Abstract

This work investigated the chemical and mineralogical properties of CaO–SiO2–Cr2O3–CaF2–MgO slags. Synthetic slags were prepared and the effect of the slag basicity (mass ratio CaO/SiO2) and MgO contents on the stability of the mineralogical species formed was analyzed. The morphology and composition of the slags were analyzed by X-ray powder diffraction (XRD) and scanning electron microscope-energy dispersive spectroscopy (SEM–EDS), whilst their chemical stability was evaluated by leaching with an aqueous acetic acid solution. It was found that in slags with CaO/SiO2 = 1, the main Cr-compound was MgCr2O4 spinel, which forms octahedron crystals. Small amounts of CaCr2O4 and CaCrO4 were also observed. It was found that with increasing the slag basicity from 1 to 2 the compounds MgCr2O4 and CaCr2O4 were formed together with the Cr(V)-containing compound complex Ca5(CrO4)3F which forms hexagonal crystals. The results showed that the highest Cr concentration levels in the leaching liquors corresponded to slags with CaO/SiO2 = 2, probably owing to the formation of CaCrO4 and Ca5(CrO4)3F, whilst the lowest chromium concentration levels corresponded to MgO-based slags owing to the stable binding of chromium in spinel with MgO. Additionally, potential–pH diagrams for the Ca–Cr–H2O and Mg–Cr–H2O systems at 25 °C were calculated.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The slags are attractive as construction material due to their excellent technical material properties. However, environmental concerns have been raised about the content and leachability of heavy metals of stainless steel and ferrochrome slags, especially chromium [1, 2]. Kilau and Shah [3] reported that the critical slag composition factors to control the chromium leachability were the CaO/SiO2 ratio and MgO content. It was reported that adding MgO to slags reduced the refractory weardown and modified the slag composition, lowering the Cr-contents in the leachate [4, 5], whereas Eriksson and Björkman [6] showed that increasing the MgO in the stainless steel slags can change the mineral composition towards formation of merwinite (3CaO∙MgO∙2SiO2) which prevents disintegration of the slag.

Stabilization and solidification are very effective tools and are becoming standard processes in hazardous waste treatment and disposal. These processes aim to attain mineralogical control of the metals to be stabilized. In previous works we have studied the effect of several slags forming agents, mainly Al2O3, on the leaching behavior of Cr [7, 8]. We found that CaCr2O4 and CaCrO4 were present in slags of the system CaO–SiO2–CaF2–Cr2O3. Gehlenite (Ca2Al2SiO7) and the Cr(VI)-containing oxide complex Ca4Al6CrO16 were present when Al2O3 was added to the slag. It was observed in the Al2O3-based slags that in increasing the slag basicity (mass % CaO/mass % SiO2) from 1 to 2 the leachability of the slags were notably increased. It was also shown that slags with MgO produced MgCr2O4 as the main mineralogical species.

In this work, chromium containing slags were prepared and the effects of slag basicity and MgO content on the stability of the mineralogical species formed were evaluated. The morphology and composition of the slags were analyzed by X-ray powder diffraction (XRD) and scanning electron microscopy coupled with energy dispersive spectroscopy (SEM–EDS). The chemical stability of chromium was evaluated analyzing the leaching levels of chromium according to the Mexican Waste Norms [9]. Additionally, the potential–pH diagrams for the Ca–Cr–H2O and Mg–Cr–H2O systems at 25 °C were constructed using the FACTSage thermodynamic software [10].

Materials and experimental procedure

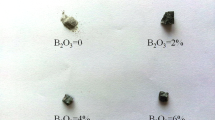

The slag was prepared with laboratory reagent-grade compounds (CaO, MgO, CaF2, SiO2 and Cr2O3) which were previously ground into fine powder whose particle size was between 45 and 74 μm. The MgO content ranged from 0 to 9 mass %, Cr2O3 and CaF2 were 10 % and the slag basicity B, defined as the ratio of CaO content to the SiO2 content (all mass %), was held at 1 and 2. In order to observe clearly the effect of chromium on the environmental behavior of the slags, the Cr2O3 contents tested were higher than those actually found in ferrochrome or stainless steel production. Table 1 shows the mixtures compositions used for the experiments.

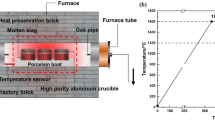

100 g of each slag system were prepared as follows. The powders were homogeneously mixed and placed in an MgO crucible which was placed in a graphite protecting crucible inside an open induction furnace. The slags were heated between 1600 and 1650 °C and the temperature was measured with an R-type thermocouple (Pt–Pt, 13 %Rh). It is worth noting that there are not reliable melting temperature values for the slags of the CaO–MgO–CaF2–SiO2–Cr2O3 system; then, to be sure that the system were completely melted at the furnace temperature, X-ray diffraction analysis were carried out after cooling the slags to verify the absence of free Cr2O3. The case where Cr formed complex compounds (CaCr2O4, Ca5(CrO4)3F, etc.) instead of free Cr2O3, was taken as evidence that the system was completely liquid.

