Abstract

Flooded mines are a groundwater reservoir that can be used geothermally. Modelling such a reservoir can be complicated because it is necessary to simultaneously solve the equations of flow and heat transport within the mine voids and the surrounding medium, whose hydraulic parameters may have been affected by mining. We present a numerical model developed for the reservoir formed by the Barredo and Figaredo shafts in the Central Coal Basin of Asturias (Spain), using FEFLOW software. Both 2- and 3-D versions of the model were used to simulate the flooding of the mine. They were calibrated by comparing the results with actual water levels measured during flooding. The hydrogeological and thermal characteristics of the reservoir were adjusted to predict the long-term temperature of the water under different scenarios of water extraction and injection.

Zusammenfassung

Geflutete Bergwerke bilden ein Grundwasserreservoir, welches geothermisch genutzt werden kann. Die Modellierung solcher Speicher ist jedoch kompliziert, da bei der Simulation Fließ- und Wärmetransportgleichungen sowohl in den Grubenhohlräumen als auch in den umgebenden Gesteinen gemeinsam gelöst werden müssen, wobei die hydraulischen Parameter zudem durch den Bergbau beeinflusst sind. Es wird ein numerisches Modell präsentiert, welches für das Grundwasserreservoir der Bergbaufelder von Barredo und Figaredo im zentralen Kohlebecken von Astriuas (Spanien) entwickelt worden ist. Sowohl 2-D als auch 3-D Versionen der Software FEFLOW wurden verwendet, um die Flutung des Untertagebergbaus nachzubilden. Die Modelle wurden kalibriert, indem die Modellergebnisse mit aktuellen Wasserständen während der Flutung verglichen wurden. Die hydrogeologischen und geothermischen Parameter des Reservoirs wurden angepasst, um langzeitliche Temperaturentwicklungen im Wasser bei verschiedenen Entnahme- und Injektionsszenarien vorherzusagen.

Resumen

Las minas inundadas constituyen un embalse de agua subterránea, del que se puede hacer un aprovechamiento geotérmico. Modelizar este tipo de embalses puede resultar complejo, ya que es necesario resolver simultáneamente las ecuaciones de flujo y transporte de calor en los huecos mineros y el medio circundante, cuyos parámetros hidrogeológicos pueden haber resultado afectados por la actividad minera. Se presenta un modelo numérico desarrollado para el embalse constituido por los pozos mineros Barredo y Figaredo en la Cuenca Carbonífera Central de Asturias (España), por medio del software FEFLOW. Se realizaron versiones del modelo en 2 y 3 dimensiones para simular la inundación de la mina, que fueron calibradas comparando los resultados con los valores reales de nivel de agua medidos durante dicha inundación. Las características hidrogeológicas y térmicas del embalse fueron ajustadas para predecir la temperatura a largo plazo del agua bajo diferentes escenarios de extracción de agua y reinyección.

抽象

闭坑(或废弃)淹没矿坑可用作提供地热的地下水库。由于需要同时求解矿坑及周围介质的水力学和热力学方程以及方程水文地质参数受矿坑严重影响,地下水库的水力与热力学数值模拟比较复杂。利用 FEFLOW建立了西班牙阿斯图里亚斯地区(Asturias)中央聚煤盆地(Central Coal Basin)Barredo井与Figaredo竖的地下水库模型。同时利用二维和三维模型模拟了矿坑淹没过程,用矿坑淹没期间实际观测水位进行了模型识别。地下水库模型经水文地质学及热力学特征校正后用以预测不同抽水、注水情形下的水温长期预测。

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The increasingly frequent closure and subsequent flooding of mines is generating large volumes of underground flooded mine voids (‘mining reservoirs’). The water in these mines is a potential substantial resource, both as drinking water and as an energy source. The latter can be exploited by means of heating networks of low-medium temperature, using geothermal energy from water (Ghoreishi et al. 2012; Hall et al. 2011; Hamm and Sabet 2010; Jardón et al. 2013; Kranz and Dillenardt 2009; Ramos and Falcone 2013; Raymond and Therrien 2008; Verhoeven et al. 2014, among others). This green and renewable energy source is particularly suited to meet the needs of residential and commercial heating. Based on current energy prices, the mine water used as a geothermal resource could substantially reduce annual costs of a district heating plant compared with conventional heating methods (Bazargan-Sabet et al. 2008).

