Abstract

Concrete is the basic building material in the world, and cement is the main material used in the production of concrete. However, there is an urgent need to reduce the consumption of cement, where cement production leads to 5–8% of global emissions of carbon dioxide. Geopolymer concrete is an innovative building material produced by alkaline activation of pozzolanic materials such as fly ash, granulated blast furnace slag, and kaolin clay. Geopolymers are widely used in the production of geopolymer concrete due to their ability to reduce carbon dioxide emissions and reduce high energy consumption. During the present study, the environmental impact of two strength grades (30 MPa and 40 MPa) of metakaolin geopolymer concrete (GPC) was evaluated to study its applicability in the construction sector. The kaolin clay extracted from the Aswan quarries was activated by a mixture of sodium hydroxide and sodium silicate solution. To introduce geopolymer concrete in the Egyptian industry sector, its environmental performance, together with its technical performance, should be competitive to the cement concrete used mainly for the time being. The cost of this new concrete system should also be evaluated. The environmental impact of GPC was evaluated and compared with cement concrete using life cycle assessment analysis and IMPACT 2002+ methodology. The cost of production was calculated for 1 m3 of geopolymer concrete and conventional cement concrete. Metakaolin geopolymer concrete achieved a high compressive strength of ~ 56 MPa, splitting tensile strength of 24 MPa, and modulus of elasticity of 8.5 MPa. The corrosion inhibition of metakaolin geopolymer concrete was ~ 80% better than that of conventional cement concrete. Geopolymer concrete achieved a reduction in global warming potential by 61% and improved the human health category by 9.4%. However, due to the heavy burdens of sodium silicate, the geopolymer concrete negatively affected the quality of the ecosystem by 68% and showed a slightly higher impact than cement concrete on the resource damage category for low strength grade of 30 MPa. The high cost of the basic ingredients of the geopolymer resulted in a high production cost of geopolymer concrete (~ 92 US$) that was three times that of cement concrete (~ 31 US$). Based on the environmental results, geopolymer concrete based on locally available metakaolin clay can be applied in the construction sector as a green alternative material for cement concrete.

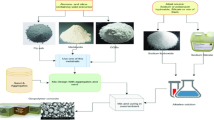

Graphic abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In the past 30 years, the cement industry in Egypt has increased in size and capacity with 16 factories producing about 55 million tons/year. Cement production is one of the most intensive industries with an average energy requirement of 240 mGJ/y, representing 59% of total energy consumption (Hussien 2015). Calcination of calcium carbonate during the production of clinker results in a significant environmental impact (Feiz et al. 2015) with intensive energy consumption in cement kilns (Habert et al. 2010a). It is estimated that 58% of the total global warming impact of cement manufacturing is due to the calcination process during clinker production (García-Gusano et al., 2015). However, cement with a higher proportion of by-products such as ground granulated blast furnace slag showed lower emissions of carbon dioxide compared to Portland cement with a higher clinker content (Feiz et al. 2015).

Chronic energy shortage has forced decision makers in Egypt to consider using coal as an alternative energy source to generate electricity and operate cement plants, which could lead to serious health and environmental concerns (Ali et al. 2016). Such growing environmental concerns have led to the search for alternative cementing materials with low carbon dioxide emissions and minimal energy consumption (Benhelal et al. 2013).

Geopolymers are three-dimensional amorphous inorganic polymers formed by the activation of aluminosilicate precursors with an alkali silicate solution at temperatures between 20 and 100 °C (Temuujin et al. 2009). Aluminosilicate precursors such as fly ash, blast furnace slag, and kaolin have been used in the preparation of geopolymers (Rajamane et al. 2015); the most commonly used alkali solution is a mixture of sodium hydroxide and sodium silicate (Palomo et al. 1999). Yao et al. (2009) described the concept of geopolymerization as a three-phase process of dissolution, reorientation, and hardening. Geopolymerization begins once the alkali solution is added to the aluminosilicate precursor where silica and alumina monomers are released. Alumina and silica monomers begin to reorganize into larger groups, water molecules are released, and a polymeric network of three-dimensional aluminosilicate structures is formed. According to the Si/Al ratio, the geopolymer network shows structures of (Na, K)-poly(sialate) (–O–Si–O–Al–O–)n, (Na, K)-poly(sialate-siloxo) (–O–Si–O–Al–O–Si–O)n, and (Na, K)-poly(sialate-disiloxo) (O–Si–O–Al–O–Si–O–Si–O–)n (Davidovits 1991).

Geopolymers showed excellent properties such as high mechanical strength, great durability against various acids and salts, low shrinkage, and low thermal conductivity (Duxson et al. 2007a), resulting in a wide range of potential applications such as low-CO2-producing cement, fire- and corrosion-resistant coatings, porous insulators, and wastewater treatment (Luukkonen et al. 2016).

In the last decades, geopolymer concrete provides tremendous potential as a building material due to its excellent durability compared to cement concrete. Lately, geopolymer based on blast furnace slag and fly ash has been used in Queensland’s Global Change Institute (GCI) and the Brisbane West Well camp airport (BWWA) in Australia, saving more than 6600 t of carbon emissions. However, for a better acceptance of geopolymer concrete among infrastructure owners, government decision makers, and society as a whole, certain constraints have to be overcome such as the absence of code standards and regulations that hinder the implementation of its various applications (Das et al. 2018).

To date, geopolymers have not been produced in Egypt despite their extreme importance and the availability of raw materials for their production. It is, therefore, time to use geopolymer concrete in the Egyptian construction sector, and the potential environmental impact of its production should be assessed.

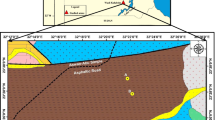

Egypt has a large reservoir of sedimentary kaolin deposits located in three main areas, namely Aswan, Red Sea, and Sinai (Baioumy et al. 2011). Previous studies have investigated the textural, mineralogical, and geochemical compositions of the Egyptian Kaolin deposits (Baioumy et al. 2012; Baioumy 2014). Aswan kaolin deposits are located approximately 105 km southwest of Aswan city at Wadi Kalabsha area. Kalabsha deposit is one of the major kaolin resources in Egypt, which is approximately 17 million metric tons and is mainly used for domestic uses such as ceramics, refractories, and white cement (Baioumy et al. 2011), as well as partial replacement of cement in the concrete mixture to improve its durability and mechanical properties (Rashwan et al. 2015). Under thermal activation, kaolin clay transforms into a reactive phase of metakaolin. When metakaolin is used as an aluminosilicate precursor, the resulting geopolymer is purer and can be more easily characterized compared to the geopolymers produced from industrial wastes that contain several hard-to-characterize amorphous phases (Rocha et al. 2018). Fly ash, for example, is not a well-defined material, but it comprises several crystalline and vitreous phases (Duxson et al. 2005).

Life cycle assessment (LCA) is a globally recognized comprehensive method for analyzing the environmental impact of materials and products during their life cycle from cradle to grave. LCA is regulated by the International Organization of Standardization ISO 14040: (2006) and ISO 14044: (2006).

Using LCA, the estimated reduction in carbon dioxide emissions of geopolymer cement is 20–80% (Komnitsas and Zaharaki 2007). Mclellan et al. (2011) estimated the improvement in greenhouse gas emissions of geopolymer concrete over cement concrete by 44–64%. Other studies showed an improvement in carbon dioxide emissions by 16% (Petrillo et al., 2016) and 40% (Nguyen et al. 2018) compared to 100% OPC.

