Abstract

Electrical and electronic waste (e-waste) has become one of the fastest growing waste streams in the world, and many countries have established e-waste treatment enterprises to solve their e-waste problems. In this study, a life cycle assessment (LCA) was undertaken to quantitatively investigate the environmental impacts of an e-waste treatment enterprise in China. The LCA is constructed by SimaPro software version 7.2 and expressed with the Eco-indicator 99 life cycle impact assessment method. For a sensitivity analysis of the overall LCA results, the so-called CML method is used in order to estimate the influence of the choice of the assessment method on the result. According to the survey data, discarded TV sets accounted for the highest proportion of e-waste treated in the enterprise in 2010. The e-waste treatment had little environmental impact, and at the same time large environmental benefits can be achieved mainly due to the recycled resources and reuse of some components. Based on the research results, it can be seen that recycled metal, especially copper, would be of more importance for environmental benefits. Relevant results and data from this study could provide decision support to enterprise managers and government sectors.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Waste electrical and electronic equipment (WEEE or e-waste) is one of the fastest growing waste streams in the world [1–3]. During the past two decades, the Chinese economy and society have experienced significant changes, as typical of an economy in transit, and the use of electrical and electronic products has become commonplace in households, governments, institutions, organizations, and business sectors. With the rapid development of information technology and economic rapid development, more and more of these electrical and electronic products (e-products) (e.g. PCs, refrigerators, washing machines, air conditioners, and TV sets) do not work properly at present and have reached the end of their useful life. In China [4–6], though annual generation per capita is small, it is growing at an exponential pace, which is three times as high as that of the common wastes in China. The increasing “market penetration” and “high obsolescence rate” also make e-waste one of the fastest waste streams in China.

E-waste is chemically and physically distinct from other forms of municipal or industrial waste. Composition of e-waste is very diverse and differs in products across different categories [7]. It contains more than 1000 different substances, which fall under “hazardous” and “non-hazardous” categories. Broadly, it consists of ferrous and non-ferrous metals, plastics, glass, wood and plywood, printed circuit boards, concrete and ceramics, rubber and other items. Iron and steel constitutes about 50 % of the e-waste followed by plastics (21 %), non ferrous metals (13 %) and other constituents. Non-ferrous metals consist of metals like copper, aluminum and precious metals, e.g. silver, gold, platinum, palladium. The presence of elements like lead, mercury, arsenic, cadmium, selenium, and hexavalent chromium and flame retardants beyond threshold quantities in e-waste classifies them as hazardous waste [8, 9].

In order to solve the e-waste issues in China, up to end of 2010, about 81 formal dismantling enterprises appointed by the governments have begun to collect and recycling e-waste in China [10–12]. The e-waste recycling can reduce the potential environmental impacts and even bring some environmental benefits, but we do not know that how much impacts and benefits has been generated, and what measures can be carried out to improve the current e-waste treatment system.

In this study, the goal is to evaluate the environmental impact of e-waste treatment in the formal enterprises in China through the LCA method from the enterprise’s perspective. Its results will allow general conclusions, applicable to the entire e-waste treatment in China, thereby providing some valuable information for the management of e-waste in China.

Materials and method

Goal and scope

Objective of this study

The environmental performance of the formal e-waste treatment enterprises in China was calculated by conducting an LCA study based on the international standards of the ISO 14040 series [13–15]. The objective of this case study was to establish a scientific baseline that evaluates the key environmental impacts related to e-waste treatment.

