Abstract

Biological treatment is effective but infrequently used for oil and gas produced water. To date, physical–chemical treatment methods have been favored due to the smaller space requirements and operational simplicity. Changing regulatory requirements and increased interest in recycling and beneficial reuse have led to increased interest in biological treatment. To elucidate its potential role, we reviewed and summarized 59 studies on the biological treatment of produced water. Oilfield produced water was predominantly studied (> 50%). More studies using real produced water were from China than from any other country (37%). Real produced water was used in most studies (73%). Studies were predominantly bench-scale experiments (69%). Fixed-film reactors were most prevalent (27%). Water quality of produced waters treated was variable; median total dissolved solids (TDS) was 28,000 mg L−1 and median chemical oxygen demand (COD) was 1125 mg L−1. Inhibition by salinity was variable according to the treatment system and study design, but efficacy generally decreased when TDS was above 50,000 mg L−1. For studies treating real samples, average COD removal was 73% when TDS was less than 50,000 mg L−1, and 54% when TDS was greater than 50,000 mg L−1. Key issues were microbial acclimation, toxicity, biological fouling, and mineral scaling. Finding an inoculum was not problematic as microorganisms capable of degrading hydrocarbons were isolated from various environments. Treatment performance was better where synthetic produced water was used in lieu of real samples. Biological treatment is promising for producing effluents suitable for reuse, particularly where it functions as part of a larger treatment train.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

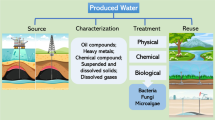

Oil and gas production, particularly in arid regions, introduces a challenge for water management (Clark and Veil 2009; Guerra et al. 2011). Water must be sourced for production. Produced water generated during production must be handled, treated, and disposed. The large volumes of produced water generated make this a significant environmental problem. In the USA alone, the total volume of produced water in 2012 was estimated as 3.4 billion m3 (Veil 2015). To date, injection of produced water has been the primary disposal method, often done to increase oil production (Veil 2015). Decreased availability of injection sites, changing regulations, and challenges associated with locating fresh water, have led the oil and gas industry to consider new strategies to treat and reuse produced water (Dahm 2014; Guerra et al. 2011; Heberger and Donnelly 2015). Recycling produced water for subsequent oil and gas production solves both sourcing and disposal problems simultaneously. Beneficial reuse outside of oil and gas production solves the disposal dilemma and creates a needed water resource. Possible beneficial uses include irrigation, livestock watering, aquifer storage, streamflow augmentation, and municipal/industrials uses (Dahm 2014; Guerra et al. 2011; Heberger and Donnelly 2015; Interstate Oil and Gas Compact Commission and ALL Consulting 2006; Veil et al. 2004).

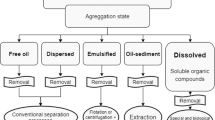

The desire to recycle and reuse produced water has led to increased interest in its treatment. Previous publications have reviewed existing produced water treatment technologies (Arthur et al. 2005; Dahm and Chapman 2014; Fakhru’l-Razi et al. 2009; Guerra et al. 2011; Hansen and Davies 1994; Igunnu and Chen 2012; Jimenez et al. 2018; Robinson 2013a, b, c). Most reviews have focused on physical–chemical treatment processes that dominate existing treatment trains. Physical–chemical treatment has been historically preferred because of the small footprint of facilities and the straightforward process control strategy; however, disadvantages include high capital and operating costs, production of hazardous sludges and brine solutions, and difficulties in removing trace contaminants (Fakhru’l-Razi et al. 2009). The high oxygen demand of produced water poses challenges for implementation of membrane technologies—that are advantageous for removing a range of contaminants—due to the potential for biological fouling and mineral scaling (Mondal et al. 2008; Xu et al. 2008).

Biological treatment has a long history of use in industrial waste treatment because of its ability in reducing oxygen demand, nutrients, metals, and trace organic contaminants (Tchobanoglous et al. 2014). Biological treatment can be used to remove specific contaminants of concern, such as arsenic that is elevated in some groundwaters (Katsoyiannis and Zouboulis 2004). Biological treatment can also function under extreme conditions of temperature, pH, and salinity (e.g., Margesin and Schinner 2001). Prior reviews have examined the biological treatment of oily wastewaters, including those from refineries and the shipping industry (Jamaly et al. 2015; Yu et al. 2017), and the treatment of salty wastewaters, including those from the agro-food industry, textiles dyeing, and tanneries (Castillo-Carvajal et al. 2014; Lefebvre and Moletta 2006; Xiao and Roberts 2010). In the previous reviews, treatment of produced water has been aggregated with other types of oil and salty wastewaters. To our knowledge, there are no review papers that solely evaluate the biological treatment of produced water generated from oil and gas production.

In this paper, we summarize peer-reviewed publications on the biological treatment of produced water and provide a meta-analysis of the data published. The summary includes information for fixed-film treatment, membrane bioreactors, wetlands and ponds, activated sludge treatment, anaerobic treatment, and bio-electrochemical treatment. We address questions regarding optimal reactor configuration, selection of process control parameters, impact of salinity, pretreatments, the need for specialized microbial consortia, and potential technological issues. Our goal is to provide information useful for advancing in-industry recycling and beneficial reuse of treated effluents by including biological treatment into treatment trains.

Literature review methodology

Studies were located using the Web of Science database to search for peer-reviewed articles with various combinations of the following search words: produced water, oil and gas, biological treatment, and wetlands. Forward and backward searches of the selected articles were also done. Only studies of the biological treatment of produced water and flowback were included. Studies that generally addressed biological treatment of oily and salty water were not included, nor were studies of the treatment of refinery wastewaters. Studies were included if the water studied mimicked produced water. Only studies of biological treatment systems were included—biodegradation studies (bottle tests) were not included in the quantitative analyses although these studies are discussed as they support advancement of biological treatment.

Literature review summary

Fifty-nine studies of the biological treatment of produced water were reviewed (Table S1). The studies were published from 1979 to 2018. Various project motivations were identified by the study authors, although environmental concern was the most prevalent (Table 1). In most studies (51%), authors cited more than one motivation for completing their work. It is clear from the studies that researchers are interested in beneficial reuse and recycling of produced water effluent and that environmental regulations are influential in developing new treatment strategies. In 32% of studies, the benefits of biological treatment are cited as project motivations due to the relatively low cost and low impact compared with other technologies.

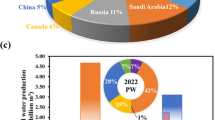

Real produced water was used in 43 of the studies (73%), with both real and synthetic produced water being used in four of these 43 studies. The real produced water originated from ten countries (Fig. S1). Of the 43 studies that used real produced water, 16 of these used produced waters from China (37%) while 12 originated from the USA (28%). Synthetic produced waters were composed of minerals, oil, and sometimes production chemicals such as surfactants. In some cases, synthetic produced water was formulated to mimic produced water from a specific region, such as Middle East oilfields (Shpiner et al. 2009a, b) or produced water from Africa where salinity is low and has total dissolved solids (TDS) of 704–1370 mg L−1 (Horner et al. 2012). In one study, removal of the surfactant dodecyl benzene sulfonic acid (DBSA), an oilfield production chemical, was observed in the produced water from an oilfield where polymer flooding was practiced (Zhang et al. 2016). In another, the surfactant nonyl phenol glycol ether was added to synthetic produced water to observe its removal (Scholzy and Fuchs 2000). Most produced water samples originated from oilfields although a few were from gas production wells; produced water samples originated from both onshore and offshore oilfields (Table S1).

Most of the studies reviewed used a bench-scale apparatus (69%), meaning that small reactors were used (no larger than several liters capacity) and these reactors were operated in the laboratory. Pilot-scale studies were considered to be those that were larger in scale (e.g., over 100 L capacity reactors) and/or those done at a field site or outdoors (27%). Wetland studies were done in large totes placed outdoors so these were considered pilot studies (based on size) although synthetic produced waters were used in these studies. Observations were made on full-scale operational facilities (Lu et al. 2006; Wang et al. 2007), and in one study, both bench-scale and pilot-scale systems were observed (Kwon et al. 2011).

