Abstract

After the closure of an underground mine, tunnels commonly become flooded and can be potentially exploited for its geothermal resource. Developing new methods for quantifying the energy content of this reservoir with a complex geometry is important to assess the economic value of its heat resource. The objective of this paper is to provide a first-order assessment of the geothermal potential of an underground mine using the Con Mine near Yellowknife, Northwest Territories, Canada, as an example. Field data allowed the development of an improved analytical approach to evaluate the geothermal potential of the Con Mine based on a thermal power budget. The sources considered in the thermal power budget are the thermal inertia of the water in the mine and the surrounding host rock, and the water that infiltrates the mine from nearby lakes. Analytical calculations are based on the finite linear heat source equation, considering cooled or heated water in the mine tunnels as heat sources or sinks. The geometry of the underground mine is consequently simplified to a linear heat source of equivalent length and fixed radius. The Thiem equation is used to calculate the water seeping into the mine. Results obtained with this approach and considering the operation of a geothermal heat pump system indicate a total energy of 17,520 MWh y−1 and 8234 MWh y−1 that can be delivered to buildings for heating and cooling purposes, respectively. This new approach provides an improvement to the volumetric method commonly used to assess geothermal resources.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Mining environments store geothermal energy from the Earth’s natural heat flux in the water contained in the mine workings. It is a sensitive heat storage medium because the energy is released as temperature decreases without a change of state of water. The advantage of a mine is that the resource is directly accessible by the wells or the openings previously drilled or excavated. The amount of thermal energy is proportional to the storage volume, the heat capacity of the materials (water and surrounding bedrock) and the temperature change of the heat storing material (Muffler and Cataldi, 1978). The high transmissivity of the mining tunnels allows pumping at high water flow rates for extraction or injection of significant energy (Banks et al., 2019). Due to the amount of water contained in closed mines, they are considered a potential geothermal resource. An investigation of the amount of energy available is required to assess the economic opportunity associated with the geothermal potential of a mine site. The estimation should provide insights into whether there is enough economic resource to be used.

Geothermal resource assessments for hydrothermal systems can give insight how to evaluate the resource potential of flooded mines. For example, the Pontgibaud area and hydrothermal system in France have been investigated for its geothermal potential (Duwiquet et al., 2019). Eyerer et al. (2020) also evaluated the potential of hydrothermal systems of the North German Basin. As geothermal energy has become increasingly used for heating and cooling in China, deep hydrothermal systems of the Yangtze Block have been studied for potential use with buildings (Luo et al., 2021). These resource studies, just to cite a few recent examples, included reservoir to power plant models that are, however, not readily applicable to a flooded mine system. One of the first steps to determine the geothermal potential of any reservoir is assessing its volume, heat capacity, and the temperature difference before and after heat exchange. Energy content is proportional to the volume and the temperature difference of the materials (Muffler and Cataldi, 1978). Estimating the reservoir enthalpy and temperature using this volumetric method requires an estimation of the Earth’s natural heat flux. The reservoir temperature can also be deduced from thermal manifestations when studying such hydrothermal systems (Lawless, 2010). This approach is simple but generally underestimates the natural heat flux from the system and may not be fully representative of the entire geothermal reservoir.

Geothermal resource assessments can also be made for a magmatic system. The volume of the magma chamber is evaluated, and the amount of geothermal energy left in the intrusion is assessed with a conductive heat loss calculation (Muffler and Cataldi, 1978). This approach gives a global overview of the accessible heat, but only applies to volcanic areas.

When production wells are available, the total well flow method can be used for a geothermal resource assessment. The field capacity is considered as the total flow of drilled wells. This method is simple but is not representative of the amount of fluid in the whole reservoir (Grant, 2010). The decline curve analysis is a method where the production history data from wells are used to assess performance and predict future production. However, the results only give reserves of the entire drainage area of the wells.

The planar fracture method for geothermal resource assessment considers that heat is transferred to the fractures by convection. The extraction of heat is calculated assuming the flow of water along planar fractures (Muffler and Cataldi, 1978). This method allows for the calculation of recoverable thermal energy with a minimum number of parameters, but it can’t be applied to all geological environments (Muffler and Cataldi, 1978). Lumped-parameter modeling is another simple approach adapted for short-term estimation (a few years). This approach evaluates resources by considering the system as a single element with average reservoir properties. The estimation does not consider heat transfer and fluid flow (Sanyal and Sarmiento, 2005). Finally, Cumming (2016) proposed assessment of geothermal potential based on the distribution of known geothermal field production capacity. This estimation method requires at least a magnetotellurics resistivity survey.

