Abstract

Municipal solid waste (MSW) becomes a complex problem in Indonesia due to various reasons such as the increase of population, increasing quantity of waste, environmental health caused by unorganized waste, and also lack of public awareness. Various considerations have influenced the methods of waste management in different countries, such as amount and type of waste produced, type of waste collection, available area, and environmental regulations practiced. One of the methods suitable for MSW condition in Indonesia is landfill gas (LFG) production. This study reports about the MSW management in Indonesia, which main focus is the landfill gas production using the LandGEM equation and Intergovernmental Panel on Climate Change (IPCC) methodology. Both approaches are applied to several cities in Indonesia including Medan, Jakarta, Semarang, Yogyakarta, Denpasar, Pontianak, and Makassar which has a higher percentage of waste generated compared to other cities. The findings of this paper indicated that 20.23 × 106 tons/year MSW produced in Indonesia could generate as much as 875,130 tons/year of methane as the main component of landfill gas. As additional information, this amount of waste theoretically could generate 54,142 MW electricity/year.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Energy crisis, environment pollution and climate change due to carbon dioxide (CO2) produced from the use of fossil fuels are the serious challenges to people worldwide. This circumstance attracts more public attention in the development and utilization of alternative, non-petroleum-based renewable sources of energy to slow down global warming and develop a society in an environmentally sustainable method. It is critical today to focus on the use of existing limited resources and to identify new technologies and renewable resources for future energy supply [1]. For a long time, various sources of renewable energy are being investigated to meet the increasing energy consumption rate. The developing countries, such as Indonesia, are going ahead to face the shortage of available energy. Currently, the final energy supply in Indonesia is dominated by oil, gas, and coal which totally achieved 95.8% of the final energy consumption of 97 MTOE [2].

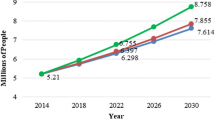

Indonesia is a country with about 242 million total populations, comprised of 33 provinces, 17,508 islands, and around 1890,000 km2 total area. Indonesia has a high population growth rate which is about 1.2% per year [3]. The Gross Domestic Product (GDP) growth rate in Indonesia averaged at 5.0% p.a. from 2013 to 2016. This growth average will be stable at 5.0% until 2021 based on the forecast of the Economist Intelligence Unit [4]. In line with the GDP growth rate, the energy and electricity demand in Indonesia has increased significantly. The electrification ratio and electricity consumption vary across the Indonesian archipelago. The national electrification ration in 2016 was 91.16% with uneven distribution. The more the industrialized areas, such as the western parts of the country, the higher the ratio, as high as 99.98% (DKI Jakarta). Meanwhile, the eastern parts of Indonesia have a lower ratio as low as 4.78% (Papua). The electrification ratio in Indonesia is set to increase to 97.4% by 2019 and to 99.7% by 2025 based on the 2017–2026 PLN Electricity Supply Business Plan [4]. In 2018, electricity consumption per capita in Indonesia is 199 billion kWh/year which is considered higher compared to some low–middle-income countries such as Vietnam (134 billion kWh/year), Philippine (74 billion kWh/year), Pakistan (86 billion kWh/year), Lao PDR (4 billion kWh/year), Cambodia (5 billion kWh/year), and Sri Lanka (12 billion kWh/year) [5].

Meanwhile, the rapid development in population and acceleration of economic activity give rise to higher volumes of organic wastes, plastic packaging, and industrial by-products. The increment of waste amount without strict waste management further has created the tendency of waste accumulation at the end point, landfill [6]. In Indonesia, Municipal Solid Waste (MSW) becomes a complex problem due to a variety of reasons such as the increasing quantity of MSW, lack of public awareness, and complicated municipal administration policies in different cities and surrounding regencies [7]. Other than the high waste generation over the past decade which is about 0.8 kg to 2.1 kg/capita/day, several problems regarding waste management in Indonesia exist such as low quality of waste management, limited final disposal sites, and financial problems [8, 9]. The amount of waste generated and low-quality waste management have created problems in almost all steps of waste management including storage, collection, transferring, and transporting [7]. Commonly, the collected waste is brought to intermediate disposal site (in Indonesia is called TPS). It is estimated that a total of 59,000 TPS are scattered throughout Indonesia. In most cases, these wastes are then transported to the landfills near the area using waste transportation trucks. However, approximately 31% of waste in Indonesia is not collected by the municipal services. This non-collected waste is managed by the communities themselves in terms of collection, transportation to dump sites, buried, composted, burnt in the open air, or thrown into the rivers [10, 11]. The percentage of MSW handling methods is shown in Fig. 1 [10, 11].

From the environmental point of view, the waste sector is the fourth biggest greenhouse gas (GHG) emission contributor among other sectors such as forestry, agriculture, and industry [12, 13]. According to the Indonesia GHG inventory, in 2000, the net emission of GHG in Indonesia was 1.38 Giga ton CO2 equivalents (GtCO2e) and will become 2.95 GtCO2e in 2020. Improper waste management not only led to CO2 emission but also methane (CH4) emission. Methane has a 21% higher global warming than CO2. It is, therefore, not surprising that eliminating methane emissions from MSW can substantially lower the world’s overall GHG emissions [13]. On the other hand, MSW is considered as one of the most promising options for the production of Landfill Gas (LFG) which acts as an alternative source of energy [14].