The most commonly used treatment configuration was fixed-film treatment (32%) (Fig. 1). The fixed-film reactors included tanks filled with high-surface area media, granular activated carbon filters, rotating biological contactors, and aerobic filters. The second most commonly used biological treatment method was the MBR (20%). Constructed wetlands and ponds, including free surface and subsurface flow wetlands, were used in 17% of studies. Each of the studies reviewed was characterized by the predominant treatment type under study (Fig. 1), although there was some ambiguity in characterization. One of the anaerobic systems could have also been classified as a sequencing batch reactor (Li et al. 2010), while three other studies of anaerobic treatment used fixed-film media (Ghorbanian et al. 2014; Khong et al. 2012; Liu et al. 2013).

In the studies reviewed, pretreatments were commonly used. At a minimum, oil–water separation was often done and sometimes pretreatment included air flotation or stripping or other technologies. Removal of floating oil is recommended because it can interfere with aeration and biological processes (Robinson 2013b). Many researchers obtained their samples after oil–water separation at a full-scale facility (Table S1). Anaerobic pretreatment, with fixed-film media to retain biomass, was used in some studies to hydrolyze organic matter (termed hydrolysis acidification) and make it more amenable to treatment (Guo et al. 2014; Li et al. 2010; Lu et al. 2009; Su et al. 2007, 2009; Wang et al. 2007; Zhang et al. 2010, 2016). Increased biodegradability and removal of recalcitrant organic compounds was observed in the anaerobic reactors (Li et al. 2010; Liu et al. 2013; Su et al. 2009). In one study, adsorption by surfactant modified zeolite was used as a pretreatment to reduce benzene, toluene, ethylbenzene, and xylene (BTEX) prior to biological treatment (Kwon et al. 2011). Nutrient limitations were addressed in many of the studies with nutrients added to support microbial growth in biological reactors (Ji et al. 2009; Liu et al. 2013; Lu et al. 2009; Piubeli et al. 2012; Tellez et al. 2005; Tong et al. 2013). Lu et al. (2009) used commercial maize powder to supplement carbon for enhanced reduction of ammonia and other contaminants. In a bottle test study of produced water, COD removal increased from 20% without nutrients to 65–80% with addition of phosphorus and carbon substrates, demonstrating the importance of nutrient addition (Piubeli et al. 2012).

In some studies, temperature stabilization was necessary prior to biological treatment. In two related studies, produced water temperature (60 °C) was reduced in stabilization ponds prior to wetland treatment (Ji et al. 2002, 2007). Lu et al. (2009) studied a treatment facility in China (Shengli Oilfield) where the produced water temperature was 55 °C and the ambient temperature varied during the study from − 15 to − 5 °C. Lu et al. (2006) used influent produced water in a heat exchange system to maintain the reactor temperature.

Total dissolved solids (TDS) and COD of the real and synthetic produced water samples varied among the studies (Fig. 2). The mean ± standard deviation of TDS of samples treated—in the 50 studies where TDS was reported—was 64,118 ± 76,024 mg L−1 (median = 28,000 mg L−1). The mean ± standard deviation of COD of samples treated—in the 46 studies where COD was reported—was 1397 ± 1270 mg L−1 (median = 1125 mg L−1). Note that in some studies more than one sample was treated and these samples are handled separately within the meta-analysis performed herein. Where conductance was reported in lieu of TDS, the relationship SpC = 1.6·TDS was used to calculate TDS. In some studies, produced water TDS was increased by adding sodium chloride in order to observe its impact (Fakhru’l-Razi et al. 2010; Pendashteh et al. 2010, 2012; Sharghi et al. 2014). If only real produced water samples are considered—and samples where sodium chloride was added to increase salinity are excluded—the TDS of samples was 28,702 ± 40,383 mg L−1 (median = 16,135 mg L−1) and the COD was 1154 ± 1254 mg L−1 (median = 727 mg L−1). Seventeen of the total samples treated had TDS ≤ 10,000 mg L−1 and 49 had TDS ≤ 40,000 mg L−1 suggesting that a large portion of the produced water tested could be treated and potentially reused (Guerra et al. 2011).

Treatment efficacy using different reactor configurations

Fixed-film treatment

Fixed-film treatment was the most commonly used treatment method, used aerobically in 16 studies (Table 2). Fixed-film reactors are favored in many industrial treatment processes because biofilm-bound microorganisms are retained and resistant to extreme conditions and shock loadings (e.g., extreme pH, high salinity, toxicity) (Gavrilescu and Macoveanu 2000).

Most fixed-film treatment systems used packed media within an aerated reactor (Campos et al. 2002; Dong et al. 2011; Guo et al. 2014; Liu et al. 2013; Lu et al. 2006, 2009; Su et al. 2007, 2009; Tong et al. 2013; Wang et al. 2007; Woolard and Irvine 1994; Zhang et al. 2016; Zhao et al. 2006). In some studies, an airlift aeration configuration was used where compressed air was introduced at the bottom of the tank in tubes and was directed into a circulating vertical pattern (Campos et al. 2002; Guo et al. 2014; Zhang et al. 2016). Other fixed-film treatment systems consisted of biologically active carbon filters (Freedman et al. 2017; Guo et al. 2014; Riley et al. 2016), rotating biological contactors (RBC) (Chavan and Mukherji 2008; Palmer et al. 1981), a biofilm sequencing batch reactor (SBR) (Woolard and Irvine 1994), and an anaerobic reactor filled with media (Ghorbanian et al. 2014; Khong et al. 2012). Ghorbanian et al. (2014) compared the performance of an anaerobic upflow fixed-bed reactor with that of an anaerobic SBR, and found that the upflow reactor with fixed-film media was more efficient in removing aromatic compounds.

The process control parameters used in the studies indicate some variability (Table 2). The hydraulic retention time (HRT) in fixed-film reactors varied from four to 48 h except in biologically active granular activated carbon (GAC) column where the HRT was lower (Freedman et al. 2017; Riley et al. 2016). Organic loading rates (OLR) varied: Guo et al. (2014) reported 0.14 kg COD m−3 d−1 while Dong et al. (2011) used an OLR as high as 4.21 kg COD m−3 d−1. In most studies, researchers used COD as one of the performance metrics, which made it possible to compare the studies. In some studies total petroleum hydrocarbons (TPH), dissolved organic carbon (DOC), total organic carbon (TOC), oil and grease (O&G), or 5-day biochemical oxygen demand (BOD5) were used in addition to, or in lieu of, COD. In some studies, multiple metrics of treatment efficacy were used. As an example, Palmer et al. (1981) reported 72% BOD5 removal and 24% COD removal in an RBC treatment system (Huntington Beach location), indicating that much of the COD was recalcitrant. Su et al. (2007) showed similar results where removal of COD was 75% while BOD5 removal was 93% (HRT = 26.7 h). The study results indicate good COD removal—typically around 60–80%—provided that the operating parameters (e.g., HRT, OLR) are adequate. Researchers also reported removal of ammonia, sulfides, and specific constituents in TPH (Guo et al. 2014; Riley et al. 2016; Tong et al. 2013; Zhang et al. 2016).

Different types of fixed-film media used. Campos et al. (2002) used 2 mm diameter polystyrene media in an airlift reactor configuration. Dong et al. (2011) added porous ceramic fixed-film carriers to an activated sludge system and found that inclusion of the carriers increased COD removal from 62 to 77%, while the modification of the carriers further increased COD removal to 79%. Ghorbanian et al. (2014) used 1 cm3 polyurethane foam cubes. Several researchers used plastic rings with fibers attached (Lu et al. 2009; Wang et al. 2007; Zhang et al. 2016).

Given the high mineral content of produced waters and potentially elevated carbonate concentrations, the potential for scaling of fixed-film media and its effect on biofilm formation should be considered. Zhang et al. (2016) reported mineral scaling within biofilms of a pilot-scale aerated lift system; however, the scaling did not inhibit biological activity as was the case in the commercial full-scale system treating the same produced water. Palmer et al. (1981) also reported mineral scaling on the disks of RBCs although scaling did not inhibit biological growth over the six month study period. Most studies focused on short-term feasible tests. Longer-term tests are needed to assess scaling potential or, alternatively, geochemical modeling can be used to assess scaling potential (Lester et al. 2015).

