Abstract

In the leap of electronic vehicle era, an enormous amount of electronic trash is produced due to the growing usage of electrical and electronic devices (e-waste), which is one of the ever-increasing urgent issues, especially in developing nations. Many e-wastes are buried, burned outdoors, or discharged into surface water bodies in these nations since there is no infrastructure to handle them properly. Many developing countries currently use inefficient and highly polluting recycling techniques. Several harmful compounds of e-wastes are detrimental to the environment and endanger human health if disposal processes are not carefully handled. Design for environment cleaner production, extended producer responsibility, standards and labelling, product stewardship, recycling, and remanufacturing are some strategies many nations take to cope with the e-waste stream. This chapter discusses an overview of traditional (landfills and dumps, recycling, thermo-chemical treatment, pyrometallurgical treatment, bio-sorption, bioleaching, bioremediation methods, phytoremediation) and modern techniques (life cycle assessment (LCA), material flow analysis (MFA), and multi-criteria analysis (MCA)) in e-waste management that contribute to the eco-friendly, sustainable management of e-waste.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1.1 Introduction

Electronic wastes (e-wastes) are the remnants of electrical or electronic equipment such as computers, mobile phones, TVs, fans, washers, and dryers that have been abandoned (Rautela et al. 2021). Approximately, 17.4% of the e-waste generated globally in 2019 was properly disposed or recycled. However, the fate of the remaining 82.6% may be disposed without sufficient treatment or recycling since it was not recorded. The development of e-waste worldwide is vital due to the enormous demand for electronic goods in contemporary society. Managing e-waste requires efficient techniques and management means because e-wastes possess of several hazardous components in the form of halogenated compounds like polychlorinated biphenyls (PCBs), tetrabromobisphenol A (TBBPA), polybrominated biphenyls (PBB), etc., and these toxic materials that are harmful to plants, microbes, and humans (Kaifie et al. 2020). The issue is made worse because the informal sector in developing nations manages heavy metals (HMs), such as As, Cr, Cd, Cu, and Hg, which must be treated carefully when deconstructing electronic garbage. Additionally, the e-waste management and treatment methods are inadequate and negatively affect human health directly and indirectly (Ganguly 2016; Garg and Adhana 2019).

Among the hazardous substances found in e-waste include lead, mercury, and brominated flame retardants, to name a few. After extended exposure during risky e-waste recycling methods, these substances cause harm to practically all significant biological systems, including the nerve and circulatory systems, brain development, skin issues, lung cancer, and heart, liver, and spleen damage. This is crucial in the unorganized sector since many unorganized e-waste workers do not adhere to preventative health and safety procedures (Garg and Adhana 2019).

Conventional methods for extracting metals from e-waste can either cause secondary contamination that requires additional treatment or be extremely expensive, whereas the biological technique is more environmentally benign (Awasthi et al. 2019). Further compared to chemical and physical processes, the equipment required for bioremediation is cost-effective (per unit volume) and minimum (readily available). Furthermore, microbial bioremediation facilitates the complete breakdown of organic toxins into simpler compounds naturally, preventing the pollutants from spreading to other ecological systems (Mudila et al. 2021). Currently, e-wastes are primarily managed by landfills, incineration, and recycling. However, some modern advanced techniques, including management of e-wastes through microbial techniques, are in the developing stage. This chapter discusses the various eco-friendly traditional, current, and advanced techniques in electronic waste management in India and worldwide. It also reviews the harmful materials in e-waste and their possible effects on the environment and human health.

1.2 Significance of E-waste in the Current Scenario

E-waste is made up of both hazardous and non-hazardous materials. It qualifies as an “urban mine” since it has a variety of valuable, essential, and non-essential metals that, when recycled, can be used as secondary materials. However, they have negative consequences on health and the ecosystem. According to various studies, unregulated e-waste recycling has recently been linked to an increasing number of harmful health effects. These include undesirable birth results (Zhang et al. 2018), change in neural development (Vymazal 2007), unfavourable effects on learning (Brusseau et al. 2020), DNA damage (Alabi et al. 2012), unfavourable cardiovascular consequences (Cong et al. 2018), adverse respiratory effects (Nti et al. 2020), adverse immune system effects (Vymazal 2007), skin diseases (Seith et al. 2019; Decharat and Kiddee 2020), hearing loss (Xu et al. 2020), and cancer (Davis and Garb 2019). Due to the rising disposable of used and repaired electric and electronic devices, more urbanization and mobility, and further industrialization in other parts of the world, the amount of EEE is increasing. As a result, global EEE consumption weight rises by 2.5 million metric tonnes (Mt) annually on average (excluding solar panels). The top six countries producing the maximum e-waste are Japan, China, the USA, India, Russia, and Germany.

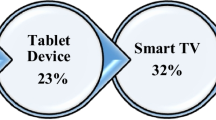

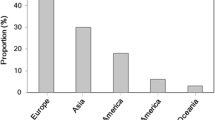

China has the highest amount of e-waste production, with 7.2 million metric tonnes produced, followed by the USA with 6.3 million metric tonnes. Asian continent generated the most electronic waste, followed by America, Europe, Africa, and Oceania, 11.7 Mt, 11.6 Mt, 1.9 Mt, and 0.6 Mt, respectively (Kumar et al. 2017). About 9 million tonnes of electronic trash are produced in the European Union each year and come from computers, televisions, and phones (Pahari and Dubey 2018). Approximately, 40 million metric tonnes of e-waste are produced annually globally, accounting for 5% of all solid wastes (Hazra et al. 2019). America generated 11.3 Mt of electronic garbage in 2016, with 7 Mt coming from North America, 3 Mt from South America, and 1.2 Mt from Central America. E-waste production varies significantly across industrialized and developing nations. In 2016, the wealthiest nations in the world generated an average of 19.6 kg per inhabitant (kg/inh), while the developing nations only produced 0.6 (kg/inh) (Baldé et al. 2017). More than 46 Mt of e-waste was produced worldwide in the year 2017. With an annual growth rate of 3–4%, the amount of e-waste is anticipated to increase to 52.2 Mt in 2021.

Approximately, 4.8 billion individuals, or 66% (67 countries) of the world’s population, were protected by national law as of January 2017 in the case of e-waste management. Since 2014, when only 44% (61 nations) were covered, improvements have been made. In 2019, formal documented collection and recycling was 9.3 Mt, and 17.4% of the total amount of e-waste produced. Since 2014, it has increased by 1.8 Mt or generates Mt each year. By 2020, it was predicted that the amount of e-waste generated worldwide would increase to 51.8 million tonnes, according to estimate (Baldé et al. 2017).

According to UNEP, e-waste from computers, mobile phones, and old and outdated televisions might increase by five, eighteen, and two times by 2020 (Leung 2019). Global e-waste production has increased by 9.2 Mt since 2014, and by 2030, it is expected to reach 74.7 Mt, practically rising in just 16 years. As a result, it is not recycled correctly, which results in a loss of materials. According to estimates, 0.6 Mt of e-waste from EU nations is in trash cans (Rotter et al. 2016). A rough estimate of USD 57 billion in raw materials can be found in the global e-waste produced in 2019. The main contributors to its value are iron, copper, and gold. A raw material worth USD 10 billion is recovered from e-waste globally in an environmentally responsible manner with the current documented collection and recycling rate of 17.4% and 4 Mt of raw materials might be made available for recycling. The emissions from recycling secondary raw materials used in place of virgin materials resulted in a net reduction of 15 Mt of CO2 due to recycling iron, aluminium, and copper. Worldwide electronic waste generation will leap from 6.40 Mt per year to 9 Mt per year by 2030 (Fig. 1.1). Global forecast on generation of e-wastes will be 75 million tonnes by 2030 and 111 million tonnes by 2050 (Table 1.1).

1.3 Data on Generation and Management in India and Globe

1.3.1 Data on Generation

According to the Indian environmental regulatory authority of the Central Pollution Control Board (CPCB), the growing rate of this e-waste is much faster (Chaurasia 2014). During 2018–19, the e-waste generation was 7.71 lakh tonnes, while in 2019–20, it was 10.14 lakh tonnes, which is a 31% increase. Global e-waste generation and forecast by year is depicted in Fig. 1.1. India is third in e-waste generation after the USA and China (Borthakur 2020). In India, most e-waste is recycled informally, and less than 5% of e-waste volume is handled through the formal sector (Jiang et al. 2020). More than 3000 units are operating informally for e-waste recycling in and around India’s big cities. Global e-waste generation continues to rise, and only 17.4% of the world’s 53.6 million metric tonnes (Mt) of waste were officially reported as appropriately recycled and managed in 2019 (Forti et al. 2020). In 2016, India dumped over 1.85 million tonnes of e-waste, accounting for approximately 12% of worldwide e-waste generation (Garg and Adhana 2019). The USA generated the highest e-waste of 11.7 million tonnes annually, followed by China with 6.1 million tonnes annually (Mishra 2020).