Despite its widespread availability (e.g. Lawson and Sonderegger 1978), the use of mine water as a geothermal resource is not yet common (Raymond and Therrien 2008). However, since the benefits of this use have been demonstrated, a number of studies assessing the potential for mine water exploitation have been developed in various places (see Álvarez et al. 2013; Clauser et al. 2005; Jardón et al. 2013; O’Sullivan et al. 2011; Van Tongeren and Dreesen 2004; Wieber and Pohl 2008; Wolkersdorfer 2008; Peralta et al. 2015, which reviews 18 projects worldwide that use abandoned mines for geothermal heat recovery). Coal mines are considered by some as the best candidates for the exploitation of geothermal energy using the heat contained in the mine water, due to their accessibility and temperature (Watzlaf and Ackman 2006). The main difficulty is understanding the hydraulic and thermal characteristics of the mining system, considering the interconnection of the various parts of the mine.

Numerical models can be very useful in water management (Dong et al. 2012; Rapantova et al. 2007), analysis of the thermal properties of mining reservoirs (Raymond et al. 2011), and as a tool for evaluating the thermal potential thereof (Blöcher et al. 2010; Renz et al. 2009; Uhlík and Baier 2012). The realization of a numerical model requires observation data, making generalizations to develop the conceptual model, selecting the appropriate solution, and testing hypotheses to try to replicate reality using the mathematical model; if it is satisfactory, it can be used to predict scenarios (Brown and Trott 2014). Notwithstanding, the use of appropriate modelling is essential to achieve precise and applicable results.

The coal mines developed in Asturias (NW Spain) over 200 years have altered the natural groundwater flow, leading to a new ‘aquifer’ of triple-porosity (primary porosity of the rock, anthropogenic voids generated by mining, and secondary porosity caused by mining-induced fracturing), which can be called a ‘mine aquifer’ according to Wolkersdorfer (2008). Mining creates new karst-type aquifers, due to the construction of galleries and the emergence of fractured areas as a result of coal extraction (Ordóñez et al. 2012). Once mining and dewatering cease, all of the connected voids in the Asturian Central Coal Basin (hereinafter CCB) will act as underground (mining) reservoirs.

Hydrogeological and thermal models of an underground reservoir located in the CCB are presented. The mining reservoir, which is located close to urban settings, consists of the mine workings of the Barredo and Figaredo shafts, which are interconnected, closed, and flooded. The water from this reservoir is being exploited as a source of geothermal energy, supplying heat and cooling by means of heat pumps and through low temperature (<35 °C) distribution networks. The model was built using the finite element simulator FEFLOW, which can be used to calculate flow in porous media of finite element discretization (Diersch 2005).

Study Area

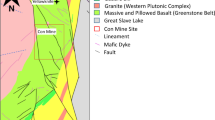

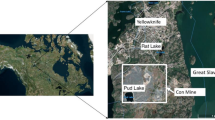

The study area is located in the River Turón valley within the CCB, in south-central Asturias, in NW Spain (Fig. 1). The average annual temperature over the last two decades in this area was 13 °C. The rainfall of an average hydrological year within the defined basin is about 1130 mm and the effective rainfall (subtracting evapotranspiration from precipitation) is 580 mm a−1 (Ordóñez et al. 2012).

Deformation of sedimentary Carboniferous sequences in the CCB is intense, with well-developed folding and large thrusts. The study area has a complex synclinal structure, represented by the Barredo syncline, which is crossed by the Barredo fault (IGME 1975) (Fig. 1b). The CCB is within the so-called ‘Palaeozoic Unit’, consisting of very low permeability materials that, although they can form small aquifers, are not relevant groundwater systems. The materials considered in this study are mainly characterized by low porosity and permeability values. They correspond to a cyclic succession of parasequences formed by marls, shales, greywackes, sandstones, and coal, grouped into “packs” (non-formal lithostratigraphical units about 300 m thick, defined from a mining criteria), and interbedded with conglomerates and breccias. They are clustered in two main units (García-Loygorri et al. 1971): (1) the “productive” or Sama Group, which includes the Generalas, San Antonio, María Luisa, Sotón, and Entrerregueras packs in the study area, and (2) the “unproductive” or Lena Group, from which only the Caleras pack is considered in this study (Fig. 1b). Previous studies in the area indicated that these materials together have a permeability around 10−7 m s−1 in unexploited areas (Fandos et al. 2004). Given this very low permeability and the limited possibility of water flow through fractures, water stored in the materials forming the undisturbed rock mass is negligible compared to that stored in the voids caused by mining (Jardón 2010). On the contrary, the hydrogeological parameters of the scarce materials of low permeability (sandstones) affected by mining increase substantially from their initial values (porosity, permeability, storage coefficient, and transmissivity increase up to 1, 3, 3, and 2 orders of magnitude, respectively; Supplemental Table 1) (García-Fuente 1996; Ordóñez et al. 2012). Supplemental files accompany the on-line version of this paper and can be downloaded for free.