According to Purba et al. (2021), the most commonly used method for geothermal resource assessment is the volumetric approach, because it is a low cost and simple method, especially when compared to those requiring numerical models which can be more reliable and accurate, but complex, time consuming, and consequently expensive. Therefore, the volumetric approach is commonly implemented at the exploration phase. For example, Chu et al. (2021) used this volumetric approach to evaluate the geothermal potential of the Jiahe Colliery in China. However, the volumetric method typically leads to an underestimation of the geothermal resource potential (Purba et al., 2021). This volumetric method has been previously adapted to estimate the geothermal potential of flooded mines. The volume considered in this approach is that of the water filling the mine as presented by Ghomshei (2007), Grasby et al. (2012), Jardón et al. (2013), Díez and Díaz-Aguado (2014), Preene and Younger (2014), Bao et al. (2019) and Menéndez et al. (2019). However, this approach can neglect important components of the energy budget of a mine system, such as heat storage in the surrounding rock mass and its effect on mine water temperature. We believe this results in an underestimation of the mine’s geothermal resources.

Thus, the objective of this work was to improve the volumetric approach commonly used for geothermal resource assessment through a thermal power budget calculation, to provide an initial resource estimate for the geothermal energy contained in a flooded mine. The closed Con Mine near Yellowknife, Northwest Territories, was used as an example.

Previous investigations of the geothermal potential of the Con Mine were made but remained incomplete. Ghomshei (2007) evaluated the potential of this mine for providing heat to the nearby City of Yellowknife, but only considered the energy contained in the volume of water flooding the mine. Ferket et al. (2012) also assessed this heat resource; they multiplied the Earth’s natural heat flux by the surface area of the mine, which can greatly underestimate its potential. The new analytical approach developed for the Con Mine in this study takes into consideration the heat associated to the water inside the mine tunnels, the heat transferred from the surrounding host rock to the water, and the heat from water infiltrating into the mine tunnels. While this novel approach has been developed with the Con Mine as an example, it can be used for any other underground mine. The methodology herein details each important component of the thermal power budget for the Con Mine.

Geological and Hydrogeological Settings

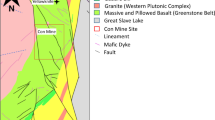

The Con Mine is located in Yellowknife, Northwest Territories, Canada (Fig. 1) and was active from 1938 to 2003. The mine site was developed in the Yellowknife Greenstone Belt of the Slave Geological Province. The Greenstone Belt is bounded to the west by younger granitic rocks of the Western Plutonic Complex (Fig. 2). The belt consists of a succession of mafic to intermediate volcanic rocks (massive and pillow basalts), with small inclusions of volcaniclastic and sedimentary rocks to the northeast. The rocks underlying the Con Mine dip 70–80° to the southeast (Miramar Con Mine Ltd, 2007). Gold mineralization is hosted in the shear zones where mining was focused (Fig. 3). The shear zones are predominantly composed of chlorite-carbonate schists with increasing sericite, sulfide and quartz content in areas of higher gold mineralization (Miramar Con Mine Ltd, 2007).

Geological map of the Con Mine and Yellowknife area (modified from Northwest Territories Geological Survey, 2021)

Mean annual precipitation in the Con Mine area is 366.5 mm, with 164.7 mm as snow and 201.8 mm as rain (Miramar Con Mine Ltd., 2007). Hydrogeological conditions are strongly influenced by water levels of lakes adjacent to the mine, including the Great Slave Lake. The bedrock has a hydraulic conductivity of 1 × 10–7 to 1 × 10–9 m s−1 (Miramar Con Mine Ltd, 2007). Groundwater flow around the mine occurs primarily within the fault network that intersects the underground workings (INTERA, 1997). Due to constant groundwater infiltration in the mine, and to avoid mine water outflow, dewatering is conducted each summer to bring the water level within the mine approximately 40 m below the level of the Great Slave Lake. Dewatering is achieved by pumping groundwater out of the C-1 shaft (Fig. 3).

The geothermal gradient, which was measured in an exploration borehole near the mine site down to a depth of 300 m, has been estimated to 17.4 °C/km after paleoclimatic corrections (Ngoyo Mandemvo, 2022).

Method

The approach we developed presents a thermal power budget that can be applied to any underground mine. Assumptions are as follows. The thermal power budget can be divided into three components: the water inside the mine, the surrounding host rock, and the water infiltrating the mine. The thermal power that can be released from the mine water is a function of its volume and the temperature difference between the initial and final state. The thermal power that can be released from the surrounding host rock considers the geometry of underground mine tunnels simplified as a linear heat source of finite length. The heat transferred from the surrounding rock mass to the water by means of conductive heat transfer is determined by the potential temperature response of the mine shafts, drifts, and workings when the water temperature inside the mine is changed. Calculation of the thermal power from the water infiltrating the mine also requires the assumption of a simplified mine geometry. Then, the Thiem equation can be used to evaluate the amount of water infiltrating a well (mine shaft in this case) under steady-state conditions.

Thus, the components considered to assess the thermal power budget of an underground mine are (Fig. 4): (a) the thermal inertia of the water that is flooding the underground mine workings; (b) the host rock surrounding the mine; and (c) the water infiltrating the underground mine. The sources of thermal power that are neglected and assumed insignificant compared to the three components above are (Fig. 4): (a) thermal exchange at the surface by solar radiation, air convection, and atmospheric temperature variations; and (b) the Earth’s heat flux.

