Abstract

Minimum flowrate targeting methods for resource conservation networks (RCNs) have been developed over the last decades. The existing methodologies still have certain drawbacks. Their design insights could be deepened and some steps should be more convenient for the users. A targeting tool called the material surplus composite curve (MSCC), which is an improvement of the surplus diagram for water and hydrogen networks is introduced. The approach is illustrated on several cases selected from the literature. Using this technique, it is possible to determine rigorous flowrate targets for different variants of the RCN problem.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

With the rising cost of fresh water and increasingly stringent environment regulations, there is a need to maximise the efficiency of the use of water, while minimising the generation of waste. Several assessments on water resources reported that by the year 2025, two-thirds of the world population will live in water scarcity (Rosegrant et al. 2002; Sandia National Laboratories 2005). Apart from the mismanagement of natural resources such as the over-extraction of water resources, the rising of population growth, water pollution problems and climate change also increase water stress (Sandia National Laboratories 2005; Rockstrom et al. 2009). Efficient use of water in industry is now recognised as being vital to achieving sustainable development. Similarly, the efficient use of industrial resources other than water is equally important to achieving both environmental goals and profitability. One important example is the utilisation of hydrogen in oil refineries. As fuel specifications change in response to current environmental issues, the proper allocation of limited hydrogen resources to various thermochemical processes within large refinery complexes has become an important engineering issue. Many problems pertaining to efficient use of resources in industrial process plants share common features, which allow them to be handled using a common family of systematic techniques known collectively as process integration.

Process integration tools such as pinch analysis techniques have been widely accepted as systematic design principle for various resource conservation networks (RCNs). Pinch analysis originated in the 1970s for heat exchanger network synthesis (Hohmann 1971; Linnhoff and Flower 1978) and subsequently for other related energy integration activities, e.g. appropriate placement of heat pumps, distillation columns, dryer, combined heat and power, total site, etc. (Linnhoff et al. 1982/1994; Klemeš et al. 1997; Smith 1995, 2005). The general philosophy of pinch analysis techniques is the use of a two-stage approach, which involves identification of various RCN optimal targets such as minimum fresh resource and waste discharge (termed as targeting); followed by subsequent detailed design.

Based on the analogy of heat and mass transfer, El-Halwagi and Manousiothakis (1989) extended the two-stage pinch analysis techniques for the synthesis of mass exchange network, which enabled more efficient use of mass separating agents. A series of other mass integration applications were also established later (El-Halwagi 1997, 2006). Two important special cases for the area were also established, i.e. water and hydrogen network synthesis.

Water network synthesis was pioneered by Wang and Smith (1994a, 1995), who made use of the limiting composite curve to target the minimum fresh water and wastewater flowrates for a reuse/recycle network. However, their targeting technique was limited to the fixed load problem where water-using processes are modelled as mass transfer operations. Following research in water network synthesis have been mainly dedicated to the fixed flowrate problem, where flowrate requirement is taken as the primary concern for water-using processes. This latter problem arises as many industrial water-using processes cannot be appropriately modelled as mass transfer operations (see discussion in Dhole et al. 1996; Hallale 2002; Manan et al. 2004). Various graphical (Hallale 2002; El-Halwagi et al. 2003; Prakash and Shenoy 2005; Bandyopadhyay 2006; Bandyopadhyay et al. 2006), algebraic (Manan et al. 2004; Almutlaq et al. 2005; Foo et al. 2006a; Foo 2007, 2008; Almutlaq and El-Halwagi 2007) and automated (Ng et al. 2009a) methods have been proposed to locate the minimum flowrates for a water reuse/recycle network. Besides, another valuable design insight from the targeting stage is the identification of the pinch location(s), i.e. the overall bottleneck of the RCN. The pinch divides the RCN into high-purity (HPR) and low-purity regions (LPR). The so-called ‘golden rule’ of pinch analysis then states that fresh water should be used only in the HPR, while wastewater is discharged only from the LPR (Tan et al. 2010). Furthermore, in an optimal network, no water should be transferred between the two regions (Tan et al. 2010).

