Abstract

Pilot-scale constructed wetland treatment systems (CWTSs) were designed and built to decrease concentrations of constituents of concern in water simulated to match characteristics of water produced from specific oilfields in sub-Saharan Africa. The oilfield produced water has low ionic strength (704–1,370 mg L−1 total dissolved solids) and contains Fe, Mn, Ni, Zn, and oil and grease (O&G). To treat these constituents, biogeochemical pathways were targeted in the design of two subsurface flow (SSF) CWTS series planted with Phragmites australis and a free-water surface (FWS) series planted with Typha latifolia. These systems were designed for prevailing conditions at the sub-Saharan site studied. Concentrations of O&G, Fe, Mn, Ni, and Zn in outflow from the SSF series met use criteria for irrigation and livestock watering. For the FWS series, outflow concentrations of O&G, Fe, and Mn met use criteria for irrigation and livestock watering, and Ni concentrations met use criteria for livestock watering. Both SSF and FWS series were effective in reducing concentrations of O&G in the produced water investigated with >98% efficiency. The high-removal efficiency is attributed to achieving aerobic conditions in the wetland cells. Both SSF and FWS series reduced concentrations of Fe and Mn but with a wider range of efficiency compared with O&G removal. The removal of Ni and Zn could be increased by the addition of organic matter, such as plant detritus, to wetland cells to promote reducing conditions and dissimilatory sulfate reduction.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

On-site treatment of oilfield-produced waters (OPWs) in sub-Saharan Africa, where reliable supplies of fresh water are greatly needed, has the potential to provide water for irrigation and livestock. With cost-effective renovation, OPWs may become important sources of water supply in many areas depending on local conditions and produced water characteristics. OPWs, which are generated in large volumes in numerous countries, are brought to the surface when oil is extracted from reservoirs within water-bearing geologic units. Khatib and Verbeek (2003) estimated that in 1999 more than 210 million barrels (33.4 million m3) of produced water were generated each day worldwide. Although the composition of OPW can vary greatly, three common fractions are hydrocarbons, metals/metalloids, and salts (Clark and Veil 2009; Knight et al. 1999; Veil et al. 2004). Physical and chemical properties depend on geographic location of the field, geological formations in contact with the water, treatment chemicals utilized, and extraction techniques (Murray Gulde et al. 2003). Current OPW management strategies include minimization of the volume generated, disposal into underground formations, utilization for enhanced recovery/pressure maintenance, and beneficial use at the surface (Clark and Veil 2009; Khatib and Verbeek 2003; Veil et al. 2004). Constructed wetland treatment systems (CWTSs) provide an option for onsite treatment of OPWs for use in irrigation and livestock watering. Robust CWTSs can be designed for removal of targeted constituents in site-specific OPW, while providing flexibility in treating multiple constituents to meet performance goals for water reuse (e.g., Al Mahruki et al. 2006; Ji et al. 2002; Knight et al. 1999; Murray Gulde et al. 2003).

Constituents of concern (COCs) are compounds or elements in a specific OPW that require treatment to meet target water use guidelines. COC removal can be achieved in CWTSs by promoting specific biogeochemical pathways and manipulating hydrosoil, vegetation, and hydroperiod to decrease the aqueous concentration and bioavailability of targeted constituents. Flow regimes utilized in CWTSs include subsurface flow (i.e., water level maintained below the hydrosoil substrate) and free-water surface (i.e., water surface open to the atmosphere). Selection of an appropriate flow regime depends primarily on the targeted constituents for treatment, geographic location, cost, available area, and treatment goals. Subsurface flow wetlands may be preferable at the sub-Saharan site of this investigation for several reasons, including lack of visibility of water, concerns for disease vectors, and evaporation.

Pilot-scale CWTS studies incorporate critical design features and facilitate experimentation, while readily allowing scaling of results to improve full-scale designs. Specifically, pilot-scale studies provide: (1) information from replicated physical model CWTSs operating at a range of conditions, (2) confidence to owners regarding realistic and robust treatment performance of the systems, and (3) refined kinetic rate coefficients and extents of removal for incorporation into full-scale systems (Rodgers and Castle 2008). Pilot-scale studies are useful in determining if CWTSs are a viable option for a specific OPW. Characteristics of the OPW and potential use options are considered in design of pilot-scale studies. Performance is measured based on achieving use criteria as well as the rate at which treatment goals are achieved.