The main environmental burdens within the geopolymer concrete life cycle have been associated with the use of alkali activators (Teh et al. 2017). Previous studies have shown the production of sodium hydroxide is the most relevant process regarding the environmental performance of geopolymer concrete, as it is a main raw material in the production of sodium silicate as well (Salas et al. 2018). In addition, the source of sodium hydroxide greatly affects the overall environmental impacts, due to both, the energy mix and the type of sodium chloride used for its production. However, in order to critically assess the geopolymer system, concerns other than CO2 emissions should be taken into consideration (Weil et al. 2009).

Contrary to previous findings, Habert et al. (2011) reported higher impacts of geopolymer concrete concerning human toxicity, ozone layer depletion, and abiotic depletion due to the use of sodium silicate solution. Furthermore, according to the SiO2/Al2O3 ratio, the global warming potential (GWP) of the metakaolin geopolymer could be either lower or higher than standard cement (Heath et al. 2014). Davidovits (2015) proved that the results of Habert et al. (2011) were improper because the calculated data were based on methodological errors.

Novel approaches have emerged to reduce the potential of global warming such as biochar, which has found its ways into various applications (Zhu et al. 2017), where it can be used as a significant sink of atmospheric carbon dioxide (Lehmann et al. 2006), and reduction of NO3 levels (Maroušek et al. 2018). With its lifetime of several centuries, biochar is being widely accepted as a promising method of carbon sequestration (Maroušek et al. 2016). Recently, biochar is used as an additive in the concrete mixture to improve the mechanical properties of conventional concrete and as an optimal solution for the reduction of CO2 in concrete production (Akhtar and Sarmah 2018).

Toniolo and Boccaccini (2017) showed additional benefit of using materials such as biomass ashes, red mud, and recycled glass in the production of geopolymer. The high alkalinity of these materials reduces the required amount of alkali activator while the high content of amorphous silica can be treated to obtain an eco-friendly water glass, thus reducing the most expensive materials used during geopolymer synthesis. Agro-industrial wastes such as rice husk ash (RHA) (> 90% silica) can be dissolved into an alkali hydroxide solution for use as a silica source in geopolymer synthesis, yielding similar mechanical properties compared to the use of commercial waterglass (Passuello et al. 2017).

Despite the availability of high-quality raw materials such as metakaolin in the region, frequent data of metakaolin application are limited to partial replacement of cement (Ibrahim et al. 2018) and in fire resistance and thermal insulation applications (Rashad 2017). In addition, no life cycle studies have been carried out on these materials to determine the applicability of metakaolin geopolymer in the construction sector.

The objective of this work is to study and evaluate the environmental impact of the production geopolymer concrete using locally available kaolin clay as a step on the way to a better understanding of its applicability in the construction sector in the future. Mechanical properties, such as compressive strength, splitting tensile strength, and modulus of elasticity, in addition to the electrochemical performance in seawater were investigated, and traditional cement concrete was used for comparison. Also, a preliminary cost study was conducted to determine the applicability of geopolymer concrete in the future.

Materials and methods

Materials

Kaolin clay from Kalabsha quarry in Aswan, Egypt, was provided from Nourmetec Refractories in Wadi Houf, Cairo, Egypt. Kaolin clay (Fig. 1a) was crushed to particle size lower than 20 mm and calcined 3 h in a rotary kiln at 850 °C to get the reactive phase of metakaolin (MK-K). Metakaolin particles were ground and sieved to particle size under 100 μm, to increase its surface area. The chemical composition of calcined kaolin clay was determined by Axios X-ray fluorescence (WD-XRF) sequential spectrometer PANalytical. The mineralogical composition and thermal behavior of kaolin clay and metakaolin were identified by X’Pert Pro PANalytical Powder and DTA-50 thermal analyzer, Shimadzu Co. The morphology of calcined kaolin clay was examined with scanning electron microscope Quanta 250 Field Emission Gun (FEG-SEM) with EDX attachment on the environmental mode.

Liquid sodium silicate solution (weight ratio of the SiO2/Na2O = 3:1) was provided from Macris Silicates Plant, Alexandria, Egypt. The concentration of the silicate solution was 40% by mass and had a density of 1.46 g/cm3. Sodium hydroxide flakes (99% purity) were provided from El Nasr Pharmaceutical Chemicals Company (ADWIC), Alexandria, Egypt.

Methods

Preparation of alkali-activated solution

Two alkali-activated solutions with a modulus ratio 2.0 (Na2SiO3/NaOH) were prepared by adding sodium hydroxide to sodium silicate solution to obtain SiO2/Al2O3 (S/A) ratios of 2.7 and 2.8. For each 100 g of metakaolin binder, 6.0 g of sodium hydroxide was dissolved in 36.6 g of silicate solution to obtain an S/A ratio of 2.7, and 7.3 g of sodium hydroxide was dissolved in 44.4 g of silicate solution to obtain an S/A ratio of 2.8. The mixtures were left 24 h at room temperature to cool before use.

Preparation of geopolymer concrete

In the current study, the geopolymerization process was conducted at room temperature to realize a better development of the late compressive strength which represents a priority in the present work. Under these conditions, the progress of the reaction is promoted and denser microstructure is obtained. Geopolymer concrete was prepared with two strength grades of 30 MPa (GPC-30) and 40 MPa (GPC-40); the S/A ratio was 2.7 in GPC-30 and 2.8 in GPC-40. The total content of aggregate in the GPC was 70% by mass, and the fine aggregate was added as 40% of the total aggregate.

All solid ingredients of metakaolin, fine aggregate (FA), and coarse aggregate (CA) were dry-mixed for 2–3 min. The alkali-activated solution was slowly added to the dry concrete constituents and mixed mechanically for 5.0 min. Tap water was slowly added during the mixing process, and the workability of the concrete mixture was adjusted according to ASTM C 143 to give a slump value of 12.5 cm (Fig. 1b). The concrete mixture was immediately cast into cubic steel molds (10 cm * 10 cm * 10 cm), vibrated for 30 s, demolded after 24 h, and left to harden in air at room temperature of 25 °C for up to 1 year.

Similarly, cement concrete (CC) was prepared with two strength grades of 30 MPa (CC-30) and 40 MPa (CC-40). The composition of both geopolymer concrete and cement concrete mixtures is given in Table 1.

Results and discussion

Characterization of kaolin clay

The chemical composition of metakaolin (Table 2) shows a high alumina content of 39.8% attributed to the dehydroxylated kaolin clay including the small undecomposed portions. The SEM micrograph of MK-K shows two distinct areas (Fig. 2). The EDX analysis of the selected spots showed the agglomerated area contains mainly O, Al, and Si as major elements in the reactive metakaolinite (Fig. 2a), while the second smooth area contains mainly O and Si that identify the non-reactive quartz phase (Fig. 2b).