Different LFG prediction models are available based on zero-order equation such as EPER Germany, and SWANA zero order; first-order decay equation such as LandGEM, Intergovernmental Panel on Climate Change (IPCC), SWANA TNO, GasSim, Afvalzorg, EPER France, Mexico, and LFGGEN. Complex mathematical model such as Halvadakis method is also available which is considered hard to be calculated since it follows the carbon in methane production chain from solid carbon up to carbon in CH4 [15]. IPCC and LandGEM are commonly used in several previous studies to predict the potential LFG (methane) production.

Several measurements have been done in Indonesia which indicates the high potential of LFG production in several cities. The measurement also becomes important to discover whether the LFG produced is feasible to be mined and recovered. In 2007, the Indonesian agency for the assessment and application of technology (BPPT) had carried out the direct LFG measurement using equation LandGEM published by the environment protection agency (EPA) under the United States [16, 17]. Asiyanthi et al. has conducted a field survey to measure CH4 concentration on three Indonesian landfill sites: Bantar Gebang landfill in Bekasi, Cipayung landfill in Depok City, and Tamangapa landfill in Makassar City [18]. They were using Laser Methane Detector (LMD) and pole measurement to measure ambient CH4 concentration, LMD and chamber to measure CH4 flux, and Geotechnical Analysis (GA) 2000 for analyzing underground CH4 concentration [19, 20]. The highest ambient CH4 concentration in Bantar Gebang, Cipayung, and Tamangapa landfill sites are 1,718.2 ppm, 4445.2 ppm, and 3043.2 ppm. The highest CH4 flux in Bantar Gebang, Cipayung, and Tamangapa landfill sites are 74.23 g/m2/h, 53.55 g/m2/h, and 53.70 g/m2/h, while underground CH4 concentration measurement are 52.93%, 54.40%, and 53.83% for Bantar Gebang, Cipayung, and Tamangapa, respectively [18]. Alan et al. has observed the potential of landfill gas production in Basirih final disposal site in Borneo Island to be developed into a waste power plant using LandGEM equation [17]. The result shows that the Basirih final disposal site has a potency to produce landfill gas as much as 8,176,975 m3/year which can be converted into 12,848,929 kWh electrical power [17].

This paper is expected to provide comprehensive information regarding waste in Indonesia, including policies, the technology to convert waste into energy, landfilling and LFG potential production, and also challenges in waste management in Indonesia. Moreover, this study also describes the significance of contribution of waste as a renewable energy resource as well as for renewable energy generation.

Waste policies in Indonesia

Compared to other developing countries, the level of MSW management quality in Indonesia provided by the municipalities is rather low. Inadequate waste regulations, low implementation, low budgets and low private participation are some of the causes for the low level of service in MSW Management. Regarding the waste policies, the first regulation on MSW in Indonesia is a National Regulation no. 21/PRT/M/2006 on the National Policy and Strategies for the Development of Waste Management System issued by The Minister of Public Works [21]. This regulation addressed that communities should be involved in waste management. However, in this law, the methods and techniques of sustainable waste management were not yet provided, therefore, resulting in negative impacts on environmental health [21, 22]. To overcome this problem, the President of the Republic of Indonesia enacted Act no. 18 the year 2008 on waste management that covers public service principles, waste minimization, handling of domestic solid waste and specific waste, incentives and disincentives mechanism, local government responsibility, financial system, and also private and public sector participation [8, 22, 23]. It is stated in the Act that the management of wastes should be done in a comprehensive and integrated manner to give economic and health benefits, and environmentally safe [8], [22]. However, this law was considered weak in terms of accommodating regional waste regulations [10].

Another regulation regarding waste management in Indonesia is Regulation of The Minister of the Interior no. 33 of 2010 on The Guidelines for Waste Management [24]. According to this regulation, waste management is systematic, comprehensive, and continuous activities including planning, reducing, and handling the wastes. The management of waste by local authorities is conducted through sorting, collection, transportation, treatment, and final disposal of waste [17, 25, 26]. The latest regulation about waste in Indonesia is the Act no. 81 the year 2012 as an implementation of Act no. 18 year 2008 [27]. One aspect that is emphasized in this legislation is to provide the implementation of the 3R (reduce, reuse, and recycle) by requiring the citizens to segregate their waste as well as establishing a formal procedure for waste handling.

Indonesia’s Ministry of Environment (MoE) in February 2014 straightens up a new regulatory framework regarding the distribution of industrial waste into three types of hazardous and toxic materials [28]. These materials include physically hazardous waste that comprised of explosive and flammable materials, dangerous to human health waste that comprised of materials capable of harming the human body, and environmentally damaging waste that comprised of materials that negatively affect marine life and the ozone [28]. In the near future, the Indonesian government (GoI) indicates the upcoming legislation to tackle the present shortcomings in waste management infrastructure and facilities.