This research utilized pilot-scale CWTSs and simulated OPW to measure treatment parameters of COCs in a specific OPW from an oilfield in sub-Saharan Africa. The COCs studied include oil and grease (O&G), Fe, Mn, Ni, and Zn. The objectives of this research were to: (1) design and construct pilot-scale vertical subsurface flow (SSF) and free-water surface (FWS) series for treatment of COCs in the OPW studied and (2) measure performance of the pilot-scale wetland series under a range of O&G loadings for simulated OPW containing COCs. Constituent loading such as O&G can vary during life of an oilfield just as the volume of water produced can vary. Effective treatment of water produced from oilfields in sub-Saharan Africa has the potential to help alleviate growing demand for water needed for irrigation and livestock watering.

2 Materials and Methods

2.1 Design and Construction of Pilot-Scale CWTSs

The sub-Saharan site of this investigation is located in an area of savanna, with the land surface covered by a mixture of tropical and subtropical grasses and scattered trees. A rainy season lasts from April to October followed by a dry season from November to March. To simulate climatic conditions at the site, the pilot-scale systems were constructed in a climate-controlled greenhouse at Clemson University, Clemson, SC, USA.

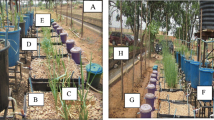

The pilot-scale CWTSs were designed and assembled to transfer or transform COCs (O&G, Fe, Mn, Ni, Zn) to decrease their aqueous concentrations and bioavailability. CWTS reactors were designed to establish conditions favorable for promoting biogeochemical processes for treating the COCs. To compare treatment performance between pilot-scale SSF wetlands and FWS wetlands, two replicate vertical series (SSF 1 and SSF 2) and one FWS series (Fig. 1) were built. Each pilot-scale series consisted of four 100 gal (378 L) Rubbermaid® Utility Tank reactors (R1–R4).

Simulated OPW was formulated for use in the pilot-scale CWTSs rather than transporting actual OPW from sub-Saharan Africa because of the cost associated with shipping and storage. In addition, simulated water allowed for more control over system inflow and therefore more precise comparisons with system outflow. The water was simulated to match actual OPW from the specific sub-Saharan site based on characterization of the OPW by Horner et al. (2011). The actual OPW is generated from non-marine geologic strata of a rift basin and is characterized by low ionic strength (838–1,500 μmhos/cm conductivity and 704–1,370 mg L−1 total dissolved solids). Four different formulations for O&G (i.e., 10, 25, 50, and 100 mg L−1) were utilized to investigate treatment over a range in concentrations that may be present under site-specific field conditions. Nominal metal concentrations (mg L−1) were 0.08 Fe, 0.50 Mn, 0.37 Ni, and 2.0 Zn in the 10 and 25 mg L−1 O&G formulations and 0.40 Fe, 1.26 Mn, 1.44 Ni, and 5.0 Zn in the 50 mg L−1 O&G formulation. Metals were not added to the 100 mg L−1 O&G formulation because of instrumental limitations regarding O&G that could affect accurate measurement of metal concentrations. Simulated OPW was formulated in a 1,000-gallon (3,785 L) polypropylene detention basin by adding the following to municipal water: (1) high purity salts (Fisher Scientific, Fair Lawn, NJ; Sigma, St. Louis, MO, USA; Acrōs, NJ, USA) of Fe, Mn, Ni, and Zn; (2) technical grade salts for bicarbonate, sulfate, and calcium; and (3) Shell Rotella T® motor oil (Table 1). A continuous mixing pump was used in the detention basin to incorporate COCs into the water and allow for a consistent inflow concentration of COCs during wetland tests. Simulated OPW was transferred from the detention basin to the first reactor (R1) in each series (SSF 1, SSF 2, and FWS) via Fluid Metering Inc. (FMI®) piston pumps calibrated by adjusting the flow rate to attain a nominal 24-h hydraulic retention time (HRT) per reactor (4-day HRT for the total system).