The data of XRD pattern (Fig. 3 ) confirm the presence of intense and sharp quartz peaks (Q) as main constituent; the kaolinite peak (K) appears as the second main constituent identified at 12.34° and 24.64° (7.16 Å and 3.349 Å). A weak peak of anatase is observed at 3.56 Å. The kaolin clay is almost totally dehydroxylated upon calcinations, and the respective lines disappear with the appearance of weak hump for the amorphous aluminosilicate phases at the 2θ range ~ 20°–30°. The X-ray pattern of the calcined clay shows main d-value lines of quartz. A weak hump is observed in the 2θ range ~ 17° to 27°. It reflects weak amorphous structure formed from the dehydroxylated kaolinite phase, and the other clay minerals. A dispersion peak of the X-ray amorphous metakaolin was previously reported in a 2θ range 18° and 25° (Chen et al. 2016) and agrees well with the present result. Figure 4 illustrates the DTA thermogram for kaolin clay and thermally treated metakaolin. The DTA of the kaolin clay shows a weak endothermic peak below 100 °C, representing the weakly adsorbed water molecules removed from the surface of kaolin clay. The endothermic peak at 523 °C represents the dehydroxylation of kaolin clay, where the crystalline structure of kaolin is destroyed and transformed into the amorphous structure of metakaolin. The sharp exothermic peak at 995 °C represents the transformation of the amorphous structure of metakaolin into crystalline spinel. The DTA of metakaolin shows a very broad endothermic peak at 370–840 °C, and this peak is a characteristic of the amorphous or near-amorphous SiO2–Al2O3 system (Živica et al. 2011). The sharp exothermic peak at 987 °C represents the reorganization of the amorphous structure of metakaolin to crystalline spinel.

Compressive strength

The compressive strength of the geopolymer concrete was measured according to ASTM C 39; three cubic replicates were tested for each concrete mixture. Figure 5 shows the compressive strength of the geopolymer concrete mixed with increasing content of SiO2/Al2O3, and both concrete mixtures achieved initial strength at an early age of 28 days of more than 70% of their final strength. The GPC-30 achieved a 3-day strength of ~ 20 MPa that increased to 28 MPa, 32 MPa, and ~ 40 MPa after 7, 28, and 360 days, respectively. The adhesion between the different concrete components in GPC-40 was significantly improved by increasing the SiO2/Al2O3 ratio to 2.8, resulting in compressive strength of ~ 29 MPa, 40 MPa, and ~ 56 MPa after 7, 28, and 360 days, respectively.

Splitting tensile strength

The splitting tensile strength of GPC-40 and CC-40 was measured according to ASTM C 496 (Fig. 6). Three replicates were tested for each concrete cylinder with 150 mm diameter and 300 mm length at the age of 7 days and 28 days. At the early age of 7 days, the geopolymer concrete showed higher splitting tensile strength (15 MPa) than conventional cement concrete (13 MPa). However, both concrete mixtures showed similar splitting strength of 24 MPa at the age of 28 days.

Modulus of elasticity

The modulus of elasticity of GPC-40 and CC-40 was measured according to ASTM C 469 (Fig. 7). Three replicates of a concrete cylinder with 150 mm diameter and 300 mm length were tested at the age of 28 days. The modulus of elasticity of GPC-40 (8.5 MPa) was ~ 50% lower than that of CC-40 (15 MPa), which is similar to the behavior of fly ash geopolymer concrete (Fernández-Jiménez et al. 2006). However, previous literature has reported a significant increase in the modulus of elasticity of the geopolymer over time (Wardhono 2015); this additional increase indicates the incomplete geopolymerization reaction at the age of 28 days.

Electrochemical impedance spectroscopy

Figure 8 shows the Nyquist plot for the GPC-40 and CC-40 in 3.5 wt% NaCl solution at 28 days. The electrochemical parameters such as the charge transfer resistance (Rct), the degree of metal surface coverage (Ɵ), and the inhibition efficiency (µEIS) are given in Table 3. The high alkalinity of the alkali-activated solution resulted in the formation of a protective passive layer that effectively reduced the penetration of chloride ion into the geopolymer matrix, resulting in efficient corrosion inhibition of ~ 80% compared to cement concrete. Such high impedance to the chloride ion penetration of the GPC-40 indicates the formation of a dense geopolymeric matrix with low porosity compared to CC-40, which has a significant impact on the service life of the reinforced geopolymer concrete in chloride environments.

Life cycle analysis

In 1960s, the concept of studying the environmental impacts and the total effects related to a product system had first initiated under the name of a resource and environmental profile analysis (REPA). However, during the period of 1975–1988, several studies were conducted using similar REPA methodology and the name of these studies changed to life cycle analyses or LCAs by other authors (Hunt et al. 1992). LCA is regulated by the International Organization of Standardization ISO 14040: (2006) and ISO 14044: (2006). Both standards can be regarded as the “mother” of almost all other standardization activities, such as ILCD-Handbook, UNEP Life Cycle Initiative, ISO 14067, GHG Protocol, and PAS 2050. They all take ISO 14040/44 as the basis and specify some general requirements, even though some do not go much beyond the original (Finkbeiner 2012). LCA addresses the potential environmental impacts throughout a product life cycle from raw material acquisition through production, use, end-of-life treatment, recycling, and final disposal. This sequence is called “cradle-to-grave” assessment (Williams 2009). In accordance with ISO 14040/44, there are four main phases in the typical LCA method, namely the goal and scope phase, the inventory analysis phase, the impact assessment phase, and the interpretation phase (ISO 14040: 2006).

Globally, previous life cycle studies have focused mainly on carbon dioxide emissions and energy consumption of cement industry (Davidovits 1994), concrete (Flower and Sanjayan 2007), concrete constituents (Gursel and Ostertag 2016) and geopolymer concrete (Habert et al. 2011). The LCA tool has been used in a limited extent in Egyptian studies, mainly for building and construction materials, which accounted for 44% of the total published documents in Egypt (Yacout 2019). Publications in this area estimated the environmental impacts of the cement industry in Egypt (Ali et al. 2016), the Egyptian typical residential building (Ali et al. 2015), and low-income housing buildings in Egypt (Marzouk et al. 2017). To date, no LCA study of geopolymers has been conducted in Egypt due to their recent history and the apparent deficiency of Egyptian databases for the production and treatment of various materials and processes.

SimaPro is a powerful program used to implement life cycle assessment of a product system in accordance with ISO 14040/44. This program is equipped with various databases for materials and processes commonly used in the construction sector. In the current analysis, SimaPro V.8.5 and Ecoinvent database V.3.0 were used to assess the potential environmental impacts of two concrete systems: the geopolymer concrete and the cement concrete.

Goal and scope definition

The goal of this LCA study is to assess the environmental impacts of two strength grades of metakaolin geopolymer concrete and compare the results with the reference cement concrete with the same strength grades. The assessments were based on four main environmental categories of climate change, human health, resources depletion, and ecosystem quality. This assessment will help Egyptian decision makers to identify and recommend an eco-friendly concrete system.

System boundary

Based on ISO 14040/44 standards, system boundary defines the unit processes involved within the LCA. There are three commonly accepted system boundaries, namely cradle to gate, cradle to site, and cradle to grave. Cradle-to-gate system boundary includes all impacts from extraction of raw materials, processing, and manufacturing into the end product. Cradle-to-site system boundary includes the cradle-to-gate impacts and the transport of the product to the site of its use, while cradle-to-grave system boundary includes cradle-to-site impacts as well as impacts associated with the maintenance, energy consumed, and end-of-life scenarios such as how the item will be disposed/reused/recycled (McGrath et al. 2018).