System boundaries

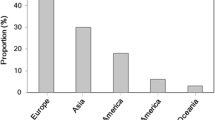

This study took into account end of life (EoL) stage of e-waste including TV sets, PCs, air conditioners, refrigerators, and washing machines. In this study, the e-waste treatment enterprise in Suzhou was chosen because it was the most typical enterprise in China, and the results of this study can lead to general observations that can be valuable for the entire e-waste treatment industry. The policy of “Old-for-New” Implementation Measures for Household Appliances in China was firstly carried into effect in 9 provinces in 2009, and the selected enterprise has been one of the first batch of pilot projects for recycling e-waste in Jiangsu Province. According to Table 1, approximately 1.57 million units discarded e-products was recycled in the enterprise during 13 months, and the ratio of different e-waste categories can also represent the basic information in China. The main treatment and disposal procedure of e-waste was shown in Fig. 1, and the boundary of this study was restricted in EoL stages based on the e-waste treatment enterprises. In Fig. 1, the difference between PWB (printed wiring board) and PCB (printed circuit board) is that the PWB will contain the components, e.g. resistors, capacitors, copper coils, and some others.

Functional units

The functional unit of this study was 1 ton of e-waste recycled in the e-waste treatment enterprise. The e-waste mainly included five kinds of discarded e-products (PCs, TV sets, washing machines, refrigerators, and air conditioners), whose percentages are given in Table 1.

Life cycle inventory

Because data availability, reliability and quality are very important, several data acquisition approaches should be performed in parallel, including direct surveys, document reviews, key informant interviews, and informal meetings. The identification, collection and review of primary and secondary documentation can provide valuable information.

In order to acquire the necessary data, a detailed survey was completed at the e-waste enterprise by research teams from December 2010 to January 2011, and at the same time the author remained physically present at this enterprise to help the teams upgrade the treatment technology for e-waste. During this period, there were many meetings and exchanges between the authors and the workers, technicians, and managers, and with their support and guidance, relevant reports, such as the local yearly sale books, and environmental reports of the enterprise, were collected.

Key informant interviews were also a valuable source of information and provided significant information on specific hard-to-find subject data. Informants can often provide information not attainable through document searches. In addition, in order to further validate collected data and information, informal meetings with local stakeholders were also held, to gather additional comments.

The e-waste types and the quantity recycled in the e-waste treatment enterprise from Jan 2010 to Feb 2011 are given in Table 1, which shows that the TV set was the most important e-waste category during the survey period.

As mentioned in Fig. 1, only the EoL stage will be evaluated in this study. The treatment and recycling processes of e-waste were restricted in the e-waste treatment enterprise; only the internal transportation was involved, not considering the previous collection and transportation of e-waste. During the recycling processes, the most important inputs would be energy, especially electricity consumption. According to the China statistics, electricity consumption consisted of coal electricity (83 %) and hydroelectricity (17 %) in mainland China. So far, no Chinese national life cycle inventory database is available for e-waste dismantling, and very little public data on e-waste or their components and materials are available. In addition, there was no practical data on the incineration and landfill for the final disposal of some dismantling waste. Therefore, Ecoinvent data v2.2 will be used to evaluate the e-waste recycling processes. The data sources as well as the assumptions and limitations described in Table 2 have been used in this study for e-waste treatment process. Tables 3, 4 show us the energy consumption and the main dismantling products in the recycling process. In order to understand well the covered processes of the energy input in Table 3, we marked the boundary in Fig. 1 (the processes between red lines). In Table 4, note that the CFC output only has a quantity of 30 kg, and compared to the input, this seems to be inadequate. According to our survey, the collected refrigerators have been used and stored for more than ten years, and were in a bad state. Before entering the treatment enterprises, most of the CFC has been emitted into the surrounding environment. In our study, the boundary was restricted in the EoL stages based on the e-waste treatment enterprises, and we did not consider the storage stage before entering the treatment enterprises. Therefore, when the refrigerators were processed in the enterprises, only very little CFC can be collected. The situation indicates that in China most CFC had been released into the air before processed, which would bring large potential threats on the ozone, and in future the governments and managers should pay more attention. Because this is beyond our research boundary, we did not consider the detailed environmental impacts in this study.