India has implied limits than China and holds fifth place in the production of electronic garbage. Computers and related accessories account for roughly one-third of e-waste, with others such telecom sector, medical equipment, and electric equipment contributing significantly to yearly e-waste output (Shittu et al. 2021). The industrial sectors contribute 75% of e-waste generation while the household sector contributes 16%. Mumbai tops the e-waste production in India, followed by other metropolitans such as New Delhi, Bangalore, and Chennai. India accounts for roughly 4% of all e-waste generated yearly (Mishra 2020). However, according to a survey by the Associated Chambers of Commerce and Industry of India (ASSOCHAM), only 1.5% of electronic waste produced in India gets recycled systematically. Globally, e-waste production is recorded as 57.4 million tonnes (Mt), while in India, the Central Pollution Control Board (CPCB) estimated that the production would reach 10 lakh tonnes in 2019–20, up from 7 lakh tonnes in 2017–18 (Awasthi et al. 2018a) which is a 31% increase. In contrast, since 2017–18, the capacity for dismantling e-waste has remained at 7.82 lakh tonnes. Among all the regions, Asia produces massive amounts (24.9 Mt) of e-waste (Table 1.1). The current status and future forecasting of electronic waste generation in India and worldwide were tabulated in Table 1.2.

1.3.2 E-waste Management in India

In developing countries like India, methods presently followed for the management and disposal of E-waste potentially affect the environment and human health. The e-waste management scenario in India includes vital concerns such as identifying various stakeholders in the generation and management of e-waste (Sharma et al. 2020a). Since 2011, India has developed legal enforcements to handle e-waste, with requirements including only approved dismantlers and recyclers collecting e-waste. India passed the E-waste (Management) Rules in 2016, and Bhopal, Madhya Pradesh, the nation’s first facility for managing e-waste gathered from residential and commercial units, has been established.

The emergence of new technologies and their subsequent upgrades in the various sectors like electrical, electronics, designing, marketing, etc., remarkably shortened the life expectancy of electronic appliances (Kiddee et al. 2013). However, more than 75% of e-waste in India remains untreated due to the indistinctness of the management options (Ramachandra and Saira-Varghese 2004). Generally, e-waste is mixed up with the domestic wastes in the household’s disposal points, making it very difficult to segregate them (de Oliveira Neto et al. 2022). An unorganized sector does the majority of segregation with no proper facilities (MoEF (Ministry of Environment and Forests) 2010). Chatterjee (2012) reported that most e-waste, i.e. 95%, is recycled through the informal sector, whereas only 5% is processed through standard units. According to Greenpeace, in 2008, only 3% of e-waste produced in India is collected by authorized recyclers, while the remaining is sent to informal recyclers operated without proper facilities (Bhaskar and Turaga 2018). Gradually, the quantity of recycled e-waste increased to 9.79% during 2017–18. Later, the awareness was raised, and regulations were enforced effectively. As a result, it rose to 21.35% in 2018–19, and 22.7% of e-wastes was recycled during 2019–20 (Panchal et al. 2021). Even though various laws and rules are enforced, less than 25% of the e-waste produced is only recycled systematically. E-waste and solid garbage, according to scientists, are improperly dumped in land and surrounding waterbodies.

Developing countries like India have well-developed networks for e-waste collection, dismantling, and recycling processes but exist as unorganized sectors. They used to collect e-waste from rag pickers and dismantle the reusable components for resale purposes (Srivastava and Pathak 2020). The unorganized sectors are not receiving much attention regarding their stakeholders, social and economic implications, environmental effects, and the health of recycling employees and neighbouring communities (Shaikh et al. 2020). The nation’s daily production of municipal solid garbage exceeds 1.6 million metric tonnes (Mt). Depending on population size, cities generate between 0.2 and 0.6 kg of trash per person every day. This is anticipated to increase at a pace of 1.33% annually. It is anticipated that by 2047, 260 million tonnes of trash will be produced annually. By 2047, the country will reportedly need more than 1400 km2 of land, about equivalent to the area of Delhi, if e-waste disposal is not made more orderly and scientifically. India produces more than 8 million tonnes of hazardous garbage annually, of which 4.8 million tonnes (or 60%) are recyclable, and the remaining 3.2 million tonnes (or 40%) are not recyclable (Garg and Adhana 2019). In India, formal recyclers or institutional processing and recycling processes recycle about 1.5% of all the e-waste produced; the remaining 8% is deemed worthless and ends up in landfills (Jeyaraj 2021).

1.4 Types of E-waste

Almost all the waste generated by electronic equipment without the intent of reuse is considered e-waste. It is classified into various types according to the source generation and waste management practices. E-waste is divided into ten general categories such as primary household gadgets, little household gadgets, user gadgets, IT and telecommunication gadgets, electric and electronics apparatus, illumination gadgets, toys, leisure and sports gadgets, medical devices, automatic dispensers, monitoring and controlling equipment based on European Waste Electrical and Electronic Equipment Directive (EU Directive 2002). According to the global e-waste monitor (2020) report, electrical and electronic equipment are categorized into six based on their way of management, and there are 54 products included under six general categories according to their material composition, weight, and product life (Forti et al. 2020). The e-waste system does not have any batteries or vehicle-related electrical items. The e-waste categorization complies with the Waste Electrical and Electronic Equipment (WEEE) directive and the e-waste statistics report of the internationally recognized framework. The classification of e-waste is depicted in Fig. 1.2.

1.4.1 Large Equipment

The equipment often used in households and offices includes dishwashers, washing machines, cloth drying machines, large copying equipment, printing machines (Xerox machines), and photovoltaic panels.

1.4.2 Temperature Exchange Equipment

The machines in this category are used for cooling, freezing, and heating, such as heat pumps, air conditioners, coolers, refrigerators, and freezers.

1.4.3 Screens and Monitors

Equipments like computer monitors, television, laptops, tablets, and notebooks are included in this category.

1.4.4 Lamps

This category includes fluorescent lamps, LED lamps, high-intensity discharge lamps (HID), compact fluorescent lights, xenon arc lamps, and filament lamps.

1.4.5 Small Equipment

This category includes equipment often used in the kitchen and other uses such as microwave ovens, vacuum cleaners, electric cookers, toasters, electric kettles, electric weighing machines, radio sets, video cameras, electrical and electronic tools, small monitoring instruments, control instruments, and small medical devices.

1.4.6 Small Information Technology and Telecommunication Equipment

The small IT and telecommunication category includes smartphones, mini calculators, smart watches, routers, modems, personal computers, small printers, landlines, and GPS devices.

Although the necessity and usage of electrical equipment in the current world are highly mandatory, waste production differs according to the per-capita purchasing capacity, directly reflecting use and e-waste generation. According to Forti et al. (2020), excluding photovoltaic panels, the e-waste generation was around 53.6 million metric tonnes in 2019, and per-capita generation was 7.3 kg. Therefore, it is estimated that e-waste generation will exceed 74 Mt in 2030. The e-waste quantity generated in 2019 comprised 17.4 Mt of small equipment, 13.1 Mt of large equipment, 10.8 Mt of temperature exchange equipment, 6.7 Mt of screens and monitors, 4.7 Mt of small IT and telecommunication equipment, and 0.9 Mt of lamps. Due to increasing consumption in lower-income countries, the weight base generation trend of e-waste primarily consists of temperature exchange equipment (7% annual average increase from 2014) followed by large equipment (> 5%) and small equipment and lamp (> 4%).

1.5 Traditional Approaches to E-waste Management

E-waste is a mixture of different product types, each requiring a distinct treatment method (Salhofer 2017). The primary pollutants from e-waste that are released into the air, water, land, and other ecosphere are polymers and VOCs, PCBs, PBDEs, or PAHs, rare earth metals, precious metals (Sn, Au, Cu, Li, Ag, Co, etc.), heavy metals (As, Hg, Cd, Pb, Cr, etc.), which account for 60% of electrical and electronics products, and heavy metals (As, Hg, Cd, Pb, Cr, etc.) (Mmereki et al. 2016; Mudila et al. 2019). Besides being a potential polluter, e-waste is a secondary source of rare metals (Awasthi et al. 2019). The five fundamental steps of the e-waste recycling process are collection, toxins removal, preprocessing, end processing, and disposal (Wang et al. 2012). After collection, the first step in separating harmful from functional components is disassembly or toxic removal. The components are broken during the preprocessing. End processing refers to the final processing of the products, such as re-melting steel scrap in steel mills (Kaya 2016; Nowakowski 2020). The remaining will be disposed of in soil as landfills, incineration, etc. (Vats and Singh 2014). Various e-waste management options are tabulated in Table 1.3.