Membrane bioreactors

After fixed-film treatment systems, membrane bioreactors were the most commonly used treatment method (Table 3). Membrane bioreactors (MBRs) are good candidates for produced water treatment since good settling sludge is not necessary because membranes are used for solids separation (Tchobanoglous et al. 2014). Since external clarifiers are not used, MBRs typically have a small footprint compared with other types of biological treatment systems.

In the studies reviewed, COD removal was typically higher than 80%, indicating good treatment and there was variability in process control parameters (Table 3). The HRT used varied from 6 to 96 h. Cycle times in membrane sequencing batch reactors (MSBR) were 12–48 h (Fakhru’l-Razi et al. 2010; Pendashteh et al. 2012). Solids retention times (SRT) in the MBRs were long: 30–100 days. The flux reported was 2.2 L m−2 h−1 and lower in several studies (Ozgun et al. 2013; Sharghi and Bonakdarpour 2013; Sharghi et al. 2014), although 10 L m−2 h−1 and higher was reported (Kose et al. 2012). Similar to the results for fixed-film treatment studies, it appears that MBRs can achieve high COD removal provided that the operating parameters are controlled. The COD removal remained high even in the presence of surfactants (Scholzy and Fuchs 2000). Kwon et al. (2011) mitigated BTEX compounds using pretreatment by modified zeolite adsorption and mitigated organic loading by the addition of PAC in the MBR. In the MBR studies, fewer pretreatments appeared to be used although Zhang et al. (2010) used anaerobic pretreatment.

Membrane fouling and scaling were observed in several of the MBR studies. Treating real produced water, Janson et al. (2015) observed reduced membrane permeability and allowed the pH to remain low (4.9–6.0) to minimize precipitation; the effect on the microbial population was not studied. In another study, membrane fouling was only observed when the organic loading rate was high (2.6 kg COD m−3 d−1) (Sharghi and Bonakdarpour 2013). Membrane fouling occurred as the result of excess extracellular polymeric substances (EPS) production and viscous sludge bulking (Sharghi and Bonakdarpour 2013). Based on microscopy by Fakhru’l-Razi et al. (2010), membrane fouling was the result of a dense cake layer containing bacteria (primarily rod-shaped) and minerals (e.g., containing magnesium, aluminum, silica, calcium, and iron). Reduced transmembrane pressure, indicative of fouling, was noted by Kwon et al. (2011). Pendashteh et al. (2011) reported membrane fouling in a MBR treating synthetic produced water, concluding that both biological and inorganic scaling were responsible. Fouling was not improved by flocculation pretreatment (Pendashteh et al. 2011). Sharghi et al. (2014) observed good treatment and no membrane fouling for treatment of a synthetic produced water with high salinity (TDS of 100,000–250,000 mg L−1) although most of the salinity was from sodium chloride. In another study based on treatment of synthetic produced water, fouling was similarly not observed (Sharghi et al. 2013).

Wetlands and pond treatment

Wetlands and treatment ponds were investigated in 10 studies (Table 4). Constructed wetland treatment systems have advantages over mechanical treatment such as lower cost and maintenance as well as providing ecosystem services (e.g., wildlife habitat). The use of treatment wetlands by the petroleum industry has been reviewed by Knight et al. (1999) although most of the data available at the time originated from studies done on refinery wastewater.

Most of the wetland studies reviewed used large containers to construct and simulate wetlands. Beebe et al. (2015) used a series of plastic containers (265 L) planted with cattails. Pardue et al. (2014) also used a series of plastic containers (378 L each) planted with reeds to simulate subsurface wetlands; free surface wetlands were simulated by planting the containers with bulrush and cattails. Alley et al. (2013) used four plastic containers (150 L each) in series, planted with bulrush and cattails, where the water depth was controlled and altered during the study. Shpiner et al. (2009a) studied pond treatment of a synthetic produced water in a laboratory setting with fluorescent lights. Murray-Gulde et al. (2003) simulated subsurface wetland treatment using a series of four 132 L barrels, with the barrels turned on the side and filled halfway. Horner et al. (2012) tested three wetland systems: one series of four plastic containers (379 L each) mimicking free surface wetlands and two series of four containers mimicking subsurface wetlands. Shallow depth was observed to be important for contaminant removal by Shpiner et al. (2009a), as was reactor baffling and recycle flows. Ji et al. (2007) used surface flow wetlands planted with reeds in a three-year experiment. In Ji et al. (2002), subsurface reed beds with variable hydraulic loading rates were observed. Aerated lagoon treatment was investigated by Beyer et al. (1979) in plastic lined steel tanks.

In the studies reviewed, wetland treatment was often used for nitrogen and metals removal in addition to reduction of oxygen demand. Beebe et al. (2015) observed both nitrification and denitrification when supplemental aeration and carbon were added in pilot-scale surface and subsurface wetlands treating a simulated produced water (TDS < 1000 mg L−1). Pardue et al. (2014) observed removal of O&G, iron, and manganese under oxidizing conditions as well as removal of nickel and zinc under reducing conditions; iron removal was variable. Redox conditions were controlled by altering the O&G loading rate (Pardue et al. 2014). In the laboratory-based photobioreactor, Shpiner et al. (2009b) reported precipitation by sulfide salts and other removal mechanisms (e.g., bio-adsorption) to remove metals (cadmium, chromium, nickel) from synthetic produced water in a laboratory photobioreactor. Alley et al. (2013) found that increased water depth increased removal of metals (cadmium, copper, nickel, and zinc) but that removal of trace contaminants (1,2-benzofluorenone and 1-methylcyclopentanol) was better in shallow wetlands. Alley et al. (2013) measured 1,2-benzofluorenone to indicate the hexane fraction of hydrocarbons and 1-methylcyclopentanol to indicate the chloroform fraction of alcohols. Ji et al. (2007) found that wetlands effectively reduced total Kjeldahl nitrogen in addition to COD. Horner et al. (2012) produced effluents suitable for livestock watering although the nickel was too high for irrigation. These studies show that wetland and pond treatment can be effective for COD removal. With the exception of one study, all studies reported COD removal rates > 70% (Table 4).

Pretreatment for wetland treatment systems is important for reducing influent loadings and stabilizing produced water temperatures. Pardue et al. (2014) found that use of an oil–water separator was important for increasing dissolved oxygen and soil redox potential within the wetland, and for maintaining oxidizing conditions. Murray-Gulde et al. (2003) used water softening and reverse osmosis upstream of a constructed wetland in a pilot-scale demonstration, observing a reduction of aquatic toxicity and 94% removal of TDS in the pretreatment processes. Temperature control was important in for wetland treatment in some studies (Ji et al. 2002, 2007).

Activated sludge

Activated sludge treatment, including conventional activated sludge and sequencing batch reactors, was investigated in eight studies (Table 5). Conventional activated sludge (CAS) treatment is a mature technology providing effective removal of oxygen demand and other contaminants; it is considered to have a low-cost and lower environmental impact compared with other treatment methods (Tchobanoglous et al. 2014). Sequencing batch reactors (SBRs) are similar to conventional activated sludge treatment but have the advantage of a smaller footprint because a separate clarifier is not required.

Only four studies were completed using SBRs (Table 5). Lester et al. (2015) treated hydraulic fracturing flowback prior to reverse osmosis, a treatment combination that was able to produce effluent meeting irrigation standards. Pendashteh et al. (2010) used a SBR to investigate treatment of synthetic and real produced water with varying TDS concentrations (sodium chloride was added to increase TDS). The COD removal was lower in real produced water (81%) than in synthetic produced water (typically > 90% at moderate TDS) (Pendashteh et al. 2010). Freire et al. (2001) managed toxicity and added nutrients in treating a real produced water sample by diluting the influent with domestic wastewater. Biological inhibition was apparent because COD removal rates increased when the produced water was further diluted (Freire et al. 2001). Woolard and Irvine (1995) observed phenol removal in an SBR, treating a synthetic produced water.