In principle, LCA should track all the processes in the life cycle of a given product system, from cradle to grave. In practice, this is impossible and a number of flows must be either roughly estimated or cut off and subsequently ignored (Guinée et al. 2002). Previous literature has shown the service life of the geopolymer paste (Mclellan et al. 2011) and geopolymer concrete (Ostwal and Chitawadagi 2014) was better than the OPC. Besides, the durability of geopolymer concrete was better than that of ordinary Portland cement concrete (Singh et al. 2013). However, the demolition of both concrete systems results in the same kind of inert materials as binder and aggregates, so the stages of service and demolition were omitted in the current study as common operations of both systems. The system boundary of the current study was chosen as cradle-to-gate type; it was set only for the manufacturing stages starting from the extraction of kaolin clay until the end of the production process of metakaolin geopolymer, as shown in Fig. 9. This type of limitation is quite common, internationally called cradle-to-gate analysis (Borges et al. 2014; Habert et al. 2010b).

Functional unit

The functional unit determines what is being studied and is therefore linked to all the inputs and outputs of the studied system. In the current study, the functional unit was identified as a cubic meter (1 m3) for both concrete systems for the same strength grades at the age of 28 days.

Life cycle inventory analysis (LCI)

Inventory analysis (LCI) indicates both the inputs and the outputs of a product where the energy and raw materials consumptions are considered as input data whereas products and different emissions into the air, water, and land are considered as output data. The production of the metakaolin geopolymer requires two types of materials, namely kaolin clay and an alkaline-activated solution. The dehydroxylation of pure kaolinite results in a mass loss of 14%, which corresponds to the mass in bound hydroxyl ions in kaolinite (Ilić et al. 2010). Thus, the production of 1.0 kg of metakaolin binder needs 1.16 kg of kaolin clay (Chandrasekhar et al. 1996). Natural kaolin clay requires few processing techniques to be transformed into the reactive metakaolin phase. Data modeling of energy consumption in the process of metakaolin production was based on field visits to the metakaolin producer site. Different types of energy have been consumed in the production of metakaolin such as gasoline in the rotary kiln feeding and electricity in the crushing and grinding of metakaolin. The production of sodium silicate heavily contributes to the global warming, as melting of quartz sand with sodium carbonate (soda) at 1300–1500 °C leads to high CO2 emissions and very high energy consumption (Habert et al. 2011). Various amounts of CO2 emissions were reported for the production of sodium silicate as 1.514 kg CO2 eq (Turner and Collins 2013), 1.066 kg CO2 eq (Fawer et al. 1999), and 1.0 kg CO2 eq (Duxson et al. 2007b) per kg sodium silicate. Fawer et al. (1999) have shown a “cradle-to-factory-gate” analysis for the production of sodium silicate, covering all production processes, notably the two basic operations of the furnace and hydrothermal route and even the processes of dissolution, blending, and filtering. Therefore, the study of Fawer et al. (1999) has been used as a reference for sodium silicate production in previous literature (Borges et al. 2014; Habert et al. 2010a). In addition, the production of sodium hydroxide through electrolysis of brine consumes high energy and leads to additional emissions of carbon dioxide (Garcia-Herrero et al. 2017a). The estimated values of CO2 emissions in the production of NaOH were 0.633 kg CO2 (Thannimalay et al. 2013), 1.0 kg CO2 (Duxson et al. 2007b), and 1.915 kg of CO2 (Turner et al. 2013) per kg NaOH. The apparent difference in CO2 emissions values for the production of sodium silicate and sodium hydroxide is due to the type of raw materials used, the difference in manufacturing processes, and the transport factor not included in many studies.

So far, databases are not available for the production of sodium silicate and sodium hydroxide, not even in the Middle East. Also, it was extremely difficult to collect actual data from different production sites because of the privacy of data. Hence, data for this work have been sourced from the Ecoinvent V3.0 database and previous work of Fawer et al. (1999) and Thannimalay et al. (2013). Inventory data for the production of all components of Portland cement concrete were adopted by the Ecoinvent V3.0 database. Inventory data for the production of one ton of metakaolin binder are given in Table 4.

Life cycle impact assessment (LCIA)

Impact assessment methodologies aim to associate each life cycle inventory with the corresponding environmental impacts. There are two main schools of impact assessment methods: (1) pressure-oriented methods such as CML (Guinée et al. 2002) or EDIP (Hauschild and Wenzel 1998) that restrict quantitative modeling to relatively early stages in the cause–effect chain to limit uncertainties and (2) damage-oriented methods such as Eco-indicator 99 (Goedkoop and Spriensma 2001) or IMPACT 2002+ (Jolliet et al. 2003) that try to model the cause–effect chain up to the endpoint, or damage (Chen et al. 2010).

IMPACT 2002+ methodology takes advantages of midpoint-based indicators such as CML (Guinée et al. 2002) and damage-based indicators such as the Eco-indicator 99 (Goedkoop and Spriensma 2001). It links all types of life cycle inventories via 14 midpoint categories to four damage categories (endpoint categories). The damage categories are attained by multiplying the midpoint characterization potentials with definite damage factors of reference substances as given in Table 5. Human health damage category is expressed as disability-adjusted life years per kg of emitted substance (DALY/kg emission), which is defined as the number of years of human life lost or in suffering from disease. Ecosystem quality damage category is expressed as a potentially disappeared fraction over a certain area and during a certain time per kg of emitted substance (PDF m2 year/kg emitted). For climate change damage category, the global warming is the only contributing midpoint category with time horizon of 500 years to account for both short-term and long-term effects and expressed as kg eq CO2. Two midpoint categories, namely mineral extraction and non-renewable energy, are belonging to the resource damage category that is expressed as the surplus of energy necessary for further extraction of minerals and fossil fuels (MJ).

Besides, IMPACT 2002+ methodology utilizes normalization factors to avoid the scale effects of the different indicators and to minimize the possibility that some parameters are of the type “higher is better” and others “lower is better” (Mateus et al. 2013). In previous literature, the normalization of the different environmental impacts of products was carried out by dividing the result for three main damage categories (human health, ecosystems, and resources) by their normalization values in the impact assessment methodology used (Prasara-A et al. 2019). The unit of all normalized midpoint/damage factors is [pers year/unitemission], i.e., the number of equivalent persons affected during 1 year per unit of emission.

In the current study, IMPACT 2002+ V2.14 damage-oriented methodology was applied to evaluate the environmental impacts of the two studied concrete systems; all calculations were done using SimaPro software.

Life cycle assessment results and interpretation

Geopolymer concrete made from pure metakaolin requires a large amount of sodium silicate solution to activate it; therefore, it showed higher environmental impacts than geopolymer concrete made of fly ash or granulated blast furnace slag (Habert et al. 2011). Previously published LCA studies were limited to estimating carbon dioxide emissions and energy consumption without addressing other environmental categories such as human health and ecosystem quality. This makes it more difficult to compare the environmental effects of metakaolin geopolymer with other geopolymer types.