Therefore, the total thermal power available from the mine Ptot (W) is considered as the sum of the power that can come from the mine water Pmw (W), the surrounding host rock Pr (W) and the groundwater infiltrating the underground mine workings Pgw (W), thus:

Mine Thermal Power Budget

The thermal energy extracted/injected from/into the mine water Ew (J) that is flooding the underground mine workings is calculated as (Jessop et al. 1995):

where Vmw (m3) is the volume of water inside the mine, T0 (K) is the initial temperature of water before being cooled or heated with a heat pump system, Tm (K) is the maximum or minimum temperature at which the water that floods the underground mine workings can be cooled or heated with the heat pump system, and cw (4186 J m−3 K−1) is the volumetric heat capacity of water. Note that Tm is a design parameter to be selected according to the heat pump system operation.

The available thermal energy is converted to power by taking into account the time of the operation (Jessop et al., 1995), thus:

where t (s) is the time, which was assumed to be 7.8 × 108 s in this study (25 years), corresponding to the typical lifetime of a geothermal heat pump system (Jessop et al., 1995).

The thermal power available from the surrounding rock mass was estimated from the conductive heat flux released when the water reaches the minimum or maximum temperature Tm. The finite line source (FLS) solution was used to determine this heat flux assuming that the temperature at an infinite distance from the mine workings remains constant (Cimmino et al., 2013). Here, the infinite line source (ILS) and cylindrical line source (CLS) solutions could also have been used. However, these latter two solutions appear most appropriate for a heat transfer of short duration (a few years; Philippe et al., 2009). As the calculations are done for the operating period of the heat pump system (25 years), axial heat transfer effects become non-negligible and require use of the FLS (Philippe et al., 2009). The total length of mine tunnels, including shafts, stopes and drifts, was considered to determine the equivalent length of the heat source when applying the FLS. Since the Con Mine has an irregular geometry, its volume was transformed into an equivalent mine tunnel length, with the formula of a cylinder, but keeping the same volume (Fig. 5). This simplification reduces the contact surface between rock and water, which minimizes the estimated thermal energy. However, it allows calculation of the conductive heat flux from the surrounding host rock using a simplified underground mine geometry. The FLS was used with the following assumptions: (a) a linear heat source where the length is greater than the radius; (b) the surrounding medium has an infinite radial distance is homogeneous and isotropic; (c) the initial temperature is uniform; (d) the temperature at an infinite radial distance remains constant; and (e) heat is transferred by conduction.

Philippe et al. (2009) analyzed the thermal response functions of underground heat source solutions used for geothermal boreholes. Their formulation of the FLS was used to calculate the power transferred from the surrounding rock to the mine water Pr (W), thus:

where λr (W m−1 K−1) is the thermal conductivity of the host rock, GFLS is the thermal response function of the finite line source or G-function, Fo* = Fo/\({\widetilde{r}}^{2}\) (−) is a normalized Fourier (Fo) number with \(\widetilde{r}\)= r/rb representing a dimensionless radius (−) with rb (m) being the radius of the heat source (borehole) or the mine tunnels in our case and r (m) is the distance at which the temperature is calculated, L (m) is the mine tunnel total length, and D (m) is the distance from the surface to the upper end of the source. Note that rb = r and thus Fo* = Fo in our case. The Fourier number is calculated according to the time t (s), the thermal diffusivity α (m2 s−1) and the radius of the heat source, thus:

As explained above, the underground workings of the Con Mine are located near Great Slave Lake and other smaller lakes (Fig. 1) and experience a constant groundwater inflow. The water is pumped out of the mine on an annual basis, and thus a significant recharge of water into the mine is contributing to the available thermal energy potential. To estimate the water flow that infiltrates into the mine, the Thiem solution for pumping in a confined aquifer under steady-state conditions was used, considering the following assumptions (Wenzel, 1935; Fig. 6): (a) the host rock aquifer has unlimited lateral extent; (b) the aquifer is homogeneous, isotropic and has a uniform thickness; (c) before pumping, the piezometric level is (almost) horizontal; (d) water is pumped at a constant flow rate; and (e) the well penetrates the entire aquifer and the water flows horizontally through the entire thickness of the aquifer.

Thus, the following equation was used to estimate the flow rate \({q}_{\mathrm{gw}}^{^{\prime}}\) (m3 s−1) at which groundwater infiltrates the mine (Wenzel, 1935):

where hL (m) is the water level measured in the surrounding lakes considered as a constant head boundary, here the Great Slave Lake, hb (m) is the water level measured in the pumping well (borehole) or the main mine shaft in our case, K (m s−1) is the hydraulic conductivity of the surrounding host rock, d is the thickness of the aquifer assumed equivalent to the mine depth (m), and rL (m) is the distance between the center of the main mine shaft and the surrounding lakes. Assuming that the water level remains constant in the mine shaft (although it can fluctuate through the year), the total volume of water infiltrated Vgw (m3) is obtained by multiplying the pumping rate and the time of infiltration, which is considered equivalent to the duration of the heat pump system operation, thus:

Using the total volume of water infiltrated over a period of 25 years and assuming it infiltrated at a temperature equivalent to T0, and that it can be changed to Tm, then it is possible to calculate Pgw with Eqs. 2 and 3.