Waste to energy

In Indonesia, although the 3R activities have the highest priority in the waste hierarchy, the most preferred method for waste handling is disposal into landfills as shown in Fig. 2a. Regulation regarding waste management hierarchy was already amended in year 2012; however, it is low implemented due to low citizen’s awareness. Lack of socialization and monitoring of the implementation of regulation also become the cause. Intensive socialization to citizen and strictly continuous monitoring by government officials are highly needed to follow the waste management hierarchy. As a comparison, waste hierarchy based on The European Union’s Sixth Environment Action Programme (2002–2012) is shown in Fig. 2b [7, 22, 29]. Meanwhile on EPA hierarchy, the strategies for handling the solid waste have been ranked into source reduction and reuse as the most preferred method, followed by recycling and composting, waste to energy, and, lastly, treatment and disposal [30]. Energy recovery, also known as waste to energy, converts the wastes into heat, electricity, or fuels through various processes such as chemical conversion, conventional incineration, and advanced thermal processing as shown in Fig. 3 [31].

Schematic summary of waste to energy technologies [31]

Landfill gas recovery has been recognized as an advanced chemical conversion technology. It technically relies on the same biological decomposition process as other anaerobic digestion technologies. Landfill gas itself takes the form of a water-saturated gas mixture produced during anaerobic decomposition of biodegradable fractions in solid wastes, by which the produced gas contains about 40–60% methane [25]. Practically, LFG production begins shortly after waste is buried in a landfill and will continue to occur as long as organic waste is present. In general, organic wastes go through four main decomposition phases to produce LFG (Fig. 4) [32, 33], which occur after waste placement in the landfills. First, an oxygen decomposition occurs, taking 7–30 days from the whole decomposition process. Second, an acidic fermentation takes 1–6 months to produce intermediate products. Third, an unsteady methanogenic process occurs, in which specific chemical reactions take place in 3–30 months to process the intermediate products from previous phases, resulting in methane as the main product. Meanwhile, a steady methanogenic process takes 5–50 years depending on waste availability. In fact, the long gas production timeframe is acknowledged as an advantage of LFG production [32, 33]. In practices, critical factors affecting the amount of LFG being produced in a landfill include the mass of waste, its period of existence, and annual precipitation within the landfill [33]. Besides, the velocity of waste degradation, moisture as well as temperature affect LFG production, all of which may vary in different parts of a landfill area [34].

LGF generation and changes overtime [33]

In the literature, waste as LFG raw material has been posited as a major source of GHG, which is responsible for ozone depletion and, therefore, global warming [35,36,37]. Due to a general consensus in which CO2 from landfills is of a biogenic origin, only CH4 is accounted for as contributing to global warming in the estimation of GHG emissions from landfills [36, 38,39,40]. Experimental researches and process modelling have generally assumed one million tons (Mt) of unsorted MSW to contain an approximately 0.3 Mt of carbon in various forms. Of the amount, about 0.2 Mt would be converted to LFG, consisting of 0.09 Mt CO2, 0.09 Mt CH4, and other trace constituents [41, 42].

LFG in many ways has the potential to act as a natural fuel source in producing high-quality natural gas that can be directly injected into pipelines with the introduction of gas recovery systems [43]. In typical applications, LFG recovery systems apply a collection field consisting of wells, trenches and networked pipes. Besides, LFG is productively utilized as a substitute for natural gas at gas burning equipment and for electricity power generation. Electrical power can practically be generated from LFG through different applications, including internal combustion engines, gas turbines and microturbines [44]. Despite being beneficial, recovering CH4 from landfills has proven to only be partially successful since up to 60% of generated CH4 escapes through various leakages. Both advantages and disadvantages of LFG-powered electricity generation are summarized in Table 1 [44]. In an LFG-powered electricity generation process, technically, a large volume of CO2 and other contaminants reduce its heating value and limiting its economic feasibility. Depending on its end use(s), therefore, different treatment steps on landfill gas are necessary. Thus, it is important to have an optimized upgrading process that consumes low energy and has a high efficiency in producing high methane content [45].

Landfilling in Indonesia

In general, wastes produced in Indonesia mainly consist of organic matters (65%) with the major sources being residential zones [7, 22]. Almost all waste streams are disposed into various landfills, making most of the landfills to approach their maximum capacity [31, 32]. Figure 5 summarizes the country’s MSW composition and sources based on data from 2008 [31, 32].

According to the data, there are approximately 550 landfills available throughout Indonesia [46] which were originally designed as controlled landfills. Some of them were even built as sanitary landfills. In fact, all of them are operated with an open dumping system. The system appears to get unintentionally applied as there are irregular soil cover applications, a lot of waste pickers on landfills, an inadequate leachate treatment, no technical treatment carried out on any incoming waste, and an open release of non-treated landfill gas emissions to the atmosphere. Table 2 provides general characteristics of open dumping, controlled landfills, and sanitary landfills [17, 33].

