicate greater critical T s values. The T s –q method is also based on the inrush sources, considering the aquifer’s water pressure and abundance. The possibility and flow of an inrush increases when the aquifer contains more water. The two methods above can improve the accuracy of predictions of the risk and likely severity of water inrushes.

Conclusions

-

1.

Water inrush flow rate (Q), water inrush coefficient (T s ), the effective thickness of the aquiclude (M), and the water abundance in aquifers were collected for 544 water inrush events. Statistical analysis of the data indicated that areas where the floor aquiclude thickness was less than 30 m were prone to inrushes. Due to the incremental improvement of the unit water-resistance, the critical T s was not constant but increased linearly with M, as expressed by the following mathematical expressions: \(\frac{{1}}{{{6000}}}M+0.02\) (when 0 < M ≤ 30 m) and \({0}{.0025}M - 0.05\) (when 30 < M ≤ 80 m). So, it is inappropriate to simply make the critical T s a constant between 0.06 and 0.1 MPa/m. The critical T s should vary with the thickness of the aquiclude.

-

2.

Our results show that the possibility and flow rate of water inrush are related to both the traditional T s , and the amount of water in the aquifer (represented by unit inflow q). 97.7% of the large or medium-sized inrushes occurred when q > 2 L/(s m), whereas small inrushes occurred mainly when 0.1 < q < 2 L/(s m). There were only a few small inrush events, approximately 3.2% of the total inrushes, when q < 0.1 L (s m).

-

3.

The T s –M and T s –q evaluation models were established as improvements to the conventional water inrush coefficient method. The water inrush coefficient, effective aquiclude thickness, and unit water inflow are the main factors that should be used to evaluate the vulnerability of floor water inrush. Based on the distribution of inrush events and the flow of water inrushes on the T s –M and T s –q charts, the vulnerability was divided into four levels: safe, moderately safe, potentially dangerous, and highly risky.

-

4.

Successful application of these evaluation charts in the Huaibei mining area proved that they are effective. Workers can determine risk levels with these two charts, independently or jointly, by simply projecting the site-specific data on the charts. These methods solved major problems with the conventional T s method, such as insufficient evidence, the amount of work required, and the high cost of inrush control, and enhanced the accuracy of predictions and assessment for deep mining inrushes in situations characterized by high water pressure but relatively little water.

References

Chen L, Feng X, Xie W, Zeng W, Zheng Z (2017) Using a fluid–solid coupled numerical simulation to determine a suitable size for barrier pillars when mining shallow coal seams beneath an unconsolidated, confined aquifer. Mine Water Environ 36(1):67–77

Coalfield Geological Central Bureau of China (2000) Coalfield hydrogeology of China. Coal Industry Publ House of China, Beijing (in Chinese)

Duan HF, Jiang ZQ, Zhu SY, Zhao LJ, Liu JG (2012) A expansive limits anti-permeability strength methodology of the coal mine floor water inrush evaluating. Procedia Environ Sci A 12:372–378

Gao MY (2013) Evaluation of water inrush from floor using the Slesarev formula. Chin Mine Eng 42(3):47–48 (in Chinese)

Guan ET (2012) Origin of water bursting coefficient and process of modification. Coal Geol Explor 24(2):30–32 (in Chinese)

Hu X, Wang L, Lu Y, Mei Y (2014) Analysis of insidious fault activation and water inrush from the mining floor. Int J Min Sci Technol 24(4):477–483

Kuznetsov SV, Trofimov VA (2002) Hydrodynamic effect of coal seam compression. J Min Sci+ 38(3):205–212

Li BY (1999) “Down three zones” in the prediction of the water inrush from coalbed floor aquifer theory, development and application. J Shandong Inst Min Technol Nat Sci 18(4):11–18

Li LP, Zhou ZQ, Li SC, Xue YG, Xu ZH, Shi SS (2015) An attribute synthetic evaluation system for risk assessment of floor water inrush in coal mines. Mine Water Environ 34(3):288–294

Liu TQ (1981) The law of surface movement of coalmine and damage of overlying rocks and its application. Coal Industry Publ House of China, Beijing (in Chinese)

Liu QS (2009) A discussion on water inrush coefficient. Coal Geol Explor 37(4):34–37 (in Chinese)

Meng Z, Li G, Xie X (2012) A geological assessment method of floor water inrush risk and its application. Eng Geol 143:51–60

Pang Y, Wang G, Ding Z (2014) Mechanical model of water inrush from coal seam floor based on triaxial seepage experiments. Int J Coal Sci Technol 1(4):428–433

Qian MG, Miao XX, Xu JL (1996) Theoretical study of key stratum in ground control. J China Coal Soc 21(3):225–230 (Chinese)

Qiao W, Li WP, Zhao CX (2009) Water inrush coefficient-unit inflow method for water inrush evaluation of coal mine floor. Chin J Rock Mech Eng 28(12):2466–2474 (in Chinese)

Qiao W, Hu G, Li WP (2013) Experimental study on the convertion from seepage to flow of water inrush aroused by fault activation in fully mechanized top-coal caving. J Min Safety Eng 30(1):30–37 (Chinese)

Qiao W, Li W, Zhang X (2014) Characteristic of water chemistry and hydrodynamics of deep karst and its influence on deep coal mining. Arab J Geosci 7(4):1261–1275