Bioleaching is a low-cost, environmentally friendly method for extracting metals from various minerals and waste products (Zeng et al. 2016a). Compared to traditional hydrometallurgy and pyro-metallurgy, which use many chemicals and produce much environmental pollution, bioleaching provides some advantages (Zeng et al. 2013). For example, some effective commercial bioleaching plants are currently in operation at the Morenci mine in the USA, which has a capacity of up to 230,000 tonnes per year (Panda et al. 2015). Additionally, it provides a broad overview of the bioleaching process and mechanism, opening the door to creating better and more effective industrial bioleaching operations.

1.6 Modern and Advanced Approaches in E-waste Management

The introduction of the waste electric and electronic equipment (WEEE) directive (Directive 2002/96/EC), which is anticipated to reduce the disposal of such waste and enhance environmental quality, has advanced the management of e-waste in industrialized countries (Directive 2003). The research includes the separation of components that could be recycled and the recovery of rare and precious electronic waste. It is also a systematic technique for defining numerous environmental effect categories, including carcinogens, climate change, ozone layer, ecotoxicity, acidification, eutrophication, and land usage, to enhance the environmental performance of products. Furthermore, Scharnhorst et al. (2005) investigated environmentally suitable EoL treatment options for mobile phone devices. Six EoL therapy scenarios were used to discover that reusing material reduces mobile phones’ adverse environmental effects.

Furthermore, an EoL personal computer’s actual recycling rate was researched, and its environmental impact was evaluated by Choi et al. (2006). There were two options for disposal: landfill or recycling, which were discussed above. And there are several tools for managing electronic waste followed by different countries. To manage e-waste, several tools such as (i) life cycle assessment (LCA), (ii) material flow analysis (MFA), (iii) multi-criteria analysis (MCA).

1.6.1 Life Cycle Assessment (LCA)

E-waste disposal demonstrated that recycling is the most cost-effective method of disposal. Economic factors, perceived risk, and environmental effects were assessed using LCA (Li et al. 2019a). The researchers revealed that a computer desktop’s optimal life cycle was 25% shorter than its optimized cost and its optimized value of its waste impacts on the environment and any perceived risk to the general population. Recycling, as opposed to landfilling or incineration, is the preferred method for managing e-waste, according to studies employing LCA in several nations. Therefore, LCA is frequently utilized for managing e-waste (Pokhrel et al. 2020). The outcomes demonstrated that, in comparison to incineration, the e-waste recycling system and take-back were undeniably advantageous from an environmental perspective (Liu et al. 2020). A software tool life cycle assessment is used to create electronic products that are less harmful to the environment, reduce e-waste issues, and manage electronic waste. Much research has been done on the LCA of electronic devices in terms of eco-design, product development, and environmental effect since 2015. A superior alternative product is one with an environmentally friendly design, which may also appeal to customers. To create eco-design items, such as printers (Pollock and Coulon 1996), desktop computers (Kim et al. 2001), heating and cooling units (Prek 2004), washing machines (Park et al. 2006), and toys (Muñoz et al. 2009), it is essential to evaluate the potential environmental implications and management of such E-waste.

1.6.2 Material Flow Analysis (MFA)

MFA tools create effective e-waste management (Tutton et al. 2022). A technology called material flow analysis (MFA) is used to track the flow of materials (including e-waste) into recycling facilities, trash disposal locations, and material stockpiles through time and space (De Meester et al. 2019). It establishes connections between the material’s sources, distribution channels, and end destinations. MFA is a tool for environmental and waste management decision-making (Paul and Helmut 2004). This involves considering how e-waste is generated and evaluating its effects on the environment, economy, and society. MFA and the assessment of economic values were utilized by Streicher-Porte et al. (2007) to conduct system analysis and recycling of personal computers in India. They discovered that the high value of these metals and the concentration of Au and Cu led to profitability for recyclers. The study combining MFA and economic evaluation can be a valuable technique when there is a lack of data and rapid economic growth (Arain et al. 2022).

1.6.3 Multi-criteria Analysis (MCA)

Multi-criteria analysis (MCA) is a tool for making judgments considering problem qualitative and quantitative components while tackling complex multi-criteria problems (Garfi et al. 2009). Environmental challenges, such as e-waste management, have been given optional e-waste management options using MCA models (Gollakota et al. 2020). For instance, Hula et al. (2003) used MCA decision-making techniques to weigh the environmental benefits against the financial gains from the EoL processing of E-waste management (Islam et al. 2021a). The following steps were part of a six-step technique that looked at EoL scenarios, defined product models, created an EoL evaluation model for electronic waste, and formulated multi-objective challenges. They developed EoL strategy graphs for the e-waste of optimal EoL strategies that minimize environmental impacts and financial costs (Gautam et al. 2022). MCA was employed by Queiruga et al. (2008) to determine the ideal location for e-waste recycling facilities in Spain. Using the MCA technique, Rousis et al. (2008) examined the various methods for handling e-waste in Cyprus and followed modern e-waste management in different countries (Sharma et al. 2020a). The best alternative was to partially disassemble the product, send the recyclable parts to the local market, and dispose of the rest in landfills (Zanghelini et al. 2018). MCA is frequently used for managing solid and hazardous waste, even though it is not generally used for managing e-waste (Hatami-Marbini et al. 2013). MCA is valuable in conjunction with other tools for managing e-waste because it has been suggested for the societal reaction to e-waste management in many countries (Williams 2005).

According to the polluter pays principle, extended producer responsibility (EPR) holds producers responsible for recovering products after use (OECD 2001; Widmer et al. 2005). In order to permit the return of goods for processing and recycling, the WEEE Act was established in 2004. In 1991, the EU designated e-waste as a priority waste stream. As a result, the WEEE Directive of the European Union established regulations based on EPR 2002/96/EC. The legislation defines producers’ accountability for managing e-waste downstream and promotes environmentally sound end-of-life reuse, recycling, and recovery of e-waste (Directive 2003). The EU recognized e-waste as a priority waste stream in 1991, and the WEEE legislation was created in 2004 to allow for the return of products for processing and recycling. Regulations based on EPR were created by the European Union’s WEEE Directive 2002/96/EC (Habib et al. 2022). The legislation defines producers’ accountability for managing e-waste downstream and promotes environmentally sound end-of-life reuse, recycling, and recovery of e-waste (Directive 2003). It was the first to be in charge of a product’s whole life cycle, from design to garbage, and it prompted import restrictions on all used electronic gadgets for charitable purposes as well as a provision to reduce the use of certain dangerous compounds in electronic devices (Ibanescu et al. 2018).

The key to effective e-waste management is eco-design of devices, proper e-waste collection, material recovery and recycling, proper e-waste disposal, prohibiting the export of used electronic devices to developing nations, and increasing consumer and manufacturer awareness of the adverse effects of e-waste pollution. Most industrialized nations currently employ this strategy regularly. In contrast, emerging countries and those in transition have not yet persuaded local communities to adopt such management techniques for E-waste (Maheswari et al. 2020). The next generation’s education could be a step towards managing e-waste in industrial countries.

1.7 Environmental Damages and Problems

A complex mixture of pollutants could be released during the handling and processing of e-waste in several different environmental matrices. Depending on the procedures and protective measures, these discharges may be more or less substantial. According to the types, ages, and handling and processing of the e-waste, contaminants are emitted in highly heterogeneous combinations with various compositions.

A complicated assemblage of several hundred tiny parts, many of which contain hazardous chemicals, make up electronic products. Both the environment and human health are put under stress by these pollutants. The majority of lead, cadmium, mercury, polyvinyl chloride (PVC), brominated flame retardants (BFRs), chromium, beryllium, and other toxic materials are present in electronic device components. In addition, these e-wastes will have long-term environmental consequences if inappropriately disposed of incinerated/landfilled instead of recycled with residential waste, contaminating the soil, water, and air.

Direct and indirect exposures to contaminated soil, air, dust, and water near e-waste recycling facilities can come from improper e-waste recycling and unlawful disposal activities, which can then impact the biota zone. The processes that cause environmental biogeochemical fluxes include atmospheric deposition (dry/wet), leaching, adsorption–desorption, complexation (during which secondary products like heavy metal–organic matter aggregations can form), plant uptake, chemical/biological degradation, and volatilization (in air/soil).