Many of these targeting tools have also been extended for the targeting with regeneration placement (Wang and Smith 1994a, 1995; Kuo and Smith 1998a; Agrawal and Shenoy 2006; Feng et al. 2007; Bai et al. 2007; Bandyopadhyay and Cormos 2008; Ng et al. 2007a, 2008, 2009b), water pre-treatment (Tan et al. 2010) and wastewater treatment (Wang and Smith 1994b; Kuo and Smith 1998b; Bandyopadhyay et al. 2006; Ng et al. 2007b, c, 2010). Two important state-of-the-art reviews for the field were done by Bagajewicz (2000) and more recently by Foo (2009). The latter article also explains the equivalence of fixed load and fixed flowrate problems for single-impurity systems.

Apart from applications for water networks, many targeting tools were also established for another special case of mass integration, i.e. hydrogen network synthesis. The latter problem is motivated by the need to use hydrogen resources efficiently within refineries, particularly as a result of changes in the quality of crude feedstock and the specifications of fuel characteristics. It includes the targeting for direct reuse/recycle (Alves and Towler 2002; El-Halwagi et al. 2003; Foo and Manan 2006; Bandyopadhyay 2006; Ng et al. 2009a) and interception placement (Foo and Manan 2006; Agrawal and Shenoy 2006; Ng et al. 2009b). These extensions are based on the conceptual equivalence between water network problems and simplified hydrogen network problems that consider only stream purity constraints.

Note that the above reported works on water and hydrogen network are both chemo-centric, where the characteristics of the process streams and constraints are described in terms of impurity concentration. However, many chemical processes are characterised by their chemical and/or physical properties. Several important works on property integration have then been reported to cater for material recovery in property integration problem. This includes the various graphical, algebraic and optimisation techniques developed for direct reuse/recycle (Kazantzi and El-Halwagi 2005; Foo et al. 2006b; Bandyopadhyay 2006), regeneration (Foo et al. 2006b; Ng et al. 2009c) and waste treatment (Ng et al. 2010).

In this article, a new graphical targeting tool known as the material surplus composite curve (MSCC) is presented to target the minimum resource and waste flowrates for direct reuse/recycle in single-impurity/property system. The MSCC is developed based on the surplus diagram for water (Hallale 2002) and hydrogen networks (Alves and Towler 2002), but the approach has been improved to avoid repetitive computations required in these techniques. In the following section, MSCC targeting technique is first demonstrated for water network problems. It is then extended into hydrogen and property networks. Literature examples are used to illustrate the new targeting tool. These examples cover a broad range of problems, i.e. networks with pure and impure fresh resource; multiple-pinch cases; waste identification and threshold problems, which illustrates the flexibility of the new methodology in dealing with different scenarios. It has to be emphasised that the methodology presented focuses primarily on targeting. The results of this step may then be used to design actual networks using established approaches such as the nearest neighbour algorithm (NNA) of Prakash and Shenoy (2005).

Problem statement

The problem to be addressed by the methodology presented here may be formally stated as follows. We consider a system with a set of internal process sources and sinks which may be matched in order to meet the objective of minimising the requirement to import an external, high quality resource (e.g. fresh water, fresh hydrogen or fresh solvent). Each internal source is characterised by a stream flowrate and quality index, the latter being defined either in terms of composition or a functional property. Likewise, each sink is defined in terms of corresponding flowrate and quality limit. The primary objective is to determine the fresh resource target for the RCN. At the same time, the waste generation target and pinch point(s) are also found.

Illustrative example: targeting for water network

In this section, the step-by-step application of the MSCC technique is demonstrated for flowrate targeting in water network synthesis. The procedure for constructing the MSCC is illustrated using a literature example taken from Polley and Polley (2000). The quality index in this case corresponds to impurity concentration.