Coal was extracted by the public company HUNOSA until 1992 in the Barredo Mine and 2006 in the Figaredo Mine. The Barredo shaft is located in the NW sector of the study area and its facilities are located in the centre of the town of Mieres on the right bank of the Caudal River. The Figaredo Mine is located south of the Barredo shaft, on the left bank of the Turón River (Fig. 1a). The Barredo shaft intersects the land surface at an elevation of 220 m; it has five levels and a total depth of 360 m. The Figaredo Mine includes two close shafts with entrances at 279 and 254 m, which are 520 and 650 m deep, respectively, with a total of ten levels.

Although coal extraction started in these mines at the beginning of the twentieth century, intense pumping of groundwater to dewater them only took place from the 1960s to 2007. In the period 2002–2007 (before flooding), an average of 4.1 million of m3 year−1 was extracted from both shafts at a temperature of about 20 °C. After mines’ closure (December 2007), pumping stopped, allowing the groundwater to rebound (Younger et al. 2002). The flooding of the Barredo–Figaredo reservoir began on July 27, 2008 when the water level was at −184 m; it ended on May 18, 2009 (295 days), when the water reached +150 m (70 m below the Barredo wellhead), where it is currently maintained to avoid flooding at the surface. Thus, pumping was resumed to extract the same amount of water that recharges the reservoir (an average of 130 L s−1), to keep a stable water level. The current geothermal use of the pumped water to heat some public buildings reduces energy consumption by 70 %, compared to conventional heating systems, and also reduces CO2 emissions (Jardón et al. 2013). Nevertheless, the long-term temperature of the water in the reservoir if pumping carries on was undetermined.

Figure 1a shows the basin considered for the Barredo–Figaredo system. This basin represents the recharge area of the mining reservoir, considering the extent of the mine workings, which induce fracturing and allow water infiltration. It is crossed by the Turón River, which loses some of its water through infiltration in the most heavily mined areas (Ordóñez et al. 2012). This basin constitutes the unit to be considered for the hereafter described modelling.

Methods

Before defining the numerical models, some hydrogeological and thermal characteristics of the reservoir, as porosity, recharge, thermal conductivity, and geothermal gradient, had to be established. Some of these were specifically measured or calculated, while others were obtained from previous studies. With those starting parameters, models were created and adjusted to optimally simulate the mine flooding. Then, the thermal model was built and run under a number of scenarios. This process was first undertaken with a 2-dimensional (2D) model; subsequently, a 3-dimensional (3D) model was also created.

Hydrogeological and Thermal Features

Total void volume was calculated based on the infiltrated water (estimated from the effective rainfall) that filled the reservoir during groundwater rebound, at an average rate of 1.1 m day−1. This volume was defined for each vertical stretch of the mine, and was used to calibrate the residual void left after coal extraction, taking into account the tonnage extracted at each level and the method of operation. It was assumed that each mine level only extracted coal between that level and the level above. Other openings, such as shafts and galleries, were also considered. Elevation versus storage graphs were then developed at +150 m, which is the current water level in the reservoir; the total void volume is estimated at 5.8 million of m3 (Ordóñez et al. 2012). The volume of the galleries supposes 46 % of the total volume, and a total length of 400 km. The porosity of the mined areas was spatially defined, exceeding 20 % in some levels. The average effective porosity of the unaffected rock mass was estimated to be 0.1 % (similar to that of a shale).

The recharge of the Barredo–Figaredo reservoir consists of the infiltrating effective rainfall and river losses. A previous study (Ordóñez et al. 2012) found that total infiltration accounts for approximately 23 % of the effective rainfall, together with a constant input (5300 m3 day−1) from river water. During the mine flooding period, the daily infiltration was calculated from rainfall data. For long-term simulations, an average rainfall infiltration of 112 mm a−1 was considered. Input from potential neighbouring aquifers was not considered in the model, due to the low permeability of the rocks, so the average total recharge is equivalent to the average pumping flow.

In contemporary studies, the thermal properties of the materials defining the geological packs shown in Fig. 1b was estimated from samples taken at their outcrops. The porosity of the samples was measured in the laboratory, and their mineral composition was determined by optical polarizing microscopy using thin sections. The thermal conductivity of each geological material was then estimated using the methodology proposed by Brigaud et al. (1990), which estimates the bulk thermal conductivity of a rock sample from the thermal conductivity of both the fluid and the rock matrix, which is defined as the geometric mean of the conductivities of its constituent minerals. The thermal conductivity was found to range from 1.42 (lutite) to 4.89 W m−1 K−1 (sublitarenite). The average thermal conductivities of the Caleras, Generalas, San Antonio, María Luisa, Sotón, and Entrerregueras geological packs are: 4.47, 2.49, 2.33, 2.95, 2.40 and 2.49 W m−1 K−1, respectively. These values were used in the thermal models of the reservoir.