The overall impact of the production of 1 m3 of geopolymer concrete was less than cement concrete by 16.9 points for the strength grade of 30 MPa and 23.1 points for the strength grade of 40 MPa, representing a decrease in the total environmental burdens by 33% for GPC-30 and 37% for GPC-40 (Fig. 10). The production of geopolymer concrete resulted in higher environmental effects on midpoint categories such as carcinogens, non-carcinogens, ionizing radiation, aquatic and terrestrial ecotoxicity, and mineral extraction compared to cement concrete (Table 6).

The heaviest environmental impacts of the production of geopolymer concrete were on the climate change and human health damage categories, followed by the resources damage category, while the least impact was on the ecosystem quality damage category. Cement concrete showed similar performance where the heaviest environmental impacts were on the climate change and human health damage categories, while the least impact was on the ecosystem quality damage category (Fig. 11). The negative impacts of geopolymer concrete were due to the heavy effects of the production of the sodium silicate solution, while cement production was the major contributor to the adverse environmental impacts of cement concrete (Fig. 12).

Climate change damage category

Both strength grades of the geopolymer concrete achieved a significant reduction in the global warming potential by ~ 61% compared to cement concretes. GPC-30 and GPC-40 showed CO2 emission values of 124 and 142 kg CO2 eq/m3, respectively, while CC-30 and CC-40 showed CO2 emission values of 297 and 363 kg CO2 eq/m3, respectively.

Geopolymer concrete made from pure metakaolin requires a higher amount of sodium silicate solution to be activated due to its low Si/Al ratio. Sodium silicate contributed 60% (84.4 kg CO2 eq) of the total global warming potential of metakaolin geopolymer concrete, sodium hydroxide contributor by 23% (33.2 kg CO2 eq), while metakaolin only contributed by 13% (18.1 kg CO2 eq) (Table 7). Moreover, cement production contributed more than 97% (357 kg CO2 eq) of the total impact of cement concrete on the climate change damage category. These results were relevant to the estimated reduction in the global warming of geopolymer concrete of 44–64% (McLellan et al. 2011), 62–66% (Rouwette 2012), and 70% (Weil et al. 2009). Others reported a lower reduction in the global warming of 25–45% (Stengel et al. 2009) and 9% (Turner and Collins 2013).

One aspect that stood out in the environmental impact studies of geopolymers is the large environmental footprint (up to 80–90%) of the sodium silicate solution that is produced using the Solvay process (Luukkonen et al. 2018). Besides, the data of sodium silicate production are outdated and the manufacturers would not disclose information on current energy usage and emissions.

Human health damage category

Due to the inclusion of the eco-friendly metakaolin as a binder rather than cement in the concrete mixture, metakaolin geopolymer concrete showed slightly less environmental effects on the human health damage category by 5.1–9.4% compared to cement concrete (Table 8).

During the production of sodium silicate, the fusion of soda ash and silica sand adversely affected several environmental indicators such as carcinogens, ionizing radiation, and the ozone layer depletion, resulting in a negative impact of geopolymer concrete on the human health damage category. Sodium silicate contributed by 60–68% to the human health damage category, followed by metakaolin (13–16%) and sodium hydroxide (10%). High environmental effects of geopolymers have been reported for categories other than global warming such as human toxicity due to the heavy effects of sodium silicate solution (Habert et al. 2011). The negative impact of cement on the human health damage category was higher than 90%.

Ecosystem quality

The two concrete systems exhibited the least negative impact on ecosystem quality (Fig. 11). However, the environmental effects of geopolymer concrete on the ecosystem quality were 68% higher than those of cement concrete (Table 8). The high sodium silicate content used in metakaolin activation adversely affected all midpoint indicators such as aquatic ecotoxicity, terrestrial ecotoxicity, aquatic acidification, aquatic eutrophication, terrestrial acid, and land occupation by more than 88% of the total negative effect of geopolymer concrete. This effect was worse than that of cement binder (70–75%) on the ecosystem quality. Sodium hydroxide and metakaolin binder also contributed to the ecosystem quality by 3.6% and 2.0% (Table 7).

Resources damage category

Contrary to by-product materials such as fly ash and slag, natural kaolin and sodium silicate contribute significantly to the depletion of resources. The non-renewable energy consumption of GPC-30 (1230 MJ) was slightly higher than that of CC-30 (1220 MJ), which was reduced by 4.7% for GPC-40 compared to CC-40 (Table 8). Sodium silicate negatively affected the depletion of the resources by ~ 62%, followed by metakaolin (~ 21%) and sodium hydroxide (~ 14%). The production of cement was the major contributor to the depletion of resources by more than 93% of the total impacts of cement concrete.

Based on the above results, it should be noted that once metakaolin is accepted as a building material in the Egyptian construction sector, its production will be significantly improved by the establishment of several extraction and processing plants. Moreover, the availability of natural raw materials in Egypt and the low energy needed to deal with kaolin compared to cement will help reduce the environmental burdens of geopolymers.

Allocation procedure

Whenever dealing with multi-functional processes, ISO 14040 (ISO, 2006) recommends a three-step procedure with regard to allocation. In the first type, the allocation should be avoided by expanding the system boundaries to include all the additional functions of the by-products. The second type, when allocation cannot be avoided, the allocation reflects an underlying physical relationship usually mass allocation. The third type is such as market value or economic allocation. No by-products are produced during the production of both the metakaolin binder and the sodium silicate solution. Therefore, their production is considered as a single function process. Industrially, caustic soda is most commonly manufactured by the electrolysis of saline solution (NaCl), which is a multi-functional process that produces chlorine, sodium hydroxide, and hydrogen.

The mass allocation coefficient Cm can be calculated as the mass ratio between main product and by-product (Chen et al. 2010), where mby-product and mmainproduct are the masses of by-product and of the main product, respectively.

The economic allocation coefficient Ce is calculated as follows:

where ($·m) is the price per unit of the materials ($) multiplied by the mass of materials produced during the process (Chen et al. 2010).

The process of electrolysis is manufactured in a fixed ratio of 1 t of chlorine, 1.13 t of caustic soda, and 0.03 t of hydrogen, this product combination called electrochemical unit (ECU) (Garcia-Herrero et al. 2017a).

Garcia-Herrero et al. (2017b) have studied both the mass allocation and the economic allocation of the electrolysis process of brine solution. Both types of allocations showed similar effects of the production of sodium hydroxide (70%) of the total environmental burdens. As opposed to mass allocation, the economic allocation has led to significantly varied results for the production of hydrogen due to economic fluctuation over time.

In the present study, the effect of sodium hydroxide production has been reduced to 70% of its total environmental impacts to investigate the new environmental burdens of the metakaolin geopolymer concrete. The mass allocation of sodium hydroxide production was applied according to Garcia-Herrero et al. (2017b). All environmental impacts of GPC-40 were slightly reduced (Table 8) except for the ecosystem quality damage category. These high environmental loads are due to the fact that the main contributor to the environmental burden of geopolymers is the production of sodium silicate, which adversely affects all environmental categories. Therefore, to reduce the environmental burden of geopolymers, it is necessary to improve production techniques and use a cleaner and cheaper energy source.

Geopolymer cost analysis

During the past few decades, there has been a growing demand for new construction materials that have low impacts on the environment and affect sustainability. Geopolymer concretes were eventually developed with the aim of reducing the carbon footprint by eliminating cement use and reducing the cost by using industrial by-products which otherwise would be dumped as waste materials (Mathew et al. 2013). In addition, geopolymer concrete as a promising green alternative to cement concrete is only effective when there is no hindrance on its adoption on a large production scale.