Targeting for single fresh water resource and wastewater identification (Example 1)

Table 1 shows the limiting water data for Example 1 (Polley and Polley 2000), which is served by a pure fresh water supply (0 ppm). The first step in the targeting procedure is to plot a material sink and source composite curves on a concentration versus flowrate diagram, as shown in Fig. 1. This graphical representation was first proposed by Hallale (2002). However, unlike the original work (Hallale 2002), the fresh water flowrate is excluded during the plotting of the source composite curve.

For Example 1, the sink composite curve lies completely above and to the right of the source composite curve (see Fig. 1). Hallale (2002) reported that this is an infeasible network as water source flowrates are insufficient to fulfil the flowrate requirement of the water sinks. In addition, the region between the two composite curves indicates that the water sinks are also under pure water deficit. In essence, the area enclosed by the two composite curves represents the pure water load needed to be satisfied at each concentration level. The cumulative load in Fig. 1 is next plotted versus its respective concentration level on a cumulative load versus concentration diagram, resulting in the resource (water) deficit diagram in Fig. 2. This step is equivalent to plotting the infeasible surplus diagram in water (Hallale 2002) or hydrogen (Alves and Towler 2002) networks. However, note that the fresh resource flowrate has been excluded in the graph.

The next step in the targeting procedure is to determine the interval fresh water flowrate (F FW,k ) at each concentration interval. In principle, this is to determine if fresh water supply is sufficient at a given concentration level. This is done by dividing the cumulative load at each concentration level k (Cum. Δm k ) by the difference between the concentration level of interest (C k ) and that of the fresh water (C FW), given as in Eq. 1:

For instance, the cumulative load at 100 and 200 ppm are determined as 6.5 and 11.0 kg/h, respectively. Equation 1 hence determines that the fresh water requirement (indicated by the negative sign) at these concentration levels as 65 and 55 t/h, respectively. Note that the concentration level in Eq. 1 is interchangeable with the corresponding quality level for a given RCN problem.

Next, an interval flowrate diagram is plotted. As shown in Fig. 3a, the interval fresh water flowrates determined by Eq. 1 are now plotted at their respective concentration levels in the interval flowrate diagram. Since the interval flowrate diagram is cumulative in nature, the surplus or deficit of fresh water can be differentiated by the direction of the curve segments. The horizontal segments that move to the right represent the water surplus; while those to the left represent the deficits. For instance, it was determined earlier that the fresh water flowrates at 100 and 200 ppm are 65 and 55 t/h, respectively. Hence, the segment of the interval flowrate diagram at 100 ppm is moving to the left (indicating water deficit), while that at 200 ppm is moving to the right (indicating water surplus). This is shown in Fig. 3a.

After identifying the fresh water surplus/deficit at each concentration level, the MSCC can now be plotted (Fig. 3b). As shown, the MSCC consists of the fresh water surplus/deficit composites, in which their segments are plotted at their respective concentration levels. For instance, the water surplus composite has two water surplus segments identified at 150 and 250 ppm, respectively, in the interval flowrate diagram in Fig. 3a. On the other hand, the water deficit segments in the interval flowrate diagram are used to construct the water deficit composite (due to space limitation, not all segment constructions are shown in Fig. 3).

To find the minimum fresh water target of the network, the water surplus composite is shifted to the right until being above and to the right of the water deficit composite (Fig. 4). As shown, the extent to which the water surplus composite is shifted from the y axis gives the fresh water flowrate (F FW) needed for the network, and is determined as 70 t/h. On the other hand, the wastewater flowrate may then be determined from the overhang of the water surplus composite from the water deficit composite. From Fig. 4, it can be seen that this corresponds to the wastewater flowrate (F WW) of 50 t/h. These flowrate targets are identical to the previously reported result (Hallale 2002; El-Halwagi et al. 2003; Manan et al. 2004; Prakash and Shenoy 2005).