According to the Waste Management Act (18/2008) in Indonesia, a sanitary system requires landfills to provide a properly functioning ventilation sub-system for the gas, an operational waste cell, a leachate control, and active treatments of LFG being produced [47, 48]. Recently, LFG treatments by utilizing advanced developments of flaring system have been applied to several cities through the Clean Development Mechanism (CDM) projects [48]. In practices, utilization of LFG produced from landfills for flaring or power generation creates a chance for Indonesia to earn carbon credits from landfill management in CDM projects [20]. One of the country’s landfills applying the system is Bantar Gebang landfill in Bekasi, West Java [48].

The Bantar Gebang Landfill (Tempat Pengolahan Sampah Terpadu—TPST) has been in operation since 1989, covering an area of 108 hectares divided into five waste deposition zones. It was first designed to handle 19 × 106 m3 of waste and still expandable. Since its opening, an approximately 8.3 × 106 m3 of waste had been deposited, by which more than 25,000 tons of CH4 had been produced yearly. Technically, it is equivalent to more than half a million tons of CO2. In the Bantar Gebang landfill, a business plan has been proposed to capture methane gas and convert the gas into electricity, which is expected to generate about 10 MW electricity during early operation and to increase to 25 MW power generation by 2023 [12, 46]. In the landfill, LFG is extracted by applying vertical and horizontal extraction wells. Then the LFG is cleaned and fed into a gas engine for electricity generation. The generated electricity has been providing an approximately 80,000 MWh of electricity per year to the national grid, which is expected to increase up to 100,000 MWh within the first few years, hence displacing the majority of coal-fired grid power generation [49]. Existing processes developed in a gas power plant within Bantar Gebang landfill area include weighing, dumping-related activities (unloading, relaying, leveling and staging the wastes), soil/plastic covering, pipeline installation, and gas collection [50]. Figure 6 depicts parts of pipeline installation and gas collection sub-system in the Bantar Gebang landfill.

In Indonesia, LFG power plant has been considered as a solution for addressing waste management problem due to the very large amount of existing wastes and landfills. As aforementioned, landfills in Indonesia are generally operated as open dumping sites, producing a large accumulation of waste without any separation of organic–inorganic and hazardous wastes. Therefore, an LFG power plant is posited as a short-to-middle-term solution in the country’s waste management problem. Existing open dumping landfills should hence be transformed into sanitary landfills, which were their first designated function, through a good handling of leachate and a thorough as well as proper functioning management of any produced gas. According to information gathered from site operators in several landfills, installing pipes for gas collection is considered as a more effective action compared to building bioreactor for gasification. In fact, it is particularly caused due to the type of landfill wastes in Indonesia. Looking at the field facts, this work primarily focuses on the potentials of LFG recovery for waste management in Indonesia.

Potential of landfill gas generation

To calculate the potentials of landfill gas production from MSW in several cities in Indonesia, data were gathered from wastes generated by some of the country’s major cities in 2017 [51]. Looking at the literature [7, 22], primary municipal waste generators in Indonesia include provincial-level capital cities such as Medan, Jakarta, Surabaya and Bandung (Table 3). In this work, methane, which is the main LFG component, was calculated according to the LandGEM model, which was first published by the United States Environmental Protection Agency (US-EPA), and the IPCC methodology. Practically, the LandGEM model was applied to calculate methane production in three final disposals, while IPCC methodology was used to predict the methane production in several Indonesian cities based on waste being generated.

Conceptually, LandGEM is a quantification model for quantifying emissions of total landfill gas, methane, carbon dioxide from the decomposition of landfilled waste in MSW landfills. It has been recognized as a preferred model since it is technically an automated tool based on a first-order decomposition rate equation for the quantification. LandGEM is possible to apply for estimating emissions by utilizing either site-specific data or default parameters if no site-specific data are available [52]. In general, the first-order decomposition rate produces an estimated amount of methane that will be generated in a specific period of time (year). In the US-EPA’s Excel-based LandGEM software, LFG generation is estimated based on the methane content of LFG, in which its default value is 50% [53]. Besides, LandGEM basically assumes that a methane generation process is at its peak shortly after anaerobic conditions achieved a stable state in a landfill (steady methanogenic phase) and decreased exponentially as organic materials are consumed by bacteria [53]. Inputs for calculation in LandGEM model include (1) landfill area and capacity, (2) annual amount of received waste, (3) methane generation rate constant (k) and methane generation potential (Lo), and (4) total years of landfill operation [15].

Figure 7 provides calculated potentials of landfill gas production in Bantar Gebang landfill (Bekasi), Sarimukti landfill (Bandung), and Benowo landfill (Surabaya) produced by utilizing the software. These results are practically based on waste recipient rates in landfills and other model parameters, including nutrients, acidity (pH), moisture content, and temperature of waste mass. In terms of LFG production timeframe, Sarimukti and Benowo landfills would reach their steady methanogenic process within 10–14 years, while Bantar Gebang landfill would achieve the state within 65–70 years. The difference might occur due to the amount of waste received per day by each landfill. Sarimukti and Benowo landfills have been receiving waste at about 1350 ton/day and 1500 ton/day streams, respectively. Due to the extensiveness of landfill area, Bantar Gebang landfill has been receiving waste at about 6800–7000 ton daily stream.