Figure 2 shows some thermal profiles measured by HUNOSA inside the Barredo shaft, once the pumping was resumed. The upper sections display seasonal temperature variations, whereas the lower sections are more stable, as pumping allows mixing of waters of different temperatures. The profiles show that there is a good mixing in the lower part of the mine (where a better hydraulic connection exists) and a diffuse flow in the upper part above the upper pump, which probably pumps only deeper mine water [see Wolkersdorfer (2008) for details about thermal stratification in a flooded underground mine]. The water used for geothermal purposes is currently pumped from the Barredo shaft at a depth of 100–200 m below the land surface at a temperature of 20–22 °C.

2D Model

First, a 2D model was constructed in order to calibrate the hydrogeological and thermal properties of the mining reservoir. This model was performed in the transverse section through the Barredo and Figaredo shafts, considering the mine workings and the connections between them (Fig. 1b), and extended within the limits of the Barredo–Figaredo basin (Fig. 1b). The model was divided into three classes of materials: (1) unaltered rock, (2) mined volume (that affected by the mining works and the associated fracturing), and (3) open mine structures (mainly shafts and galleries).

Both in the galleries and the mined volume, water was assumed to be in thermal equilibrium with the surrounding rock mass at the start of the simulations. Water will flow first through these mine workings, which represent much of the voids, at relatively high speed, compared to a much slower velocity in the undisturbed rock mass. According to Wolkersdorfer (2008), mine water flows in rough mine voids with mean velocities (determined by means of tracer tests) of 0.3–1.6 m min−1. In a multiple shaft mine, high effective velocities in areas of high hydraulic gradient can be reached, leading to a turbulent flow regime, particularly during the groundwater rebound. A mine environment is so complex that Darcy’s law for flow, laminar flow, turbulent flow or even almost no flow can occur together (Wolkersdorfer 2008).

To define the hydrogeological model, a prior calibration of the hydraulic parameters of the materials was made. For that, the mine flooding was simulated, using actual rainfall data. Thus, parameters such as the hydraulic conductivity of the materials affected by mining (which define the reservoir) were modified by successive approximations to obtain an optimal adjustment to the real process, which had been monitored.

Considering the topography and the limits of the basin, a 2D mesh with 57,448 nodes and 114,557 elements was created. The mesh was defined to adapt the model to the mine workings, so the size of the elements ranged from 2.5 to 20 m, with a finer meshing around the galleries. Because the unaffected rock mass is practically impermeable, water contributions from the sides were not considered. Only rainfall recharge and river losses were assumed as inputs to the system. The conceptual model assumes an isotropic porous medium, heterogeneous and unconfined. It works as a saturated/variably saturated (Van Genuchten-type) model. The entry of water through the surface by rainfall infiltration (variable rate) was assumed as a type 2 (Neumann) boundary condition. Recharge from the Turón River was divided into several injection wells along the stretch of river intercepted by the 2D model section.

As a simplification, all the galleries were considered to have a rectangular geometry with a section of 8 m2 and a height of 2.5 m. The shafts were assumed to have a circular section of 25 m2. The mined volume (zones extending between galleries) consists of altered material with porosity and hydraulic conductivity values greater than the surrounding (unaltered) rock mass. Porosities of 0.1 and 100 % were used for the unaffected rock mass and the galleries, respectively. The variable porosity obtained for each mine stretch, ranging from 2 to 22 %, was considered for the mined volume. Hydraulic conductivities of 10−7 and 1 m s−1 were assumed for the unaffected rock mass (Fandos et al. 2004) and the shafts and galleries, respectively. Moreover, the potential influence of the Barredo fault was considered; it was given a porosity of 1 % and a hydraulic conductivity of 10−3 m s−1 (Supplemental Table 2).

The flooding process occurring in 2008–2009 was then simulated with the above data. The initial water table was set at −184 m. Only the recharge from the river and the daily rainfall infiltration were used to produce the groundwater rebound up to +150 m, and then the obtained flooding curve was compared to the real one. The parameters that allowed the best fit between both the curves were established and used for the next simulations.

The thermal model was programmed to start after the flooding period, with a stable water level at 150 m maintained by pumping. The total pumped flow was apportioned between both shafts, and set equal to the average recharge, so that a water balance is maintained in the system (inflow equals outflow). This allows long-term thermal modelling to be carried out.