Wetland parameters monitored prior to and during treatment included oxidation–reduction (redox) potential of wetland hydrosoil and plant health indices (i.e., plant density and new shoot growth). Redox potential of the wetland hydrosoil was measured using a millivolt meter connected to in situ platinum-tipped electrodes and an Accumet® calomel reference electrode (Faulkner et al. 1989). Two electrodes were placed in the hydrosoil near the upstream and downstream ends of each wetland reactor. Electrodes were installed at 30 cm below the hydrosoil surface in SSF reactors and approximately 5 cm below the interface between hydrosoil and water in FWS reactors. All measurements were adjusted based on hydrogen ion potential. Plant health was measured to evaluate the ability of selected wetland plant species to tolerate and produce new shoots in reactors treating simulated OPW, ensuring sustainability and productivity of the macrophytes exposed to OPW in the CWTSs. Plant health was measured by counting the number of green shoots and young shoots (≤12.7 cm). Plants were inspected on a monthly basis for indicators of toxicity (e.g., chlorosis, necrosis, and malformation). To provide essential nutrients (e.g., nitrogen, phosphorous, and potassium) for microbes and plants, approximately 30 g Osmocote® time-release fertilizer (19-6-12) was applied to hydrosoil monthly throughout the experiments. Metals such as Cu+2, Ni+2, Zn+2 are not part of the formulation of the fertilizer used.

2.2 Measurement of Treatment Performance

For each CWTS series, aqueous samples were collected at the series inflow and reactor outflows. Sampling for general water chemistry parameters and concentrations of COCs was initiated in October 2007, following a 5-month maturation period after wetland reactor construction. Each O&G formulation was treated for 5–7 months and experiments were completed in June 2009. Outflow samples were collected based on HRT of the wetland; for example, Reactor 2 outflow was sampled 24 h (HRT) after Reactor 1 outflow was sampled. Chemical and physical parameters (temperature, pH, conductivity, alkalinity, hardness, DO, chemical oxygen demand, and 5-day biological oxygen demand) were measured using standard methods (APHA 2005). Total and dissolved metals were analyzed using inductively coupled plasma-atomic emission spectrometry (ICP-AES; SPECTROFLAME-EOP, Spectro Analytical Instruments, Kleve, Germany) according to Environmental Protection Agency (EPA) method 200.7 (USEPA 1994). Detection limits were 0.0062 mgL−1 Fe, 0.0014 mgL−1 Mn, 0.015 mgL−1 Ni, and 0.0018 mgL−1 Zn. Metals were not analyzed during the 100 mgL−1 O&G loading because instrumental limitations regarding O&G could cause inaccurate measurement of metal concentrations. O&G concentrations were measured using gravimetric methods with n-hexane extraction using an apparatus manufactured by Environmental Express according to EPA method 1664 revision A (USEPA 1999). Detection limit for O&G was 1.4 mgL−1.

Quality assurance and quality control (QA/QC) measures for ICP-AES metal analyses included a standard recovery and standard addition every ten samples. Sample analyses were considered acceptable if standard recoveries were within ±10% of the calibration concentration for individual metals and standard addition percent recoveries were within 70–130% (USEPA 1994). QA/QC for O&G analyses included measurement of motor oil standards and a matrix spike every ten samples. Sample analyses were considered acceptable if percent recoveries of standards and matrix spikes were within 78–114% (USEPA 1999).

Treatment performance of the SSF and FWS reactor series was evaluated using removal efficiencies and removal rate coefficients for COCs. Removal efficiency, which is the percent decrease in concentration of a COC from inflow to outflow, was calculated using Eq. 1:

where, [C]o (mg L−1) is concentration of a COC in the inflow and [C] (mg L−1) is concentration of the constituent in the outflow. Removal rate coefficients (k, day−1) for COCs were calculated using first-order rate kinetics (Eq. 2). First-order kinetics is the standard approach to calculating treatment rates in constructed wetland systems (e.g., Crites 1994; Johnson et al. 2008; Jou et al. 2008; Kadlec 1997; Kadlec and Wallace 2009; Knight et al. 1999; Reed and Brown 1995; Siracusa and La Rosa 2006; Wood 1995). In a comparison of different rate models, Rousseau et al. (2004) confirmed the applicability of first-order kinetic models to treatment in constructed wetland systems.

where, t (days) is time, which in this equation is time between sampling the inflow and outflow of a reactor. Both removal efficiencies and removal rate coefficients were calculated for each metal in unfiltered samples. In addition to evaluation of treatment performance using removal efficiencies and rate coefficients, measured outflow concentrations of COCs were compared with water use criteria from Horner et al. (2011). The criteria were 0.3 mgL−1 Fe, 0.05 mgL−1 Mn, 1.0 mgL−1 Ni, 20 mgL−1 Zn, and 35 mgL−1 O&G for use in livestock watering and 1.0 mgL−1 Fe, 0.2 mgL−1 Mn, 0.2 mgL−1 Ni, 1.0 mgL−1 Zn, and 35 mgL−1 O&G for use in irrigation.