Preliminary cost study of manufacturing normal strength grade (30 MPa) and high strength grade (40 MPa) geopolymer concrete was conducted and compared with that of OPC concrete (Table 9). Market prices were used for the ingredients of geopolymer concrete and cement concrete because the actual production cost is not available at the present time. An initial cost analysis can be applied for a new product without considering all its stages (Zhang et al. 2019).

The total cost of producing 1 m3 GPC was three times higher than the total cost of producing 1 m3 OPC concrete for both strength grades. This is due to the high cost of basic ingredients of geopolymer system. Contrary to waste by-products materials such as fly ash and slag, metakaolin with its low Si/Al ratio, high finesse, and its plate-like structure consumes large quantities of sodium silicate and sodium hydroxide during the alkaline activation step. For the metakaolin geopolymer concrete (Fig. 13), sodium hydroxide was the major contributor to the total production cost by ~ 41%, followed by metakaolin binder (~ 31%) and sodium silicate (~ 19%). Cement as a main constituent of conventional concrete contributed by ~ 62% of the total production cost of OPC concrete.

Despite the low temperature required to convert natural kaolin clay to the reactive metakaolin phase (850 °C), the production cost of metakaolin is similar to the cost of cement production due to the apparent lack of plants that can perform various treatment processes for kaolin clay.

The results of Tempest et al. (2015) revealed the cost of geopolymer concrete based on fly ash was three times more than that of cement concrete of equivalent strength. Although industrial by-product materials such as fly ash and GGBFS are often inexpensive and consume significantly less content of the alkaline-activated solution than the metakaolin, the addition of the activating chemicals has made the cost of geopolymer concrete ($210.36/m3) much higher than Portland cement concrete ($66.55/m3). Mclellan et al. (2011) showed a wide variation in the calculated cost of geopolymers ranging from 7% lower to 39% higher compared with OPC depending on the source location, the energy source, and the mode of transport.

The price of concrete using materials such as fly ash was several times higher than the cost of conventional concrete using Portland cement (Dange and Suryawanshi 2017); fly ash concrete can only replace Portland cement concrete, provided that the price of water glass is reduced to a level similar to that of Portland cement (Vilamová and Piecha 2016). However, Thaarrini and Dhivya (2016) showed the cost of production of OPC concrete was 11% higher than that of GPC for higher grades, while for lower grades the cost of production of GPC was 1.7% higher than that of production of OPC concrete.

Assi et al. (2018) proposed a new mix design for geopolymer concrete based on the use of sodium hydroxide and silica fume-based activating solution with the addition of OPC to the mixture. The new mixture showed superior properties, lower cost of up to a 50%, which represents a cost-competitive, more environmentally friendly alternative to OPC. However, adding OPC to the geopolymer mixture does not seem to be a good solution for producing a green system as the resulting product is not a pure geopolymer.

Since the metakaolin geopolymer in the present work is the first attempt to an environmentally friendly concrete system, further improvements are required to reduce its production cost. However, once metakaolin is accepted as a building material in the industry, its price is expected to be lower than cement due to its natural availability as well as the difference in the processing temperature (1450 °C for cement and 850 °C for metakaolin). Besides, both sodium silicate and sodium hydroxide can be manufactured or extracted from waste-stream materials in a form adequate for construction (Tempest et al. 2015). Thus, the high cost of the production of geopolymer concrete at present work should not be taken as a deterrent for further investigation because the materials used were above the level required for construction and their prices were based on the market price, not production price.

Conclusions

The current study highlighted the environmental impact of the production of two strength grades of geopolymer concrete (30 MPa and 40 MPa) using the life cycle assessment methodology. A mixture of sodium hydroxide and sodium silicate solution was used in the alkaline activation of the locally available metakaolin binder.

Geopolymer concrete with a content of 30% metakaolin binder showed high mechanical strength (~ 56 MPa) and excellent corrosion inhibition in 3.5% NaCl solution (~ 80%) compared with cement concrete. A detailed environmental assessment of geopolymer concrete production was performed using the LCA methodology. Compared to cement concrete, metakaolin geopolymer concrete achieved a reduction in global warming potential up to 61% and improved indicators of human health damage category such as respiratory inorganics, ozone layer depletion, and respiratory organics by 9.4%. This excellent environmental performance of geopolymer concrete resulted from the total replacement of Portland cement with the eco-friendly metakaolin binder. However, the production of geopolymer concrete showed higher impacts regarding other environmental categories such as aquatic and terrestrial ecotoxicity, aquatic eutrophication, and the depletion of resources due to the heavy effects of sodium silicate solution production.

The high preliminary market price of geopolymer ingredients, mainly for sodium hydroxide, was the main cause of the high production cost of geopolymer concrete (92 US$), which reached three times the cost of cement concrete (31 US$).

Based on the environmental results of the current research, geopolymer concrete based on locally available metakaolin clay can be applied in the construction sector as a green alternative material for cement concrete, and it is highly recommended to invest in the region using geopolymer concrete in the near future. The high production cost of geopolymer concrete can be significantly reduced by the establishment of new special production lines for the alkali-activated solution and the processing of metakaolin. The adverse impact of geopolymer on some environmental categories can also be reduced by the incorporation of available materials such as biochar and rice husk ash. The high alkalinity of these materials reduces the required amount of alkali activator, while the high content of amorphous silica can be processed to obtain an eco-friendly waterglass, which reduces the depletion of resources and reduces the high cost of materials used during geopolymer synthesis.

References

Akhtar A, Sarmah AK (2018) Novel biochar-concrete composites: manufacturing, characterization and evaluation of the mechanical properties. Sci Total Environ 616–617:408–416

Ali AAM, Negm AM, Bady MF, Ibrahim MGE (2015) Environmental life cycle assessment of a residential building in Egypt: a case study. Proc Technol 19:349–356

Ali AAM, Negm AM, Bady MF, Ibrahim MGE, Suzuki M (2016) Environmental impact assessment of the Egyptian cement industry based on a life-cycle assessment approach: a comparative study between Egyptian and Swiss plants. Clean Technol Environ Policy 18(4):1–16

Assi L, Carter K, Deaver EE, Anay R, Ziehl P (2018) Sustainable concrete: building a greener future. J Clean Prod 198:1641–1651

Baioumy H (2014) Provenance of sedimentary kaolin deposits in Egypt: evidences from the Pb, Sr and Nd isotopes. J Afr Earth Sci 100:532–540

Baioumy H, Gilg HA (2011) Pisolitic flint kaolin from Kalabsha, Egypt: a laterite-derived facies. J Sedim Geol 236(1–2):141–152

Baioumy H, Gilg HA, Taubald H (2012) Mineralogy and geochemistry of the sedimentary kaolin deposits from Sinai, Egypt: implications for control by the source rocks. Clay Clay Miner 60(6):633–654

Benhelal E, Zahedi G, Shamsaei E, Bahadori A (2013) Global strategies and potentials to curb CO2 emissions in cement industry. J Cleaner Prod 51:142–161

Borges PHR, de Lourenço TMF, Foureaux AFS, Pacheco LS (2014) Comparative study of the life cycle assessment of geopolymer concrete and CP II Portland cement concrete. Ambiente Constr 14(2):153–168