Life cycle assessment

For the impact assessment, two well-known Dutch LCIA methods were used: the Eco-Indicator 99 and the so-called Centrum voor Milieuwetenschappen (CML) methodology [16]. The Eco-Indicator 99 method is an example of a multi-step, fully aggregating method, leading to a result of one single number. The various environmental impacts examined within this method can be summed up into one of three damage categories: human health, ecosystem quality and resource consumption. The final normalization and weighting steps are then performed at this damage level [17, 18]. The overall method is an example of the damage-oriented approach. The CML method is an example of the so-called problem-oriented or mid-point approach. It is acknowledged as a proven reference in the field of LCA, and also known as the “CML Guide”. This guide provides a list of different impact assessment categories, grouped into three major types—obligatory impact categories (i.e. all those category indicators used in most LCA studies), additional impact categories (i.e. categories that have operational indicators, but are not often included in LCA studies) and other impact categories (i.e. no operational indicators available and, therefore, impossible to include quantitatively in LCA). The Eco-Indicator 99 (end-point) and CML method (mid-point) are complementary. The results of one method can be tested and verified by another method, and at the same time, the method sensitivity analysis of life cycle assessment can be completed through the two methods.

Results and discussions

Environmental impacts of e-waste treatment

The results of the impact assessment of an e-waste treatment enterprise in China are shown in Fig. 2. Because of the large ratio of discarded TV sets, the environmental performance of e-waste treatment in this study mainly stands for the environmental impacts of its treatment. Under the current processing technologies, not only environmental impacts were diminished, but substantial environmental benefits were actually derived, compared with the informal treatment in China. The recycling of metals could bring the most important environmental benefits, accounting for 52.42 % of the total benefits, followed by plastics recycling, PCB treatment, and funnel glass reuse. Among all the recycled metals, the copper was the most important, and contribute to 72.49 % of environmental benefits of metals. The main environmental impacts were from the consumption of energy (including electricity, diesel oil, and petrol) and waste treatment. From Fig. 2, it can be also seen that the environmental benefits were, first, in human health, accounting for 48.52 %, and then in resources (41.61 %) and ecosystem quality (9.87 %).

Main contributions to environmental impact

These environmental impact results are shown in more detail in Table 5, which lists the main contributors to the environmental impacts. According to the data in Table 5, it can be seen that e-waste treatment could bring large environmental benefits through avoiding the energy use and emissions to air or water, etc. Here, the highest benefits were from emissions avoided from arsenic and cadmium (ion) to water, accounting for about 49 % of the benefit, attributable to the avoidance of extraction and processing of these metals. Because of the high energy requirements in the extraction and processing of the materials, avoiding consumption of fossil resources appears to be much more important than the other three environmental impacts (metal resources, emissions to air, and emissions to water). In details, however, there were rather large differences among the various recycling processes. For example, for the recycled metal, avoiding the extraction of copper metal and arsenic emissions to water will be more important; while in the recycling of plastics, reducing the consumption of fossil resource showed the prominent environmental benefits.

Environmental impacts with the CML method

The 10 kinds of environmental impacts expressed by CML method are given in Table 6. The e-waste treatment can reduce the potential impacts on the environment and human health, e.g. for abiotic depletion and marine aquatic ecotoxicity, about 1.16E−02 kg Sb eq and 2320 kg 1,4-DB eq can be avoided through the e-waste treatment processes, and the other impact categories were also similar.

Sensitivity analysis to the methods

As can be seen from Fig. 3, all the CML factors—and also the total value of Eco-Indicator 99 (EI’99)—show a similar picture, i.e. that the recycling of metal and plastics, and PCB treatment created more important environmental impacts, while the others show less environmental benefits. Therefore, it is clear that different analysis methods will have a small influence on the results, and there was a low sensitivity to methods for the life cycle assessment of the MSW management system in this study.

In details, there are rather large differences among the various impact factors—e.g. in the recycling of metal, impacts varied from −24.93 % for ADP to −83.71 % for FAETP. And the environmental benefits due to PCB treatment varied between about 0.26 % for ADP and −46.64 % for TETP.