Only four studies were completed on CAS, and two of them were done at the same facility (Table 5). In Kardena et al. (2017), 82% COD removal was achieved using process control parameters typically used at domestic wastewater facilities (Tchobanoglous et al. 2014). Tellez et al. (2002; 2005) demonstrated effective activated sludge treatment (> 95% COD removal) for treatment of produced water using a typical solids retention time (SRT) of 20 days. In the study by Dalmacija et al. (1996), microbial inhibition was remedied by diluting the produced water with river water. Powered activated carbon (200 mg L−1) was added to the aeration basin, which likely provided a substrate for biofilm formation and mitigated toxicity (Dalmacija et al. 1996). In the CAS studies, COD removal was 82% and higher, where reported.

Anaerobic treatment

Anaerobic treatment was used in seven studies and in three of these studies, fixed-film media were also used (Table 6). Anaerobic treatment is beneficial because of the additional benefit of energy production. Although anaerobic treatment can be used for produced water, the salinity can be inhibitory and most of the hydrocarbons found in produced water are degraded aerobically, excluding some recalcitrant halogenated aromatics (Xiao and Roberts 2010).

Different configurations of anaerobic treatment were used. In four studies, upflow anaerobic sludge blanket (UASB) reactors were used, and in two studies fixed-film media were incorporated into the UASB (Ghorbanian et al. 2014; Khong et al. 2012; Liu et al. 2013; Rincon et al. 2003). Liu et al. (2013) used a UASB followed by an aerated biological filter. Ji et al. (2009), used a baffled reactor for anaerobic treatment.

The removal rates in anaerobic treatment studies varied depending on the study conditions, and COD removal ranged from 37 to 87% (Table 6). While COD was not reported, Ghorbanian et al. (2014) reported almost complete removal (> 98%) of TPH in both an anaerobic UASB with fixed-film media and in an anaerobic SBR. Li et al. (2010) increased COD removal to 53% by including a micro-electrolysis pretreatment step, which partially degraded hydrocarbons and increased their biodegradability. Khong et al. (2012) increased COD removal by diluting the produced water treated. In one study, 74% COD removal was the result of both anaerobic and aerobic treatment, and 94% removal of ammonia was observed (Liu et al. 2013). The HRT in the anaerobic reactors varied from 12 h to 15 days, which likely explains the variability in COD removal observed.

The differing study conditions allowed for observation of different issues that can be helpful in future studies. Mineral crystallization (Fe2O3, FeS, and CaCO3) was observed in the anaerobic sludge in one study, suggesting that mineral precipitation could be a concern in anaerobic reactors treating produced water (Ji et al. 2009). Control of hydrogen sulfide—done by altering the pH and periodically purging with nitrogen gas—was an issue in another study (Vieira et al. 2005). Rincon et al. (2003) studied produced waters originating from the separation of light, medium, and heavy crude oil, which yielded different COD removal rates (87, 20 and 37%), demonstrating treatment variability depending on the produced water characteristics.

Bio-electrochemical systems

Although an evolving technology, six studies were located using bio-electrochemical systems (BES) for produced water (Table 7). In BES treatment, energy from microbially mediated redox reactions is harnessed via electron flow between electrodes (Jain et al. 2017). In the microbial aerobic conversion of organic compounds to carbon dioxide, electrons are released at the anode and water is produced at the cathode; organic carbon removal also occurs when compounds adhere to activated carbon surface used in BES (Forrestal et al. 2015; Stoll et al. 2015). An advantage of electrochemical treatment is that the electrical current disrupts the oil present in produced water, making it more amenable to treatment (Jamaly et al. 2015). Since BES technologies capture ions at cathodes and anodes, desalination occurs in addition to degradation of organic matter and oxidation of other contaminants.

The studies reviewed had different configurations (Table 7). In two studies microbial fuel cells (MFC) were studied that consist of anaerobic treatment with biofilm-coated anodes and cathodes that form a cell contained within the reactor (Sheikhyousefi et al. 2017; Shrestha et al. 2018). As described by Sheikhyousefi et al. (2017), the anodes and cathodes are constructed of treated carbon cloth. Microbial capacitive desalination cells (MCDC) were also studied where the anode and cathode are placed in separate compartments and a desalination compartment resides between the anode and cathode compartments (Forrestal et al. 2015; Shrestha et al. 2018; Stoll et al. 2015). As described by Forrestal et al. (2015), the desalination compartment consists of a series of nickel/copper electron collectors that have activated carbon cloth on either side and are separated from other collectors by plastic mesh. In one study, an electrochemical system was combined with a biological filter where a voltage was applied to titanium-mixed metal oxide electrodes prior to filtration (Mousa 2016). In another study, a spiral anode was used with a cathode in the center; the spiral anode was intended to grow the biofilm to facilitate the redox reactions (Naraghi et al. 2015).

The COD removal in the BES studies was consistently higher than 70%. In a study comparing MFC with MCDC, Shrestha et al. (2018) found that the MFC yielded higher COD removal rates (85–96%) than MCDC (71–85%). Conversely, TDS was better removed in MCDC (65–74%) than in MFC (20–40%) (Shrestha et al. 2018). Sheikhyousefi et al. (2017) observed almost identical COD removal in real produced water (96%) compared with synthetic produced water (96–97%). The COD removal rates reported are impressive, especially considering that the TDS must be approximately 100,000 mg L−1 based on the water quality and dilution described (Sheikhyousefi et al. 2017). Although COD removal rates are high in EBS, recovery of ion adsorption capacity during regeneration can be limited as noted by Forrestal et al. (2015) where 75% recovery was observed. Also, COD removal rates can decrease as the ion adsorption capacity is reduced; Stoll et al. (2015) observed lower COD removal rates in subsequent runs of a MCDC. While still an evolving technology, EBS appear promising for high salinity wastes such as produced water and will likely improve with further testing (Jain et al. 2017).

Effect of salinity on biological treatment

Salinity can inhibit biological treatment (Castillo-Carvajal et al. 2014; Xiao and Roberts 2010). Here, treatment efficacy, as measured by a reduction in COD, appeared related to TDS concentration (Fig. 3). It also appears that TDS was more inhibitory in real produced water than in synthetic produced water. Not all of the studies reviewed reported TDS and COD, so not all studies are represented in Fig. 3. Where ranges of values were reported, mean values were used. Where the TDS of the produced water treated was altered, each test was plotted separately in Fig. 3. When only real produced water samples are considered, it appears that MBRs typically provided the best treatment (Fig. S2). One activated sludge study with data available showed good removal (Tellez et al. 2002, 2005), but data from other activated sludge studies are not available to corroborate this result. The BES study using real produced water exhibited COD removal higher than other types of reactors with similar TDS (Sheikhyousefi et al. 2017).

Controlled increases in salinity allowed for its impact on treatment efficacy to be studied in a controlled manner. For example, Sharghi et al. (2014) varied the TDS of synthetic produced water (144,000, 184,000, 255,000, and 299,000 mg L−1), and observed an impact on COD removal (95, 89, 88, and 82%, respectively) and O&G removal (94, 92, 90, 85%, respectively). Pendashteh et al. (2012) observed similar results when the TDS of both synthetic and real produced water were varied (35,000, 50,000, 100,000, 150,000, 200,000, and 250,000 mg L−1). Pendashteh et al. (2012) observed differences between real and synthetic produced waters that were apparent—when the TDS was 250,000 mg L−1, COD removal was 90% in the synthetic produced water, but only 18% in the real produced water. In an earlier study, Pendashteh et al. (2010) observed greater than 90% removal of COD when the synthetic produced water TDS was 35,000 mg L−1, but only 74% removal when the TDS was increased to 250,000 mg L−1. In small-scale tests of hydraulic fracturing fluids and flowback, the effects of salinity on aerobic degradation have been studied—Kekacs et al. (2015) found that TDS > 40,000 mg L−1 inhibited biological activity in bottle tests. In small-scale treatability tests, Akyon et al. (2015) observed biodegradation of 1.45 mg COD g−1 wet d−1 when TDS = 91,351 mg/L.