Chandrasekhar S (1996) Influence of metakaolinization temperature on the formation of zeolite from kaolin. Clay Miner 31:253–261

Chen C, Habert G, Bouzidi Y, Jullien A, Ventura A (2010) LCA allocation procedure used as an incitative method for waste recycling: an application to mineral additions in concrete. Resour Conserv Recycl 54(12):1231–1240

Chen L, Wang Z, Wang Y, Feng J (2016) Preparation and properties of alkali activated metakaolin-based geopolymer. Materials 9(9):767–779

da Silva Rocha T, Dias DP, França FC, de Salles Guerra RR, de Oliveira LR (2018) Metakaolin-based geopolymer mortars with different alkaline activators (Na+ and K+). Constr Build Mater 178:453–461

Dange S, Suryawanshi Y (2017) Comparison of geopolymer concrete based on strength and cost with concrete. Imp J Interdiscip Res 3(9):1026–1029

Das SK, Mishra J, Mustakim SM (2018) An overview of current research trends in geopolymer concrete. Int Res J Eng Technol 5(11):376–381

Davidovits J (1991) Geopolymers inorganic polymeric new materials. J Therm Anal 37(8):1633–1656

Davidovits J (1994) Global warming impact on the cement and aggregates industries. World Resour Rev 6(2):263–278

Davidovits J (2015) False values on CO2 emission for geopolymer cement/concrete published in scientific papers. Technical paper no. 24, Geopolymer Institute Library, pp 1–9

Duxson P, Provis JL, Lukey GC, Mallicoat SW, Kriven WM, Van Deventer JSJ (2005) Understanding the relationship between geopolymer composition, microstructure and mechanical properties. Colloids Surf A 269(1–3):47–58

Duxson P, Fernández-Jiménez A, Provis JL, Lukey GC, Palomo A, Van Deventer JSJ (2007a) Geopolymer technology: the current state of the art. J Mater Sci 42(9):2917–2933

Duxson P, Provis JL, Lukey GC, van Deventer JSJ (2007b) The role of inorganic polymer technology in the development of “green concrete”. Cem Concr Res 37(12):1590–1597

Fawer M, Concannon M, Rieber W (1999) Life cycle inventories for the production of sodium silicates. Int J Life Cycle Assess 4(4):207–212

Feiz R, Ammenberg J, Baas L, Eklund M, Helgstrand A, Marshall R (2015) Improving the CO2 performance of cement, part I: utilizing life-cycle assessment and key performance indicators to assess development within the cement industry. J Cleaner Prod 98:272–281

Fernández-Jiménez AM, Palomo A, Lopez-Hombrados C (2006) Engineering properties of alkali-activated fly ash concrete. ACI Mater J 103(2):106–112

Finkbeiner M (2012) Gap analysis for the life cycle assessment of container packaging. FEVE aibsl, Brussels. Final report for the European container glass federation: 2012-60

Flower DJM, Sanjayan JG (2007) Green house gas emissions due to concrete manufacture. Int J Life Cycle Assess 12(5):282–288

García-Gusano D, Garraín D, Herrera I, Cabal H, Lechón Y (2015) Life cycle assessment of applying CO2 post-combustion capture to the Spanish cement production. J Clean Prod 104:328–338

Garcia-Herrero I, Margallo M, Onandía R, Aldaco R, Irabien A (2017a) Environmental challenges of the chlor-alkali production: seeking answers from a life cycle approach. Sci Total Environ 580:147–157

Garcia-Herrero I, Margallo M, Onandía R, Aldaco R, Irabien A (2017b) Life cycle assessment model for the chlor-alkali process: a comprehensive review of resources and available technologies. Sustain Prod Consum 12:44–58

Goedkoop M, Spriensma R (2001) The eco-indicator 99 methodology: a damage oriented method for life cycle impact assessment, methodology report. PRA Consultants, Netherlands

Guinée JB, Gorree M, Heijungs R, Huppes G, Kleijn R, Van Oers L, Wegener Sleeswijk A, Suh S, Udo de Haes HA, de Bruijn H, Van Duin R, Huijbregts MAJ (2002) Life cycle assessment: an operational guide to the ISO standards: part 2a—guide. Center of Environmental Science, Netherlands

Gursel AP, Ostertag CP (2016) Impact of Singapore’s importers on life-cycle assessment of concrete. J Cleaner Prod 118:140–150

Habert G, Billard C, Rossi P, Chen C, Roussel N (2010a) Cement production technology improvement compared to factor 4 objectives. Cem Concr Res 40(5):820–826

Habert G, D’Espinose De Lacaillerie JB, Lanta E, Roussel N (2010b) Environmental evaluation for cement substitution with geopolymers. Second international conference on sustainable construction materials and technologies. Ancona, Italy

Habert G, D’Espinose De Lacaillerie JB, Roussel N (2011) An environmental evaluation of geopolymer based concrete production: reviewing current research trends. J Cleaner Prod 19(11):1229–1238

Hauschild M, Wenzel H (1998) Environmental assessment of products, vol. 2: scientific background. Chapman and Hall, London

Heath A, Paine K, McManus M (2014) Minimising the global warming potential of clay based geopolymers. J Cleaner Prod 78:75–83

Hunt RG, Sellers JD, Frankling WE (1992) Resource and environmental profile analysis: a life cycle environmental assessment for products and procedures. Environ Impact Assess Rev 12:245–269

Hussien M (2015) Egyptian regulations for coal related activities and cement industries in Egypt. Ministry of Environment, Egypt

Ibrahim SS, Hagrass AA, Boulos TR, Youssef SI, El-Hossiny FI, Moharam MR (2018) Metakaolin as an active pozzolan for cement that improves its properties and reduces its pollution hazard. J Miner Mater Char Eng 6:86–104

Ilić BR, Mitrović AA, Miličić LR (2010) Thermal treatment of kaolin clay to obtain metakaolin. Hem Ind 64(4):351–356

ISO 14040 (2006) International Organization for Standardization. Environmental management-life cycle assessment-principles and framework. Switzerland, Geneva

ISO 14044 (2006) International Organization for Standardization. Environmental management-life cycle assessment-requirements and guilelines. Switzerland, Geneva

Jolliet O, Margni M, Charles R, Humbert S, Payet J, Rebitzer G (2003) IMPACT 2002+: a new life cycle impact assessment methodology. Int J Life Cycle Assess 8(6):324–330

Komnitsas K, Zaharaki D (2007) Geopolymerisation: a review and prospects for the minerals industry. Miner Eng 20(14):1261–1277

Lehmann J, Gaunt J, Rondon M (2006) Bio-char sequestration in terrestrial ecosystems: a Review. Mitig Adapt Strateg Glob Change 11(2):403–427

Luukkonen T, Sarkkinen M, Kemppainen K, Rämö J, Lassi U (2016) Metakaolin geopolymer characterization and application for ammonium removal from model solutions and landfill leachate. Appl Clay Sci 119:266–276

Luukkonen T, Abdollahnejad Z, Yliniemi J, Kinnunen P, Illikainen M (2018) One-part alkali-activated materials: a review. Cem Concr Res 103:21–34

Maroušek J, Vochozka M, Plachý J, Žák J (2016) Glory and misery of biochar. Clean Technol Environ Policy 19(2):311–317