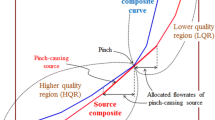

The vertical segment of the water surplus composite that intercepts with the water deficit composite indicates the pinch concentration of the water network; and hence the former is termed as the pinch-causing source (Manan et al. 2004; Foo et al. 2006a). In this case, the pinch concentration corresponds to 150 ppm (see Fig. 4). Note that the pinch point divides the network into high-concentration (HCR) and low-concentration regions (LCR), which correspond to the LPR and HPR respectively. This is shown using the balanced water and sink composite curves (Fig. 5). The latter diagram is constructed following the same steps as in Fig. 1, however, with the targeted fresh water flowrate (i.e. 70 t/h). As shown in Fig. 5, the all water sinks and sources are located in either the HCR or LCR, except the pinch-causing source which belongs to both regions (Hallale 2002; Manan et al. 2004). The allocated flowrates of the pinch-causing source to the HCR and LCR are given by its segment length in each region. This corresponds to 10 and 60 t/h for the LCR and HCR, respectively (see Fig. 5). These network targets are also identical to the result reported previously (Manan et al. 2004; Foo et al. 2006a).

Apart from pure fresh water feed, the WSCC can be readily used for targeting the impure fresh water source. Example 1 is revisited with an impure fresh water feed of 10 ppm to demonstrate this aspect. The same flowrate targeting procedure for pure fresh water feed in the previous section is applied here, resulting in the MSCC in Fig. 6. As shown, the minimum fresh water and wastewater flowrate targets for this case are determined as 75 and 55 t/h, respectively, with the pinch concentration at 150 ppm (Fig. 6). This is identical to the result reported previously (Foo 2009). Note that, however, when several impure fresh water sources are available for service, a revised targeting procedure is needed. This remains as the scope for future work.

Wastewater identification using MSCC (Example 1 revisited)

The MSCC can further be used to identify the individual wastewater streams, following the procedure of Ng et al. (2007b). For Example 1 with pure fresh water source (data given in Table 1), the MSCC determines that the pinch concentration is located at 150 ppm (see Fig. 4) and total wastewater amount of 50 t/h (see Fig. 4). The targeting procedure is next repeated for the HCR by including all water sinks and sources in the region (SK4 and SR4) except the pinch-causing source segment.

Figure 7 shows the MSCC for the HCR. Note that the fresh water segment in water flowrate targeting is now replaced by the pinch-causing source segment that is supplied at 150 ppm (i.e. the cleanest source below the pinch). The minimum flowrate of the pinch-causing source (called the minimum pinch flowrate, F PN) needed for this region is determined as 35 t/h (Fig. 7). As reported in Fig. 5, the allocated flowrate of the pinch-causing source to the HCR corresponds to a flowrate of 60 t/h. The first wastewater stream (F WW1) can be identified by deducting the minimum pinch flowrate (35 t/h) from its allocated flowrate (60 t/h), i.e. 25 t/h. Since this wastewater stream originates from the pinch concentration, it has a concentration of 150 ppm. On the other hand, the overhang of the water surplus composite from the water deficit composite in Fig. 7 gives the flowrate for the second wastewater stream (F WW2), i.e. 25 t/h. Hence, a total of two wastewater streams are emitted from this network. This is verified with the network design for the example, shown in Fig. 8, which was designed using the NNA (Prakash and Shenoy 2005).

Note that, in general, there may be multiple network design options that are able to achieve the targets found (Dunn and Wenzel 2001). However, identification of alternative designs is beyond the scope of this work.

The sections that follow give further examples of applications of MSCC. However, the detailed steps are omitted due to space constraints.

Further examples on water network targeting

This section describes additional case studies on water network. These examples involve the special cases of multiple-pinch points and threshold problems.