The data on TDS and COD removal indicate a complex and site-specific relationship between COD removal and TDS, but the data also indicate good treatment (Fig. 3). In treating real produced water samples, average COD removal was 73% when TDS was < 50,000 mg L−1 and 54% when TDS was < 100,000 mg L−1. While these COD removal rates suggest that sole use of biological treatment is insufficient for beneficial reuse and recycling, it does appear that biological treatment provides the benefit of reduced oxygen demand which may make effluents suitable for other treatment technologies to further reduce organic matter and other contaminants (Camarillo et al. 2016).

Biological treatment for membrane systems

Biological treatment can serve as a pretreatment for membrane technologies, reducing organic loads to reduce biofouling. In nine of the studies reviewed, biological treatment was investigated with the intent of biological treatment serving as a pretreatment for membranes (Campos et al. 2002; Fakhru’l-Razi et al. 2010; Freedman et al. 2017; Kwon et al. 2011; Lester et al. 2015; Ozgun et al. 2013; Pendashteh et al. 2012; Riley et al. 2016; Zhao et al. 2006). Riley et al. (2016) used a biologically active GAC filter followed by ultrafiltration and nanofiltration in series; the combined treatment reduced organic compounds by 99% and TDS by 94%, producing an effluent with TDS as low as 700 mg L−1. Fakhru’l-Razi et al. (2010) used a MBR followed by reverse osmosis, reduced TDS to 450 mg L−1 and removed most organics (effluent COD was 23 mg L−1). Ozgun et al. (2013) compared an MBR with the combination of microfiltration (MF) and ultrafiltration (UF) as pretreatment steps for nanofiltration followed by reverse osmosis. The MBR provided better COD removal than MF/UF, achieving 83% COD removal, although O&G removal was better in the MF/UF system (Ozgun et al. 2013). Lester et al. (2015) found that biological treatment followed by RO was sufficient to produce effluents meeting standards for irrigation.

Chemical pretreatments for biological treatment

The efficacy of biological treatment could be improved by chemical pretreatments. Electrocoagulation appears technically promising as a pretreatment, as it can reduce many produced water constituents, including boron and those that contribute to hardness, COD, and total hydrocarbons (Esmaeilirad et al. 2015; Ezechi et al. 2014; Zhao et al. 2014). Lu and Wei (2011) investigated treatment with zerovalent iron (20 g/L) and EDTA (150 mg/L) prior to studying biotreatability of produced water from a polymer flooded oilfield—45% COD removal was observed despite the presence of recalcitrant polymer hydrolyzed polyacrylamide. Coagulation-flocculation was used as a pretreatment in an aerobic batch test study with other pretreatments (flotation, sedimentation, and filtration), resulting in 91% TPH removal (Steliga et al. 2015).

Although not specific to produced water, other studies outside of the 59 studies reviewed suggest pretreatments that would be effective for produced water. Fenton’s reagent and ozonation were shown to increase biodegradability of process water from a sour gas sweetening plant in Mexico that contained diethanolamine (Duran-Moreno et al. 2011). Correa et al. (2010) used ozone-photocatalytic oxidation (O3/UV/TiO2) to treat petroleum refinery effluents prior to algae-based treatment, effectively reducing phenol, sulfide, COD, O&G, and ammonia. Nam et al. (2001) used hydrogen peroxide pretreatment to biodegrade soil contaminated with PAH.

Inoculum used in biological treatment

A variety of inoculum sources were used to introduce microorganisms acclimated to the high salinities and toxic conditions found in produced water. Researchers used indigenous microorganisms from the produced water to establish biofilms in reactors (Freedman et al. 2017; Riley et al. 2016). Microorganisms were isolated from oily sludge collected from an oil tank or settling tanks (Liu et al. 2013; Naraghi et al. 2015; Zhang et al. 2016), activated sludge was used that may or may not have been acclimated to the feedstock (Ghorbanian et al. 2014; Stoll et al. 2015), microbes were obtained from soil contaminated by oil spills (Lu and Wei 2011; Sharghi and Bonakdarpour 2013; Sharghi et al. 2013, 2014), commercial laboratory microorganisms were cultured and used (Shpiner et al. 2009a, b; Tong et al. 2013), some samples were scraped from lake rocks (Chavan and Mukherji 2008), and microorganisms were isolated from a salty lake (Woolard and Irvine 1994, 1995). In one study where the impact of using different commercially available cultured organisms were used as the inoculum, Zhao et al. (2006) observed 84% PAH removal using one strain and 90% removal using another. In another study, isolation and inclusion of heat-resistant bacteria in the inoculum was important (Guo et al. 2014). Zhang et al. (2016) used bioaugmentation and supported its efficacy by genetic analysis of the biofilms, which showed incorporation of the augmented bacteria into the biomass. In a study of biotreatability in bottle tests, immobilized cells were used to inoculate the solutions (Li et al. 2005).

Conclusions

This review successfully aggregates results from previous studies on the biological treatment of produced water. Information from the studies is summarized, including descriptions of the types and origins of produced water treated, influent water quality (COD and TDS), pretreatments, biological process under study, posttreatment, process control parameters, and major study results. We also reviewed the studies to determine the authors’ motivations for performing their studies, adding insight into this global environmental issue. Inclusion of a meta-analysis allowed us to quantify COD and TDS of the produced water under study and to clarify the relationship between TDS and COD removal efficiency.

The results indicate that biological treatment of produced water is being studied globally. While most real produced water samples originated from China and the USA (37 and 28%, respectively), produced water from ten countries was used in the studies. While most researchers cited environmental concerns as the motivation for their study (51%), stringent regulations were also noted as a study motivator (32%), suggesting that increasing regulations are causing researchers to consider more treatment options. Most studies to date have been laboratory based, bench-scale studies (69%) and fewer larger-scale, field-based studies have been conducted. The most commonly studied biological processes were fixed-film technologies and membrane bioreactors (32 and 20%, respectively), although studies were located that used wetlands and treatment ponds, activated sludge, and anaerobic treatment. Several of the most recent studies have been conducted on innovative bio-electrochemical systems that integrate carbon oxidation and salt removal into one technology.

Overall, biological treatment of produced water appears a viable approach, particularly where salinity is not too high (e.g., below 50,000 mg L−1). In the studies reviewed, COD removal was typically above 50% and much higher depending on study conditions. In real produced water samples where TDS was < 50,000 mg L−1, average COD removal was 73%. Removal of COD appeared related to the produced water TDS although the relationship was not linear. Removal rates for COD in studies using synthetic solutions were higher than in studies using real produced water samples (given similar TDS).

Several conclusions can be drawn based on the results of the studies reviewed. Effective pretreatment and nutrient addition are important in the biological treatment of produced water. Chemical pretreatments that alter organic matter and make it more amenable to treatment are promising and should be further pursued. A specialized microbial consortium is likely unnecessary although microbial acclimation should be considered in start-up of reactors. The effects of salinity and other forms of toxicity can likely be mitigated in biological treatment systems using fixed-film media and other approaches. Special consideration should be given to mineral scaling in fixed-film and membrane treatment process because such scaling has been observed and can be detrimental to treatment outcomes. Based on the study results, it appears that biological treatment can effectively serve as pretreatment for membrane and desalination technologies, producing effluents suitable for reuse. Future studies are recommended where biological systems operate under realistic field conditions over a long period of time. Such studies would be useful for developing guidelines for recycling and beneficial reuse of produced water effluents.