The slags were left inside the furnace to cool down slowly until room temperature, to promote the formation of well defined crystalline structures. The cooling rate from the melting point to complete solidification was about 8 °C/min. Attention was given to the morphology, shape and compositions of the solid crystallized phases: the presence of crystals homogeneous in composition, with well-developed facets was taken as indication of the attainment of equilibrium.

Samples of each slag were crushed into fine powders and characterized by X-ray diffraction (XRD Bruker D8 Focus) and scanning electron microscopy coupled with energy dispersive spectroscopy (SEM–EDS, Jeol 6300). The chemical stability of the Cr-containing species present in the materials was evaluated by the following leaching technique, according to the Mexican environmental regulations [9]. Twenty-five g of each slag were crushed below 74 μm and contacted with 500 cm3 of an aqueous acetic acid solution at pH 2.88 ± 0.05 in a rotary system during 20 h at 30 ± 2 rpm and 23 ± 2 °C. The solid residues were filtered through ashless filter paper (Whatmann 542) and the chromium present in the leachate was determined by atomic absorption spectrophotometry.

Results and discussion

Identification of species

The XRD patterns for slags with 0 % MgO are shown in Fig. 1. Cuspidine (Ca4Si2O7F2) and wollastonite (CaSiO3) are the main species for the slags with CaO/SiO2 = 1 and 2. Calcium chromite (CaCr2O4) is also present in both cases. Calcium chromate (CaCrO4) was observed in slags with CaO/SiO2 = 1, whereas a Cr(V)-containing compound, Ca5(CrO4)3F, was detected in slags with CaO/SiO2 = 2.

Wollastonite (CaSiO3) and cuspidine (Ca4Si2O7F2) are again the main species present in the slag with 3 % MgO and CaO/SiO2 = 1; magnesium chromite (MgCr2O4), CaCrO4 and CaCr2O3 are also obtained, as can be observed in the XRD patterns shown in Fig. 2a. Increasing the slag basicity from 1 to 2, new calcium silicate are produced (Ca2SiO4 and Ca3Si2O7) and the main chromium compounds are MgCr2O4, CaCrO4 and Ca5(CrO4)3F. Peaks corresponding to free CaO are also observed.

Figure 3 shows the scanning electron microscope (SEM) micrograph, X-ray spectra and the composition obtained by this semiquantitative method for the slab-shaped crystals observed in the slag with 3 % MgO and CaO/SiO2 = 1. These crystals, containing almost the same atom % of Ca and Cr, probably correspond to CaCrO4, identified by XRD (see Fig. 2). Figure 4 shows the micrographs of the crystalline phases of the slag with 3 % MgO and CaO/SiO2 = 2. Octahedron crystals (labeled S) have high contents of chromium, magnesium and oxygen; then, they correspond to MgCr2O4 spinel. It has been reported [11] that magnesium chromite (MgCr2O4) crystallizes in cubes or octahedrons, such as those observed in this sample. Monoclinic crystals, labeled C, correspond to cuspidine (Ca4Si2O7F2), according to the EDS analysis. The hexagonal crystals (CF) contain calcium, chromium, fluorine and oxygen which probably is the complex compound Ca5(CrO4)3F.

Figure 5 shows the X-ray diffraction patterns for slags with 6 % MgO and CaO/SiO2 = 1, 2. As in the previous case, the slag with CaO/SiO2 = 1 contains cuspidine (Ca4Si2O7F2), MgCr2O4 and wollastonite (CaSiO3). Figure 5b shows that the number of chemical species is increased by increasing the slag basicity. In this case calcium and magnesium silicates are formed together with the Cr-based compounds (MgCr2O4, CaCr2O4, CaCrO4 and Ca5(CrO4)3F).

The SEM–EDS analysis confirm the XRD results, as can be observed in the micrographs shown in Fig. 6, corresponding to slag with 6 % MgO and CaO/SiO2 = 2. Hexagonal and monoclinic crystals were observed in this system. According to the EDS analysis, the hexagonal crystal (labeled CF) corresponds to Ca5(CrO4)3F, whereas elongated crystals (labeled C) contain fluorine, calcium and silicon, which might correspond to cuspidine. EDS analysis and XRD results indicate that crystals labeled C3S are calcium silicate (Ca3SiO5).