Targeting for multiple-pinch problems (Example 2)

Example 2 taken from Sorin and Bédard (1999) is used to illustrate the flowrate targeting procedure for a multiple-pinch problem, with the limiting water data shown in Table 2. The result of the targeting procedure is shown in Fig. 9, where the minimum fresh water and wastewater flowrates are identified as 200 and 120 t/h, respectively. As shown in this figure, two pinch concentrations are observed, i.e. 100 and 180 ppm, respectively. This matches the result reported by earlier works (Hallale 2002; El-Halwagi et al. 2003; Manan et al. 2004; Prakash and Shenoy 2005). Figure 10 shows a network designed using NNA (Prakash and Shenoy 2005) which achieves these targets.

Targeting for threshold problems (Examples 3 and 4)

The MSCC is now applied for some special cases of water network synthesis problems, namely, the threshold problems. In such problems, the optimal network will either have zero fresh water demand or zero wastewater discharge. For the first case, a zero discharge network is considered. Example 3 taken from Foo (2008) is used for illustration, with the limiting water data shown in Table 3.

The result of the targeting procedure is shown in the MSCC in Fig. 11. The minimum fresh water flowrate target is determined as 60 t/h; while no wastewater is generated from the network. The threshold concentration is given by the concentration in the MRCC, i.e. 1,000,000 ppm. This matches the result reported by earlier work (Foo 2008).

Next, Example 4 is taken from Jacob et al. (2002) to illustrate the flowrate targeting procedure for a zero fresh water network, with the limiting data shown in Table 4. Figure 12 shows the material sink and source composite curves for Example 4. The source composite is located to the right of the sink composite curve, even prior to the addition of fresh water in the network. In other words, the network has a surplus of water sources. The overhang of the source composite curve indicates that a total wastewater flowrate of 700 t/h is discharged from the network. This agrees with the result reported earlier (Foo 2008).

If one were to plot the MSCC (see Fig. 13), it can be seen that the water surplus composite is completely on the right side of the water deficit composite. This means that no fresh water is needed by the water network. Hence, plotting the MSCC is not necessary for this case. Figure 14a, b shows water networks that achieve the flowrate targets in Examples 3 and 4, respectively.

Extension for hydrogen and property-based networks

This section demonstrates the extension of the MSCC methodology to two important problems in process integration, namely, hydrogen and property integration. These extensions follow directly from a simple analogy with the water integration problem, and the methodology may be applied without any major modifications.

Targeting for hydrogen integration (Example 5)

Hydrogen integration has been motivated by the need to efficiently utilise hydrogen streams in petroleum refineries. This trend arises from the need to produce fuels that meet increasingly stringent environmental standards, coupled with the necessity of utilising increasingly lower grades of crude petroleum (Alves and Towler 2002). Significantly, the problem of hydrogen integration can also be reduced to one of the matching available internal hydrogen sources to appropriate hydrogen sinks, in order to minimise the need for externally fresh hydrogen. The problem follows the same pattern as water integration, and thus pinch analysis techniques that apply to the latter have been shown to be suitable for hydrogen integration as well (Alves and Towler 2002; El-Halwagi et al. 2003; Bandyopadhyay 2006; Foo and Manan 2006). Among these techniques, the hydrogen surplus diagram (Alves and Towler 2002) serves as the basis of the MSCC developed in this work.

Table 5 shows the limiting process data for Example 5. The fresh external hydrogen source is available with an impurity of 5 mol%. The methodology for constructing the MSCC is exactly the same as for water integration. The resulting MSCC diagram is shown in Fig. 15, with the fresh hydrogen demand target (F H2) being 268.8 mol/s. The corresponding unutilised hydrogen (F P) emanating from the network is 102.5 mol/s; this stream may be flared as waste gas, used as fuel, or otherwise exported from the plant. The pinch concentration is found to be 30 mol%. These results match those found previously (Alves and Towler 2002; El-Halwagi et al. 2003; Foo and Manan 2006). Figure 16 shows a network designed using NNA (Prakash and Shenoy 2005) which achieves these targets.