For the thermal modelling, a variable water temperature (equivalent to the daily ambient temperature) was set at the surface as a boundary condition. At the bottom edge of the model, a constant heat flow of 65 mW m−2 was defined, since the area of study falls in a zone ranging from 60 to 70 mW m−2, according to available local heat flow maps (GEOELEC 2015). The value of 65 mW m−2 is also the mean heat flow over the continental crust, and has been used in similar models (e.g. Renz et al. 2009). It is also comparable to local values found in other studies as per the Atlas of Geothermal Resources in Europe (European Commission 2002). As an initial condition, the temperature of the rock mass was established at 13 °C at the surface (average annual temperature in the study area); other temperatures at depth were calculated considering the geothermal gradient, reaching up to 33 °C. According to the local data (European Commission 2002), the geothermal gradient in this area varies from 0.027 to 0.032 °C m−1, so an average value of 0.03 °C m−1 was used. The thermal conductivities obtained for each geological pack were considered in this model.

Once the model was defined, several scenarios of the geothermal system were simulated to assess its long-term viability. The first scenario contemplated the use of mine water for heating and/or cooling without water return to the mining reservoir. At present, pumping equals the natural recharge of the reservoir, and part of the pumped water is geothermally used. In this case, the used water, after passing through the heat pump, is discharged to the Caudal River. The second scenario also considers hydropower generation by means of return of the mine water employed in heat pumps to the reservoir. Micro-turbines can be used to produce energy from this water as it flows back down the shaft during peak hours. In an optimal (high) use of the mine water, this would also help to keep the reservoir full. According to Jardón et al. (2013), the optimal geothermal use would need a flow up to 40 % of the total pumped flow to be reinjected into the reservoir after being used. This returned water has a temperature around 15 °C, which corresponds to that at the exit of the heat pumps. Used water would be injected through the Figaredo shaft, so that it would not affect the temperature of the water pumped at the Barredo shaft for geothermal use. Although coal from the CCB is not rich in sulphides, and mine water quality problems are not frequent, the risk of water quality deterioration due to recycling oxygenated water into the reservoir should be considered in the case of reinjection.

Both scenarios have been simulated with the calibrated model. Long-term working of the system (30, 60, and 90 years) was simulated, considering annual average recharge and pumping with and without reinjection.

3D Model

The 2D model was calibrated to better define the hydrogeological and thermal parameters of the system. However, this model does not provide volumetric information, so a three-dimensional model was developed. The results of the 2D model served as starting points for the 3D model, which is its natural extension. Still, a number of simplifications were necessary to account for the three-dimensional complexity of the mining galleries.

First, the original outline of the basin was smoothed to reduce mesh complexity, avoiding obtuse angles in the elements. The resulting basin, extending 18 km2, is shown in Fig. 1a. Slices of 2.5 m high were considered to represent the galleries at each mine level. An average porosity of 10 % and a hydraulic conductivity of 0.5 m s−1 were assigned to the area to where the galleries extend within these slices. The mined volume around this zone of galleries was assigned a 1 % effective porosity. Vertical shafts were considered to have 100 % porosity; they were surrounded by a narrow ring of higher porosity and permeability (10 % and 0.5 m s−1, respectively) to ease the water flow through them (Fig. 3). A porosity of 0.1 % was kept for the unaffected rock mass. Analogously to the 2D model, hydraulic conductivities of 10−7, 2 × 10−4, and 1 m s−1 were considered for the unaltered rock mass, the mined volume, and the shafts, respectively (Supplemental Table 2).

The model was created with 110 slices, 3.9 million triangular prismatic elements, and 2.0 million nodes. The bottom elevation is −494 m, and the top elevation ranges between +200 and +900 m, depending on the topography. The deepest layer is located deep enough to ensure an impermeable boundary not influenced by the galleries or the mining-altered rocks. The high number of slices satisfied the need to increase the vertical discretization of the model, as it is extremely important to work with a sufficient vertical resolution when running unsaturated models to avoid convergence errors. Additionally, an increased number of nodes were necessary to represent the galleries. The size of the elements in the model was conditioned by the layout of galleries, to avoid obtuse angles (which would cause divergence problems).

The boundary conditions for both the hydrogeological and thermal 3D models were those assigned to the 2D versions. The flooding period was first simulated using daily recharge, so the 3D model was calibrated to adapt to real data. With the resulting model, both potential scenarios of geothermal use were simulated. For the sake of simplicity, the weighted average thermal conductivity (based on the percentages of the rocks in each geological unit) of 2.86 W m−1 K−1 was considered for the whole model.