1.7.1 Effect on Soil

Acidification of the soil occurs when acids and sludge from melting computer chips are dumped on the ground. Landfills that are not adequately inspected may pose environmental risks. When plastics containing brominates or polymers that are flame retardant or contain cadmium are landfilled, polybrominated diphenyl ethers (PBDE) and cadmium may leak into the soil and groundwater. Improper e-waste disposal affects soil fertility since it includes few chemical and hazardous compounds that are not decomposable for a long time (Pant and Kumar 2018).

Large amounts of persistent organic pollutants (POPs), such as polyaromatic hydrocarbons (PAHs), polychlorinated biphenyls (PCBs), polybrominated diphenyl ethers (PBDEs), and dioxin, will be released into the environment during the processes of informal e-waste recycling or disposing of like uncontrolled dumping and combusting. Persistent organic pollutants (POPs) can quickly accumulate inside living things, move through soil food or water food cycles, and are generally stable in the natural environment (Shi et al. 2019). Typically, soils from the e-waste recycling zone unintentionally release PCBs, PAHs, and polychlorinated dibenzo-p-dioxins and dibenzofurans (PCDD/Fs) into the environment (Shi et al. 2019).

1.7.2 Effect on Air

E-waste incinerators have the potential to release hazardous gases and pollutants into the air, greatly contaminating it. The highly toxic consequences of open-air burning influence the local ecosystem, and more importantly, global air currents, depositing them in numerous locations worldwide. The burning of the PCB and other plastic components of electrical gadgets emits acutely poisonous gaseous dioxins and furans, endangering key ecosystem components (Wang et al. 2005; Awasthi et al. 2016). In regions with open flames, numerous e-waste pollutants dissipate into the air as dust or fume, dominating human exposure pathways through inhalation, ingestion, and skin absorption. Studies have also shown that halogenated flame retardants (HFRs) and polychlorinated biphenyls (PCBs) from e-waste recycling sites cause bioaccumulation in wildlife (Li et al. 2019b; Peng et al. 2019).

Severe consequences of air pollution by improper e-waste management include ozone layer damage and global warming (Gangwar et al. 2019; Rautela et al. 2021). Greenhouse gases are released when raw materials are extracted and purified from e-waste. Chlorofluorocarbons (CFCs) are greenhouse gases that raise the earth’s temperature and are found in refrigerants and other temperature exchange devices. The ozone layer, a shield encircling the earth, is weakened by CFCs, allowing dangerous UV radiation to enter. UV exposure can cause many conditions, including cataracts, weakened immune systems, and cancerous skin growth. In addition, 98 million metric tonnes of carbon dioxide equivalents were released into the environment due to improper management of abandoned cooling and freezing equipment (Forti et al. 2020).

1.7.3 Effect on Water

E-waste disposal is a problem prevalent in many parts of the world—landfilling computer waste results in contaminated leachates that eventually affect groundwater. For example, Guiyu, Hong Kong, a significant centre of illegal e-waste recycling, is experiencing severe water shortages due to tainted water sources. This results from recycling wastes like acids and sludge being dumped in rivers. As a result, water is now being carried from remote towns to meet the population’s needs.

One cell phone battery’s cadmium concentration can contaminate 600 m3 of water. In addition, through processes of effluent leaching and diffusing from electric and electronic equipment (EEE) dumping industries or other e-waste disposal locations, processed e-waste toxins can reach aquatic systems (both groundwater and surface water), contaminating the aquatic biota as well. Acidification can kill marine and freshwater organisms, disturb biodiversity, and harm ecosystems.

When lead, barium, mercury, lithium, and other heavy metals from electronic equipment are improperly disposed, they can leak into the groundwater and flow with rainwater, causing water contamination. As a result, small ponds and rivers that receive this water become contaminated (Awasthi et al. 2018b).

1.7.4 Effect on Human Health

Poor e-waste processing has long-lasting effects beyond those that directly affect human health (Roychowdhury et al. 2019) (Fig. 1.3). Ingesting food cultivated on soil contaminated with E-waste also has indirect health effects (Tiller 1989). Similar to open incineration, acid leaching of E-waste exposes harmful gases into the environment, causing death or permanent damage to the respiratory organs of those involved in the process as well as the local population (Babu et al. 2007; Kiddee et al. 2013; Patil and Ramakrishna 2020).

Once these dangerous compounds of e-waste are introduced into the body, they may accumulate in the fatty tissues and have an adverse impact on the health of nearby residents who live close to unregulated e-waste industries (Zeng et al. 2017; Zhang 2017; Liu et al. 2018). In addition, there may be secondary exposure dangers in remote places due to the alleged long-term transmission of pollutants (Peng et al. 2019). For example, a decline in topsoil fertility brought on by heavy metal contamination in the soil penetrates the food chain. Additionally, metal exposure can lead to genotoxicity, which alters the genetic code and results in diseases like cancer. Children, pregnant women, and workers in processing facilities are most at risk of being impacted.

The environment and people are significantly impacted by the massive influx of e-waste, alongside the reduced collection, reuse rates, incorrect disposal, and management of this e-waste debris. In addition to being the largest producers of e-waste, developing nations with rapid economic expansion, like China and India, are also regarded as the global market for discarded e-waste (Pathak and Srivastava 2017; Zeng et al. 2017). The top recipients of e-waste from developed nations are China, Peru, Ghana, Nigeria, India, and Pakistan (Mmereki et al. 2016). Every living thing is adversely affected when e-wastes are discharged into the atmosphere. Anything that comes into contact with poorly regulated e-waste is at risk. Large quantities of e-waste materials and by-products are dumped in open fields along riverbanks, rivers, wetlands, and irrigation ditches without recycling. The poisoning of drinking water sources has been made worse by indiscriminate dumping and landfills. Dumping in open fields contaminates soil, thus harming grasses, herbs, plants, bushes, trees, and other cash crops. When electronic waste is burned or incinerated, it emits fumes, fly ash, and tiny particles into the air that are harmful to human and animal life when inhaled/exposed (Jeyaraj 2021).

Human exposure to e-waste may modify thyroid function, harm neonates, change cellular function and expression, cause psychological changes in behaviour and temperament, and even cause a decline in lung function (Huang et al. 2016). Leachates can enter the cell and change the pH inside and outside, impacting the enzymes and changing the DNA’s structure (Youcai 2018). Due to recycling e-waste, a significant amount of lead was found in children’s blood. IgE is produced as a result, which causes asthma in people and a weakened immune system that makes it difficult for the body to fight off diseases like hepatitis (Xu et al. 2015a; Zeng et al. 2016c). Long-term consumption of these substances or their accumulation in the body for a prolonged period can result in neurological, physical, and muscular degeneration, which may lead to Parkinson’s disease, Alzheimer’s disease, multiple sclerosis, and muscular dystrophy (Mohod and Dhote 2013).

Various metals have different harmful effects on people. For instance, lead (Pb) has a negative impact on behaviour and cognitive capacities (Sharma et al. 2020b), copper impairs liver function (Danzeisen et al. 2007), and excessive levels of cadmium can lead to lung cancer and kidney damage (Ebrahimi et al. 2020). Even the unborn were affected by e-waste toxins after being exposed in gestation. According to a study using umbilical cord blood lymphocytes and epigenome-wide DNA methylation analyses, high levels of heavy metals were significantly linked to abnormal DNA methylation in 79 genes that are involved in a variety of biological processes, including calcium ion binding, cell adhesion, and embryonic morphogenesis, as well as signalling pathways that are associated to NFkB activation, adherens junction, TGF beta, and apoptosis (Zeng et al. 2019). Additional data analysis suggests that high lead exposure may have hampered the growth of brain neurons in the developing embryos. The same researchers found a connection between preschool children’s sensory integration issues and high levels of lead exposure from e-waste sites (Cai et al. 2019). In addition, neonatal development was impacted by increased maternal urine PAH metabolites, which were substantially linked to decreases in new-born weight, head circumference, BMI, and Apgar 1 score (Huo et al. 2019).

Children with recurrent wheezing might have an impaired antioxidant system due to increased serum levels of lead and mercury and low levels of zinc and selenium (Hasan Razi 2011). According to population studies, exposure to heavy metals is associated with hypertension, endothelial damage, arteriosclerosis, and cardiovascular problems (Zeng et al. 2016b). PBDD/Fs are lipophilic and can accumulate in the human body via the food chain (Dai et al. 2020). Incineration of e-waste converts PBDEs into PBDDs and PBDFs, the anthropogenic carcinogens that remain very long (Table 1.4). As a result, long-term health hazards are linked to several genetic abnormalities and other adverse effects, like contamination of human breast milk (Darnerud et al. 2001; Devika 2010).