Cuspidine (Ca4Si2O7F2), calcium silicate (Ca2SiO4) and the spinel structured compound (MgCr2O4) are present in the slags with 9 % MgO and CaO/SiO2 = 1 and 2, as can be observed in the XRD patterns shown in Fig. 7. Besides, the slag with CaO/SiO2 = 1 contains magnesium silicates (MgSiO3 and Mg2SiO4) and in the slag with CaO/SiO2 = 2 three Ca–Cr compounds were formed; CaCr2O4, CaCrO4 and Ca5(CrO4)3F, where chromium has an oxidation state of 3+, 6+, and 5+, respectively.

Figure 8 shows micrographs of the crystalline structures obtained in the slag with 9 % MgO and CaO/SiO2 = 2. There were obtained as tetragonal crystals (labeled C2S), which contained mainly calcium, silicon and oxygen, probably corresponding to Ca2SiO4, identified by XRD (see Fig. 7). The octahedron crystals (labeled S) correspond again to magnesium chromite (MgCr2O4). The crystal labeled C corresponds to cuspidine, according to the EDS analysis.

Finally, elongated crystals (labeled CC) correspond to calcium chromite (CaCr2O4). Hashimoto et al. [12] also obtained needle-like CaCr2O4 crystals by heating a powder mixture of CaCO3 and Cr2O3, which are very similar to the crystals shown in Fig. 8.

Spinel-type compounds, such as MgCr2O4, are very resistant to oxidation and dissolution in acid environments; low chromium levels of leaching are expected in the MgO modified slags from stainless steelmaking. Therefore, it can be said that the presence of MgO leads to the formation of MgCr2O4 instead of CaCrO4 or Ca5(CrO4)3F in these slags, diminishing the formation of leachable chromium compounds; however, the CaO/SiO2 ratio must be maintained in a low level to avoid the formation of the Ca–Cr compounds, which may be leached in acid environments.

Leaching trials

Figure 9 shows the effect of MgO and the CaO/SiO2 ratio in the slags on the leaching behavior of chromium. As can be seen, the maximum chromium extraction, 40 mg/l Cr and 98 mg/l Cr, are reached when MgO is not added in the slag and the basicity is 1 and 2, respectively; whilst 29 mg/l Cr and 68 mg/l Cr are leached from slags with 9 %MgO and CaO/SiO2 equals 1 and 2, respectively. These results showed that the lowest chromium concentration levels in the leaching liquors corresponded to MgO-based slags and low slag basicity (CaO/SiO2 = 1) owing to the stable binding of chromium in spinel with MgO (MgCr2O4).

The effect of slag basicity on the leaching behavior of Cr was analyzed in the Al2O3-based slags in a previous work. It was shown that by using Al2O3 instead of MgO to modify the slag, the slag basicity strongly affected the Cr extraction, when the CaO/SiO2 ratio was increased from 1 to 2. This behavior was mainly due to the formation of the Cr(VI)-containing compounds CaCrO4 and Ca4Al6CrO16. In the MgO-based slags, the systems with high slag basicity (CaO/SiO2 = 2) produced compounds where chromium had a high oxidation state (CaCrO4 or Ca5(CrO4)3F), which increased the leachability of the slags.

Potential–pH diagrams

Potential–pH diagrams can be used to identify the conditions required to dissolve a metallic compound in an aqueous solution at specific temperature and pressure. The FACTSage computational thermodynamic package [10] and its database were used to determine the potential–pH diagrams at 25 °C for the Ca–Cr–H2O and Mg–Cr–H2O systems. To complete the database of FACTSage we included the following thermodynamic information for the solid calcium chromate (CaCrO4) reported by Lee and Nassaralla [13].

Figure 10 shows the potential–pH diagrams at 298.15 K (25 °C) for the Ca–Cr–H2O and Mg–Cr–H2O systems calculated with the FACTSage thermodynamic software [10]. Water is only stable in the region bounded by the dashed lines. The equilibrium conditions that can be utilized for the leaching of minerals or any solid compound in aqueous solutions at ambient temperature and pressure are constrained to those defined by the region of water stability.

Figure 10 was constructed specifically to compare the domains of CaCr2O4, CaCrO4 and MgCr2O4 and in this way to establish which compound makes the slag more vulnerable to leaching. The molality of all the aqueous species in these systems have been fixed at m = 1. CaCrO4 is not stable in acid solutions. CaCr2O4 becomes unstable when the pH of the leaching solution is slightly acid, about pH <6, where Ca2+ and Cr(OH)2+ ions are produced. The domain of MgCr2O4 is larger than that corresponding to CaCr2O4 and it is stable in solutions with pH >4. Then, it is important to promote the stabilization of chromium in the slag using MgO. It is worth noting that the thermodynamic information for Ca5(CrO4)3F was not available and this species was not included in the E-pH diagrams.