References

Akyon B, Stachler E, Wei N, Bibby K (2015) Microbial mats as a biological treatment approach for saline wastewaters: the case of produced water from hydraulic fracturing. Environ Sci Technol 49:6172–6180. https://doi.org/10.1021/es505142t

Alley BL, Willis B, Rodgers J, Castle JW (2013) Water depths and treatment performance of pilot-scale free water surface constructed wetland treatment systems for simulated fresh oilfield produced water. Ecol Eng 61:190–199. https://doi.org/10.1016/j.ecoleng.2013.09.021

Arthur DJ, Langhus BG, Patel C (2005) Technical summary of oil & gas produced water treatment technologies. ALL Consulting, LLC, Tulsa

Beebe DA, Castle JW, Rodgers JH (2015) Biogeochemical-based design for treating ammonia using constructed wetland systems. Environ Eng Sci 32:397–406. https://doi.org/10.1089/ees.2014.0475

Beyer AH, Palmer LL, Stock J (1979) Biological oxidation of dissolved compounds in oilfield-produced water by a pilot aerated lagoon. J Petrol Technol 31:241–245

Camarillo MK, Domen JK, Stringfellow WT (2016) Physical–chemical evaluation of hydraulic fracturing chemicals in the context of produced water treatment. J Environ Manag 183:164–174. https://doi.org/10.1016/j.jenvman.2016.08.065

Campos JC, Borges RMH, Oliveira AM, Nobrega R, Sant’Anna GL (2002) Oilfield wastewater treatment by combined microfiltration and biological processes. Water Res 36:95–104. https://doi.org/10.1016/s0043-1354(01)00203-2

Castillo-Carvajal LC, Sanz-Martin JL, Barragan-Huerta BE (2014) Biodegradation of organic pollutants in saline wastewater by halophilic microorganisms: a review. Environ Sci Pollut Res 21:9578–9588. https://doi.org/10.1007/s11356-014-3036-z

Chavan A, Mukherji S (2008) Treatment of hydrocarbon-rich wastewater using oil degrading bacteria and phototrophic microorganisms in rotating biological contactor: effect of N:P ratio. J Hazard Mater 154:63–72. https://doi.org/10.1016/j.jhazmat.2007.09.106

Clark CE, Veil JA (2009) Produced water volumes and management practices in the United States. Argonne National Laboratory (ANL), Environmental Science Division

Correa AXR, Tiepo EN, Somensi CA, Sperb RM, Radetski CM (2010) Use of ozone-photocatalytic oxidation (O-3/UV/TiO2) and biological remediation for treatment of produced water from petroleum refineries. J Environ Eng ASCE 136:40–45. https://doi.org/10.1061/(asce)ee.1943-7870.0000111

Dahm K (2014) Manuals and standards: guidance for the evaluation of water management strategies to provide regional water supplies for the oil and gas industry, Project 4097. U.S. Department of the Interior, Bureau of Reclamation, Denver, CO

Dahm K, Chapman M (2014) Produced water treatment primer: case studies of treatment applications, S&T Project #1617. U.S. Department of the Interior, Bureau of Reclamation, Denver, CO

Dalmacija B, Karlovic E, Tamas Z, Miskovic D (1996) Purification of high-salinity wastewater by activated sludge process. Water Res 30:295–298. https://doi.org/10.1016/0043-1354(95)00170-0

Dong ZY, Lu M, Huang WH, Xu XC (2011) Treatment of oilfield wastewater in moving bed biofilm reactors using a novel suspended ceramic biocarrier. J Hazard Mater 196:123–130. https://doi.org/10.1016/j.jhazmat.2011.09.001

Duran-Moreno A, Garcia-Gonzalez SA, Gutierrez-Lara MR, Rigas F, Ramirez-Zamora RM (2011) Assessment of Fenton’s reagent and ozonation as pre-treatments for increasing the biodegradability of aqueous diethanolamine solutions from an oil refinery gas sweetening process. J Hazard Mater 186:1652–1659. https://doi.org/10.1016/j.jhazmat.2010.12.043

Esmaeilirad N, Carlson K, Ozbek PO (2015) Influence of softening sequencing on electrocoagulation treatment of produced water. J Hazard Mater 283:721–729. https://doi.org/10.1016/j.jhazmat.2014.10.046

Ezechi EH, Isa MH, Kutty SRM, Yaqub A (2014) Boron removal from produced water using electrocoagulation. Process Saf Environ Protect 92:509–514. https://doi.org/10.1016/j.psep.2014.08.003

Fakhru’l-Razi A, Pendashteh A, Abdullah LC, Biak DRA, Madaeni SS, Abidin ZZ (2009) Review of technologies for oil and gas produced water treatment. J Hazard Mater 170:530–551. https://doi.org/10.1016/j.jhazmat.2009.05.044

Fakhru’l-Razi A, Pendashteh A, Abidin ZZ, Abdullah LC, Biak DRA, Madaeni SS (2010) Application of membrane-coupled sequencing batch reactor for oilfield produced water recycle and beneficial re-use. Bioresour Technol 101:6942–6949. https://doi.org/10.1016/j.biortech.2010.04.005

Forrestal C, Stoll Z, Xu P, Ren ZJ (2015) Microbial capacitive desalination for integrated organic matter and salt removal and energy production from unconventional natural gas produced water. Environ Sci Water Res Technol 1:47–55. https://doi.org/10.1039/c4ew00050a

Freedman DE, Riley SM, Jones ZL, Rosenblum JS, Sharp JO, Spear JR, Cath TY (2017) Biologically active filtration for fracturing flowback and produced water treatment. J Water Process Eng 18:29–40. https://doi.org/10.1016/j.jwpe.2017.05.008

Freire DDC, Cammarota MC, Sant’anna GL (2001) Biological treatment of oil field wastewater in a sequencing batch reactor. Environ Technol 22:1125–1135. https://doi.org/10.1080/09593332208618203

Gavrilescu M, Macoveanu M (2000) Attached-growth process engineering in wastewater treatment. Bioprocess Eng 23:95–106. https://doi.org/10.1007/s004490050030

Ghorbanian M, Moussavi G, Farzadkia M (2014) Investigating the performance of an up-flow anoxic fixed-bed bioreactor and a sequencing anoxic batch reactor for the biodegradation of hydrocarbons in petroleum-contaminated saline water. Int Biodeterior Biodegrad 90:106–114. https://doi.org/10.1016/j.ibiod.2014.02.009

Guerra K, Dahm K, Dundorf S (2011) Oil and gas produced water management and beneficial use in the Western United States, S&T Report No. 157. U.S. Department of the Interior, Bureau of Reclamation, Denver

Guo CM et al (2014) Combined hydrolysis acidification and bio-contact oxidation system with air-lift tubes and activated carbon bioreactor for oilfield wastewater treatment. Bioresour Technol 169:630–636. https://doi.org/10.1016/j.biortech.2014.07.018

Hansen BR, Davies SRH (1994) Review of potential technologies for the removal of dissolved components from produced water. Chem Eng Res Des 72:176–188

Heberger M, Donnelly K (2015) Oil, food, and water: challenges and opportunities for California Agriculture. Pacific Institute, Oakland

Horner JE, Castle JW, Rodgers JH, Gulde CM, Myers JE (2012) Design and performance of pilot-scale constructed wetland treatment systems for treating oilfield produced water from Sub-Saharan Africa. Water Air Soil Pollut 223:1945–1957. https://doi.org/10.1007/s11270-011-0996-1

Igunnu ET, Chen GZ (2012) Produced water treatment technologies. Int J Low Carbon Technol. https://doi.org/10.1093/ijlct/cts049:1-21

Interstate Oil and Gas Compact Commission and ALL Consulting (2006) A guide to practical management of produced water from onshore oil and gas operations in the United States, DE-PS26-04NT15460-02. Oklahoma City

Jain P, Sharma M, Dureja P, Sarma PM, Lal B (2017) Bioelectrochemical approaches for removal of sulfate, hydrocarbon and salinity from produced water. Chemosphere 166:96–108. https://doi.org/10.1016/j.chemosphere.2016.09.081

Jamaly S, Giwa A, Hasan SW (2015) Recent improvements in oily wastewater treatment: progress, challenges, and future opportunities. J Environ Sci 37:15–30. https://doi.org/10.1016/j.jes.2015.04.011

Janson A, Santos A, Katebah M, Hussain A, Minier-Matar J, Judd S, Adham S (2015) Assessing the biotreatability of produced water from a Qatari gas field. SPE J 20:1113–1119

Ji GD, Sun T, Zhou QX, Sui X, Chang SJ, Li PJ (2002) Constructed subsurface flow wetland for treating heavy oil-produced water of the Liaohe Oilfield in China. Ecol Eng 18:459–465. https://doi.org/10.1016/s0925-8574(01)00106-9

Ji GD, Sun TH, Ni JR (2007) Surface flow constructed wetland for heavy oil-produced water treatment. Bioresour Technol 98:436–441. https://doi.org/10.1016/j.biortech.2006.01.017