1.8 Regulations Mechanism of E-waste in India and Other Countries

The level of preparedness for handling e-waste and regulations for managing e-waste through laws, rules, and other legal means are essential in both developed and developing nations (Abalansa et al. 2021). The Environment (Protection) Act of 1986 is a broad act, and e-waste regulations are solely the responsibility of the EPA.

1.8.1 Regulations for E-waste Management in India

India faces significant difficulty in managing e-waste effectively. The principal Acts and Regulations for E-Waste Control are given as

-

The Batteries (Management and Handling) Rules, 2001

-

The Environment Impact Assessment Notification, 2006

-

The Hazardous and Other Wastes (Management and Transboundary Movement) Rules, 2016

-

The E-Waste Management Rules, 2016

-

The Battery Waste Management Rules, 2022.

The e-waste legislation/regulations/guidelines listed are well-known and substantial endeavours. The Environment (Protection) Act, the first comprehensive environmental law, was passed in 1986 in reaction to the Bhopal Gas Tragedy (Anju et al. 2010). The Hazardous Waste (Management and Handling) Rules and the Batteries Waste (Management and Handling) Rules are two specific restrictions established under laws concerning e-waste for possible extent. E-waste is not mentioned in the Indian Municipal Solid Wastes (Management and Handling) Rules of 2000 (Singh et al. 2018). In E-waste Management Rules, 2016, by obtaining extended producer responsibility (EPR) authorization, producers are now responsible for managing a system of e-waste collection, storage, transportation, ecologically responsible disassembly, and recycling (Gupt and Sahay 2019). The central government can authorize the treatment or repurposing of hazardous waste. The HWM Rules were amended in 2000 to incorporate import or export requirements of e-waste, expanding their scope (Arya and Kumar 2020). The most current attempt to control e-waste in India is the E-waste (Management and Handling) Rules 2011 (Awasthi et al. 2018a) and Battery Waste Management Rules 2022. Lack of knowledge about the effects of inappropriate e-waste disposal is another challenge in applying the new criterion (Patil and Ramakrishna 2020). Informal recycling of e-waste dominates the sector, making up 90–95% of overall recycling (Chakraborty et al. 2018). Market actors are incentivized to avoid compliance by selling harmful material to informal recyclers, and recyclers can pay more for e-waste (Ganguly 2016). Increasing operational expenditures to organized recyclers already fighting to continue will make organized management difficult (Kumar and Singh 2013).

1.8.2 E-waste Regulations—European Union of Countries (EU)

The EU has tackled e-waste issues and has comprehensive and progressive e-waste regulations since the 1990s. For example, the EU passed the e-waste directive/legislation in 2003 to change product designs, increase recycling rates of discarded e-waste, and restrict the use of some dangerous compounds (Kumar and Singh 2013). In addition, higher target for e-waste collection, proper monitoring standards, and implementation of legal provisions for segregating new, used, and recycled trash items have all been implemented to combat the mismanaging of e-waste (Skinner et al. 2010).

1.8.3 E-waste Regulations—USA

E-waste policies in the USA have undergone fragmented creation and passage of directives, laws, and regulations because of no federal law, particularly the country’s management or export of e-waste (Gollakota et al. 2020). The law mandates that anybody who manages or disposes of or ships hazardous waste obtain permission from the EPA or approval from importing countries (Ajibo 2016). Because the federal government does not consider most e-waste hazardous, American recyclers are free to ship the devices overseas (Arain et al. 2020). Individual states in the USA have also started to address their e-waste problems through adequate regulatory and management systems (Kahhat et al. 2008). For starters, while state recycling restrictions are limited in scope, exports are expanding, and the rate of e-waste collected for recycling has been enhanced nowadays (Xavier et al. 2021). The fact that American recyclers and manufacturers export electronic waste to developing and transitional nations may cause the country’s deliberate inaction. These nations’ recyclers can extract valuable materials more affordably due to more readily available labour, and the ill effects are also transferred (Kumar and Singh 2013).

1.8.4 Regulations in China Regarding E-waste

The government of China has released a flurry of laws, rules, standards, technical directives, and guidelines for the disposal of e-waste over the decade (Schumacher 2016). China has ratified two international environmental treaties: The Basel Convention on the Control of Transboundary Movements and the Disposal of Hazardous Wastes and the Basel Ban Amendment Technical Policy on Pollution Prevention and Control of WEEE, the second significant policy was established in 2006 with the goals of lowering the amount of e-waste, increasing the rate of utilization of electronic equipment, and enhancing the standards for recycling of e-waste (Li et al. 2006). The 3R principle, which stands for reduce, reuse, recycle, and polluter pays, was developed to take environmental precautions to reduce pollution due to storing, reusing, recycling, and disposing of e-waste (Gaur et al. 2022). The specification for the pollution aspect in e-waste management is also provided (Wang et al. 2013). In addition, the rules establish a fund to finance official e-waste collection and recycling (Zeng et al. 2017).

1.8.5 E-waste Legislations in Korea

In Korea, 9455 thousand tonnes of expected e-waste were generated in 2017. The industrial laws and legal initiatives for e-waste management must also consider their impact on ecology and pollution control that include requirements for indirect restrictions for e-waste (Ilankoon et al. 2018). The particularly accessible efforts for e-products and e-wastes are also taken. For example, to encourage producers to recycle their e-waste and inform the government of their findings, the act on the Promotion of Saving and Recycling of Resources was introduced in 2003. The act includes provisions for recycling design and production considerations to eliminate hazardous substances, design products to be easily dismantled, and use easy-to-recycle substances in an environmentally pleasant collection, treatment, and recycling environment (Wath et al. 2010).

1.8.6 E-waste Regulations in Bangladesh

Utilizing electronic equipment is an everyday activity in Bangladesh, according to the country’s status of e-waste. Bangladesh created its National Environmental Policy in 1992 to govern all actions that degrade and affect the environment (Alam and Bahauddin 2015). The Electrical and Electronic Waste (Management and Handling) Rules, 2011, are the most recent initiative and include the following elements (Khuda 2021). The regulation provided by various schedules are as follows: Schedule 1 discusses the categorization of e-waste, whereas Schedule 2 lists the products that fall into the various categories stated in Schedule I, and Schedule 3 addresses the use of particular hazardous chemicals and their threshold limits. In addition, Bangladesh has signed the Basel Convention, which prohibits the transboundary transfer of hazardous waste (Ananno et al. 2021).

1.8.7 Extended Producer Responsibility (EPR)

EPR has been seen as a promising alternative to traditional waste management strategies. However, companies find it expensive and infeasible to operate their EPR activities. Therefore, they contract them to third parties known as producer responsibility organizations (PRO). In a few nations, EPR initiatives have included many items (Mazhandu et al. 2020). Packaging material was one of the first goods to be included, which was introduced in Germany in the 1990s and is currently used in several nations, including the UK, Japan, and Slovakia (Rautela et al. 2021). WEEE is now included in EPR policies in several countries, including the Netherlands, Japan, Switzerland, South Korea, the USA, Taiwan, Colombia, China, Thailand, India, and Argentina (Bhadra and Mishra 2021). In India, EPR is confined to plastic and electronic waste (E-Waste). The Plastic Waste Management Rules and the E-Waste Management Rules in India contain the criteria for EPR implementation (Arya and Kumar 2020). In India, EPR is described as “the producer’s duty for the ecologically sound management of the product to the end of its life” (MoEF (Ministry of Environment and Forests) 2010). WEEE scope varies by country, with some including only mobile phones and small equipment and others including large equipment such as air conditioners and refrigerators. Old lead acid batteries (ULAB), polyethylene terephthalate (PET) bottles, metal cans, used oil, oil containers, oil filters, end-of-life vehicles (ELV), end-of-life tyres, and glass are also included (bottles). A wide range of factors led to the success of EPR in various countries around the world (Bhadra and Mishra 2021).

1.9 E-waste Management Relevance in SDG and Ecosystem Restoration

Electronic waste generation is increasing gallopingly, and it is now expanding faster in the world than any other waste. The primary forces behind this tendency are rapid socioeconomic progress and technical innovation (Hossain et al. 2015). As a result, the quantity of e-waste is increasing, yet not enough of it is being recycled. Only 20% of the 44.7 million metric tonnes (Mt) of e-waste produced worldwide in 2016 was appropriately recycled. Although e-waste law covers 66% of the world’s population, more has to be done to enforce, implement, and motivate more nations to create e-waste rules (Baldé et al. 2017).