Power Made Available to Buildings

The total power produced from the mine (Eq. 1) is different from the power available to heat and cool buildings; the latter also depends on the efficiency of the heat pump system. It is also important to evaluate the power needed to pump water out of the mine. Thus, the electrical power for the water pump Pp (W) is approximated as (Cengel and Boles, 2006):

where \({q}_{\mathrm{hp}}^{^{\prime}}\) (m3 s−1) is the water flow rate going through the heat pump or the water flow rate that will be circulated in the mine for the heat pump operation, ρw (kg m−3) is the density of water, g (9.81 m s−2) is the gravitational acceleration and hp (m) is the head difference at the pump assumed here as the pump depth for the worst-case scenario.

The flow rate is determined based on the temperature difference at the entry and exit of the heat pump, thus:

The mechanical work required for the heat pump Whp (W) is determined based on the coefficient of performance (COP (-)) of the heat pump system in the heating or cooling mode. The COP for a heat pump is the ratio of the thermal power (heat or cold) delivered to the building over the electric power required to operate the heat pump. Equations 10 and 11 express the mechanical work in the heating and cooling mode as a function of the total power released from the mine water (Cengel and Boles, 2006), thus:

The COP is determined based on the temperature of water entering the heat pump being assumed to Tm and the flow rate \({q}_{\mathrm{hp}}^{^{\prime}}\) of the heat pump with performance data reported by manufacturers for commercial heat pumps (Raymond, 2018). Finally, the COP and total power released from the mine allows evaluation of the thermal power made available to the buildings (Cengel and Boles, 2006), thus:

where Qheating (W) is the power delivered to the buildings in heating mode and Qcooling (W) is the power extracted from the buildings in cooling mode.

Heat Loss in the Case of Underground Heat Storage

Water in an underground mine can be used for underground heat storage. During the cooling operation of buildings, the water injected in the mine will be warmer than the mine water and can be stored. However, an amount of heat from the injected water will be lost by conduction. The heat conduction in the surrounding host rock contributes to the spread of heat in the cold water of the equivalent mine tunnel length (Bloemendal and Hartog, 2018). The heat loss depends on the geometric shape of the thermal storage volume (Doughty et al., 1982). To evaluate the heat loss, the thermal storage volume can be simplified into a cylinder where the thermal radius rth (m) is defined as (Doughty et al., 1982):

where cb = θ cw + (1-θ) cr with θ (−) being the porosity of the host rock and cr (MJ m−3 K−1) the volumetric heat capacity of the host rock, and Vinj (m3) is the volume of water injected in the mine tunnel for storage. Vinj (m3) can be determined by multiplying the injected flow rate or the operating flow rate of the heat pump \({q}_{\mathrm{hp}}^{^{\prime}}\) (Eq. 9) by the operating lifetime of the system (here 25 years). The heat loss in the case of underground thermal energy storage H (W) is finally evaluated as:

where Ab is the lateral area of the cylindrical volume where heat is stored (m2).

Number of Buildings that Can be Heated

As a last step, the number of buildings that can be heated or cooled with a heat pump system using the Con Mine water was evaluated according to the energy demand of archetype buildings (e.g., elementary school, offices, etc.) available in a database of the American Society of Heating, Refrigerating and Air Conditioning Engineers (Crawley et al., 2000). This database provides essential information about buildings located in Denver, USA. The simulation files of archetype buildings were taken, and new building simulations were made with the EnergyPlus software (Energy plus, 2021; Tab 1) considering the climate of Yellowknife (Engineering Climate Services, 2021). This allowed assessment of the heating and cooling needs of typical buildings that could potentially be constructed in Yellowknife. The number of buildings that can be heated or cooled n (−) was determined as:

where Eheating (Wh) is the energy delivered to the buildings determined by multiplying Qheating by the number of hours in a year (8760 h) and Ebuilding (Wh) is the energy annually consumed by the buildings.