Ji GD, Sun TH, Ni JR, Tong JJ (2009) Anaerobic baffled reactor (ABR) for treating heavy oil produced water with high concentrations of salt and poor nutrient. Bioresour Technol 100:1108–1114. https://doi.org/10.1016/j.biortech.2008.08.015

Jimenez S, Mico MM, Arnaldos M, Medina F, Contreras S (2018) State of the art of produced water treatment. Chemosphere 192:186–208. https://doi.org/10.1016/j.chemosphere.2017.10.139

Kardena E, Hidayat S, Nora S, Helmy Q (2017) Biological treatment of synthetic oilfield-produced water in activated sludge using a consortium of endogenous bacteria isolated from a tropical area. J Petrol Environ Biotechnol. https://doi.org/10.4172/2157-7463.1000331

Katsoyiannis IA, Zouboulis AI (2004) Application of biological processes for the removal of arsenic from groundwaters. Water Res 38:17–26. https://doi.org/10.1016/j.watres.2003.09.011

Kekacs D, Drollette BD, Brooker M, Plata DL, Mouser PJ (2015) Aerobic biodegradation of organic compounds in hydraulic fracturing fluids. Biodegradation 26:271–287. https://doi.org/10.1007/s10532-015-9733-6

Khong FC, Isa MH, Kutty SRM, Farhan SA (2012) Anaerobic treatment of produced water. World Acad Sci Eng Technol 6:55–59

Knight RL, Kadlec RH, Ohlendorf HM (1999) The use of treatment wetlands for petroleum industry effluents. Environ Sci Technol 33:973–980. https://doi.org/10.1021/es980740w

Kose B et al (2012) Performance evaluation of a submerged membrane bioreactor for the treatment of brackish oil and natural gas field produced water. Desalin 285:295–300. https://doi.org/10.1016/j.desal.2011.10.016

Kwon S, Sullivan EJ, Katz LE, Bowman RS, Kinney KA (2011) Laboratory and field evaluation of a pretreatment system for removing organics from produced water. Water Environ Res 83:843–854. https://doi.org/10.2175/106143011x12928814445212

Lefebvre O, Moletta R (2006) Treatment of organic pollution in industrial saline wastewater: a literature review. Water Res 40:3671–3682. https://doi.org/10.1016/j.watres.2006.08.027

Lester Y, Ferrer I, Thurman EM, Sitterley KA, Korak JA, Aiken G, Linden KG (2015) Characterization of hydraulic fracturing flowback water in Colorado: implications for water treatment. Sci Total Environ 512:637–644. https://doi.org/10.1016/j.scitotenv.2015.01.043

Li QX, Kang CB, Zhang CK (2005) Waste water produced from an oilfield and continuous treatment with an oil-degrading bacterium. Process Biochem 40:873–877. https://doi.org/10.1016/j.procbio.2004.02.011

Li G, Guo SH, Li FM (2010) Treatment of oilfield produced water by anaerobic process coupled with micro-electrolysis. J Environ Sci 22:1875–1882. https://doi.org/10.1016/s1001-0742(09)60333-8

Liu GH, Ye ZF, Tong K, Zhang YH (2013) Biotreatment of heavy oil wastewater by combined upflow anaerobic sludge blanket and immobilized biological aerated filter in a pilot-scale test. Biochem Eng J 72:48–53. https://doi.org/10.1016/j.bej.2012.12.017

Lu M, Wei XF (2011) Treatment of oilfield wastewater containing polymer by the batch activated sludge reactor combined with a zerovalent iron/EDTA/air system. Bioresour Technol 102:2555–2562. https://doi.org/10.1016/j.biortech.2010.11.103

Lu JR, Wang XL, Shan BT, Li XM, Wang WD (2006) Analysis of chemical compositions contributable to chemical oxygen demand (COD) of oilfield produced water. Chemosphere 62:322–331. https://doi.org/10.1016/j.chemosphere.2005.04.033

Lu M, Zhang Z, Yu W, Zhu W (2009) Biological treatment of oilfield-produced water: a field pilot study. Int Biodeterior Biodegrad 63:316–321. https://doi.org/10.1016/j.ibiod.2008.09.009

Margesin R, Schinner F (2001) Biodegradation and bioremediation of hydrocarbons in extreme environments. Appl Microbiol Biotechnol 56:650–663

Mondal S, Hsiao CL, Wickramasinghe SR (2008) Nanofiltration/reverse osmosis for treatment of coproduced waters. Environ Progress 27:173–179. https://doi.org/10.1002/ep.10271

Mousa IE (2016) Total petroleum hydrocarbon degradation by hybrid electrobiochemical reactor in oilfield produced water. Mar Pollut Bull 109:356–360. https://doi.org/10.1016/j.marpolbul.2016.05.053

Murray-Gulde C, Heatley JE, Karanfil T, Rodgers JH, Myers JE (2003) Performance of a hybrid reverse osmosis-constructed wetland treatment system for brackish oil field produced water. Water Res 37:705–713. https://doi.org/10.1016/s0043-1354(02)00353-6

Nam K, Rodriguez W, Kukor JJ (2001) Enhanced degradation of polycyclic aromatic hydrocarbons by biodegradation combined with a modified Fenton reaction. Chemosphere 45:11–20. https://doi.org/10.1016/s0045-6535(01)00051-0

Naraghi ZG, Yaghmaei S, Mardanpour MM, Hasany M (2015) Produced water treatment with simultaneous bioenergy production using novel bioelectrochemical systems. Electrochim Acta 180:535–544. https://doi.org/10.1016/j.electacta.2015.08.136

Ozgun H et al (2013) Effects of the pre-treatment alternatives on the treatment of oil-gas field produced water by nanofiltration and reverse osmosis membranes. J Chem Technol Biotechnol 88:1576–1583

Palmer LL, Beyer AH, Stock J (1981) Biological oxidation of dissolved compounds in oilfield produced water by a field pilot biodisk. J Petrol Technol 33:1136–1140

Pardue MJ, Castle JW, Rodgers JH, Huddleston GM (2014) Treatment of oil and grease in produced water by a pilot-scale constructed wetland system using biogeochemical processes. Chemosphere 103:67–73. https://doi.org/10.1016/j.chemosphere.2013.11.027

Pendashteh AR, Fakhru’l-Razi A, Chuah TG, Radiah AD, Madaeni SS, Zurina ZA (2010) Biological treatment of produced water in a sequencing batch reactor by a consortium of isolated halophilic microorganisms. Environ Technol 31:1229–1239. https://doi.org/10.1080/09593331003646612

Pendashteh AR, Fakhru’l-Razi A, Madaeni SS, Abdullah LC, Abidin ZZ, Biak DRA (2011) Membrane foulants characterization in a membrane bioreactor (MBR) treating hypersaline oily wastewater. Chem Eng J 168:140–150. https://doi.org/10.1016/j.cej.2010.12.053

Pendashteh AR, Abdullah LC, Fakhru’l-Razi A, Madaeni SS, Abidin ZZ, Biak DRA (2012) Evaluation of membrane bioreactor for hypersaline oily wastewater treatment. Process Saf Environ Protect 90:45–55. https://doi.org/10.1016/j.psep.2011.07.006

Piubeli F, Grossman MJ, Fantinatti-Garboggini F, Durrant LR (2012) Enhanced reduction of COD and aromatics in petroleum-produced water using indigenous microorganisms and nutrient addition. Int Biodeterior Biodegrad 68:78–84. https://doi.org/10.1016/j.ibiod.2011.11.012

Riley SM, Oliveira JMS, Regnery J, Cath TY (2016) Hybrid membrane bio-systems for sustainable treatment of oil and gas produced water and fracturing flowback water. Sep Purif Technol 171:297–311. https://doi.org/10.1016/j.seppur.2016.07.008

Rincon N, Chacin E, Marin J, Torrijos M, Moletta R, Fernandez N (2003) Anaerobic biodegradability of water separated from extracted crude oil. Environ Technol 24:963–970

Robinson D (2013a) Oil and gas: treatment and discharge of produced waters offshore. Filtr Sep 50:20–23