Results

The simulated water level rise during the mine flooding was compared to the monitored actual rise, with a calculated Pearson correlation coefficients of 0.93 for the 2D model and 0.97 for the 3D model (Fig. 4).

2D simulation of the water rebound began with a hydraulic conductivity of 10−4 m s−1 for the mined volume, achieving a fit between real and simulated flooding curves of 89 %. By successive approximations, the value which allowed the best fit (93 %) with the real flooding data was 2 × 10−4 m s−1. This was assumed for all the material that fills the exploitation voids in consecutive simulations. Supplemental Table 3 shows a sensitivity analysis of the model parameters (hydraulic conductivity, specific retention, and specific storage, Ss) on the hydraulic head. The model is more sensitive to the Ss, as its variation affects the modelled water table stably and significantly (a 20 % increase or decrease of Ss results in an error ≥40 %). After the calibration, the parameters that would lead to a minor error (3 %) and a better fit with the real flood curve were chosen (Supplemental Table 3). Figure 5 shows the thermal map of the Barredo–Figaredo section after 30 years, without considering reinjection. There were no substantial differences between the two scenarios (with and without reinjection). Recharge water flows preferentially through the mining galleries, cooling them, whereas the rock mass keeps a stable temperature. In 30 years, if the system is exploited as it is now, water would be pumped at a temperature ≈19 °C, so the rock mass temperature would be reduced by 1–3 °C, independently of the scenario considered (Fig. 2). This reduction almost falls within the natural fluctuations of the system throughout the year. However, much lower temperatures were observed in both scenarios around the Figaredo shaft, reaching values of 17 °C in the highest levels of this mine. The current water temperature from Figaredo is as an average 2 °C less than that from Barredo, and the reason might be infiltration of water from the Turón River. It was proven that the Barredo fault acts as a preferential flow path, but ultimately it does not greatly influence the temperature of the system.

Figure 6a shows the temperatures in the 3D model under the scenario of no reinjection after 30 years. The results of the 3D model are consistent with those of the 2D model; nevertheless, the deepest low temperatures extend more around the Figaredo shaft in the 3D model. The rate budget supplied by FEFLOW in the scenarios of no reinjection agrees with the equilibrium established to keep a stable water table; therefore, capture (−) and release (+) is in the order of 130 L s−1, with an imbalance ranging from 1 to 9 %.

The 2D and 3D simulations gave similar results for both scenarios, so it seems that the decision of selecting one type of the use or the other should be based on management criteria, depending on the energy end-users, rather than on the potential effect on the reservoir. Although the returned water is 2 °C warmer than rainfall and river water, it is continuously injected and pumped out of the reservoir again in the Figaredo shaft. Also, the pumping rate is higher in this case, as it equals the natural recharge plus the returned flow to maintain the water table at the same elevation.

Longer simulations (60 and 90 years; Fig. 6b, c) shows that the water temperature gradually equilibrates with the geothermal gradient below the pumps, reaching a steady-state. A sort of loop is established, so colder water stays mainly in the upper part of the reservoir, being constantly renewed by pumping from the Barredo and Figaredo shafts, whereas higher temperatures are maintained in the lower areas.

An underground mining system behaves like a complex karst aquifer. Other FEFLOW users trying to undertake a similar study should try to achieve equilibrium between the reality and the simplified model of a highly deformed, fractured, and mined sedimentary system. In this case, we proved that an optimal long-term energy use of the reservoir is possible if it is adequately managed and regulated.

Conclusions

The defined models efficiently represent the temporal evolution of the water level in the reservoir during its flooding, with correlation coefficients of 0.93 and 0.97 for the 2D and 3D models, respectively. This fit was achieved by considering a hydraulic conductivity in the order of 10−4 m s−1 in the zones affected by coal extraction. Discrepancies between observed and simulated data are probably due to the fact that the reservoir does not behave exactly like a porous isotropic medium, as assumed in the conceptual model.

The temperature of water in the reservoir after 30 years of simulation is slightly reduced around the Barredo shaft (where it is pumped for geothermal applications) and notably cooler around the Figaredo shaft, due to river water infiltration. It does not appear that the temperature in the reservoir would be influenced by reinjection of the water used for geothermal applications. The temperature of the water entering the reservoir after use in a heating cycle is slightly higher than the average temperature of the water naturally recharging the reservoir; however, the injected water is then pumped out, without substantial temperature changes once equilibrium is reached. Longer simulations show that the temperature of the water below the pumps tends to equilibrate with that of the enclosing rocks. Cold recharge water enters the system and it is pumped again at 100–200 m of depth, so an equilibrium loop is established, maintaining warmer water in the deepest zones.