Results

Input Parameters Needed for Resource Assessment

The geothermal gradient was measured in an exploration borehole near the mine site down to a depth of 300 m (Ngoyo Mandemvo, 2022). This near-surface gradient was corrected for paleoclimate to estimate heat flux and the host rock temperature was extrapolated to a depth of 1.9 km, or the depth of the deepest (Robertson) mine shaft (Ngoyo Mandemvo, 2022). T0 results from a volume-weighted average where the volume represents the mine voids and is the weighting coefficient. The extrapolated geothermal gradient was used to estimate the temperature of the mine voids at depth. The minimum operating temperature in heating mode was fixed to 2 °C. Below this temperature, water can freeze and damage piping systems. In Yellowknife, cooling is not an important component of the building loads. However, the maximum cooling temperature was fixed to 35 °C, which is the maximum water temperature that can enter the heat pump to function properly. The total volume of the mine is 3,670,000 m3 (Silke, 2009) and, to determine the void volume filled with water, the total volume was multiplied by a tonnage factor of 64%, characteristic of basaltic rock considering subsidence in the mine although difficult to exactly determine (Ofoegbu et al., 2008). The COPheating and COPcooling have been evaluated to 4.2 and 5.7 according to the selected operating temperature (Table 1). Thermal properties required for this calculation are the thermal conductivity and diffusivity of the surrounding host rocks, which were evaluated with laboratory measurements on 25 samples collected at the mine site. A thermal conductivity scanner was used to measure the thermal properties (Popov, 2017) that are detailed in Ngoyo Mandemvo (2022).

Buildings simulated with Yellowknife weather conditions using EnergyPlus are presented in Table 2 giving the annual heating energy demand and area.

Total Thermal Power Released from the Mine and Heat Loss

The total thermal power that can be released from the mine is the summation of the power from mine water, host rock and infiltrating water. The power from mine water was estimated with Eqs. 2 and 3 and is equivalent to 0.24 MW in heating and 0.18 MW in cooling, the power from the rock was estimated with Eq. 4 and equals 0.96 MW in heating and 0.7 MW in cooling, and the power from groundwater infiltration was estimated with Eqs. 2 and 3, and is 0.3 MW in heating and 0.22 MW in cooling (Table 3). Equation 1 gives the total power extracted from the mine site for heating operations, which is 1.5 MW, and 1.1 MW for cooling operations. This calculation shows that power extracted or injected from the rock is the main component of the thermal power budget used to define the geothermal potential, although the contact surface between rock and water was decreased for the estimation with the finite line source equation. In the case of the Con Mine, where there is a water body near the mine and a significant hydraulic conductivity, the power associated with the infiltrated water also gives a non-negligible contribution to the mine thermal power budget. The total thermal power and energy that can be delivered to the buildings for one year are 2 MW and 17,520 MWh in heating and 0.94 MW and 8234 MWh in cooling (Table 3). Equation 9 gives the pumping rate in the heating and cooling cases, which is 0.02 m3 s−1. During the cooling operation, the heat stored through water in the ground dissipates. The thermal radius where it occurs is 55 m and the amount of heat loss is estimated to 0.2 MW.

Number of Buildings that Can be Heated

An estimation of the number of buildings that can be heated with a heat pump system using the Con Mine water is given based on the heat delivered to the buildings (Table 2) and a comparison with the heating demand for buildings simulated with EnergyPlus. Figure 7 shows that at least 18 medium offices of a total of 89,676 m2 or 17 elementary schools of a total of 116,807 m2 or 17 small hotels of a total of 68,221 m2 or 13 outpatient healthcare of a total of 49,452 m2 could be heated by the mine water. Knowing the heat demand for these buildings, other infrastructure with similar demand can also be considered. Note that given heat loss during transportation, results can vary if buildings are to be heated in Yellowknife that is away from the Con Mine. It may be more efficient to examine development potential on the mine site itself or in a nearby industrial park.

Discussion

The study of the geothermal potential of the Con Mine previously conducted by Ghomshei (2007) used the volumetric method of Muffler and Cataldi (1978), and the study of Ferket et al. (2012) used the surface thermal flux method of Lawless (2010). The geothermal potential reported for the Con Mine by Ghomshei (2007) was 0.3 MW and that reported by Ferket et al. (2012) was 0.4 MW. These methods underestimated the geothermal potential, because they did not consider heat that can be transferred by conduction from the surrounding host rock and heat from groundwater continuously infiltrating the mine. The thermal power budget achieved in this study provides a more complete first-order assessment of the geothermal power that can be produced from the mine site, estimated at 2 MW for heating conditions. Our assessment neglected surface heat exchange and the natural terrestrial heat flux. We assume that heat gained and lost at the surface will balance throughout a year such that it can be omitted from the energy budget. The calculations made by Ferket et al. (2012) based on the terrestrial heat flux can be considered as the rate at which the geothermal resource is being renewed, and it is smaller than the resource itself benefiting for the thermal inertia of the water and rock masses as well as the water infiltrating the mine. Our results showed that the heat released from the surrounding rock mass is the main source of the thermal power budget. One parameter that plays a major role in this calculation is the radius of the well. The higher the radius, the less the heat exchange surface between the rock and water will be. A good knowledge of the mine geometry can help assess the average radius. Thus, it is recommended to use updated maps of the current state of the mine to get a reasonable estimate of the average radius. It is also recommended to perform a detailed bedrock characterization when applying the method to a similar mine as thermal conductivity influences the amount of heat that can be extracted by conduction. Moreover, when there is water infiltration into a mine, this component of the thermal power budget should be considered for the geothermal potential assessment. The energy extracted from the volume of water flooding the mine is the component of the thermal power budget that had the smallest contribution to the total power that can be extracted from the Con Mine system. This component depends on the mine water volume that was estimated with a tonnage factor. Coal mines commonly collapse, reducing the potential reservoir volume (Andrews et al., 2020). Water volume is expected to be about 13 to 34% of a coal mine’s volume (Song et al., 2020). This number should be higher for base metal mines where collapse is not as frequent as in coal mines but should take into account potential backfilling. Old mines are typically not backfilled while backfilling has been adopted with most recent mining operations.