3 Results

3.1 Design and Construction of Pilot-Scale CWTSs

3.1.1 Design for Geochemistry

Reactors 1 and 2 in CWTS series SSF 1, SSF 2, and FWS were designed as reducing reactors to promote dissimilatory sulfate reduction. Loading of an organic carbon source into the CWTS series in the form of suspended and dissolved oil in the simulated OPW and subsequent degradation can serve as an electron donor/energy source for microbial activity, promoting reducing conditions in hydrosoil and dissimilatory sulfate reduction (Dvorak et al. 1992). Using equilibrium geochemistry (Brookins 1988), target Eh in the reducing reactors was −50 to −250 mV to favor dissimilatory sulfate reduction and formation of insoluble metal sulfides (Kadlec and Wallace 2009; Kröpfelová et al. 2009) of divalent cationic metals typically found in OPW including Ni and Zn (Clark and Veil 2009; Veil et al. 2004). Requirements for sulfate-reducing bacteria include: sulfur source, nutrients, carbon and energy source, and an anaerobic environment (Tuttle et al. 1969). Sulfate concentration (3.2 mg L−1) in the simulated OPW was representative of the actual OPW from sub-Saharan Africa.

Reactors 3 and 4 in series SSF 1, SSF 2, and FWS were designed to promote oxidizing conditions and a target Eh of +50 to +250 mV. Oxidizing conditions favor the formation of solid Fe and Mn oxyhydroxide precipitates (Barton and Karathanasis 1998) and enable co-precipitation of metal oxide complexes and adsorption of Ni and Zn to amorphous Fe hydroxides (Kadlec and Wallace 2009).

Hydrosoil and vegetation in the CWTS reactors (Table 2) were selected to promote the targeted biogeochemical processes, including biodegradation and sorption of O&G to hydrosoil particles and plant roots. Hydrosoil in the SSF reactors was constructed with a 20-cm thickness of pea gravel (5–10 mm diameter) overlain by 40 cm of medium-sized gravel (20–30 mm diameter) and planted with Phragmites australis (i.e., common reed). FWS reactors were constructed with a 36-cm thickness of medium-sized quartz sand collected from 18 Mile Creek, near Clemson, SC, USA and planted with Typha latifolia (i.e., broadleaf cattail). Kanagy et al. (2008) described particle size distribution, organic matter content, pH, Eh, and acid volatile sulfide concentration in hydrosoil composed of sand from the same location.

P. australis and T. latifolia were planted in the wetland reactors at a density of 70 and 30 shoots m−2, respectively. These macrophytes were selected because they are fast growing, provide oxygen to the root zone by convective transport through live and dead stems (Kadlec and Wallace 2009), are commonly used as emergent macrophytes in constructed wetlands, and are native to sub-Saharan Africa. Oxygen diffusion from root surfaces of emergent macrophytes can help support the oxygen demand of microorganisms in the rhizosphere for aerobic biodegradation of organics (Kadlec and Wallace 2009; Laskov et al. 2006).

3.1.2 Design for Plant Health

To ensure the sustainability of selected macrophytes in the CWTS reactors, plant health indices were monitored during wetland maturation (i.e., before experimental treatment of simulated OPW), and over the course of wetland treatment. Initial shoot density immediately after planting was 70 shoots m−2 for SSF reactors and 30 shoots m−2 for FWS reactors. After 200 days, shoot density had increased to approximately 260 shoots m−2 for SSF reactors and 60 shoots m−2 for FWS reactors (Fig. 2). After a year of simulated OPW treatment, shoot density in the SSF reactors was approximately 285 shoots m−2, and the density of new shoots ≤5 in. (12.7 cm) in height ranged from 22 to 43 shoots m−2 in the reactors indicating that P. australis was tolerant to conditions in the wetland reactors. Shoot density in FWS reactors planted with T. latifolia declined after a year of wetland loading to an average of 41 shoots m−2 with minimal new growth observed.

3.2 Treatment Performance

3.2.1 General Chemistry

Values for general water chemistry parameters measured in inflow to CWTS series and outflow from each reactor are listed in Table 3. Dissolved oxygen concentration of inflow water ranged from 7.82 to 9.26 mg L−1 and decreased to an average of 7.32 mg L−1 in SSF 1 outflow, 7.29 mg L−1 in SSF 2 outflow, and 7.71 mg L−1 in FWS series outflow. Ninety-five percent of the pH values measured in reactor outflows was between 6.0 and 8.0.