Maroušek J, Kolář L, Vochozka M, Stehel V, Maroušková A (2018) Biochar reduces nitrate level in red beet. Environ Sci Pollut Res 25:18200–18203

Marzouk M, Azab S (2017) Analyzing sustainability in low-income housing projects using system dynamics. Energy Build 134:143–153

Mateus R, Neiva S, Bragança L, Mendonça P, Macieira M (2013) Sustainability assessment of an innovative lightweight building technology for partition walls-comparison with conventional technologies. Build Environ 67:147–159

Mathew BJ, Sudhakar M, Natarajan C (2013) Strength, economic and sustainability characteristics of coal ash -GGBS based geopolymer concrete. Int J Comput Eng Res 3(1):207–212

McGrath TE, Cox S, Soutsos M, Kong D, Mee LP, Alengaram JUJ (2018) Life cycle assessment of geopolymer concrete: a Malaysian context. IOP Conf Ser Mater Sci Eng 431:092001

Mclellan BC, Williams RP, Lay J, Riessen AV, Glen D (2011) Costs and carbon emissions for geopolymer pastes in comparison to ordinary Portland cement. J Cleaner Prod 19(9–10):1080–1090

Nguyen L, Moseson AJ, Farnam Y, Spatari S (2018) Effects of composition and transportation logistics on environmental, energy and cost metrics for the production of alternative cementitious binders. J Clean Prod 185:628–645

Ostwal T, Chitawadagi MV (2014) Experimental investigations on strength, durability, sustainability and economic characteristics of geopolymer concrete blocks. Int J Res Eng Technol 3(6):115–122

Palomo A, Grutzeck MW, Blanco MT (1999) Alkali-activated fly ashes: a cement for the future. Cem Concr Res 29(8):1323–1329

Passuello A, Rodríguez ED, Hirt E, Longhi M, Bernal SA, Provis JL, Kirchheim AP (2017) Evaluation of the potential improvement in the environmental footprint of geopolymers using waste-derived activators. J Cleaner Prod 166:680–689

Petrillo A, Cioffi R, Ferone C, Colangelo F, Borrelli C (2016) Eco-sustainable geopolymer concrete blocks production process. Agric Agric Sci Proc 8:408–418

Prasara-A J, Gheewala SH, Silalertruksa T, Pongpat P, Sawaengsak W (2019) Environmental and social life cycle assessment to enhance sustainability of sugarcane-based products in Thailand. Clean Technol Environ Policy 21(7):1447–1458

Rajamane NP, Nataraja MC, Jeyalakshmi R, Nithiyanantham S (2015) Greener durable concretes through geopolymerisation of blast furnace slag. Mater Res Express 2(5):055502

Rashad AM (2017) Insulating and fire-resistant behaviour of metakaolin and fly ash geopolymer mortars. Proc Inst Civil Eng Constr Mater 172:1–8

Rashwan MM, Megahed AR, Essa MS (2015) Effect of local metakaolin on properties of concrete and its sulfuric acid resistance. J Eng Sci 43:183–199

Rouwette R (2012) LCA of geopolymer concrete (E-Crete). Aurora construction materials, Melbourne, Australia. Project report, pp 1–36

Salas DA, Ramirez AD, Ulloa N, Baykara H, Boero AJ (2018) Life cycle assessment of geopolymer concrete. Constr Build Mater 190:170–177

Singh N, Vyas S, Pathak RP, Sharma P, Mahure NV, Gupta SL (2013) Effect of aggressive chemical environment on durability of green geopolymer concrete. Int J Eng Innov Technol 3(4):277–284

Stengel T, Reger J, Heinz D (2009) Life cycle assessment of geopolymer concrete: what is the environmental benefit. Paper presented at the proceeding of the 24th biennial conference of the Concrete Institute of Australia, Sydney, Australia 17–19 September

Teh SH, Wiedmann T, Castel A, de Burgh J (2017) Hybrid life cycle assessment of greenhouse gas emissions from cement, concrete and geopolymer concrete in Australia. J Clean Prod 152:312–320

Tempest B, Snell C, Gentry T, Trejo M, Isherwood K (2015) Manufacture of full-scale geopolymer cement concrete components: a case study to highlight opportunities and challenges. PCI J 60(6):39–50

Temuujin J, Williams RP, Van Riessen A (2009) Effect of mechanical activation of fly ash on the properties of geopolymer cured at ambient temperature. J Mater Process Technol 209(12–13):5276–5528

Thaarrini J, Dhivya S (2016) Comparative study on the production cost of geopolymer and conventional concretes. Int J Civ Eng Res 7(2):117–124

Thannimalay L, Yusoff S, Zawawi NZ (2013) Life cycle assessment of sodium hydroxide. Aust J Basic Appl Sci 7(2):421–431

Toniolo N, Boccaccini AR (2017) Fly ash-based geopolymers containing added silicate waste: a review. Ceram Int 43(17):14545–14551

Turner LK, Collins FG (2013) Carbon dioxide equivalent (CO2-e) emissions: a comparison between geopolymer and OPC cement concrete. Constr Build Mater 43:125–130

Vilamová Š, Piecha M (2016) Economic evaluation of using of geopolymer from coal fly ash in the industry. Acta Montanistica Slovaca 21(2):139–145

Wardhono A (2015) The durability of fly ash geopolymer and alkali-activated slag concretes. Dissertation, RMIT University

Weil M, Dombrowski K, Buchwald A (2009) Life-cycle analysis of geopolymers. In: Provis JL, Van Deventer JSJ (eds) Geopolymers-structure, processing, properties and industrial applications. CRC Press, North America, pp 194–210

Williams AS (2009) Life cycle analysis: a step by step approach. Illinois Sustainable Technology Center, Institute of Natural Resource Sustainability University of Illinois, Urbana-Champaign Champaign

Yacout DMM (2019) Assessing status of life cycle assessment studies in Egypt. Curr Appl Sci Technol 19(2):177–189

Yao X, Zhang Z, Zhu H, Chen Y (2009) Geopolymerization process of alkali-metakaolinite characterized by isothermal calorimetry. Thermochim Acta 493(1–2):49–54

Zhang P, Huang G, An C, Fu H, Gao P, Yao Y, Chen X (2019) An integrated gravity-driven ecological bed for wastewater treatment in subtropical regions: process design, performance analysis, and greenhouse gas emissions assessment. J Clean Prod 212:1143–1153

Zhu X, Chen B, Zhu L, Xing B (2017) Effects and mechanisms of biochar-microbe interactions in soil improvement and pollution remediation: a review. Environ Pollut 227:98–115

Živica V, Balkovic S, Drabik M (2011) Properties of metakaolin geopolymer hardened paste prepared by high-pressure compaction. Constr Build Mater 25(5):2206–2213

Acknowledgements

The authors appreciatively acknowledge the Ministry of Scientific Research and the Science and Technology Development Fund (STDF) who provided the financial support for the project “Green Building System for Low-Cost Housing,” Grant Number 5848 under which this research was performed.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Abbas, R., Khereby, M.A., Ghorab, H.Y. et al. Preparation of geopolymer concrete using Egyptian kaolin clay and the study of its environmental effects and economic cost. Clean Techn Environ Policy 22, 669–687 (2020). https://doi.org/10.1007/s10098-020-01811-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-020-01811-4