Conclusions

The e-waste issue in China is drawing increasing attention as a result of the rapid course of industrialization and modernization. In order to deal with e-waste, recently many formal e-waste treatment enterprises have been established in China. LCA is a suitable instrument for environmental impacts of e-waste treatment processes. Results from a life-cycle environmental assessment can be used to compare the relative environmental impacts of different enterprises, or help to focus efforts toward making environmental improvements to the treatment enterprises. These LCA results provide separate analyses for each impact category to managers and government officials, to focus on particular areas of interest. For an impact category of interest, the materials or processes that drive the impacts can be identified and can help to focus on improvement efforts.

References

Widmer R, Krapf HO, Khetriwal DS et al (2005) Global perspectives on e-waste. Environ Impact Assess Rev 25(5):436–458

Peralta GL, Fontanas PM (2006) E-waste issues and measures in the Philippines. J Mater Cycles Waste Manage 8:34–39

Waste electrical and electronic equipment (WEEE) (2005): innovating novel recovery and recycling technologies in Japan. Report of a DTI Global Watch Mission September

Liu X, Yang J, Wang R (2005) Estimation of WEEE generation in China. China Popul Resour Environ 15(5):113–117 (In Chinese)

Lin F, Wang J (2003) Study on prediction of amount of obsolete computers in China and countermeasures. Shanghai Environ Sci 22(7):479–482 (In Chinese)

Mao J (2004) “How difficult WEEE recycling is in China?” China Economic Times (In Chinese)

MEFCPCB (Ministry of Environment and Forests Central Pollution Control Board) (2008) Guidelines for Environmentally Sound Management of E-waste

Leung A, Cai ZW, Wong MH (2006) Environmental contamination from electronic waste recycling at Guiyu, Southeast China. J Mater Cycles Waste Manage 8:21–33

Robinson BH (2009) E-waste: an assessment of global production and environmental impacts. Sci Total Environ 408:183–191

Song Q, Wang Z, Li J, Duan H (2011) Effect analysis of the TOHANO policy on WEEE Recycling in China. The Sixth International Conference on Waste Management and Technology, Suzhou, China

Song Q, Wang Z, Li J, Duan H (2012) Sustainability evaluation of an e-waste treatment enterprise based on energy analysis in China. Ecol Eng 42:223–231

Song Q, Wang Z, Li J, Zeng X (2012) Life cycle assessment of TV sets in China: A case study of the impacts of CRT monitors. Waste Manage. http://dx.doi.org/10.1016/j.wasman.2012.05.007

ISO (International Standard Organization) (2012) 14040 series: environmental management—life cycle assessment—principles and framework. ISO 14040 series. http://www.iso.org/iso/iso_catalogue/catalogue_tc/catalogue_detail.htm?csnumber=37456. Accessed 29 Feb 2012

Rebitzer G, Ekvall T, Frischknecht R, Hunkeler D, Norris G, Rydberg T et al (2004) Life cycle assessment Part 1: framework, goal and scope definition, inventory analysis, and applications. Environ Int 30(5):701–720

Pennington DW, Potting J, Finnveden G, Lindeijer E, Jolliet O, Rydberg T et al (2004) Life cycle assessment Part 2: current impact assessment practice. Environ Int 30(5):721–739

Guinee J, Gorrée M, Heijungs R, Huppes G, Kleijn R, de Koning A et al (2001) Life cycle assessment—an operational guide to the ISO standards. Leiden University, Centre of Environmental Sciences (CML), Leiden

Josa A, Aguado A, Cardim A, Byars E (2008) Comparative analysis of the life cycle impact assessment of available cement inventories in the EU. Cem Concr Res 37(5):781–788

Vlasopoulos N, Memon FA, Butler D, Murphy R (2006) Life cycle assessment of wastewater treatment technologies treating petroleum process waters. Sci Total Environ 367(1):58–70

Acknowledgments

The work is financially supported by the Environmental Protection Public Welfare Project (grant number 201109035), and University of Macau.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Song, Q., Wang, Z., Li, J. et al. The life cycle assessment of an e-waste treatment enterprise in China. J Mater Cycles Waste Manag 15, 469–475 (2013). https://doi.org/10.1007/s10163-013-0152-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-013-0152-7