Redox measurements indicated that oxidizing conditions (+50 to +250 mV) were attained in the downstream portion of SSF reactors (Fig. 3a). Reducing conditions (−50 to −250 mV) developed near the upstream probe in reactors R2 and R3 during the experiments (Fig. 3b). Decreasing redox potential was observed in the downstream portion of FWS reactors R1 and R3 and in the upstream portion of R3 (Fig. 3c, d). Development of reducing conditions in portions of the wetland reactors during treatment may have been caused by organic loading as water containing O&G moved through the systems.

3.2.2 COC Concentrations and Removal Rates

Inflow and outflow concentrations of metals in reactor series operating at a 4-day HRT are listed in Table 4. Removal efficiencies for metals were greater in the SSF series than in the FWS series. In the two SSF series removal ranged from 48.0% to 97.3% for Fe, 99.3% to 99.7% for Mn, 64.2% to 97.0% for Ni, and 79.9% to 99.6% for Zn. Removal in the FWS reactor series ranged from no removal to 89.2% for Fe, 88.3% to 98.0% for Mn, 23.1% to 63.2% for Ni, and 11.5% to 84.0% for Zn. O&G concentration decreased to below the method limit of detection (1.4 mg L−1) for all treatment periods at 10, 25, 50, and 100 mg L−1 O&G inflow (Fig. 4), indicating removal efficiencies greater than 86.7% for SSF and FWS reactor series.

Removal rate coefficients, assuming first-order rate kinetics, for the two SSF series ranged from 0.263 to 1.15 day−1 for Fe, 1.64 to 1.77 day−1 for Mn, 0.265 to 0.949 day−1 for Ni, and 0.409 to 1.57 day−1 for Zn. Removal rate coefficients for the FWS series ranged from no removal to 0.594 day−1 for Fe, 0.595 to 1.04 day−1 for Mn, 0.080 to 0.257 day−1 for Ni, and 0.045 to 0.465 day−1 for Zn. Removal rate coefficients for O&G ranged from 0.649 to 2.45 day−1 for the two SSF reactor series and from 0.518 to 2.04 day−1 for the FWS reactor series.

Chemical oxygen demand (COD) and 5-day biochemical oxygen demand (BOD5) were measured in CWTS inflow and SSF and FWS series outflows as secondary parameters to indicate O&G treatment. Average inflow concentrations of COD were 29 mg L−1 COD at 10 mg L−1 O&G loading, 38 mg L−1 COD at 25 mg L−1 O&G loading, 98 mg L−1 COD at 50 mg L−1 O&G loading, and 210 mg L−1 COD at 100 mg L−1 O&G loading. For 12 of the 18 sampling dates during treatment in the SSF series, COD decreased to near background concentrations (2.7–8.2 mg L−1 COD), indicating O&G treatment. In the FWS series, background concentrations of COD (2.7–13.6 mg L−1) were achieved for 8 of 15 sampling dates. COD removal efficiencies ranged from 46.9% to >95.3% for SSF series and 6.1% to 97.5% for FWS. Five-day BOD measured in wetland reactors was <2 mg L−1 in SSF 2 reactors and <6 mg L−1 in FWS reactors for all O&G loadings. COD values were greater than BOD5, probably because more compounds can be oxidized chemically than degraded biologically (Knight et al. 1999).

4 Discussion

A neutral pH of 7.0 is optimal for hydrocarbon degradation (Margesin and Schinner 2001; Salmon et al. 1998) although microorganisms (acidophiles and alkaliphiles) capable of degrading hydrocarbons in acid and basic environments (i.e., pH = 2–3 and 9–10.5) have been isolated (Margesin and Schinner 2001). Sulfate-reducing bacteria contribute to metal/metalloid–sulfide precipitation and require a pH of 5.0–8.0 (Brown et al. 1973); all measured pH values for the SSF outflow and 95% of the pH values for the FWS outflow were within this range. The circumneutral pH of the simulated OPW was favorable for forming ferric hydroxide precipitates (pH > 3.5; Ye et al. 2001) and Mn hydroxides (pH > 8.0; Barton and Karathanasis 1998). Manganese co-precipitates in water containing high Fe concentrations at pH < 8.0 (Stumm and Morgan 1981) or adsorbs to reactive surfaces of crystalline Fe minerals (Barton and Karathanasis 1998).