Targeting for property integration (Example 6)

In conventional mass integration techniques, stream quality is denoted by the concentration of impurities. More recently, applications in which stream quality is measured in terms of physical properties (e.g. density, vapour pressure, electrical conductivity, etc.) have been systematically studied under the new field of property integration (Kazantzi and El-Halwagi 2005; Foo et al. 2006b; Ng et al. 2009c, 2010). Note that, in general, physical properties do not follow the same conservation rules as do chemical impurities. However, in many cases, it is possible to identify a suitable property operator (ψ) that conforms to linear mixing rules, which effectively allows one to calculate the final property of a mixed stream, given the proportions and properties of its constituent streams. Once a suitable property operator is found, property integration problems can be solved with the same approaches that are used for conventional, chemo-centric mass integration problems.

This example illustrates the use of the MSCC on a property integration problem involving metal degreasing (Kazantzi and El-Halwagi 2005). Limiting process data is given in Table 6. Note that stream quality is indicated by Reid vapour pressure (RVP) which itself is not conserved during mixing. However, the property operator ψ = RVP1.44 follows linear mixing rules, in the same manner as impurity concentrations. The property operator may be seen as an arbitrary, empirically determined function whose purpose is to linearise the conservation of the physical property during stream mixing; however, the function itself does not necessarily have physical meaning. Thus, it is possible to apply the MSCC without further modification, simply by using ψ in place of concentration values in the previous examples. The fresh resource is available at 2 atm, corresponding to an operator of 2.713 atm1.44. The resulting MSCC is illustrated in Fig. 17, which shows both fresh solvent demand (F S) and waste solvent generation (F W) to be 2.38 kg/s. Furthermore, the pinch point occurs at ψ = 13.2 atm1.44, from which it is possible to calculate that the corresponding RVP to be 6 atm. Once again, the result matches what has been reported in the literature (Kazantzi and El-Halwagi 2005; Foo et al. 2006b; Ng et al. 2009c). It should be noted that the property operators in atm1.44 are fictitious values which have no real physical meaning. Hence, the upper limit of 1000 atm1.44 used in Fig. 17 does not have the same significance as the corresponding upper limits in concentration-based problems; any arbitrarily large value can be used instead. Figure 18 shows a network designed using NNA (Prakash and Shenoy 2005), which achieves these targets.

Conclusion

This article presents a graphical targeting tool known as the MSCC for determination of the minimum fresh resource and waste flowrates for direct reuse/recycle scheme in a concentration/property-based RCN. This algorithm is an extension of the earlier methods based on the water and hydrogen surplus diagram and applies equally well to single and multiple pinch, impure fresh resource, as well as the threshold problems. In addition, it can be used to identify the individual waste streams discharged from a network, which facilitates subsequent network design. As with most pinch analysis approaches, the main restriction of the methodology is that it is limited to single-impurity or single-property systems. Further work is also needed to extend the targeting procedure for multiple impure fresh resources.

References

Agrawal V, Shenoy UV (2006) Unified conceptual approach to targeting and design of water and hydrogen networks. AIChE J 52(3):1071–1081

Almutlaq AM, El-Halwagi MM (2007) An algebraic targeting approach to resource conservation via material recycle/reuse. Int J Environ Pollut 29(1/2/3):4–18

Almutlaq AM, Kazantzi V, El-Halwagi MM (2005) An algebraic approach to targeting waste discharge and impure fresh usage via material recycle/reuse networks. Clean Technol Environ Policy 7(4):294–305

Alves JJ, Towler GP (2002) Analysis of refinery hydrogen distribution systems. Ind Eng Chem Res 41(23):5759–5769

Bagajewicz M (2000) A review of recent design procedures for water networks in refineries and process plants. Comput Chem Eng 24(9–10):2093–2113

Bai J, Feng X, Deng C (2007) Graphical based optimization of single-contaminant regeneration reuse water systems. Chem Eng Res Des 85(A8):1178–1187