The results obtained in the 2D and 3D models were very similar. Notwithstanding, more simplifications are necessary in the 3D model to reduce its complexity. Thus, 2D models constitute a simpler and preferable option when modelling complex mining reservoirs.

The numerical models that have been created and calibrated can be used for different exploitation scenarios of the underground reservoir. The flow model allows the development of strategies for pumping-reinjection of water, while the heat transport model predicts long term temperatures in the case of changes in both the weather and the water and energy needs. The methodology described here could be extended to other (mining) reservoirs and geothermal systems to be modelled.

References

Álvarez J, Jardón S, Andrés C, Ordóñez A (2013) Valoración técnico-económica del aprovechamiento del agua de mina como recurso geotérmico mediante una red térmica de distribución en La Felguera, Asturias. In: Proc, Congreso sobre aspectos tecnológicos e hidrogeológicos de la geotermia, Barcelona, Spain

Bazargan-Sabet B, Demollin E, Van Bergermeer JJ (2008) Geothermal use of deep flooded mines. In: Proceedings of the post-mining symposium, Nancy, France

Blöcher MG, Zimmermann G, Moeck I, Brandt W, Hassanzadegan A, Magri F (2010) 3D numerical modelling of hydrothermal processes during the lifetime of a deep geothermal reservoir. Geofluids 10:406–421. doi:10.1111/j.1468-8123.2010.00284.x

Brigaud F, Chapman DS, Le Douoran S (1990) Estimating thermal conductivity in sedimentary basins using lithologic data and geophysical well logs. Am Assoc Petrol Geol Bull 74(9):1459–1477

Brown K, Trott S (2014) Groundwater flow models in open pit mining: can we do better? Mine Water Environ 33:187–190. doi:10.1007/s10230-014-0270-z

Clauser C, Heitfeld M, Rosner P, Sahl H, Schetelig K (2005) Beispiel Aachener Steinkohlenrevier—Nutzung von Erdwärme in aufgelassenen Bergwerken. Beratende Ing 6:14–17 (in German)

Diersch H-JG (2005) FEFLOW finite element subsurface flow and transport simulation system, reference manual. WASY, Institute for Water Resources Planning and Systems Research, Berlin

Dong D, Sun W, Xi S (2012) Optimization of mine drainage capacity using FEFLOW for the no. 14 seam of China’s Linnancang coal mine. Mine Water Environ 31:353–360. doi:10.1007/s10230-012-0205-5

European Commission (2002) Atlas of geothermal resources in Europe. In: Hurter S, Haenel R (eds) Publication no. EUR 17811, Luxembourg

Fandos P, Rodríguez F, Gutiérrez AM, Álvarez JJ (2004) El yacimiento de Hunosa en la Cuenca Carbonífera Central. Unpublished report, Servicios de Geología del Caudal y del Nalón

García-Fuente PA (1996) Sistema experto de predicción de desagües en minas subterráneas de carbón. Aplicación al Grupo Aller de HUNOSA. Ph.D. thesis, University of Oviedo, Spain, unpubl (in Spanish)

García-Loygorri A, Ortuño G, Caride de Liñán C, Gervilla M, Greber CH, Feys R (1971) El Carbonífero de la Cuenca Central Asturiana. Trabajos de Geología Univ de Oviedo 3:101–150

GEOELEC (Geothermal Potential for Electricity Generation for the EU-27) (2015) Surface heat flow and temperature maps. http://www.thermogis.nl/geoelec/ThermoGIS_GEOELEC.html

Ghoreishi SA, Ghomshei MM, Hassani FP, Abbasy F (2012) Sustainable heat extraction from abandoned mine tunnels: a numerical model. Renew Sustain Energy Rev 4(3):1–16. doi:10.1063/1.4712055

Hall A, Scott JA, Shang H (2011) Geothermal energy recovery from underground mines. Renew Sustain Energy Rev 15:916–924. doi:10.1016/j.rser.2010.11.007

Hamm V, Sabet BB (2010) Modelling of fluid flow and heat transfer to assess the geothermal potential of a flooded coal mine in Lorraine, France. Geothermics 39:177–186. doi:10.1016/j.geothermics.2010.03.004

Instituto Geológico y Minero de España (IGME) (1975) Mapa Geológico de España. MAGNA, Hoja 53. Memoria. Ministerio de Educación y Ciencia, Madrid

Jardón S (2010) Aprovechamiento de las aguas de mina en la Cuenca Central Asturiana como recurso energético. Aplicación al embalse minero Barredo–Figaredo. Ph.D. thesis (in Spanish)