Furthermore, methane gas being generated is also estimated by applying IPCC methodology [38, 41]. The method has also been preferably used since it is a considerably simple approach to perform the first-order decomposition model that has a linear correlation with maximum potentials of methane production per weight unit of waste, providing an estimated annual methane emission [15]. According to IPCC methodology, methane emission from a landfill is estimated by applying the following equation:

where MSWT is the total MSW generated (tons), MSWF is the fraction of MSW disposed of to landfills, MCF is the methane correction factor, DOC is the fraction of degradable organic carbon, DOCF is the fraction of total DOC that actually degrades, and F represents fraction of methane in LFG.

In a typical situation, MCF has default values of 0.4–1.0, depending on different practices of MSW landfill operation. If most of the observed landfills are considerably unmanaged, the MCF value is set at 0.6 [41]. Technically, an MCF value represents the possibility of aerobic decomposition of top-layer waste fraction that leads to less-than-theoretically possible methane production in landfills [54]. According to IPCC, DOC ranges from 0.08 to 0.21, while its estimation is expressed as

where P is the fraction of papers in MSW, K is the fraction of kitchen garbage in MSW, and W is the fraction of woods/leaves in MSW.

In this study, the default DOC value was set at 0.16. The value was applied by considering organic carbon fraction in waste that was accessible to anaerobic decomposition. On the other hand, the default DOCF value was set at 0.77 by considering that the biodegradation of DOC is not completely occurred over a long period of time. In fact, only a fraction of DOC was practically converted into CH4 and CO2, while the rest were stored in a landfill as stable organic matters or degrade through other biological or chemical processes. Table 4 provides calculation results of methane generation in various areas in Indonesia based on the IPCC methodology.

In the current study, the potentials of electricity production from waste processing were investigated according to an existing approach proposed by Siddiqui et al. [55]. Taking data from Table 3, the quantity of MSW generated per year in Indonesia appeared to be at 20.23 × 106 tons/year. Looking at the calculation, 20.23 × 106 tons/year waste produced from several major cities in Indonesia could generate as much as 875,130 tons/year of methane as the main component of landfill gas. The amount of waste as such could theoretically generate 54,142 MW electricity/year. Input for calculation by Siddiqui et al.‘s approach include (1) quantity of MSW generated per year in Indonesia, (2) collection efficiency of MSW, (3) quantity of MSW collected per year 2017, (4) percentage of MSW disposed in open dumping landfill, (5) quantity of MSW disposed in landfill in year 2017, (6) percentage of organics/biodegradables in MSW, and (7) quantity of organics disposed in landfill in year 2017. Table 5 provides the technical steps of the calculation. Meanwhile, Table 6 provides a comparative calculation of methane being generated and its potentials for electric power generation for several provinces in Indonesia [46, 47].

Prospect and challenges in MSW management in Indonesia

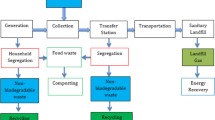

Furthermore, Fig. 8 provides data on the flow of waste treatment from sources to final recovery and methane as well as electricity production potentials based on IPCC methodology and Siddiqui et al.’s approach [55]. Both theoretical calculations take the real situation of waste management in Indonesia into account, including less percentage of waste collection and less percentage of waste brought to a landfill. In fact, the real amount of LFG being produced within a specific year was smaller than the theoretical calculations, which might occur due to an inefficient LFG collection system applied in Indonesia. To improve the country’s MSW management, the Government of Indonesia must progressively pursue a comprehensive MSWM concept involving various societal and governmental levels from household to city/country. Besides, it must also be integrated into every level of waste handling from sources of the waste to landfills. At household, community and city/country levels, the concept needs to recover MSW materials through a reuse–reduce–recycle–segregate MSW mindset. To support the purpose, the Government of Indonesia must improve MSW service access and quality for the public, including a continuous development of sanitary landfills and active technical and financial supports for implementing the MSW management concept. Figure 9 depicts the proposed solid waste management concept for Indonesia. In general, advantages being offered include a comprehensive treatment of waste as a recoverable and reusable resource to produce more beneficial materials. Besides, it can deliver simultaneous benefits across a multitude of fields, including less investments, opening job opportunities, supporting livelihoods, contributing to economic growth, protecting public health and improving quality of the environment [25].

Municipal solid waste management concept in Indonesia [25]

Then other strategic actions to improve waste management in Indonesia include a continuous improvement of the efficiency of waste collection and transportation, which would reduce waste quantity disposed through improper ways, and a progressive enhancement of utilizing the waste into energy generation [7]. Besides, intermediate treatments include a national-level composting management. In practice, the critically required action includes establishing an active collaboration involving a wide range of different stakeholders and sectoral interests. Those stakeholders must include national, regional and local governments; the private sectors, which usually play a major role and make a major contribution of waste generation; workers, including those in the informal sectors; communities and their leaders; and others related parties such as non-governmental organizations (NGOs) and academics. Furthermore, the government should show its willingness and commitment to strengthen MSW management through the promulgation of new policies and regulation detailing MSW management steps; an increased financial support; and updated technologies for converting waste to energy. Table 7 provides key points, including prospects and challenges, for a good MSW management in Indonesia.