Qiu M, Shi L, Teng C, Zhou Y (2017) Assessment of water inrush risk using the fuzzy delphi analytic hierarchy process and grey relational analysis in the Liangzhuang coal mine, China. Mine Water Environ 36(1):39–50

SACMSC (State Administration of Coal Mine Safety of China) (2009) Interpretation of the regulations of mine water disaster prevention. China Univ of Mining and Technology Press, Xuzhou, pp 227–236 (in Chinese)

SAWSC, SACMSC (2009) Coal Mine Water Prevention and Control Regulations. China Coal Industry Publ House, Beijing, pp 84–85 (in Chinese)

SAWSC (State Administration of Work Safety of China) (2008) Standard for exploration and evaluation of hydrogeology, engineering geology and environment geology in coal beds. China Coal Industry Publ House, Beijing (in Chinese)

Shi L, Singh RN (2001) Study of mine water inrush from floor strata through faults. Mine Water Environ 20(3):140–147

Wang XL, Liu ZX (2007) Mine hydrological geology. Coal Industry Press, Beijing, pp 180–182 (Chinese)

Wang Y, Yang W, Li M, Liu X (2012) Risk assessment of floor water inrush in coal mines based on secondary fuzzy comprehensive evaluation. Int J Rock Mech Min 52:50–55

Wang X, Wang T, Wang Q, Liu X, Li R, Liu BJ (2017) Evaluation of floor water inrush based on fractal theory and an improved analytic hierarchy process. Mine Water Environ 36(1):87–95

Wu Q, Zhang ZL, Ma JF (2007) A new practical methodology of the coal floor water bursting evaluating I: the master controlling index system construction. J China Coal Soc. doi:10.13225/j.cnki.jccs.2007.01.009 (in Chinese)

Wu Q, Xu H, Pang W (2008) GIS and ANN coupling model: an innovative approach to evaluate vulnerability of karst water inrush in coalmines of north china. Environ Geol 54(5):937–943

Wu Q, Wang JH, Liu DH, Cui FP, Liu SQ (2009) A new practical methodology of the coal floor water bursting evaluating IV: the application of AHP vulnerable index method based on GIS. J China Coal Soc. doi:10.13225/j.cnki.jccs.2009.02.025 (in Chinese)

Wu Q, Liu Y, Liu D, Zhou W (2011) Prediction of floor water inrush: the application of GIS-based AHP vulnerable index method to Donghuantuo coal mine, China. Rock Mech Rock Eng 44:591–600

Wu Q, Liu Y, Zhou WF, Li B, Zhao B, Liu S, Zeng Y (2015) Evaluation of water inrush vulnerability from aquifers overlying coal seams in the Menkeqing coal mine, China. Mine Water Environ 34(3):258–269

Wu Q, Guo X, Shen J, Xu S, Liu S, Zeng Y (2017) Risk assessment of water inrush from aquifers underlying the Gushuyuan coal mine, China. Mine Water Environ 36(1):96–103

Yang TH, Tu XL, Yu B, Zhang YB, Li LC, Tang CA, Tan GH (2005) A micromechanical model for simulating the coupling of fracture and flow of rock. Acta Mech Solida Sin 26(3):333–337

Yao B, Bai H, Zhang B (2012) Numerical simulation on the risk of roof water inrush in WuYang coal mine. Int J Min Sci Technol 22(2):273–277

Ye YX, Liu GY (2005) Research on coupling characteristics of fluid flow and stress within rock. Chin J Rock Mech Eng 24(14):2518–2523 (in Chinese)

Yin H, Wei J, Lefticariu L, Guo J, Xie D, Li Z (2016) Numerical simulation of water flow from the coal seam floor in a deep longwall mine in China. Mine Water Environ 35(2):243–252

Yu B, Chen Z, Yu L (2016) Water-resisting ability of cemented broken rocks. Int J Min Sci Technol 26(3):449–454 (in Chinese)

Zhang R, Jiang Z, Zhou H, Yang C, Xiao S (2014) Groundwater outbursts from faults above a confined aquifer in the coal mining. Nat Hazards 71(3):1861–1872

Zhou WF (1997) Karst water control and management in the Hanxing mining area of north China. Environ Geol 30(3):280–284

Zhou W, Li G (2001) Geological barrier–a natural rock stratum for preventing confined karst water from flowing into mines in north China. Environ Geol 43(8):1003–1009

Zhu WC, Wei CH (2011) Numerical simulation on mining-induced water inrushes related to geologic structures using a damage-based hydromechanical model. Environ. Earth Sci 62(1):43–54

Acknowledgements

The authors thank everyone who provided assistance in the present study, which was jointly supported by the State Key Program of National Natural Science of China (Grant 41430643) and the Natural Science Foundation of China (Grant 41302248). Thanks also to the editors and reviewers for their suggestions and help.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Li, W., Liu, Y., Qiao, W. et al. An Improved Vulnerability Assessment Model for Floor Water Bursting from a Confined Aquifer Based on the Water Inrush Coefficient Method. Mine Water Environ 37, 196–204 (2018). https://doi.org/10.1007/s10230-017-0463-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10230-017-0463-3