Conclusions

Slags samples of the system CaO–CaF2–SiO2–Cr2O3–MgO were prepared in order to analyze the effect of the CaO/SiO2 ratio and MgO content on the stability of the mineralogical species and the leachability of slags. The following results were obtained:

-

a.

Slags with CaO/SiO2 = 1 and low MgO content (3 %) contained magnesium chromite (MgCr2O4) together with CaCr2O4 and the hexavalent chromium species CaCrO4. Increasing the MgO content, the only Cr-containing compound formed was MgCr2O4, a spinel structured compound.

-

b.

Slags with CaO/SiO2 = 2 contained MgCr2O4 together with CaCr2O4, CaCrO4 and the Cr(V)-containing compound complex Ca5(CrO4)3F which was formed with hexagonal crystals. However, the presence of MgO in the slag leads to the formation of MgCr2O4, diminishing the formation of leachable Ca–Cr compounds.

-

c.

The leaching trials results showed that the slags with high slag basicity produced the highest chromium extraction in the leachates. The presence of MgO in the slag diminished the formation of leachable chromium compounds; however, the CaO/SiO2 ratio must be maintained in a low level to avoid the formation of Cr(V) and Cr(VI) compounds, which may be leached by acidic solutions. MgO helped to control the chromium leachability, which is due to the stable binding of chromium in MgCr2O4. The E-pH diagrams showed that the stability domain of MgCr2O4 is larger than that corresponding to CaCr2O4 and CaCrO4; therefore, the formation of the Mg-spinel minimizes the leachability of the slag.

-

d.

A topic of future research will be the stabilization and solidification as processes of hazardous waste treatment and disposal.

References

Lind BB, Fällman A-M, Larsson LB (2001) Environmental impact of ferrochrome slag in road construction. Waste Manag (Oxford) 21:255–264

Hiltunen R, Hiltunen A (2004) Environmental aspects of the utilization of steel industry slags.VII international conference on molten slags, fluxes and salts, pp 357–361

Kilau HW, Shah ID (1984) Chromium-bearing waste slag: evaluation of leachability when exposed to simulated acid precipitation. Hazardous and industrial waste management and testing: third symposium, ASTM, pp 61–80

Kindness A, Macias A, Glasser FP (1994) Immobilization of chromium in cement matrices. Waste Manag (Oxford) 14:3–11

Duchesne J, Laforest G (2004) Evaluation of the degree of Cr ions immobilization by different binders. Cem Concr Res 34:1173–1177

Eriksson J, Björkman B (2004) MgO modification of slag from stainless steelmaking. VII international conference on molten slags, fluxes and salts, pp 455–459

Arredondo-Torres V, Romero-Serrano A, Zeifert B, Cruz-Rivera J, Flores P, Cruz-Ramírez A (2006) Stabilization of MgO∙Cr2O3 spinel in slags of the SiO2–CaO–MgO–Cr2O3 system. Revista de Metalurgia de Madrid 42:417–424

García E, Romero-Serrano A, Zeifert B, Flores P, Hallen M (2008) Immobilization of chromium in slags using MgO and Al2O3. Steel Res Int 79:332–338

Mexican Official Norms. NOM-053-ECOL (1993). http://www.Semarnat.gob.mx

Thompson WT, Bale CW, Pelton AD (2010) FACTSage—facility for the analysis of chemical thermodynamics (FACTSage). Ecole Polytechnique, Montreal. http://www.crct.polymtl.ca

Chesterman CW, Lowe KE (eds) (1988) The Audubon Society. Field guide to North American rocks and minerals. Alfred A. Knopf, Inc., New York, pp 416–419

Hashimoto S, Yamaguchi A, Takahashi Y (1997) Growth and characterization of needle-like β-CaCr2O4 crystals. Mater Res Bull 32:1593–1602

Lee YM, Nassaralla CL (2006) Standard free energy of formation of calcium chromate. Mater Sci Eng 437:334–339

Acknowledgments

The authors wish to thank the Institutions CONACyT, SNI, COFAA and Instituto Politecnico Nacional for their permanent assistance to the Process Metallurgy Group at ESIQIE-Metallurgy and Materials Department.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cabrera-Real, H., Romero-Serrano, A., Zeifert, B. et al. Effect of MgO and CaO/SiO2 on the immobilization of chromium in synthetic slags. J Mater Cycles Waste Manag 14, 317–324 (2012). https://doi.org/10.1007/s10163-012-0072-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-012-0072-y