Furthermore, electronic waste should be appropriately managed. Or otherwise, it may cause an adverse and severe impact on the environment. This poses a pressing obstacle to accomplishing sustainable development objectives (Hossain et al. 2015).

The ambitious 2030 Agenda for Sustainable Development was endorsed by the United Nations and all of its members in September 2015. To alleviate poverty, safeguard the environment, and assure prosperity for everyone over the next 15 years, this new agenda defined 17 Sustainable Development Goals (SDGs) and 169 goals. However, the environment, human health, and the attainment of the SGDs are seriously threatened by rising volumes of e-waste, incorrect and dangerous treatment, and disposal in landfills or incinerators (Baldé et al. 2017).

Goal 3 (Health and Well-Being), Goal 6 (Clean Water and Sanitation), Goal 11 (Sustainable Cities and Communities), Goal 12 (Responsible Consumption and Production), Goal 14 (Life Below Water), and Goal 8 are all intimately related to a better knowledge and management of e-waste (Decent Work and Economic Growth) (Baldé et al. 2017). E-waste presents significant health risks when improperly handled since it includes dangerous components that may contaminate the air, water, and land and endanger people’s lives. Additional risks to people and the environment come from decommissioning procedures that don’t use suitable tools, resources, and qualified personnel (Baldé et al. 2017). Therefore, this article adopts the SDG indicators 9.2.1 (manufacturing value added per capita) and 12.4.1 (e-waste per capita) as the two indicators to represent industrial growth and environmental protection within the SDGs framework since they are appropriate and have data readily available (Liu 2020).

The United Nations declared 2021–2030 as “the Decade on Ecosystem Restoration” on March 1st, 2019. Recently, from the studies of Luo et al. (2017a, b), the soil being cleaned up in areas where an e-waste recycling facility has had adverse environmental effects. Various remediation and restoration techniques are already used to remediate and restore polluted ecosystems (Cui and Zhang 2008; Andrade et al. 2019). In addition, bioremediation or microbial collaboration may improve a greener method of e-waste treatment (Pant et al. 2018).

Removing metal from ores and e-wastes has been investigated for a long time, using microbiological techniques to extract copper and other vital metals from e-waste (Cui and Zhang 2008; Andrade et al. 2019). Bioleaching is an ecologically beneficial technique for extracting metals from primary and secondary metal sources (Andrade et al. 2019). Compared to traditional procedures, using microbes for metal extraction has various benefits, including reduced operating costs (an economical approach), less waste production, and effective effluent detoxification (Cui and Zhang 2008; Andrade et al. 2019). Every management approach focuses on the organic e-wastes and inorganic components. The organic component comprises various thermoplastics and thermosetting plastics that include halogenated materials. The inorganic fraction of e-waste, consisting of metallic and non-metallic components, may be managed by microbes during the leaching process (Pant et al. 2018).

Bioleaching techniques used moderate thermophilic bacteria for extracting the most metals from electronic garbage (Ilyas et al. 2014; Xia et al. 2017; Andrade et al. 2019). Hazardous organics (represented by polycyclic aromatic hydrocarbons, polychlorinated biphenyls, and polybrominated diphenyl ethers), and heavy metals were created during the recycling of matching materials from various components of electrical and electronic devices (Li et al. 2022). In the previous decades, the dismantling and disposal of electronic wastes were done by recycling resources, but it negatively affects the soil ecosystem. So, ecosystem restoration is a critical need for the upcoming decades.

Recycling e-waste is essential from an environmental and economic standpoint because it can be quantified as a “secondary ore” or “artificial ore” due to its higher metal concentration, which can be efficiently separated by bioleaching with the help of microbes and other eco-friendly biological techniques can be used for e-waste management (Marappa et al. 2017). The advantages and disadvantages of microbial treatment for e-waste are summarized below:

Advantages of microbial treatment for e-waste

-

i.

Microbial leaching of metals from e-waste has provided future possibilities for extractive metallurgy (Gopikrishnan et al. 2020).

-

ii.

Improved microorganisms, bioengineering, mutant enzymes like metal-binding peptides and their cell surface potential, and metallothioneins expression are all breakthroughs that will aid in improved e-waste treatment (Gupta et al. 2016; Awasthi et al. 2019; Sharma et al. 2022).

-

iii.

Microbial consortiums improved the efficiency of the bioremediation process rather than monocultures (Khanpour-Alikelayeh and Partovinia 2021).

Disadvantages of microbial treatment for e-waste

-

i.

The physical (oxygen availability, temperature, time, etc.) and chemical (humidity, nutrition, pH, etc.) external conditions have a sensitive impact on the activity of microbes during bioremediation (Mudila et al. 2021).

-

ii.

Microbial functions have revealed their limited efficiency in the contaminated area due to lack of competition and high levels of heavy metals (Sharma et al. 2021).

-

iii.

There has been minimal work identifying microbes that thrive in high-temperature conditions that could be used in e-waste management. The acid released into the groundwater system via microbial leaching of e-waste is still a significant issue (Gopikrishnan et al. 2020).

-

iv.

Microbial consortium may be rendered inefficient due to antagonistic interactions in which the microbial population produces substances that hinder the growth and function of other species (Hibbing et al. 2010; Khanpour-Alikelayeh and Partovinia 2021).

-

v.

Microbial bioremediation is a time-consuming process that must be monitored regularly, and to assess the microbial activity on the pollutant, monitoring the biodegradation rate is necessary. In addition, controlling volatile organic compounds (VOCs) is complex, and residue in large amounts might be harmful if it persists in the ecosystem (Juwarkar et al. 2010; Mudila et al. 2021).

1.10 Challenges and Future Perspectives of E-waste Management

Modern technology has shortened the lifespans of electrical and electronic equipment (EEE) goods. The point at which EEE goods are deemed to be out of date and destroyed as trash (e-waste) is referred to as the end of life (EoL) (Rautela et al. 2021). The challenges in managing the e-waste include illegal e-waste imports and periodic functional testing of imported used EEE, which render it useless garbage (e-scrap), ignorance regarding the nature or toxicity of e-harmful waste, as well as a lack of understanding of the potential dangers of present EoL management among the general public (Osibanjo and Nnorom 2007) (Fig. 1.4).

Most developing countries do not have particular e-waste regulations compared to developed countries. E-waste collection, handling, recycling, and processing are brutal because of their complex combination of ceramics, glass, plastics, halogen compounds, base, and hazardous elements (Sahle-Demessie et al. 2018; Sahajwalla and Hossain 2020). Lack of area and infrastructure facilities for recycling and managing e-waste, lack of finances, investment, and policies to support sustainable advancements in e-waste recycling, e-waste's thermodynamic constraints in separation, which lead to expense recovery, a lack of eco-friendly chemicals that are permitted for use in e-waste management, and different laws and regulations that vary from country to country are other obstacles in e-waste treatment (Shahabuddin et al. 2022).

In developing countries, inadequate knowledge, planning, and strategies among actively involved stakeholders in e-waste management, as well as a lack of detailed information for the long-term management of products and the generation of significant e-waste, hinder the strategic processing plan for e-waste management systems. Corruption results in improper trash and e-waste collecting system installation (Garg and Adhana 2019), which leads to inadequate funding for e-waste research. The accumulation of e-waste at the domestic level is two other significant problems (Ranasinghe and Athapattu 2020). In addition, in urban local bodies, e-waste management is not handled by a distinct department. Since rag pickers have no social security, they are not successfully integrated into the waste management process and have more occupational risk while working. Furthermore, they are very diverse due to the participation of several stakeholders and the unpredictable aspects they must deal with it. Such reasons will necessitate a multilevel strategy (Ranasinghe and Athapattu 2020; Aslam et al. 2022; Sakhuja et al. 2022).

Furthermore, the operating method of the informal sector’s networking is poorly understood, making integrating the formal and informal sectors in e-waste management a considerable problem. In conformity with the cost internalization and polluter pays principle, extended producer responsibility (EPR) forces companies to bear the physical and financial responsibility for end-of-life (EoL) or used item management. This policy reduces the burden on municipalities and transfers management from taxpayers to producers (Leclerc and Badami 2020). However, implementing EPR has been noted as a significant difficulty due to a lack of legislative provisions, the establishment of credit facilities to conduct EPR, and the competition to access e-waste between both the informal and formal sectors (Arya and Kumar 2020; Ranasinghe and Athapattu 2020; Herat 2021).