Robinson D (2013b) Oil and gas: treatment and discharge of produced waters onshore. Filtr Sep 50:40–46

Robinson D (2013c) Oil and gas: Treatment of produced waters for injection and reinjection. Filtr Sep 50:36–43

Scholzy W, Fuchs W (2000) Treatment of oil contaminated wastewater in a membrane bioreactor. Water Res 34:3621–3629. https://doi.org/10.1016/s0043-1354(00)00106-8

Sharghi EA, Bonakdarpour B (2013) The study of organic removal efficiency and halophilic bacterial mixed liquor characteristics in a membrane bioreactor treating hypersaline produced water at varying organic loading rates. Bioresour Technol 149:486–495. https://doi.org/10.1016/j.biortech.2013.09.110

Sharghi EA, Bonakdarpour B, Roustazade P, Amoozegar MA, Rabbani AR (2013) The biological treatment of high salinity synthetic oilfield produced water in a submerged membrane bioreactor using a halophilic bacterial consortium. J Chem Technol Biotechnol 88:2016–2026. https://doi.org/10.1002/jctb.4061

Sharghi EA, Bonakdarpour B, Pakzadeh M (2014) Treatment of hypersaline produced water employing a moderately halophilic bacterial consortium in a membrane bioreactor: effect of salt concentration on organic removal performance, mixed liquor characteristics and membrane fouling. Bioresour Technol 164:203–213. https://doi.org/10.1016/j.biortech.2014.04.099

Sheikhyousefi PR, Esfahany MN, Colombo A, Franzetti A, Trasatti SP, Cristiani P (2017) Investigation of different configurations of microbial fuel cells for the treatment of oilfield produced water. Appl Energy 192:457–465. https://doi.org/10.1016/j.apenergy.2016.10.057

Shpiner R, Liu G, Stuckey DC (2009a) Treatment of oilfield produced water by waste stabilization ponds: Biodegradation of petroleum-derived materials. Bioresour Technol 100:6229–6235. https://doi.org/10.1016/j.biortech.2009.07.005

Shpiner R, Vathi S, Stuckey DC (2009b) Treatment of oil well “produced water” by waste stabilization ponds: Removal of heavy metals. Water Res 43:4258–4268. https://doi.org/10.1016/j.watres.2009.06.004

Shrestha N, Chilkoor G, Wilder J, Ren ZJ, Gadhamshetty V (2018) Comparative performances of microbial capacitive deionization cell and microbial fuel cell fed with produced water from the Bakken shale. Bioelectrochem 121:56–64. https://doi.org/10.1016/j.bioelechem.2018.01.004

Steliga T, Jakubowicz P, Kapusta P (2015) Changes in toxicity during treatment of wastewater from oil plant contaminated with petroleum hydrocarbons. J Chem Technol Biotechnol 90:1408–1418. https://doi.org/10.1002/jctb.4442

Stoll ZA, Forrestal C, Ren ZJ, Xu P (2015) Shale gas produced water treatment using innovative microbial capacitive desalination cell. J Hazard Mater 283:847–855. https://doi.org/10.1016/j.jhazmat.2014.10.015

Su DL, Wang JL, Liu KW, Zhou D (2007) Kinetic performance of oil-field produced water treatment by biological aerated filter. Chin J Chem Eng 15:591–594. https://doi.org/10.1016/s1004-9541(07)60129-3

Su DL, Cong L, Wang JL, Zhou D (2009) Treatment of oil-field produced water by combined process of anaerobic baffled reactor (ABR)-biological aerated filter (BAF): a pilot study. Int J Environ Pollut 38:69–80

Tchobanoglous G, Stensel HD, Tsuchihashi R, Burton F (2014) Wastewater engineering: treatment and resource recovery, 5th edn. McGraw Hill Education, New York, NY

Tellez GT, Nirmalakhandan N, Gardea-Torresdey JL (2002) Performance evaluation of an activated sludge system for removing petroleum hydrocarbons from oilfield produced water. Adv Environ Res 6:455–470. https://doi.org/10.1016/s1093-0191(01)00073-9

Tellez GT, Nirmalakhandan N, Gardea-Torresdey JL (2005) Kinetic evaluation of a field-scale activated sludge system for removing petroleum hydrocarbons from oilfield-produced water. Environ Prog 24:96–104. https://doi.org/10.1002/ep.10042

Tong K, Zhang YH, Liu GH, Ye ZF, Chu PK (2013) Treatment of heavy oil wastewater by a conventional activated sludge process coupled with an immobilized biological filter. Int Biodeterior Biodegrad 84:65–71. https://doi.org/10.1016/j.ibiod.2013.06.002

Veil J (2015) U.S. produced water volumes and management practices in 2012. Prepared for: ground water protection council. Veil Environmental, LLC, Annapolis

Veil JA, Puder MG, Elcock D, Redweik Jr RJ (2004) A white paper describing produced water from production of crude oil, natural gas, and coal bed methane. Argonne National Laboratory for the US Department of Energy, National Energy Technology Laboratory

Vieira DS, Servulo EFC, Cammarota MC (2005) Degradation potential and growth of anaerobic bacteria in produced water. Environ Technol 26:915–922. https://doi.org/10.1080/09593332608618499

Wang ZY, Li J, Hesham AEL, He SW, Zhang Y, Wang ZJ, Yang M (2007) Co-variations of bacterial composition and catabolic genes related to PAH degradation in a produced water treatment system consisting of successive anoxic and aerobic units. Sci Total Environ 373:356–362. https://doi.org/10.1016/j.scitotenv.2006.11.020

Woolard CR, Irvine RL (1994) Biological treatment of hypersaline waste-water by a biofilm of halophilic bacteria. Water Environ Res 66:230–235

Woolard CR, Irvine RL (1995) Treatment of hypersaline waste-water in the sequencing batch reactor. Water Res 29:1159–1168. https://doi.org/10.1016/0043-1354(94)00239-4

Xiao YY, Roberts DJ (2010) A review of anaerobic treatment of saline wastewater. Environ Technol 31:1025–1043. https://doi.org/10.1080/09593331003734202

Xu P, Drewes JE, Heil D (2008) Beneficial use of co-produced water through membrane treatment: technical-economic assessment. Desalin 225:139–155. https://doi.org/10.1016/j.desal.2007.04.093

Yu L, Han M, He F (2017) A review of treating oily wastewater. Arab J Chem 10:S1913–S1922. https://doi.org/10.1016/j.arabjc.2013.07.020

Zhang YQ, Gao BY, Lu L, Yue QY, Wang QA, Jia YY (2010) Treatment of produced water from polymer flooding in oil production by the combined method of hydrolysis acidification-dynamic membrane bioreactor-coagulation process. J Petrol Sci Eng 74:14–19. https://doi.org/10.1016/j.petrol.2010.08.001

Zhang M et al (2016) A field pilot-scale study of biological treatment of heavy oil-produced water by biological filter with airlift aeration and hydrolytic acidification system. Environ Sci Pollut Res 23:4919–4930. https://doi.org/10.1007/s11356-015-5721-y

Zhao X, Wang YM, Ye ZF, Borthwick AGL, Ni JR (2006) Oil field wastewater treatment in biological aerated filter by immobilized microorganisms. Process Biochem 41:1475–1483. https://doi.org/10.1016/j.procbio.2006.02.006

Zhao S, Huang GH, Cheng GH, Wang YF, Fu HY (2014) Hardness, COD and turbidity removals from produced water by electrocoagulation pretreatment prior to Reverse Osmosis membranes. Desalin 344:454–462. https://doi.org/10.1016/j.desal.2014.04.014

Acknowledgements

This study was supported in part by Laboratory Directed Research and Development (LDRD) funding from Berkeley Lab, provided by the Director, Office of Science, of the U.S. Department of Energy under Contract No. DE-AC02-05CH1123. This material includes work supported by the Department of Energy CERC-WET project under Award Number DE-IA0000018.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Camarillo, M.K., Stringfellow, W.T. Biological treatment of oil and gas produced water: a review and meta-analysis. Clean Techn Environ Policy 20, 1127–1146 (2018). https://doi.org/10.1007/s10098-018-1564-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-018-1564-9