Bandyopadhyay S (2006) Source composite curve for waste reduction. Chem Eng J 125(2):99–110

Bandyopadhyay S, Cormos C-C (2008) Water management in process industries incorporating regeneration and recycle through a single treatment unit. Ind Eng Chem Res 47(4):1111–1119

Bandyopadhyay S, Ghanekar MD, Pillai HK (2006) Process water management. Ind Eng Chem Res 45(15):5287–5297

Dhole VR, Ramchandani N, Tainsh RA, Wasilewski M (1996) Make your process water pay for itself. Chem Eng 103:100–103

Dunn RF, Wenzel H (2001) Process integration design methods for water conservation and wastewater reduction in industry. Part 1. Design for single contaminant. Clean Prod Process 3:307–318

El-Halwagi MM (1997) Pollution prevention through process integration: systematic design tools. Academic Press, San Diego

El-Halwagi MM (2006) Process integration. Elsevier, Amsterdam

El-Halwagi MM, Manousiothakis V (1989) Synthesis of mass-exchange networks. AIChE J 35(8):1233–1244

El-Halwagi MM, Gabriel F, Harell D (2003) Rigorous graphical targeting for resource conservation via material recycle/reuse networks. Ind Eng Chem Res 42(19):4319–4328

Feng X, Bai J, Zheng X (2007) On the use of graphical method to determine the targets of single-contaminant regeneration recycling water systems. Chem Eng Sci 62:2127–2138

Foo DCY (2007) Water cascade analysis for single and multiple impure fresh water feed. Chem Eng Res Des 85(8):1169–1177

Foo DCY (2008) Flowrate targeting for threshold problems and plant-wide integration for water network synthesis. J Environ Manag 88(2):253–274

Foo DCY (2009) State-of-the-art review of pinch analysis techniques for water network synthesis. Ind Eng Chem Res 48(11):5125–5159

Foo DCY, Manan ZA (2006) Setting the minimum utility gas flowrate targets using cascade analysis technique. Ind Eng Chem Res 45(17):5986–5995

Foo DCY, Manan ZA, Tan YL (2006a) Use cascade analysis to optimize water networks. Chem Eng Progr 102(7):45–52

Foo DCY, Kazantzi V, El-Halwagi MM, Manan ZA (2006b) Surplus diagram and cascade analysis technique for targeting property-based material reuse network. Chem Eng Sci 61(8):2626–2642

Hallale N (2002) A new graphical targeting method for water minimisation. Adv Environ Res 6(3):377–390

Hohmann EC (1971) Optimum networks for heat exchange. PhD thesis, Chemical Engineering Department, University of Southern California, Los Angeles

Jacob J, Kaipe H, Couderc F, Paris J (2002) Water network analysis in pulp and paper processes by pinch and linear programming techniques. Chem Eng Commun 189(2):184–206

Kazantzi V, El-Halwagi MM (2005) Targeting material reuse via property integration. Chem Eng Progr 101(8):28–37

Klemeš J, Dhole VR, Raissi K, Perry SJ, Puigjaner L (1997) Targeting and design methodology for reduction of fuel, power and CO2 on total sites. Appl Therm Eng 17:993–1003

Kuo WCJ, Smith R (1998a) Design of water-using systems involving regeneration. Process Saf Environ Prot 76(2):94–114

Kuo WCJ, Smith R (1998b) Designing for the interactions between water-use and effluent treatment. Chem Eng Res Des 76(3):287–301

Linnhoff B, Flower JR (1978) Synthesis of heat exchanger networks. AIChE J 24:633–642

Linnhoff B, Townsend DW, Boland D, Hewitt GF, Thomas BEA, Guy AR, Marshall RH (1982/1994) A user guide on process integration for the efficient use of energy. IChemE, Rugby