The sustainability of bitcoin has been a hot topic of discussion because of its rising energy usage (Gundaboina et al. 2022). However, most studies have so far neglected the fact that bitcoin miners are using more and more brittle technology, which might accelerate the increase of global electronic waste. As dangerous compounds and heavy metals seep into the soil and incorrect recycling results in air and water contamination, e-waste threatens the environment. The yearly amount of electronic trash generated by bitcoin, which, as of May 2021, amounts to 30.7 metric kilotonnes. The annual volume of e-waste may exceed 64.4 metric kilotonnes at the peak bitcoin price levels predicted early in 2021 (De Vries and Stoll 2021). So, managing e-wastes from bitcoin and other cryptocurrencies will soon be challenging.

Insufficient data on current public health services and people involved in recycling e-waste in developing nations and lack of data on the types of materials and new chemical products entering the e-waste are some of the existing data gaps and recommended aspects of research needed (Fowler 2017).

-

i.

Without considering the heterogeneity between urban and rural areas, only urban consumption patterns and activities are considered (Islam and Huda 2019), and in future studies, this must be considered.

-

ii.

The primary study interests in this discipline are the handling and recycling of the electronic waste in developing nations, the degradation and extraction of waste metals, the consequences of heavy metals on children’s health, and the evaluation of health risks associated with exposure to organic contaminants. As a result, scientists should broaden their research outside the abovementioned areas (Gao et al. 2019).

-

iii.

The assessment of e-waste production from the top thirty countries that produced significant amounts of e-waste revealed that just a few countries, including China and India, could be classified as the most prolific in this research field (Ismail and Hanafiah 2020). Therefore, nations of e-waste origin must perform more productive research and publish their findings to create effective e-waste handling by employing advanced technologies, infrastructure, appropriate laws, and policies.

-

iv.

Most research in this area aims to improve individuals’ knowledge of e-waste through education programs, public media, etc. The involvement of government and corporations in encouraging customers to exchange their end-of-life items through incentive programs could be a significant concern in future. Future research on factors influencing e-waste reverse supply chain operations in rural and urban regions can be conducted (Doan et al. 2019).

-

v.

It is necessary to have reliable data to develop more reliable and precise inferences and create appropriate frameworks to tackle the problems of e-waste. Furthermore, it is essential to integrate mechanical, physical, and chemical research methodologies (a multidisciplinary approach), as well as to work collaboratively with other nations and adhere to international law. Finally, develop sustainable technologies for recovering, recycling, and identifying new pollutants (Ghimire and Ariya 2020).

-

vi.

Collaborations with informal e-waste collectors are encouraged to formalize (Yong et al. 2019) and develop the e-waste recycling industry. When incentive and subsidy programs are introduced, the delivery of collected household e-waste by informal e-waste collectors to licensed recovery centres will expand.

-

vii.

More emphasis should be given to global views on e-waste, particularly material-, element- and product-specific studies. Understanding consumer recycling behaviour may provide unique insights into the stock of outmoded material, which is one of the crucial criteria in estimating the material flow of e-waste.

-

viii.

The total lifespan of an item is an essential characteristic that should be taken into account, and a dynamic evaluation of the product’s lifetime is required rather than a static value.

-

ix.

The use of online recycling platforms must be promoted. Consumers are more inclined to utilize online-based services for product disposal and buying in today’s world, driven by digital data. It has been discovered that incentives and participation in a digital recycling network are connected. The desire to participate in the platforms is more extensive than for informal sector collection and recycling because of the greater financial rewards (Islam et al. 2021b).

-

x.

Recycling discarded parts and materials from old electronic goods and encouraging manufacturers are essential.

-

xi.

To ensure that electronic trash is collected from the appropriate location, an e-waste collecting system must be implemented. Therefore, it is necessary to establish an institutional infrastructure for e-waste collection, storage, distribution, handling, recycling, and disposal (Rode 2012).

-

xii.

Urban mining of metal recovery from discarded electrical and electronic equipment and a rapid transition to circular economic methods of e-waste management (Shittu et al. 2021).

-

xiii.

Promote the full-scale application of the best physicochemical treatment techniques currently available.

-

xiv.

Promote the idea of product life extension, i.e. repairing the damaged products rather than buying a new one. This is accomplished by strengthening repair or servicing facilities (Gollakota et al. 2020).

1.11 Conclusion

Booming electronics industries throughout the globe, combined with quick product obsolescence and a lack of end-of-life management solutions, have all contributed to the unsustainable management of e-waste. Thus, developing eco-design devices, proper collection of e-waste, safe material recovery and recycling, proper disposal of e-waste, prohibiting the export of used electronic devices to developing nations, and creating awareness about the effects of e-waste are essential for effective e-waste management. The absence of recycling methods, the lack of cost recovery of e-waste services, inadequate legal constraints, poor civic awareness, and the paucity of approved disposal locations are the major obstacles in e-waste management. No single management technique is sufficient to help and resolve this emerging e-waste disposal problem. To overcome this risk, combined efforts among the community and the government are a must. Each should accept responsibility, and the system for recycling e-waste needs to be updated with the help and support of all industries. Extended producer responsibility (EPR) may help solve the e-waste management problem. EPR is one national program that is an excellent choice for addressing the rising e-waste issues.

Change history

30 March 2023

The original version of the chapter was inadvertently published with incorrect affiliation for co-authors “Sudha Kannojiya and Shiv Prasad”. Both authors affiliation has been updated as “Division of Environment Science, ICAR-Indian Agricultural Research Institute (IARI), New Delhi, 110012, India”.

The correction chapter and the book have been updated with the change.

References

Abalansa S, El Mahrad B, Icely J, Newton A (2021) Electronic waste, an environmental problem exported to developing countries: the good, the bad and the ugly. Sustainability 13:5302

Adanu SK, Gbedemah SF, Attah MK (2020) Challenges of adopting sustainable technologies in e-waste management at Agbogbloshie, Ghana. Heliyon 6:e04548

Ahmed S, Panwar RM, Sharma A (2014) Forecasting e-waste amounts in India. Int J Eng Res Gen Sci 2:2091–2730

Ajibo KI (2016) Transboundary hazardous wastes and environmental justice: implications for economically developing countries. Environ Law Rev 18:267–283

Alabi OA, Bakare AA, Xu X et al (2012) Comparative evaluation of environmental contamination and DNA damage induced by electronic-waste in Nigeria and China. Sci Total Environ 423:62–72. https://doi.org/10.1016/j.scitotenv.2012.01.056

Alam M, Bahauddin K (2015) Electronic waste in Bangladesh: evaluating the situation, legislation and policy and way forward with strategy and approach. Present Environ Sustain Dev 81–102

Alkorta I, Garbisu C (2001) Phytoremediation of organic contaminants in soils. Bioresour Technol 79:273–276. https://doi.org/10.1016/S0960-8524(01)00016-5

Ananno AA, Masud MH, Dabnichki P et al (2021) Survey and analysis of consumers’ behaviour for electronic waste management in Bangladesh. J Environ Manage 282:111943

Andrade DF, Romanelli JP, Pereira-Filho ER (2019) Past and emerging topics related to electronic waste management: top countries, trends, and perspectives. Environ Sci Pollut Res 26:17135–17151

Anju A, Ravi SP, Bechan S (2010) Water pollution with special reference to pesticide contamination in India. J Water Resour Prot 2010

Arain AL, Pummill R, Adu-Brimpong J et al (2020) Analysis of e-waste recycling behavior based on survey at a Midwestern US University. Waste Manag 105:119–127

Arain AL, Neitzel RL, Nambunmee K et al (2022) Material flow, economic and environmental life cycle performances of informal electronic waste recycling in a Thai community. Resour Conserv Recycl 180:106129

Arvaniti OS, Kalantzi O-I (2021) Determinants of flame retardants in non-occupationally exposed individuals—a review. Chemosphere 263:127923

Arya S, Kumar S (2020) E-waste in India at a glance: current trends, regulations, challenges and management strategies. J Clean Prod 271:122707

Aslam S, Ali F, Naseer A, Sheikh Z (2022) Application of material flow analysis for the assessment of current municipal solid waste management in Karachi, Pakistan. Waste Manag Res 40:185–194

Awasthi AK, Zeng X, Li J (2016) Environmental pollution of electronic waste recycling in India: a critical review. Environ Pollut 211:259–270

Awasthi AK, Cucchiella F, D’Adamo I et al (2018a) Modelling the correlations of e-waste quantity with economic increase. Sci Total Environ 613:46–53

Awasthi AK, Wang M, Wang Z et al (2018b) E-waste management in India: a mini-review. Waste Manag Res 36:408–414

Awasthi AK, Hasan M, Mishra YK et al (2019) Environmentally sound system for E-waste: biotechnological perspectives. Curr Res Biotechnol 1:58–64. https://doi.org/10.1016/j.crbiot.2019.10.002