Most geothermal potential assessments of mine sites have been conducted based on the volumetric method. The comparison of the geothermal potential from the Con Mine to other mines is challenging because every mine is different, but it should be kept in mind that different assessment methods could have been used. Moreover, the extractable heat related for each case depends on potential temperature increase or decrease of the mine water, which is different from one study to another. The heating potential of deep flooded copper mines in the USA has been assessed by Bao et al. (2019) using the volumetric method; results are, for a total mine water volume of 1.47 ×107 m3 and a temperature difference of 38 °C, an available energy content of 652 GWh. In Spain, the geothermal potential of Lieres Mine was assessed for a use of 1700 h per year. The mine water had been assumed to be 26 °C and a heat extraction of 5 °C would produce 0.41 GWh per year for a pumped volume of 60,000 m3 (Menéndez et al., 2019). Díez and Díaz-Aguado (2014) estimated for the Collieries in Spain that 2.5 MW of thermal power could be available for each 10,000,000 tonnes of rock extracted. The potential of the previous studies are very different than those of the Con Mine, but give an idea of the expected order of magnitude of thermal power contained in mines.

The thermal power budget proposed here can be applied to other mines knowing key parameters such as mine volume, water level in the mine, average subsurface temperature, and thermal conductivity and diffusivity of the surrounding host rock. Thus, it does not require intensive field work or numerical model development to give a first-order assessment of a mine’s geothermal potential. This method is in contrast to the Cumming (2016) approach, which requires a geophysical survey to accurately define the volume of the reservoir. The planar fracture method requires a good understanding of the structural geology and groundwater flow, which is not always evident. Sanyal and Sarmiento's (2005) method could be used to assess the geothermal potential of a mine but requires extensive numerical simulations of the system operation. This can be seen as the next step to better define the geothermal potential of the Con Mine site. The advantage of the thermal power budget method we propose is to provide a quick estimation of the geothermal potential of an underground mine. The simplifications of the mine geometry needed to be made to evaluate heat transferred from the surrounding host rock and to evaluate the quantity of water infiltrating the mine, but the approach can be widely applied. However, convective heat transfer is neglected with this method, the temperature of the subsurface is assumed constant, and the cylindrical geometry reduces the heat exchange surface between water and the host rock, meaning that the available thermal energy is likely underestimated. The method also assumes continuous heating or cooling during the life of the system, which may not be the case. We believe that the proposed thermal power budget provides an improved estimate of the Con Mine geothermal potential compared to the one of Ghomshei (2007) and Ferket et al. (2012), but that it still likely underestimates the full potential.

In any case, the geothermal potential of a flooded mine system is often above the heating need of proximal buildings, like for the Rožná deposit in the Czech Republic (Vokurka and Kunz, 2022). This and other studies reporting 44 geothermal demonstration projects that have been inventoried at mine sites around the globe clearly showed the vast potential of flooded mines that can be used sustainably for geothermal purposes (Chu et al., 2021). Another potential use of flooded mines is large-scale pumped hydro storage (Jiang et al., 2021). Despite these options for sustainable usages of flooded mines, operational challenges such as scaling and corrosion management may persist and needs to be carefully considered (Banks et al., 2022).

Conclusions

Our results provide an improved volumetric approach and thermal power budget calculation to better estimate the geothermal potential of flooded mines. The thermal power budget used in this work combined with an analysis of the heat pump system efficiency revealed that the energy, in the example case of the Con Mine, that can be delivered annually to buildings is 17,520 MWh in heating mode and 8234 MWh in cooling for a heat pump system continuously operated using the Con Mine water. The number of building units that could be heated with this system depend on the heat demand that is different for each building type. Several buildings of each archetype considered are feasible, showing a significant district heating potential. However, it must be emphasized that archetype buildings considered for this analysis may not be feasible to build near the Con Mine site and were only used as an example. Technical and economic constraints will most likely affect the type and number of buildings that can be supplied by such a heat pump system. For example, the initial construction cost of a district heating system can be important if infrastructure to carry water out of the site is needed.

The next step of this research is to develop a numerical model that can simulate advective heat transfer in the mine and surrounding fractured host rock considering production and injection of groundwater in the shafts and varying heat demand during the year. This will provide a complete estimate of the geothermal potential of the Con Mine that can be compared with that obtained with the thermal power budget.