Conclusion

This study shows that waste management in Indonesia should be improved through various considerations including the technology, community, and policy aspects. From theoretical calculation, the findings of this paper indicated that 20.23 × 106 tons/year MSW produced in Indonesia could generate as much as 875,130 tons/year of methane as the main component of landfill gas. The amount of waste as such could theoretically generate 54,142 MW electricity/year. The real LFG and electrical power produced from MSW are possible to increase or decrease depending on the total amount of waste generated and the implementation of LFG recovery system in landfills. Seeing this great opportunity, the handling of MSW in landfills must be more comprehensive and efficient by considering various aspects such as method of waste handling, waste separation, type of engine and engine efficiency for electricity production.

Abbreviations

- MSWT:

-

Total municipal solid waste generated (tons)

- MSWF :

-

Fraction of municipal solid waste disposed of to landfills

- MCF:

-

Methane correction factor

- DOC:

-

Fraction of degradable organic carbon

- DOCF :

-

Fraction of total DOC that actually degrades

- F:

-

Fraction of methane in LFG

- P:

-

Fraction of papers in municipal solid waste

- K:

-

Fraction of kitchen garbage in municipal solid waste

- W:

-

Fraction of woods/leaves in municipal solid waste

- MSW:

-

Municipal solid waste

- CO2 :

-

Carbon dioxide

- CH4 :

-

Methane

- MTOE:

-

Million tons of oil equivalent

- GDP:

-

Gross domestic product

- TPS:

-

Intermediate disposal site

- GHG:

-

Greenhouse gas

- GtCO2e:

-

Giga ton CO2 equivalents

- LFG:

-

Landfill gas

- MoE:

-

Ministry of environment

- EPA:

-

Environment protection agency

- Mt:

-

Million tons

- IPCC:

-

Intergovernmental panel on climate change

- CDM:

-

Clean development mechanism

- NGO:

-

Non-governmental organizations

- 3R:

-

Reduce, reuse, recycle

References

Jasko J, Skripsts E, Dubrovskis V (2012) Novel substrates for biogas production: Paxillus involutus and Phaeolus schweinitzii mushroom biomass. In: Energy, biomass Biol. residues. Int. Conf. Agric. Eng.—CIGR-AgEng 2012 Agric. Eng. a Heal. Life, Val. Spain, 8–12 July 2012

Ibrahim HD, Thaib NM, Abdul Wahid LM (2010) Indonesian energy scenario to 2050: projection of consumption, supply options and primary energy mix scenarios. In: The joint symposium within APEC project: energy links between Russia and East Asia: development strategies for the XXI century

Statista (2018) Indonesia: total population from 2012 to 2022 (in million inhabitants). https://www.statista.com/statistics/294100/total-population-of-indonesia/

PWC (2017) Power in Indonesia: investment and taxation guide. https://www.pwc.com/id/en/pwc-publications/industries-publications/energy--utilities---mining-publications/power-indonesia-2017.html

Index Mundi (2019) Electricity—consumption by country—thematic map—Asia. Online https://www.indexmundi.com/map/?v=81&r=as&l=en. Accessed 1 Mar 2019

Meidiana C (2010) Development of waste management practices in Indonesia. Eur J Sci Res 40(2):199–210

Chaerul M, Tanaka M, Shekdar AV (2007) Municipal solid waste management in Indonesia: status and the strategic actions. J Fac Environ Sci Technol 2:41–49

Kardono (2007) Integrated solid waste management in Indonesia. In: Proceedings of international symposium on ecotopia science 2007. https://inis.iaea.org/search/searchsinglerecord.aspx?recordsFor=SingleRecord&RN=39089454

UNCRD (2010) Implementation of 3R in Indonesia. In: The 2nd meeting of the 3R regional forum in Asia. Kuala Lumpur, Malaysia. http://www.uncrd.or.jp/content/documents/RT2_03_Indonesia.pdf

DHV B.V. (2011) Scoping study for solid waste management in Indonesia. https://www.academia.edu/4432666/scoping_study_for_solid_waste_management_in_indonesia_scoping_study_for_solid_waste

Pandyaswargo A, Onoda H, Nagata K (2012) Energy recovery potential and life cycle impact assessment of municipal solid waste management technologies in Asian countries using ELP model. Int J Energy Environ Eng 3(1):28

Sidik US (2012) Landfill gas in Indonesia: challenges and opportunities. https://www.globalmethane.org/documents/events_land_120702_msw_indonesia.pdf

KNOEMA (2012) Indonesia—methane emissions in energy sector. World Data Atlas. https://knoema.com/atlas/Indonesia/topics/Environment/Emissions/Methane-emissions-in-energy-sector

Andriani D, Wresta A, Santosa A, Kusnadi (2017) A review on the potential of biogas production from various substrates. In: Biogas: production, applications and global developments. NovaScience Publisher, pp 45–77