Jardón S, Ordóñez A, Álvarez R, Cienfuegos P, Loredo J (2013) Mine water for energy and water supply in the Central Coal Basin of Asturias (Spain). Mine Water Environ 32:139–151. doi:10.1007/s10230-013-0224-x

Kranz K, Dillenardt J (2009) Mine water utilization for geothermal purposes in Freiberg, Germany: determination of hydrogeological and thermophysical rock parameters. Mine Water Environ 29:68–76. doi:10.1007/s10230-009-0094-4

Lawson DC, Sonderegger JL (1978) Geothermal data-base study—mine-water temperatures, vol 38. Special Publications, Montana Bureau of Mines and Geology, Montana, p 79

O’Sullivan J, Croucher A, O’Sullivan M, Stevenson L, Esberto M (2011) Modelling the evolution of a mine pit in a geothermal field at Lihir Island, Papua New Guinea. In: Proceedings of the New Zealand workshop

Ordóñez A, Jardón S, Álvarez R, Andrés C, Pendás F (2012) Hydrogeological definition and applicability of abandoned coal mines as water reservoirs. J Environ Monit 14:2127–2136. doi:10.1039/c2em11036a

Peralta E, Breede K, Falcone G (2015) Geothermal heat recovery from abandoned mines: a systematic review of projects implemented worldwide and a methodology for screening new projects. Environ Earth Sci 73:6783–6795. doi:10.1007/s12665-015-4285-y

Ramos EP, Falcone G (2013) Recovery of the geothermal energy stored in abandoned mines. In: Hou MZ, Xie H, Were P (eds) Clean energy systems in the subsurface: production, storage and conversion. Springer, Berlin, pp 143–155

Rapantova N, Grmela A, Vojtek D, Halir J, Michalek B (2007) Ground water flow modelling application in mining hydrology. Mine Water Environ 26(4):264–270. doi:10.1007/s10230-007-0017-1

Raymond J, Therrien R (2008) Low-temperature geothermal potential of flooded Gaspé mines, Québec, Canada. Geothermics 37(2):189–210. doi:10.1016/j.geothermics.2007.10.001

Raymond J, Therrien R, Gosselin L, Lefebvre R (2011) Numerical analysis of thermal response test with a groundwater flow and heat transfer model. Renew Energy 36(1):315–324. doi:10.1016/j.renene.2010.06.044

Renz A, Rühaak W, Schäzl P (2009) Numerical modelling of geothermal use mine water: challenges and examples. Mine Water Environ 28:2–14. doi:10.1007/s10230-008-0063-3

Uhlík J, Baier J (2012) Model evaluation of thermal energy potential of hydrogeological structures with flooded mines. Mine Water Environ 31:179–191. doi:10.1007/s10230-012-0186-4

Van Tongeren P, Dreesen R (2004) Residual space volumes in abandoned coal mines of the Belgian Campine basin and possibilities for use. Geol Belg 7(3–4):157–164

Verhoeven R, Willems E, Harcouet-Menou V, De Boever E, Hiddes L, Opt-Veld P, Demollin E (2014) Minewater 2.0 project in Heerlen the Netherlands: transformation of a geothermal mine water pilot project into a full scale hybrid sustainable energy infrastructure for heating and cooling. Energy Proc 46:58–67. doi:10.1016/j.egypro.2014.01.158

Watzlaf GR, Ackman TE (2006) Underground mine water for heating and cooling using geothermal heat pump systems. Mine Water Environ 25:1–14. doi:10.1007/s10230-006-0103-9

Wieber G, Pohl S (2008) Mine water: a source of geothermal energy—examples from the Rhenish Massif. In: Proceedings of the 10th International Mine Water Association Congress, Karlovy Vary, Czech Republic, pp 113–116

Wolkersdorfer C (2008) Water management at abandoned flooded underground mines: fundamentals, tracer test, modelling, water treatment. Springer, Heidelberg

Younger PL, Banwart SA, Hedin RS (2002) Mine water—hydrology, pollution, remediation. Kluwer, Dordrecht

Acknowledgments

The authors thank the HUNOSA company for providing valuable information, as well as DHI-WASY for their support regarding FEFLOW software. We are also very grateful to Dr. R. Kleinmann and Dr. C. Wolkersdorfer for their useful comments on an earlier version of the manuscript.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Andrés, C., Ordóñez, A. & Álvarez, R. Hydraulic and Thermal Modelling of an Underground Mining Reservoir. Mine Water Environ 36, 24–33 (2017). https://doi.org/10.1007/s10230-015-0365-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10230-015-0365-1