References

Andrews, B. J., Cumberpatch, Z. A., Shipton, Z. K., & Lord, R. (2020). Collapse processes in abandoned pillar and stall coal mines: Implications for shallow mine geothermal energy. Geothermics, 88, 101904.

Banks, D., Steven, J. K., Berry, J., Burnside, N., & Boyce, A. J. (2019). A combined pumping test and heat extraction/recirculation trial in an abandoned hematite ore mine shaft, Egremont, Cumbria, UK. Sustainable Water Resources Management, 5(1), 51–69.

Banks, D., Steven, J., Black, A., & Naismith, J. (2022). Conceptual modelling of two large-scale mine water geothermal energy schemes: Felling, Gateshead, UK. International Journal of Environmental Research and Public Health, 19(3), 1643.

Bao, T., Meldrum, J., Green, C., Vitton, S., Liu, Z., & Bird, K. (2019). Geothermal energy recovery from deep flooded copper mines for heating. Energy Conversion and Management, 183, 604–616.

Bloemendal, M., & Hartog, N. (2018). Analysis of the impact of storage conditions on the thermal recovery efficiency of low-temperature ATES systems. Geothermics, 71, 306–319.

Cengel, Y., & Boles, M. (2006). Thermodynamics. An engineering approach (5th ed.). McGraw-Hill.

Chu, Z., Dong, K., Gao, P., Wang, Y., & Sun, Q. (2021). Mine-oriented low-enthalpy geothermal exploitation: A review from spatio-temporal perspective. Energy Conversion and Management, 237, 114123.

Cimmino, M., Bernier, M., & Adams, F. (2013). A contribution towards the determination of g-functions using the finite line source. Applied Thermal Engineering, 51, 401–412.

Crawley, D. B., Pedersen, C. O., Lawrie, L. K., & Winkelmann, F. C. (2000). EnergyPlus: Energy simulation program. ASHRAE Journal, 42, 49–56.

Cumming, W. (2016). Resource conceptual models of volcano-hosted geothermal reservoirs for exploration well targeting and resource capacity assessment: Construction, pitfalls and challenges. GRC Transactions, 40, 623–638.

Díez, R. R., & Díaz-Aguado, M. B. (2014). Estimating limits for the geothermal energy potential of abandoned underground coal mines: A simple methodology. Energies, 7(7), 4241–4260.

Doughty, C., Hellström, G., Tsang, C. F., & Claesson, J. (1982). A dimensionless parameter approach to the thermal behavior of an aquifer thermal energy storage system. Water Resources Research, 18(3), 571–587.

Duwiquet, H., Arbaret, L., Guillou-Frottier, L., Heap, M. J., & Bellanger, M. (2019). On the geothermal potential of crustal fault zones: A case study from the Pontgibaud area (French Massif Central, France). Geothermal Energy, 7(1), 1–29.

Energy Plus. (2021). All Regions—North and Central America (WMO Region 4)—Canada—Northwest Territories (9.4.0) [Computer software]. Energy plus. Philadelphia. https://energyplus.net/. Accessed 2 Sept 2020.

Engineering Climate Services. (2021). Engineering Climate Datasets. Canada. https://climate.weather.gc.ca/prods_servs/engineering_e.html. Accessed 5 Oct 2021.

Eyerer, S., Schifflechner, C., Hofbauer, S., Bauer, W., Wieland, C., & Spliethoff, H. (2020). Combined heat and power from hydrothermal geothermal resources in Germany: An assessment of the potential. Renewable and Sustainable Energy Reviews, 120, 109661.

Ferket, H., Laenen, B., Harcouët-Menou, V., Lagrou, D., & Van Tongeren, P. (2012). Presentation. Evaluation of Con Mine energy resource. VITO. Yellowknife.

Ghomshei, M. (2007). Geothermal energy from Con Mine for Heating the City of Yellowknife, NWT: A concept study. 18. University of British Columbia. Yellowknife.

Grant, M. (2010). Geothermal resource proving criteria. In Proceedings World Geothermal Congress, 4 pp. Netherlands.

Grasby, S., Allen, D., Bell, S., Chen, Z., Ferguson, G., Jessop, A. M., Kelman, M., Ko, M., Majorowicz, J., Moore, M., Raymond, J., & Therrien, R. (2012). Geothermal energy resource potential of Canada, Geological Survey of Canada, 2012, Open File 6914 (revised), 322 pp. https://doi.org/10.4095/291488

INTERA. (1997). Hydrogeological and hydrogeochemical study of the miramar con mine. Technical report. INTERA consultants. Ottawa.

Jardón, S., Ordóñez, A., Álvarez, R., Cienfuegos, P., & Loredo, J. (2013). Mine water for energy and water supply in the central coal basin of Asturias (Spain). Mine Water and the Environment, 32(2), 139–151.

Jessop, A. M., MacDonald, J. K., & Spence, H. (1995). Clean Energy from abandoned mines at Springhill, Nova Scotia. Energy Sources, 17(1), 93–106.