Kamalan H, Sabour M, Shariatmad N (2011) A review on available landfill gas models. J Environ Sci Technol 4(2):79–92

Tchobanoglous G, Theisen H, Vigil SA (1993) Integrated solid waste management : engineering principles and management issues. McGraw-Hill, New York

Haq AN, Hermawan, Karnoto (2012) Studi Potensi Pembangkit Listrik Tenaga Sampah di Kota Banjarmasin. University of Diponegoro. http://eprints.undip.ac.id/35561/

Lando AT, Nakayama H, Shimaoka T (2013) Monitoring of methane concentration in Indonesia landfill sites. In: Proceedings of the 1st IWWG-ARB symposium. https://www.tuhh.de/iue/iwwg/infos-materials/conference-proceedings/arb-2013.html

Jacobs J, Scharff H (2001) Comparison of methane emission models and methane emission measurements. https://www.afvalzorg.nl/content/uploads/2018/03/Comparison-of-Methane-emission-models-to-Methane-emission-measurements.pdf

Indrasari NN (2007) Mekanisme Pembangunan Bersih di Sektor Persampahan. Buletin Cipta Karya - POKJA AMPL. http://www.ampl.or.id/digilib/read/mekanisme-pembangunan-bersih-di-sektor-persampahan/21103

Kementerian Pekerjaan Umum (2006) Regulation of Minister of Public Works Republic of Indonesia No: 21/PRT/M/2006: Kebijakan Dan Strategi Nasional Pengembangan Sistem Pengelolaan Persampahan. Indonesia. http://ciptakarya.pu.go.id/plp/upload/peraturan/Permen_PU_No_21_Tahun_2006_-_Jakstranas_persampahan.pdf

Helmy M, Laksono TB, Gardera D (2006) 3R Implementation in Indonesia. https://www.env.go.jp/recycle/3r/en/s_officials/02_02/06.pdf

President of Republic of Indonesia (2008) ACT of the republic of Indonesia number 18 year 2008: waste management. Indonesia. http://www.vertic.org/media/National Legislation/Indonesia/ID_Waste_Management_Act_2008.pdf

Minister of Home Affair (2010) Regulation of minister of home affairs republic of Indonesia No 33 Year 2010: Pedoman Pengelolaan Sampah. Indonesia. https://pelayanan.jakarta.go.id/download/regulasi/permen-dalam-negeri-nomor-33-tahun-2010-tentangpedoman-pengelolaan-sampah.pdf

Minister of Home Affair (2010) Regulation of Minister of Home Affairs Republic of Indonesia No 33 Year 2010: Pedoman Pengelolaan Sampah. Indonesia. http://www.unep.or.jp/Ietc/Publications/spc/SPC_Training-Module.pdf

Lamb DT, Venkatraman K, Bolan N, Ashwath N, Choppala G, Naidu R (2014) Phytocapping: an alternative technology for the sustainable management of landfill sites. Crit Rev Environ Sci Technol 44(6):561–637

President of Republic of Indonesia (2012) Peraturan Pemerintah Republik Indonesia Nomor 81 Tahun 2012 Tentang Pengelolaan Sampah Rumah Tangga dan Sampah Sejenis Sampah Rumah Tangga, Indonesia. http://jdih.menlh.go.id/pdf/ind/IND-PUU-3-2012-PP-81-2012.pdf

GBG Indonesia (2014) Sweeping opportunities in Indonesia’s waste management industry. Global Business Guide Indonesia, Business Update. http://www.gbgindonesia.com/en/main/business_updates/2014/upd_sweeping_opportunities_in_indonesia_s_waste_management_industry.php

EU Publications (2010) Being wise with waste: the EU’s approach to waste management. Publications Office of the European Union, Luxembourg. http://ec.europa.eu/environment/waste/pdf/WASTE BROCHURE.pdf

USEPA (2016) Waste management hierarchy and homeland security incidents. https://www.epa.gov/homeland-security-waste/waste-management-hierarchy-and-homeland-security-incidents

Rawlins J, Beyer J, Lampreia J, Tumiwa F (2014) Waste to energy in Indonesia. United Kingdom. https://www.carbontrust.com/media/512147/ctc831-waste-to-energy-in-indonesia.pdf

Ministry of Energy and Mineral Resources (2015) Waste to energy guidebook. https://www.esdm.go.id/assets/media/content/content-handbook-of-energy-and-economic-statistics-of-indonesia.pdf

Davis G (2002) Economic and financial aspects of landfill gas to energy project development in California. http://tharwahbata.tk/download/SSrTCe_HPjQC-economic-and-financial-aspects-of-landfill-gas-to-energy-project-development-in-california

Damanhuri E, Handoko W, Padmi T (2014) Municipal solid waste management in Indonesia. In: Pariatamby A, Tanaka M (eds) Municipal solid waste management in Asia and the Pacific Islands. Environmental science and engineering. Springer, Singapore, pp 139–155. https://springerlink.bibliotecabuap.elogim.com/chapter/10.1007/978-981-4451-73-4_8