Water temperature measured year round in the wetland reactors ranged from 13.4 to 27.2°C (Table 3), indicating that the systems were operating below optimal conditions of 30°C for oil degradation (Rahman et al. 2002). Warmer temperatures at the field location are expected to promote strong treatment performance.

The ability of macrophytes to transport oxygen though aerenchyma tissues to the roots and into adjacent sediment can result in Fe oxyhydroxide precipitation and co-precipitation (i.e., with Mn) on and around roots in SSF reactors (Ye et al. 2001). Similarly, Fe and Mn precipitate formation can be promoted by photosynthetic production of oxygen by algal mats (Knauer et al. 1999; USEPA 1988). Algal mats were observed on the water’s surface in FWS reactors and may have contributed to removal of Fe and Mn through plaque formation on the underside of algal mats and litter. In a study of a CWTS for treating mine water, Edenborn and Brickett (2002) concluded that the formation of algal mats and associated MnO2 precipitation likely influenced accumulation of Mn. They reported that floating algal mats in the CWTS were dark in color and contained manganese oxides. Black residues observed on the underside of algal mats in the current investigation may be analogous to the dark, manganese-rich material identified by Edenborn and Brickett (2002).

O&G removal rate coefficients were similar for SSF 1, SSF 2, and FWS reactor series, while removal efficiencies and removal rate coefficients were greater for Fe, Mn, Ni, and Zn in the SSF series than in the FWS series. The greater removal of metals in the SSF series is probably the result of greater surface area of solids in SSF reactors from gravel and proliferous root networks of P. australis, which provided sorption sites. To maximize contact between flow and hydrosoil in FWS reactors and to regulate flow, USEPA (1988) suggested dense planting, litter, shallow water, low flow velocities, and narrow channels.

Applying water use criteria from Horner et al. (2011), concentrations of COCs (O&G, Fe, Mn, Ni, and Zn) in outflow from the SSF series met use criteria for irrigation and livestock watering on all sampling dates. Outflow concentrations of Mn from the FWS series on one sampling date (03-27-09) exceeded criteria for use in livestock watering. Outflow concentrations of Ni from the FWS series met use criteria for livestock watering, but exceeded criteria for use in irrigation on three sampling dates (02-07-08, 01-24-09, 03-27-09). Concentrations of Zn exceeded irrigation use criteria on three sampling dates (10-23-07, 03-11-09, 03-27-09). With intervention, for example adding organic matter such as plant detritus, redox could be decreased and percent removal of Ni and Zn increased (Hawkins et al. 1997; Johnson et al. 2008; Kanagy et al. 2008; Table 5).

The pilot-scale CWTS series were designed based on characteristics of the produced water studied and for the prevailing conditions at specific sub-Saharan oilfields. A SSF design is preferable to a FWS design at the sub-Saharan location because exposure of the water to the atmosphere is minimized, which helps to reduce evaporative water loss and exposure to disease-carrying insects.

5 Conclusion

Four different O&G concentrations (10, 25, 50, 100 mg L−1) in simulated oilfield produced water were investigated to represent the range of loadings anticipated at a sub-Saharan field site. For all four O&G loadings, both the SSF and FWS series were very effective in reducing concentrations of O&G, with >98% efficiency. The high removal efficiency is attributed to achieving aerobic conditions in the wetland series, which were designed primarily for O&G removal. The SSF and FWS series were effective in reducing concentrations of Fe and Mn, but with a wider range of efficiency compared with O&G removal. Most redox values measured in the wetland cells were within the range of oxidizing conditions, which limited dissimilatory sulfate reduction and therefore limited the removal of Ni and Zn. Ni and Zn removal could be increased by the addition of organic matter, such as plant detritus, to the wetland cells to promote reducing conditions and dissimilatory sulfate reduction. Concentrations of all five COCs (O&G, Fe, Mn, Ni, and Zn) in outflow from the SSF series met use criteria for irrigation and livestock watering. Results of this pilot-scale study suggest that CWTSs are a viable option for treating the specific OPW studied for potential use in irrigation and livestock watering.

References

Al Mahruki, A., Alloway, B., & Patzelt, H. (2006). The use of reed-bed technology for treating oil-production waters in the Sultanate of Oman. Society of Petroleum Engineers Paper, 98548, 1–6.

APHA. (2005). Standard methods for the examination of water and wastewater (21st ed.). Washington: American Public Health Association.

Barton, C. D., & Karathanasis, A. D. (1998). Aerobic and anaerobic metal attenuation processes in a constructed wetland treating acid mine drainage. Environmental Geosciences, 5, 43–56.