Babu BR, Parande AK, Basha CA (2007) Electrical and electronic waste: a global environmental problem. Waste Manag Res 25:307–318

Baldé CP, Forti V, Gray V et al (2017) The global e-waste monitor 2017: quantities, flows and resources. United Nations University (UNU), International Telecommunication Union (ITU) & International Solid Waste Association (ISWA), Bonn/Geneva/Vienna

Barbieri L, Giovanardi R, Lancellotti I, Michelazzi M (2010) A new environmentally friendly process for the recovery of gold from electronic waste. Environ Chem Lett 8:171–178

Beula D, Sureshkumar M (2021) A review on the toxic E-waste killing health and environment—today’s global scenario. Mater Today Proc 47:2168–2174

Bhadra U, Mishra PP (2021) Extended producer responsibility in India: evidence from Recykal, Hyderabad. J Urban Manag 10:430–439

Bhaskar K, Turaga RMR (2018) India’s E-waste rules and their impact on E-waste management practices: a case study. J Ind Ecol 22:930–942

Birloaga I, Coman V, Kopacek B, Vegliò F (2014) An advanced study on the hydrometallurgical processing of waste computer printed circuit boards to extract their valuable content of metals. Waste Manag 34:2581–2586

Borthakur A (2020) Policy approaches on E-waste in the emerging economies: a review of the existing governance with special reference to India and South Africa. J Clean Prod 252:119885

Boyle D, Catarino AI, Clark NJ, Henry TB (2020) Polyvinyl chloride (PVC) plastic fragments release Pb additives that are bioavailable in zebrafish. Environ Pollut 263:114422

Brandl H, Lehmann S, Faramarzi MA, Martinelli D (2008) Biomobilization of silver, gold, and platinum from solid waste materials by HCN-forming microorganisms. Hydrometallurgy 94:14–17

Brusseau ML, Anderson RH, Guo B (2020) PFAS concentrations in soils: background levels versus contaminated sites. Sci Total Environ 740. https://doi.org/10.1016/j.scitotenv.2020.140017

Budnik LT, Casteleyn L (2019) Mercury pollution in modern times and its socio-medical consequences. Sci Total Environ 654:720–734

Cai H, Xu X, Zhang Y et al (2019) Elevated lead levels from e-waste exposure are linked to sensory integration difficulties in preschool children. Neurotoxicology 71:150–158

Campos VM, Merino I, Casado R, Gómez L (2008) Phytoremediation of organic pollutants: a review. Span J Agric Res 6:38–47. https://doi.org/10.5424/sjar/200806S1-372

Cao Y, Chen A, Radcliffe J et al (2009) Postnatal cadmium exposure, neurodevelopment, and blood pressure in children at 2, 5, and 7 years of age. Environ Health Perspect 117:1580–1586

Chakraborty P, Selvaraj S, Nakamura M et al (2018) PCBs and PCDD/Fs in soil from informal e-waste recycling sites and open dumpsites in India: levels, congener profiles and health risk assessment. Sci Total Environ 621:930–938

Chatterjee S (2012) Sustainable electronic waste management and recycling process. Am J Environ Eng 2:23–33

Chatterjee R (2017) Bioremediation: a tribute to green chemistry. CONSCIENTIA 35

Chaurasia PK (2014) E-waste management approaches in India. Int J Eng Trends Technol 15:21–24

Chen Y, Tang X, Cheema SA et al (2010) β-cyclodextrin enhanced phytoremediation of aged PCBs-contaminated soil from e-waste recycling area. J Environ Monit 12:1482–1489

Chen A, Dietrich KN, Huo X, Ho S (2011) Developmental neurotoxicants in e-waste: an emerging health concern. Environ Health Perspect 119:431–438

Cheng W-H (2021) Revisiting selenium toxicity. J Nutr 151:747–748

Choi B-C, Shin H-S, Lee S-Y, Hur T (2006) Life cycle assessment of a personal computer and its effective recycling rate (7 pp). Int J Life Cycle Assess 11:122–128

Cong X, Xu X, Xu L et al (2018) Elevated biomarkers of sympatho-adrenomedullary activity linked to e-waste air pollutant exposure in preschool children. Environ Int 115:117–126. https://doi.org/10.1016/j.envint.2018.03.011

Copani G, Picone N, Colledani M et al (2019) Highly evolvable E-waste recycling technologies and systems. In: Factories of the future. Springer, Cham, pp 109–128

Cui J, Zhang L (2008) Metallurgical recovery of metals from electronic waste: a review. J Hazard Mater 158:228–256

Dai Q, Xu X, Eskenazi B et al (2020) Severe dioxin-like compound (DLC) contamination in e-waste recycling areas: an under-recognized threat to local health. Environ Int 139:105731

Danzeisen R, Araya M, Harrison B et al (2007) How reliable and robust are current biomarkers for copper status? Br J Nutr 98:676–683

Darnerud PO, Eriksen GS, Jóhannesson T et al (2001) Polybrominated diphenyl ethers: occurrence, dietary exposure, and toxicology. Environ Health Perspect 109:49–68

Davis JM, Garb Y (2019) A strong spatial association between e-waste burn sites and childhood lymphoma in the West Bank, Palestine. Int J Cancer 144:470–475. https://doi.org/10.1002/ijc.31902

Decharat S, Kiddee P (2020) Health problems among workers who recycle electronic waste in southern Thailand. Osong Public Health Res Perspect 11(1):34–43

De Meester S, Nachtergaele P, Debaveye S et al (2019) Using material flow analysis and life cycle assessment in decision support: a case study on WEEE valorization in Belgium. Resour Conserv Recycl 142:1–9

de Oliveira Neto JF, Monteiro M, Silva MM et al (2022) Household practices regarding e-waste management: a case study from Brazil. Environ Technol Innov 102723

Devika S (2010) Environmental impact of improper disposal of electronic waste. In: Recent advances in space technology services and climate change 2010 (RSTS & CC-2010). IEEE, pp 29–31

De Vries A, Stoll C (2021) Bitcoin’s growing e-waste problem. Resour Conserv Recycl 175:105901

Diep P, Mahadevan R, Yakunin AF (2018) Heavy metal removal by bioaccumulation using genetically engineered microorganisms. Front Bioeng Biotechnol 6:157

Directive EU (2002) 96/EC of the European Parliament and of the Council of 27 January 2003 on waste electrical and electronic equipment (WEEE). Off J Eur Union L 37:24–38

Directive EU (2003) Directive 2003/108/EC of the European Parliament and of the Council of 8 December 2003 amending Directive 2002/96/EC on waste electrical and electronic equipment (WEEE). Off J Eur Communities L 345:12

Doan LT, Amer Y, Lee S-H et al (2019) E-waste reverse supply chain: a review and future perspectives. Appl Sci 9

Ebrahimi M, Khalili N, Razi S et al (2020) Effects of lead and cadmium on the immune system and cancer progression. J Environ Health Sci Eng 18:335–343

Edmunds WM (2011) Beryllium: environmental geochemistry and health effects

Forti V, Balde CP, Kuehr R, Bel G (2020) The global e-waste monitor 2020: quantities, flows and the circular economy potential

Fowler B (2017) Current e-waste data gaps and future research directions, pp 77–81

Ganguly R (2016) E-waste management in India—an overview. Int J Earth Sci Eng 9:574–588

Gangwar C, Choudhari R, Chauhan A et al (2019) Assessment of air pollution caused by illegal e-waste burning to evaluate the human health risk. Environ Int 125:191–199

Gao Y, Ge L, Shi S et al (2019) Global trends and future prospects of e-waste research: a bibliometric analysis. Environ Sci Pollut Res 26:17809–17820. https://doi.org/10.1007/s11356-019-05071-8

Garfi M, Tondelli S, Bonoli A (2009) Multi-criteria decision analysis for waste management in Saharawi refugee camps. Waste Manag 29:2729–2739

Garg N, Adhana D (2019) E-waste management in India: a study of current scenario. Int J Manag Technol Eng 9

Gaur A, Gurjar SK, Chaudhary S (2022) Circular system of resource recovery and reverse logistics approach: key to zero waste and zero landfill. In: Advanced organic waste management. Elsevier, pp 365–381

Gautam A, Shankar R, Vrat P (2022) Managing end-of-life solar photovoltaic e-waste in India: a circular economy approach. J Bus Res 142:287–300

Ghimire H, Ariya P (2020) E-wastes: bridging the knowledge gaps in global production budgets, composition, recycling and sustainability implications. Sustain Chem 1:154–182. https://doi.org/10.3390/suschem1020012