Manan ZA, Tan YL, Foo DCY (2004) Targeting the minimum water flowrate using water cascade analysis technique. AIChE J 50(12):3169–3183

Ng DKS, Foo DCY, Tan RR, Tan YL (2007a) Ultimate flowrate targeting with regeneration placement. Chem Eng Res Des 85(9):1253–1267

Ng DKS, Foo DCY, Tan RR (2007b) Targeting for total water network. 1. Waste stream identification. Ind Eng Chem Res 46(26):9107–9113

Ng DKS, Foo DCY, Tan RR (2007c) Targeting for total water network. 2. Waste treatment targeting and interactions with water system elements. Ind Eng Chem Res 46(26):9114–9125

Ng DKS, Foo DCY, Tan RR (2008) Extension of targeting procedure for ‘Ultimate flowrate targeting with regeneration placement’ by Ng et al Chem. Eng. Res. Des. 85(A9):1253–1267. Chem Eng Res Des 86(10):1182–1186

Ng DKS, Foo DCY, Tan RR (2009a) Automated targeting technique for single-component resource conservation networks. Part 1: direct reuse/recycle. Ind Eng Chem Res 48(16):7637–7646

Ng DKS, Foo DCY, Tan RR (2009b) Automated targeting technique for single-component resource conservation networks. Part 2: single-pass and partitioning waste-interception systems. Ind Eng Chem Res 48(16):7647–7661

Ng DKS, Foo DCY, Tan RR, Pau CH, Tan YL (2009c) Automated targeting for conventional and bilateral property-based resource conservation network. Chem Eng J 149:87–101

Ng DKS, Foo DCY, Tan RR, El-Halwagi MM (2010) Automated targeting technique for concentration and property-based total resource conservation network. Comput Chem Eng 34(5):825–845

Polley GT, Polley HL (2000) Design better water networks. Chem Eng Progr 96(2):47–52

Prakash R, Shenoy UV (2005) Targeting and design of water networks for fixed flowrate and fixed contaminant load operations. Chem Eng Sci 60(1):255–268

Rockstrom J, Steffen W, Noone K, Persson A, Chapin FS, Lambin EF, Lenton TM, Scheffer M, Folke C, Schellnhuber HJ, Niykvist B, De Wit CA, Hughes T, Van der Leeuw S, Rodhe H, Sorlin S, Snyder PK, Constanza R, Svedin U, Falkenmark M, Karlberg L, Corell RW, Fabry VJ, Hansen J, Walker B, Liverman D, Richardson K, Crutzen P, Foley JA (2009) A safe operating space for humanity. Nature 461:472–475

Rosegrant MW, Cai X, Cline SA (2002) Global water outlook to 2025—averting an impending crisis. International Food Policy Research Institute and International Water Management Institute, Washington

Sandia National Laboratories (2005) Global water futures. www.sandia.gov. Retrieved February 1, 2010

Smith R (1995) Chemical process design. McGraw-Hill, New York

Smith R (2005) Chemical process design and integration. Wiley, New York

Sorin M, Bédard S (1999) The global pinch point in water reuse networks. Process Saf Environ Prot 77(5):305–308

Tan RR, Ng DKS, Foo DCY (2010) Graphical approach to minimum flowrate targeting for partitioning water pretreatment units. Chem Eng Res Des 88:393–402

Wang YP, Smith R (1994a) Wastewater minimisation. Chem Eng Sci 49(7):981–1006

Wang YP, Smith R (1994b) Design of distributed effluent treatment systems. Chem Eng Sci 49(18):3127–3145

Wang YP, Smith R (1995) Wastewater minimization with flowrate constraints. Chem Eng Res Des 73:889–904

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Saw, S.Y., Lee, L., Lim, M.H. et al. An extended graphical targeting technique for direct reuse/recycle in concentration and property-based resource conservation networks. Clean Techn Environ Policy 13, 347–357 (2011). https://doi.org/10.1007/s10098-010-0305-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-010-0305-5