Brookins, D. G. (1988). Eh–pH diagrams for geochemistry. New York: Springer.

Brown, D. E., Groves, G. R., & Miller, J. D. A. (1973). pH and Eh control of cultures of sulphate-reducing bacteria. Journal of Applied Chemistry & Biotechnology, 23, 141–149.

Clark, C. E., & Veil, J. A. (2009). Produced water volumes and management practices in the United States. ANL/EVS/R-09/1. Washington: Argonne National Laboratory, Environmental Science Division.

Crites, R. W. (1994). Design criteria and practice for constructed wetlands. Water Science and Technology, 29, 1–6.

Dorman, L., Castle, J. W., & Rodgers, J. H., Jr. (2009). Performance of a pilot-scale constructed wetland system for treating simulated ash basin water. Chemosphere, 75, 939–947.

Dvorak, D. H., Hedin, R. S., Edenborn, H. M., & McIntrye, P. E. (1992). Treatment of metal contaminated water using bacterial sulfate reduction: results from pilot scale reactors. Biotechnology and Bioengineering, 40, 609–616.

Edenborn, H. M., & Brickett, L. A. (2002). Determination of manganese stability in a constructed wetland sediment using redox gel probes. Geomicrobiology Journal, 19, 485–504.

Faulkner, S. P., Patrick, W. H., Jr., & Gambrell, R. P. (1989). Field techniques for measuring wetland soil parameters. Soil Science Society of America Journal, 53, 883–890.

Gillespie, W. B., Jr., Hawkins, W. B., Rodgers, J. H., Jr., Cano, M. L., & Dorn, P. B. (1999). Transfers and transformations of zinc in flow-through wetland microcosms. Ecotoxicology and Environmental Safety, 43, 126–132.

Hawkins, W. B., Rodgers, J. H., Jr., Gillespie, W. B., Jr., Dunn, A. W., Dorn, P. B., & Cano, M. L. (1997). Design and construction of wetlands for aqueous transfers and transformations of selected metals. Ecotoxicology and Environmental Safety, 36, 238–248.

Horner, J. E., Castle, J. W., & Rodgers, J. H., Jr. (2011). A risk assessment approach to identifying constituents in oilfield produced water for treatment prior to beneficial use. Ecotoxicology and Environmental Safety, 74, 989–999.

Ji, G., Sun, T., Zhou, Q., Sui, X., Chang, S., & Li, P. (2002). Constructed subsurface flow wetland for treating heavy oil-produced water of the Liaohe Oilfield in China. Ecological Engineering, 18, 459–465.

Ji, G. D., Sun, T. H., & Ni, J. R. (2007). Surface flow constructed wetland for heavy-oil produced water treatment. Bioresource Technology, 98, 436–441.

Johnson, B. M., Kanagy, L. E., Rodgers, J. H., Jr., & Castle, J. W. (2008). Feasibility of a pilot-scale hybrid constructed wetland treatment system for simulated natural gas storage produced waters. Environmental Geosciences, 15, 91–104.

Jou, C. J., Chen, S. W., Kao, C. M., & Lee, C. L. (2008). Assessing the efficiency of a constructed wetland using a first-order biokinetic model. Wetlands, 28, 215–219.

Kadlec, R. H. (1997). Deterministic and stochastic aspects of constructed wetland performance and design. Water Science and Technology, 35, 149–156.

Kadlec, R. H., & Wallace, S. D. (2009). Treatment wetlands (2nd ed.). Boca Raton: CRC Press.

Kanagy, L. E., Johnson, B. M., Castle, J. W., & Rodgers, J. H., Jr. (2008). Hydrosoil conditions in a pilot-scale constructed wetland treatment system for natural gas storage produced waters. Environmental Geosciences, 15, 105–113.

Khatib, Z., & Verbeek, P. (2003). Water to value-produced water management for sustainable field development of mature and green fields. Journal of Petroleum Technology, 55(1), 26–28.

Knauer, K., Jabusch, T., & Sigg, L. (1999). Manganese uptake and Mn (II) oxidation by the alga Scenedesmus subspicatus. Aquatic Sciences, 61, 44–58.

Knight, R. L., Kadlec, R. H., & Ohlendorf, H. M. (1999). The use of treatment wetlands for petroleum industry effluents. Environmental Science & Technology, 33, 973–980.