Ayalon O, Avnimelech Y, Shechter M (2000) Alternative MSW treatment options to reduce global greenhouse gases emissions—the Israeli example. Waste Manag Res 18(6):538–544. https://onlinelibrary.wiley.com/doi/abs/10.1034/j.1399-3070.2000.00158.x

Lou XF, Nair J (2009) The impact of landfilling and composting on greenhouse gas emissions—a review. Bioresour Technol 100(16):3792–3798. https://doi.org/10.1016/j.biortech.2008.12.006

USEPA (2015) Documentation for greenhouse gas emission and energy factors used in the waste reduction model (WARM). https://www.epa.gov/warm/documentation-chapters-greenhouse-gas-emission-energy-and-economic-factors-used-waste-reduction

IPCC (2006) IPCC guidelines for national greenhouse gas inventories. https://www.ipcc-nggip.iges.or.jp/public/2006gl/

Department of Environment and Energy (2017) National greenhouse accounts factor. https://www.environment.gov.au/climate-change/climate-science-data/greenhouse-gas-measurement/publications/national-greenhouse-accounts-factors-july-2018

Department of Climate Change (2007) Australian Methodology for the Estimation of Greenhouse Gas Emissions and Sinks 2006. http://www.ravenridge.com/wp-content/uploads/Australian-Methodology-for-the-Estimation-of-Greehouse-Gas-Emission-and-Sinks-20031.pdf

Tsai WT (2007) Bioenergy from landfill gas (LFG) in Taiwan. Renew Sustain Energy Rev 11(2):331–344

Zurbrügg C, Gfrerer M, Ashadi H, Brenner W, Küper D (2012) Determinants of sustainability in solid waste management—the Gianyar Waste Recovery Project in Indonesia. Waste Manag 32(11):2126–2133

Bolan NS et al (2013) Landfills as a biorefinery to produce biomass and capture biogas. Bioresour Technol 135:578–587

USEPA (2017) Landfill and LFG energy project database: project technology options. In: Landfill and LFG energy project database. USEPA. https://19january2017snapshot.epa.gov/sites/production/files/2016-09/documents/pdh_chapter3.pdf

Petersson A, Wellinger A (2009) Biogas upgrading technologies—developments and innovations Task 37 Energy from biogas and landfill gas. https://www.iea-biogas.net/files/daten-redaktion/download/publi-task37/upgrading_rz_low_final.pdf

Sutanto H (2013) Country report on the Indonesian landfill gas to energy activity: six challenge, prospects & opportunity. In: 2nd ASEAN-SCSER (SCNCER) seminar workshop: capacity building on landfill gas utilization in ASEAN

Kardono K, Purwanta W (2008) Landfill gas for energy: its status and prospect in Indonesia. J Teknol Lingkung. http://ejurnal.bppt.go.id/index.php/JTL/article/view/437

Indonesia Solid Waste Association (2013) Mei, TPA Open Dumping Harus Tutup. Indonesia Solid Waste Newsletter. http://inswa.or.id/wp-content/uploads/2013/04/Newsletter-Edisi-II-Maret-20131.pdf

Carbon Neutral Company (2015) Indonesia: Bantargebang Landfill Gas

Manurung R (2013) Managing TPST Bantargebang in a Nut Shell. 2nd ASEAN-SCSER (SCNCER) Seminar Workshop: Capacity building on landfill gas utilization in ASEAN

Badan Pusat Statisik Indonesia (2018) Statistik Lingkungan Hidup Indonesia 2018. https://www.bps.go.id/publication/2018/12/07/d8cbb5465bd1d3138c21fc80/statistik-lingkungan-hidup-indonesia-2018.html

Amalia Chusna N, Maryono M (2018) Preliminary evaluation of method to monitor landfills resilience against methane emission. Hadiyanto, Sudarno, Maryono, editors. E3S Web Conf 31:05006. https://www.e3s-conferences.org/10.1051/e3sconf/20183105006

USEPA (2005) US EPA - landfill gas emissions model (LandGEM) version 3.02 User’s Guide. https://nepis.epa.gov/Exe/ZyPURL.cgi?Dockey=P1009C8L.TXT

Scarlat N, Motola V, Dallemand JF, Monforti-Ferrario F, Mofor L (2015) Evaluation of energy potential of municipal solid waste from African urban areas. Renew Sustain Energy Rev 50:1269–1286

Siddiqui FZ, Zaidi S, Pandey S, Khan ME (2013) Review of past research and proposed action plan for landfill gas-to-energy applications in India. Waste Manag Res 31(1):3–22

Acknowledgements

The writers would like to thank Henky Sutanto from PLT-BPPT as interviewees who presented much information regarding waste management in Indonesia that support this paper. This work is part of a renewable energy research project funded by Research Centre for Electrical Power and Mechatronics—LIPI.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Andriani, D., Atmaja, T.D. The potentials of landfill gas production: a review on municipal solid waste management in Indonesia. J Mater Cycles Waste Manag 21, 1572–1586 (2019). https://doi.org/10.1007/s10163-019-00895-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-019-00895-5