Jiang, D., Chen, S., Liu, W., Ren, Y., Guo, P., & Li, Z. (2021). Underground hydro-pumped energy storage using coal mine Goafs: system performance analysis and a case study for China. Frontiers in Earth Science, 9, 760464.

Lawless, J. (2010). Geothermal lexicon for resources and reserves definition and reporting (2e éd.). Australian Geothermal Energy Group. The geothermal Code Committe. Adelaide. https://www.petroleum.sa.gov.au/media/shared/pdf/geothermal/ageg_tigs/tig_02/Geothermal_Lexicon_2010.pdf

Miramar Con Mine Ltd. (2007). Miramar Con Mine, Ltd. Final closure and reclamation plan (p. 302). Technical report. Yellowknife. Miramar Con Mine Ltd. https://bit.ly/3air9IE. Accessed 3 Apr 2020.

Luo, J., Xue, W., & Lu, X. (2021). Characterization of the hydrothermal potential for the cap strata of Yangzte Block (YB), China. Geothermics, 96, 102148.

Menéndez, J., Ordóñez, A., Álvarez, R., & Loredo, J. (2019). Energy from closed mines: Underground energy storage and geothermal applications. Renewable and Sustainable Energy Reviews, 108, 498–512.

Muffler, P., & Cataldi, R. (1978). Methods for regional assessment of geothermal resources. Geothermics, 7(2), 53–89.

Ngoyo Mandemvo, D. (2022). Potentiel géothermique des mines inondées: étude de la mine Con (p. 153). Master’s Thesis. Institut national de la recherche scientifque. Quebec city.

Ofoegbu, G., Read, R., & Ferrante, F. (2008). Bulking factor of rock for underground openings. Book. Center for Nuclear Waste Regulatory Analyses. San Antonio. https://www.nrc.gov/docs/ML0807/ML080700314.pdf

Philippe, M., Bernier, M., & Marchio, D. (2009). Validity ranges of three analytical solutions to heat transfer in the vicinity of single boreholes. Geothermics, 38(4), 407–413.

Popov, Y. (2017). Thermal conductivity (TC) and Thermal diffusivity (TD) scanner (Allemagne). TCS - Lippmann and Rauen GbR. Manual. Schaufling. http://www.geophysik-dr-. rauen.de/tcscan/downloads/TCS-Manual.pdf. Consulté, le 07/08/2021.

Preene, M., & Younger, P. L. (2014). Can you take the heat? – Geotherma energy in mining. Mining Technology, 123(2), 107–118.

Purba, D., Nugraha, R. P., Adityama, D. W., Ayuningtyas, R. R., Chandra, V. R., Al-Hassan, M. A., Ramadhan, R. F., Rizqy, M. M. (2021). Resource assessment methods selection for geothermal exploration project in Indonesia: What are the consideration? In Proceedings in 46th workshop on geothermal reservoir engineering Stanford University, Stanford, California, February, pp. 15–17.

Raymond, J. (2018). Colloquium 2016: Assessment of subsurface thermal conductivity for geothermal applications. Canadian Geotechnical Journal, 55(9), 1209–1229.

Sanyal, S., & Sarmiento, Z. (2005). Booking geothermal energy reserves. Geothermal Resources Council Transactions, 29, 467–474.

Silke, R. (2009). The operational history of mines in the Northwest territories. Technical report. N.W.T. Geoscience Office Yellowknife. Yellowknife.

Song, H., Xu, J., Fang, J., Cao, Z., Yang, L., & Li, T. (2020). Potential for mine water disposal in coal seam goaf: Investigation of storage coefficients in the Shendong mining area. Journal of Cleaner Production, 244, 118646.

Northwest Territories Geological Survey. (2021). Map of the geological provinces of the Northwest Territories [Map]. Yellowknife. Northwest Territories Geological Survey. Yellowknife. https://webapps.nwtgeoscience.ca/Html5Viewer/index.html?viewer=NTGSwebGIS2.NTGSwebGIS. Consulté, le 12/09/2021.

Vokurka, M., & Kunz, A. (2022). Case study of using the geothermal potential of mine water for central district heating—The Rožná deposit, Czech Republic. Sustainability, 14(4), 2016.

Wenzel, L. (1935). The Thiem method for determining permeability of water-bearing materials. Book. Conservation and Survey Division of the University of Nebraska. Nebraska. https://core.ac.uk/download/pdf/188132752.pdf

Acknowledgments

The support of the Northwest Territories Geological Survey, the Geological Survey of Canada, Newmont Mining and the Northern geothermal potential research chair funded by the Institut nordique du Québec is acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ngoyo Mandemvo, D.D., Comeau, FA., Raymond, J. et al. Geothermal Potential of Closed Underground Mines: Resource Assessment Study of the Con Mine, Northwest Territories, Canada. Nat Resour Res 32, 1579–1593 (2023). https://doi.org/10.1007/s11053-023-10214-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11053-023-10214-3