Kröpfelová, L., Vymazal, J., Švehla, J., & Štíchová, J. (2009). Removal of trace elements in three horizontal sub-surface flow constructed wetlands in the Czech Republic. Environmental Pollution, 157, 1186–1194.

Laskov, C., Horn, O., & Hupfer, M. (2006). Environmental factors regulating the radial oxygen loss from roots of Myriophyllum spicatum and Potamogeton crispus. Aquatic Botany, 84, 333–340.

Lee, B.-H., & Scholz, M. (2007). What is the role of Phragmites australis in experimental constructed wetland filters treating urban runoff? Ecological Engineering, 29, 87–95.

Margesin, R., & Schinner, F. (2001). Biodegradation and bioremediation of hydrocarbons in extreme environments. Applied Microbiology and Biotechnology, 56, 650–663.

Murray Gulde, C., Heatley, J. E., Karanfil, T., Rodgers, J. H., Jr., & Myers, J. E. (2003). Performance of a hybrid reverse osmosis-constructed wetland treatment system for brackish oil field produced water. Water Research, 37, 705–713.

Rahman, K. S. M., Thahira-Rahman, J., Lakshmanaperumalsamy, P., & Banat, I. M. (2002). Towards efficient crude oil degradation by mixed bacterial consortium. Bioresource Technology, 85, 257–261.

Reed, S. C., & Brown, D. (1995). Subsurface flow wetlands—a performance evaluation. Water Environment Research, 67, 244–248.

Rodgers, J. H., Jr., & Castle, J. W. (2008). Constructed wetland treatment systems for efficient and effective treatment of contaminated waters for reuse. Environmental Geosciences, 15, 1–8.

Rousseau, D. P. L., Vanrolleghem, P. A., & De Pauw, N. (2004). Model-based design of horizontal subsurface flow constructed treatment wetlands: a review. Water Research, 38, 1484–1493.

Salmon, C., Crabos, J. L., Sambuco, J. P., Bessiere, J. M., Basseres, A., Caumette, P., et al. (1998). Artificial wetland performances in the purification efficiency of hydrocarbon wastewater. Water, Air, and Soil Pollution, 104, 313–329.

Siracusa, G., & La Rosa, A. D. (2006). Design of a constructed wetland for wastewater treatment in a Silician town and environmental evaluation using the emergy analysis. Ecological Modelling, 197, 490–497.

Stumm, W., & Morgan, J. J. (1981). Aquatic chemistry: an introduction emphasizing chemical equilibria in natural waters (2nd ed.). New York: Wiley.

Tuttle, J. H., Dugan, P. R., & Randles, C. I. (1969). Microbial sulfate reduction and its potential utility as an acid mine water pollution abatement procedure. Applied Microbiology, 17, 297–302.

USEPA. (1988). Design manual: constructed wetlands and aquatic plant systems for municipal wastewater treatment. EPA/625/1-88/022. Cincinnati: US Environmental Protection Agency, Office of Research and Development.

USEPA. (1994). Method 200.7: determination of metals and trace elements in water and wastes by inductively coupled plasma-atomic emission spectrometry. Revision 4.4 EMMC version. Cincinnati: US Environmental Protection Agency, Office of Research and Development.

USEPA. (1999). Method 1664: n-hexane extractable material and silica gel treated n-hexane extractable material by extraction and gravimetry, revision A. Contract 68-C-98-139. Washington: US Environmental Protection Agency, Engineering and Analysis Division.

Veil, J. A., Puder, M. G., Elcock, D., & Redweik, R. J., Jr. (2004). A white paper describing produced water from production of crude oil, natural gas, and coal bed methane. Washington: Argonne National Laboratory.

Wood, A. (1995). Constructed wetlands in water pollution control: fundamentals to their understanding. Water Science and Technology, 32, 21–29.

Ye, Z. H., Whiting, S. N., Lin, Z. Q., Lytle, C. M., Qian, J. H., & Terry, N. (2001). Removal and distribution of iron, manganese, cobalt, and nickel within a Pennsylvania constructed wetland treating coal combustion by-product leachate. Journal of Environmental Quality, 30, 1464–1473.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Horner, J.E., Castle, J.W., Rodgers, J.H. et al. Design and Performance of Pilot-Scale Constructed Wetland Treatment Systems for Treating Oilfield Produced Water from Sub-Saharan Africa. Water Air Soil Pollut 223, 1945–1957 (2012). https://doi.org/10.1007/s11270-011-0996-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11270-011-0996-1